High fuel consumption of the VAZ 2114 today is one of the most common problems faced by owners of domestic cars. The fuel consumption rate of the machine can be found in the technical documentation.

For the injection “fourteenth” engine, the consumption rate is within 8.5 liters per 100 km in the urban cycle and about 6.5-7 liters on the highway. But more often, VAZ 2114 owners record completely different indicators that go far beyond its limits. What is the most common problem and are there effective ways to fix it? Sometimes we are faced with the acute question of how to reduce fuel consumption on a VAZ 2114 8-valve injector?

What is the real gasoline consumption of VA3 2114?

Today it is a real rarity when a car fully complies with the specifications of the technical documentation. Most often, the manufacturer indicates data obtained during testing of the car under ideal conditions. The actual fuel consumption of almost all modern cars is 1-2 liters higher than the norm. You should not neglect important factors that contribute to increasing the “appetite” of the machine.

These factors are:

- Vehicle operating conditions.

- Driving manner and style.

- The presence of various types of malfunctions.

- Fuel quality.

High fuel consumption VAZ 2114 injector 8 valves, how much is this in numbers? Most owners of the 8-valve “fourteenth” note consumption in the range of 8.5 – 9 liters in the urban cycle and 7-7.5 liters per 100 km on the highway. This is an average figure that is close to the fuel consumption rate specified by the manufacturer.

The main signs and reasons for the increase in fuel consumption of the VAZ 2114

If it’s summer and you drive on normal roads, but at the same time you notice an abnormal “appetite” of the fuel-injected 8-valve VAZ 2114, then it’s time to conduct a full diagnosis of the car’s condition. Excessive fuel consumption is easy to notice not only by the frequency of visits to gas stations. Often, owners note some oddities in the operation of the engine. Unstable operation of the “heart” of the car is accompanied by black smoke from the exhaust pipe and the presence of popping noises in the muffler or intake manifold.

Black smoke from the exhaust pipe most often occurs due to the formation of an overly rich fuel mixture. This disease occurs due to clogged injectors, faults in the ECU, and low-quality spark plugs.

Gasoline consumption can increase, both for a simple and harmless reason, and in the event of serious malfunctions in the car system. For example, a clogged fuel filter increases the fuel consumption of the “fourteenth” by as much as 2-3 liters. Low tire pressure and non-standard wheel radius also contribute. It has long been a known fact that the larger the radius of the wheel, the more effort must be made to turn it.

Other reasons for excessive fuel consumption include:

- malfunction of the oxygen supply sensor;

- low level compression;

- problems with the air flow sensor;

- late ignition, clogged catalyst.

Ways to reduce fuel consumption of a VAZ 2114 with an injector

What to do if the VAZ 2114 has high fuel consumption and the reasons are unknown? Of course, it is best to go to a service station and undergo a full computer diagnostic. The fact is that the VAZ 2114 injection system with 8 valves contains a large number of different sensors. A failure in the operation of one of them can lead to the fact that the owner of the car will rack his brains for a long time in search of faults, but will never find them without special software.

One of the most effective ways to reduce gasoline consumption by a car and its subsequent control is timely prevention of vehicle components and components and scheduled maintenance.

Not every faulty sensor affects the “appetite” of the car. The lambda probe plays the greatest role in the excessive consumption of the fuel-air mixture. This device regulates the formation of a combustible mixture based on the volume of oxygen in the exhaust. The presence of errors in the operation of the lambda probe can be determined by the on-board computer. This device most often fails due to poor fuel quality and an incorrectly set advance angle.

The car owner can independently eliminate or partially reduce the high fuel consumption of a VAZ 2114 injector with an 8-valve engine through the following measures:

- Regularly replace the air and fuel filter. In this case, preference should be given to factory elements.

- Monitor the condition of the spark plugs and replace them according to the recommendations.

- Periodically measure the tire pressure level and monitor the condition of the brake system parts.

- Refuel your car only at time-tested gas stations.

- Maintain cleanliness of components and assemblies of the engine compartment.

Checking the mass air flow sensor

Before you start experimenting, take the time to read the service manual. It describes in detail what a mass air flow sensor on a VAZ 2114 is and how to replace it.

We are looking for a sensor. Open the hood and find the air filter pipe. The mass air flow sensor is located on it, which determines the flow of air passing through the filter. I will give several options on how to check the mass air flow sensor yourself.

- Disable the sensor. Disconnect the block with wires from the connector by pressing the latch located below. Start the engine (1500 rpm or more). The controller understands the shutdown of the mass air flow sensor as an emergency condition and prepares the fuel-air mixture based on the position of the throttle valve. Try driving a short distance. If the car accelerates noticeably faster, this indicates a non-working mass air flow sensor. I would like to note that in the disabled state for ECUs Y7.2 and M7.9.7. RPM doesn't increase!

- Replacing the controller firmware. The original ECU firmware could have been replaced with an alternative one. In such a situation, we do not know which algorithm is prescribed in the case of operation in the mode discussed in the first paragraph. The throttle valve has a stop under which you need to place a thin plate (about 1 mm) to raise the speed. Then you need to disconnect the chip with the sensor. If the sensor is faulty, the engine should stall. If the engine is running, then the reason is due to the firmware features: the IAC steps are written incorrectly.

- Voltage measurement. Testing gives good results when working with Bosch sensors. You will need a multimeter. Select the DC voltage measurement mode and set the maximum value to 2 V.

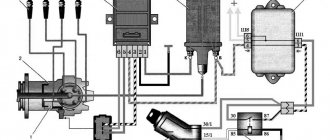

The connection diagram for the VAZ 2114 looks like this:

- yellow – incoming signal;

- gray with white – power output;

- green – grounding;

- pink with black – output to the main relay.

The colors may be different, but the sequence of connectors is the same.

Next, you need to turn on the ignition with the engine off. Connect the red (positive) probe of the tester to the yellow output, and the black (negative) probe to the green. Multimeter probes are inserted along the specified wires directly through the rubber seals of the connectors without damaging the insulation. For prevention, I recommend moistening the probes with WD-40. Intermediates or needles are not recommended due to the additional error they introduce. Measure the voltage. Compare the result with the table:

| Voltage, V | State |

| 1,01 – 1,02 | Good. The sensor is almost new and will last a long time. |

| 1,02 – 1,03 | Satisfactory. The sensor is old, but works properly. |

| 1,03 – 1,04 | Bad. The resource is almost exhausted. Will have to replace it soon. |

| 1,04 – 1,05 | Deplorable. The resource has been exhausted. Suitable for use if there are no alarming symptoms. It is advisable to replace |

| 1.05 – and above | Emergency. The sensor is faulty (possibly for a long time). Replacement is required. |

A newly installed sensor gives an output voltage of 0.996–1.01 V. Over time, it increases. A higher value means a higher percentage of wear.

Voltage data from the sensors is recorded by the on-board computer and can be viewed by selecting the appropriate group of parameters.

- Inspection and cleaning. Use a Phillips screwdriver to loosen the clamp holding the air intake pipe. We remove the corrugation and check whether there are traces of oil and/or condensation inside it, as well as on the inner surface of the sensor. Normally they shouldn't be there. The sensing element of the mass air flow sensor often breaks due to dirt getting on it. This can easily be avoided by regularly replacing the air filter. Reasons for oil getting into the air flow sensor:

- the permissible oil level in the crankcase has been exceeded

- The oil separator of the ventilation system is clogged

The sensor is attached to the pipe with two screws. We unscrew them with an open-end wrench (x10) and remove the sensor itself. There is an entrance at the front, which must be protected from the leakage of untreated air with an o-ring rubber seal. If it is missing or remains in the filter housing, dust clogs the sensor input grid. It needs to be cleaned, the seal installed, the leaks checked and the sensor put back in.

- Comparison with a working sensor. From personal experience, I was convinced that the most accurate test is to install a sensor that is known to work and compare the behavior of the engine with the “native” one.

In addition to the options considered for how to check the mass air flow sensor yourself, you can also contact a service center that has special equipment and carry out 100% diagnostics, for example, using the method of evaluating an oscillogram.

MITROFAN

Useful video

You can learn more about the possibilities of reducing fuel consumption by watching the video below:

Maintaining the proper condition of the car in the future will save the owner from hassle and unexpected expenses. You just need to promptly replace clogged filters and damaged spark plugs, and then increased fuel consumption will bypass your car.

- I was told 4 times

- I said 19 times

Login required to view!

To view you need to log in. If you are not registered yet, follow the link: Registration.

Hello. There is a VAZ 2114 mileage 180,000 km ECU M73 stock ident I317DA02. Disabled DC firmware E-2. Gasoline 95. The essence of the problem. Increased air consumption at idle is about 15 kg, the ignition timing fluctuates from 1.5 to 12 and the engine load is 27-30%, resulting in uneven engine operation. This is observed on all firmwares. First of all, I decided to check the mass air flow sensor due to the increased air flow, I checked the readings 0.99-1.00 with a multimeter (the mass air flow sensor is normal). Then I replaced the knock sensor with a completely new one in order to correct the ignition angle, but this did not help either. Replaced the IAC, still the same. I adjusted the valves, but it didn't help. I've already tried everything, looked for air leaks, checked the throttle valve. All the same. Tell me where to look for the reason. I am attaching the captured log.

What should be the air flow for the VAZ-2114

During normal operation of the sensor, the engine of this machine consumes from 10±0.5 kg of air per hour of operation. If the quantity is miniaturized, then the car’s dynamics are miniaturized, which saves fuel, but when it increases, fuel, on the contrary, is greatly consumed. In cold weather, this can lead to problems with starting the engine. If the sensor characteristics deviate from the real ones, then the engine begins to work intermittently, or even does not start at all. What can cause a sensor to deviate? Let's try to find out.

Optimal air flow

If the mass air flow sensor is operational, then when the engine is running at 900 rpm, the volume of air used will be at least 10 kg per hour. When the speed increases to 2 thousand, this figure will increase to approximately 20 kg. If the volume of air at such speeds drops, the dynamics of the vehicle will also decrease, and accordingly, this will lead to a decrease in gasoline consumption.

If these indicators increase, this will also contribute to an increase in fuel volume. If the parameter deviates by 2-4 kg, you should not allow it, since in this case the operation of the power unit may be incorrect.

Causes of sensor failure: when replacement is required

The error of the sensor significantly aggravates the functioning of the car as a whole, but mainly it affects the operation of the controller. When using a sensitive controller, this can lead to floating idle speed, but with all this there will be no noticeable dips during acceleration. In general, the readings should be normal, so it is necessary to monitor this and, in case of malfunction, replace the device.

The crankcase ventilation system can cause inaccurate readings. If the throttle is closed, the gases are diverted through the line into a free space. A certain amount of these gases goes into the idle line, where it comes into contact with the mass air flow sensor. Then the resin settles on the resistor, which leads to errors in the sensor readings.

Mass air flow at idle on Prior 1.6 V16

mass air flow

at idle speed on Prior 1.6 V16 oxygen sensor voltage 1 period of sensor signal...

What is a mass air flow sensor on a VAZ 2114: operating principle and design

For the engine to operate in optimal mode, an approximate amount of fuel and air is required in proportions of 1:14. Violation of such proportions can lead to two things: a decrease in engine power or excessive fuel consumption.

In this case, a mass air flow sensor is needed, which will accurately measure the amount of air entering the car engine. The sensor is installed between the engine intake and the vehicle air filter.

The air flow meter has a thin platinum filament that is sensitive to high temperatures. During operation, the thread heats up, and under the influence of passing air it cools, that is, the temperature decreases.

Having calculated the amount of air, the sensor sends information to the computer (ECU), which in turn, based on the data received, calculates the required amount of fuel to form the optimal mixture.

The harder the driver presses the accelerator pedal, the more air enters the internal combustion engine through the throttle valve. Thus, having measured its quantity, the mass air flow sensor sends information to the computer to increase the fuel supply through the injector. Note that with uniform movement the air flow will be small. Accordingly, fuel consumption is reduced.

The main components of the DVMR VAZ 2114 device:

- frame;

- metal screen;

- air deflector;

- mass air flow sensor;

- MAF diagram;

- power connector.