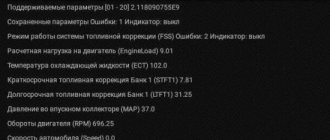

The manufacturer of a budget car has provided the opportunity to repair the car yourself. VAZ 2114 error codes can be read by yourself or using external equipment. Typical symbols are displayed on the dashboard and indicate the presence of a specific problem in the on-board circuits of the machine. In the minimum configurations, the indication is made as a special light on the tidy. More advanced versions, which have a BC on board with a remote display, display the indication on a special screen. This makes it easier to read the data and understand where exactly the fault is located. All fault codes are displayed in two-digit codes, which greatly complicates the repair procedure. On-board systems can only indicate the area where the problem is located. For more specific diagnostics, you will need a special scanner.

Error codes for VAZ 2114 with an injection engine of 8 and 16 valves: decoding

The eight-valve Lada engine and the more advanced “shesnar” do not differ radically in design. The list of faults and their causes are usually identical, which makes it easier to diagnose cars in different trim levels.

Below are the most common problems and malfunctions encountered when diagnosing a car.

Lada 2114 - check light on: error 0

The diagnostic procedure showed that there are no problems in the system. On-board equipment is in perfect order.

Error 1 on VAZ 2114

Microprocessor malfunction. The system shows problems with the firmware - the module needs to be reflashed.

Error 2

Code number 2 indicates problems with the fuel level sensor in the gas tank. This often happens after an impact or strong shaking. To make repairs, simply open the fuel tank cap and adjust the float.

Error 3

The code combines the first and second errors.

2114: error 4

Excessively high voltage, more than 16 Volts, was detected in the on-board circuit. There is a short or problem with the generator set voltage regulator.

Error 6

Typical wiring problem. Codes 4 and 2 overlap and may occur due to a short circuit in the wiring at the fuel sensor.

Error 8 on VAZ 2114

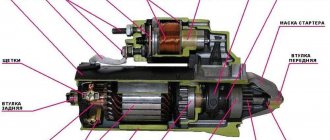

The voltage in the on-board network is excessively low. The system shows one of several possible problems.

- The battery is low or the battery is faulty. Indicates a serious battery discharge.

- The generator set is damaged. A typical sign is worn brushes. The elements are replaced with new ones and the problem goes away.

- If the components are working properly, you will need to check the car's voltage regulator. A detail can give a similar effect.

Fault 10

On the dashboard, VDO No. 10 indicates problems 2 and 8. Check the fuel level sensor and its wiring.

Lada 2114: fault 11 on the tidy

Similar meaning to the above problem. The combination of problems may be unique to each specific case. A more thorough diagnosis will be required.

Fault 12

The warning lamp diagnostic circuit is faulty.

Code 13

The oxygen sensor is reporting incorrect data. Check the sensor wiring and sensor element for damage.

Code 14

Excessively high signal from DTOZH. This means that the motor has overheated or the sensor has failed.

VAZ 2114: fault 16

High voltage in the on-board network. There is a short circuit or the voltage regulator is broken.

Breakdown 18

In a standard series of errors, the problem is a combination of several possible faults. For full diagnostics, connect an external scanner to the car.

Fault 19

The DPKV transmits incorrect data to the ECU module. The problem is a worn sensor.

Error 20 for Lada 2114 on the instrument panel

It is a combination of several problems and requires a more thorough diagnosis.

Error 26

UER system fault code.

2114: error 30

This is the sum of two fault codes like 13 and 17. The solution is similar to standard errors.

Malfunction P0030

The DK1 heater circuit is not working correctly. Problem 0030 can be resolved by replacing the sensor or restoring the wiring.

Fault 0031

The opposite meaning to the code above.

Breakdown P0036

DK1 is not working correctly, error 0036 indicates that the module will have to be replaced.

Fault 01

Standard microprocessor problem. You need to reflash the on-board computer.

Error P0101: VAZ 2114 E - Gas

Problem 0101 constantly appears on cars with HBO. The code indicates the presence of glitches in the mass air flow sensor.

Malfunction P0102

Code 0102 The air flow sensor circuit is characterized by excessively low voltage.

Code P0103

Completely opposite meaning of the problem stated above.

Code P0113

The actual intake air temperature differs from the calculated one. To repair, replace the sensitive area of the sensor.

Code 0116

The characteristic value of the ECT sensor differs from the calculated one. Check that the module is working properly.

Code 0118

High signal level of the antifreeze temperature sensor controller.

Code 0123

The TPS is not working correctly or there are problems with the mechanical part of the throttle/pedal. It is enough to clean the mechanics well and remove all dirt.

Code 0122

Low signal level from the same sensor.

Code 0132

DK1 is not functioning correctly.

P0133 - error

The first lambda probe responds to load changes too slowly.

P0134 - error

Very low signal level from DC1. Error 0134 can be resolved by replacing the part.

Code P0135

DK1 heater circuit problem. Replace the damaged part or repair the wiring.

P0140 - breakdown

DK2 does not respond to manipulations with the gas pedal.

Code P0171

The fuel mixture is too lean. Perhaps there are holes or leaks in the lines - air is being sucked somewhere.

Code P0172

The opposite meaning of the above error. P0172 says the mixture is too rich. This is especially noticeable at idle. The machine may not operate properly, the engine may shake.

Code 0200

Loss of injector control.

Error P0203

Likewise for the third cylinder.

Error 0204

The same for working chamber 4.

Error 0302 VAZ 2114: reasons

There are multiple misfires in the second cylinder of the car. Check spark plugs and lines.

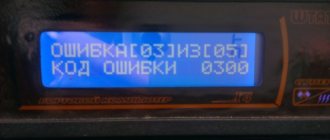

Error P0300

There are misfires in the cylinders. Troubleshooting is carried out after checking all elements of the system design.

P0301 - fault 2114

Talks about a similar problem in the first cylinder.

Code P0303

Likewise for the third working chamber.

Malfunction P0304

Also for the fourth cylinder.

Code 0325

The knock sensor is damaged or has an open circuit. Check all sensor lines.

Code P0326

Code 0326 indicates a short circuit in the above element.

Malfunction P0327

Knock sensor readings are below the set threshold.

Code 0328

Opposite meaning.

P0335 - error 2114

The wiring or crankshaft position sensor is not working correctly.

Error P0336

A similar problem, exceeding the set threshold value.

Error 0338

The automatic transmission control module has detected an incorrect crankshaft position sensor A value.

P0340 - code 2114

The valve timing sensor is not functioning correctly. Error 0340 when you press the gas is accompanied by degranulation or tripping of the engine.

Code P0341

The DPRV transmits incorrect data to the control unit. The module needs to be serviced or replaced.

Code P0342

The signal from the above module is too weak.

Code P0346

The automatic transmission control module receives an incorrect signal from the DPRV.

Code P0343

Phase sensor fault. Error 0343 indicates a device failure.

Code P0351

Damage to the ignition coils.

Code P0352

The ignition coil of the second cylinder is broken.

Code P0363

Likewise for the third working chamber. The solution to the problem is also identical.

Fault 0400

Problems with the exhaust recirculation system.

Code P0441

The gasoline vapor recovery system in the canister purge valve is not working properly.

Code P0422

Error 0422 says that the efficiency of the catalytic converter has fallen below the established standard.

Breakdown 0443 2114: how to fix

General malfunction of the gasoline vapor recovery valve circuit. It is enough to clean the system of carbon deposits and dirt.

P0444 - code

Short circuit of the canister purge valve driver wiring to ground.

Malfunction P0480

The first cooling fan drive is not working properly.

P0500 - code

The vehicle speed sensor is damaged or not working properly. The speedometer needle may float or hang in one position.

Error P0501

The signal from the DSA is unstable or exceeds acceptable limits.

Malfunction P0504: Lada 2114

The problem appears consistently on cars until 2011. Incorrect signal from the brake pedal position sensor. The problem must be solved by cleaning the sensor from dirt or restoring the wiring.

Code 0505

The idle system is not working properly. Adjustments need to be made.

Code P0506

Idle speed too low. The problem often occurs on 16 valve cars. Malfunctions should be looked for in the injector adjustment.

Code 0507: how to fix

Idle speed too high.

Code P0511

The automatic transmission control module cannot adjust the speed of the crankshaft and the input shaft of the shift module.

Code P0560

The automatic transmission control module indicates that the on-board voltage is too low.

Code P0562

Likewise, the opposite meaning. Code 0562 indicates that the voltage in the circuits is too high.

Code 0563

Excessive voltage of the on-board network, over 16V.

P0650 error

Malfunction of the control circuit of the error indicator lamp.

Code P0628

The fuel pump is receiving too low voltage. Error 0628 indicates the need for network diagnostics.

Code 0685

Main relay – control circuit open. Perform on-board network diagnostics.

Code P0691

The error says that the radiator fan motor is not working properly. This may also indicate his complete refusal.

Code 45

The air-fuel mixture is not formed correctly. Review the system elements for correct settings and integrity of the lines.

Code 102

Low signal from the mass air flow sensor.

Error 113

Failure The intake air temperature sensor is faulty or not working properly.

Fault 118

Increased signal from the coolant level sensor.

Code 134

DC1 transmits incorrect data. The signal is below the set threshold.

Code 171

Loss of tightness of the intake tract on the first cylinder.

Breakdown 172

Likewise for the second cylinder.

Error P300

There are random or multiple misfires in the working chambers. Error 300 is a copy of problem 0300.

Code 301

Same for cylinder 1.

Error 302

The same for the second working chamber.

Code 304

For the fourth piston.

Code 335

Incorrect signal from DPKV. Check the sensor and its wiring.

Code 340

The DPRV circuit is damaged or not functioning correctly.

Code 346

The valve timing sensor is damaged or there are problems in its wiring.

Code 422

Low catalyst efficiency. The system needs to be replaced. Many drivers cut out the device, updating the car to a lower environmental class.

Code 427

DTOZH low signal.

Code 441

The air flow through the canister purge valve exceeds the established limits.

Code 444

Problems with the fuel system. Check everything from the gas tank to the injectors.

Code 507

Excessively high idle speed. Carry out more detailed diagnostics of the system.

Code 603

Data loss has occurred in RAM. Restart the device; if the error persists, the module must be replaced.

Code 602

No power to the ECM. The module wiring is obviously damaged or oxidized.

Code 628

Excessively low voltage in the onboard pump control wiring.

Fault 685

Problems in the main power plant control relay.

Code1102

The No. 1 oxygen sensor heater resistance is too low. The module needs to be checked.

P1135 - breakdown

Error 1135 indicates that there is an open circuit on the DK1 heater.

Malfunction P1301

Ignition delay in the first cylinder.

Code P1302

Likewise for the second cylinder.

Malfunction P1303

The same for the third camera.

Code P1304

Also for 4 cameras.

P1335 - code

The throttle position actuator is out of position.

Fault 1336

The mass air flow sensor is faulty or does not work correctly.

Code 1426

Open circuit for controlling the canister purge valve.

Error 1514: how to fix it

Open circuit IAC. The vehicle's wiring should be checked.

P1545 - error 2114

The throttle position angle is incorrect. Clean the device and check the operation of the sensors.

P1578 - error

Throttle angle adaptation is not carried out correctly.

Fault 1602

The BC detected a short-term voltage interruption in the on-board network. In this case, the car does not start or stalls. Check the power supply under terminal 30 and the connections of the battery/generator power wires.

Code 1621

The RAM module is not working properly. Treatment consists of complete replacement of the device.

Code P2020

Faulty fuel pump power relay.

Code 2127

The problem with TPS is the pressure is too low.

P2135 - error

Inconsistency of throttle position sensor signals.

Error P2187

Check the lines for air leaks and correct operation of the mass air flow sensor.

Code P2188

The opposite meaning of the above paragraph.

Code 5353

P5353 says that there is not enough voltage on the ECU module.

Code 6060

The motor controller is not initialized correctly. Carry out the procedure again, if this does not help - the entire module is changed.

Engine errors

Motor malfunctions occur due to lack of maintenance or after improper repairs. Such problems must be corrected immediately, as they can lead to serious consequences.

Canister error

The system is sensitive to changes and damage. If problems arise, faults with codes from 0400 to 0480 will light up on the device.

Phase sensor error

There are current problems with numbers 0340-0343. If the indicated codes light up on the diagnostic tool, it is recommended to check the phase distributor.

Camshaft sensor error

On a car, a situation often occurs when the driver has replaced a damaged controller, but the problem in the on-board computer’s memory remains. Perform a complete restart of the device or reset faults using a diagnostician.

Error 328: high signal level from the knock sensor VAZ 2114

The problem indicates a DD short circuit. An open circuit is impossible since the system indicates a short circuit in case of fault 328.

Oxygen sensor error

Usually they fail when the catalyst wears out. The system may malfunction due to mechanical damage. The wiring is sensitive to dirt and road chemicals.

Crankshaft sensor error

Here the system is complex and simple at the same time. DCPV works on the principle of reading the teeth on a gear. Errors begin when the sensor counts fewer or more teeth per shaft revolution.

The problem can be resolved by replacing the entire controller or restoring its power lines.

Fuel gauge sensor circuit error

It may fail after strong shocks, shaking, or simply due to oxidation of the moving part of the float. Partial repair or cleaning of the module is usually ineffective. The problem is solved by completely replacing the part.

Brake sensor error

It is very easy to check and fix. The sensor rarely breaks. Its contact group is oxidized. Clean the block from oxide and everything will be fine.

HF synchronization sensor malfunction

Only a complete replacement of the device will help.

Error 2114: Server service is not running

Try restarting the controller. There is an unexpected malfunction in the system.

DPKV error

The information is already listed above.

Mass air flow sensor error

Already available in the description above.

Misfire: Causes

The causes of the problems are problems with the electronic ignition system. It is necessary to check the lines from the coils to the spark plugs.

ECU error

If problems arise with the controller, it is recommended to seek professional help. Do-it-yourself repairs can cause even more complex problems.

On-board network malfunctions

The problems are due to the fact that the voltage in the lines is too low or too high. There may be several errors, the numbers are scattered across the fault table.

The solution to the problem depends on the specific malfunction.

External RAM error

Controller malfunctions require qualified repair and maintenance. If there are problems with the device, you should contact an electronics technician.

Lambda probe error

It all depends on the wiring. The system malfunctions due to damaged wiring or oxidation of contacts. The module may also provide incorrect data due to catalyst wear.

TPS malfunctions

The throttle valve generates errors associated with incorrect operation of the drive. The position of the damper is controlled by a servomotor, weak enough to rotate the part in the coked housing.

If the module malfunctions, it is enough to clean the inductor and check the contact groups of the sensors.

Error DK1

Issues codes related to its own functionality or improper operation of the system, formation of the fuel mixture. If the sensor is working properly and transmits signals correctly, problems should be looked for in the throttle valve settings and ignition system.

Catalyst error

Occur when the catalyst efficiency is insufficient. Most car enthusiasts cut out the worn-out module and reflash the ECU to EURO-2/3 class. You can also replace the part, but its price deters most drivers.

How to troubleshoot P0141?

This code can only be caused by problems in the DC heater circuit or the sensor itself.

Typically, heated sensors have four wires - two of which go to the heater circuit, and two for powering and grounding the sensor. In this case, we are dealing only with a circuit with a heater.

Typical DC heater circuit and connectors:

Source: alldata.com

Find the wiring diagram for your vehicle to make sure you are testing the correct wires.

Check heater circuit wiring

Disconnect the O2 sensor connector. Check the voltage and ground of the heater. You can do this using a digital multimeter.

After reviewing the wiring diagram for your vehicle, determine which pin on the connector is power and which is ground. Set the multimeter switch to "Constant Voltage".

Touch the black lead of the multimeter to the housing and the other to the power lead on the connector. You will see a reading close to the battery voltage. If not, you have a problem with the DC power supply. It will be necessary to examine the electrical circuit on the power side to determine the cause of the circuit failure.

To test the ground wire circuit, connect the red lead of the multimeter to the positive terminal of the battery and the black lead to the ground on the connector. You should see a voltage of about 12 volts. If this is not the case, you need to look for the cause of the circuit malfunction using the wiring diagram on the ground side.

Checking the heating element

If everything is fine with power and grounding, you need to check the sensor heating element for high resistance or an open circuit. This can be done using a digital multimeter.

Set the device to resistance measurement mode (Ohms). Then connect the multimeter leads to both contacts of the heater circuit on the sensor connector side.

Look up the specifications for your oxygen sensors to see if the resistance value is within normal limits. Otherwise, the heating element inside the sensor has high resistance and the sensor should be replaced.

If during the test you measure infinity, then there is a break in the heating element. In this case also the sensor must be replaced.

How to view VAZ 2114 faults through the dashboard

You can check for errors in your car yourself, without using OBD2, as follows.

- Insert the key into the ignition.

- Hold down the odometer key and, without releasing it, turn the key to the first position.

- Release the key and look at the tidy. After this, the arrows will start running in a circle.

- Next, press the key again and quickly release it. This will allow you to install the firmware version.

- If you press the button on the dashboard again, fault codes will be displayed and they can be read.

Codes related to P0141

- P0030 - DC heater control circuit, bank 1, sensor 1.

- P0036 - DC heater control circuit, bank 1, sensor 2.

- P0053 - DC heater resistance, bank 1, sensor 1.

- P0054 - DC heater resistance, bank 1, sensor 2.

- P0135 - DC heater performance, bank 1, sensor 1.

- P0141 - DC heater performance, bank 1, sensor 2.

- P0050 - DC heater control circuit, bank 2, sensor 1.

- P0056 - DC heater control circuit, bank 2, sensor 2.

- P0059 - DC heater resistance, bank 2, sensor 1.

- P0060 - DC heater resistance, bank 2, sensor 2.

- P0155 - DC heater performance, bank 2, sensor 1.

- P0161 - DC heater performance, bank 2, sensor 2.

Diagnosis of errors

When you begin to notice something unusual in the behavior of your car, or there are obvious problems in its operation, then it certainly makes sense to have it diagnosed. Naturally, the OBD-II diagnostic connector will show errors most efficiently and accurately, however, not everyone has sockets to control this connector and has to use the standard one.

In order to enter self-diagnosis mode, you must:

- Turn off the ignition.

- Click on the daily vehicle mileage button.

- Then, continuing to hold it, turn the key in the lock.

- Thanks to this, all available indicators will light up, and the dial indicators will go into self-test mode and show data from zero to maximum.

- When this happens, use the button located on the steering column switch and use it to switch the data on the instrument panel.

- To read the fault codes, we need the last one - the third screen. Unambiguous error codes will be displayed there.

Displaying the error code on the third screen of the bookmaker. The photo shows error 4 (faulty coolant temperature sensor).

Error codes (decoding)

These are the most common error codes that can appear if there is a malfunction on the Lada Kalina.

Code Explanation 2 Excess of voltage in the vehicle's on-board network. 3 Malfunction of the gasoline level sensor in the fuel tank

Possible circuit break. 4 When this code appears, the car owner needs to pay attention to the operation of the antifreeze temperature sensor. There is also a possibility of a circuit break. 5 There is a problem with the outside temperature sensor. 6 The control unit has detected engine overheating

It is recommended to deal with this problem before further operation of the car. 7 Emergency lubricant pressure in the internal combustion engine is reported. 8 If you see this code on the dashboard, then you need to check the functionality of the brake system. The on-board computer recorded an error or breakdown in its operation. 9 The on-board computer reports that the battery charge is too low. It is recommended to perform a more thorough check of the battery. E An error has been reported in the data packet stored in the EEPROM.

Checking the system using special equipment

If the system is checked through a diagnostic block using OBD-II, then the code combination will consist of four characters, preceded by a letter at the very beginning.

We connect the PC to the diagnostic connector of LADA Kalina

P - indicates a problem with the engine or transmission. C - displayed when an error occurs in the “running”. B - when such a letter designation appears, you should pay attention to the serviceability of the central locking system, airbags, and power windows.

The second digit means:

- 0 – common code for OBD-II;

- 1 – number of the car manufacturer;

- 2 – number of the car manufacturer;

- 3 – reserve code.

The third character refers directly to the type of failure:

- 1 – malfunction in the air supply system and fuel system.

- 2 – similar to code “1”.

- 3 – failures and malfunctions in the ignition system.

- 4 – auxiliary control.

- 5 – malfunctions during idle operation.

- 6 – malfunction of the ECU or its circuit.

- 7 and 8 – malfunction in the transmission.

Stages of diagnosis and repair

A few words about the electronic throttle. This system is incredibly sensitive and more vulnerable to damage than any other. Handle it with extreme care. One fall or rough handling and it cannot be restored.

Apart from the accelerator pedal sensor, the remaining components are located in the throttle body. Upon inspection, you will notice a flat plastic cover on the top of the throttle body. It contains mechanisms for actuating the throttle valve.

The motor has a small metal gear protruding through the housing under the cover. It drives a large "plastic" gear attached to the throttle body.

The pin that centers and supports the gearbox fits into the throttle body and into the “thin” plastic cover. If the cover becomes warped in any way, the transmission will be compromised, requiring a complete throttle body replacement.

- The first thing to do is go online and search for TSBs (Technical Service Bulletins) for your vehicle related to the code. These TSBs are the result of customer complaints or identified problems and the factory recommended repair procedure.

- Look on the Internet or in the service manual to see how you can retrain the control unit. For example, for Nissan you need to turn on the ignition and wait 3 seconds. Over the next 5 seconds, press and release the gas pedal 5 times. Wait 7 seconds, press and hold the pedal for 10 seconds. When the Check Engine light starts flashing, release the pedal. Wait 10 seconds, press the pedal again for 10 seconds and release. Turn off the ignition.

- If additional codes such as P2136 were present, fix them first as they are part of the system and could be the direct cause of the P2135 code.

- Pull the electrical connector out of the throttle body. Look for bent or missing terminals. Look for corrosion. Clean out the corrosion using a small flathead screwdriver. Apply a small amount of electrical grease to the connector and plug it back in.

- If the connector has bent or missing pins, you can get a new pigtail at most auto parts stores or your dealer.

- Inspect the throttle body top cover for cracks or deformation. If they do, call the dealer and ask if they only sell the top cap. If not, replace the throttle body.

- Use a multimeter to check the accelerator pedal sensor. For comparison, it will receive 5 volts and an alternating signal. Turn on the ignition key and slowly press the pedal. The voltage should rise smoothly from 0.5 to 5.0 volts. Replace it if there are voltage surges or no voltage on the signal wire.

- Find the wire assignments on your car's throttle body on a diagram or search. Check that the throttle body connector is receiving power to the throttle motor. Have an assistant turn on the key and lightly press the pedal. If there is no power, the ECU is faulty. If voltage comes, there is a malfunction in the throttle body.

Sensor malfunctions

The table shows a list of controller errors that in practice occur most often when diagnosing the Lada Kalina.

| Fault code | Description and recommendations for elimination |

| 0030-0032, 0036-0038 | The microprocessor module detected malfunctions in the operation of the lambda probe heating device. We are talking about sensors installed before and after the neutralizer. The problem may be a burnt-out spiral or a short circuit of the device to ground or ground. A detailed check of the controllers, including wiring, is required |

| 0101-0103 | Malfunctions in the operation of the sensor responsible for supplying air to the cylinders of the power unit. Its parameters may be out of tolerance or the signal may be too high or low |

| 0112-0118 | The microprocessor module detected malfunctions in the temperature controller. The signal coming from the sensor may be too high or too low. Also, the device sometimes produces incorrect data. A detailed check of the regulator is required |

| 0122, 0123 | Malfunctions in the operation of the throttle angle controller. The signals produced by the sensor can be increased or decreased. It is necessary to check the device as well as the electrical circuit |

| 0130-0134 | Problems with the first oxygen controller. There may be problems with the sensor itself, as well as the wiring. |

| 0132 | Malfunction of the crankshaft position regulator. If the controller fails, detailed diagnostics will be required. With such a breakdown, the engine will not be able to start. The problem may be a clogged sensor connector |

| 0135 | The heating device of the first oxygen regulator is not working correctly. Detailed check required |

| 0365 | The microprocessor module detected a short circuit of the second oxygen regulator |

| 0137, 0138 | An incorrect signal is coming from the same sensor. You need to check the wiring of the device |

| 0140, 0141 | The heating element of the second oxygen sensor is not working properly. Detailed device diagnostics required |

| 0326-0328 | Malfunction of the knock controller or camshaft sensor. Detailed check required |

| 0335-0338 | The microprocessor module has detected damage to the electrical signal circuit from the crankshaft controller. Wiring diagnostics required |

| 0340 | The camshaft sensor has failed. There may be malfunctions in the machine's engine. This error is accompanied by the appearance of a Check indicator on the dashboard. It is typical only for power units equipped with 16 valves |

| 0342-0346 | The control unit has detected a fault in the phase controller. The problem appears only in 16-valve units |

| 0500 | The microprocessor module reports problems in the operation of the speed controller |

| 0504 | Brake pedal position sensor malfunction. Possible wiring problems |

| 0511 | There is no signal from the idle speed controller. It is necessary to check the serviceability of the wiring and connector |

| 1135 | The electrical circuit of the heating device of the first oxygen sensor has shorted. Check the wiring with a multimeter |

| 1171, 1172 | The CO sensor does not work correctly, a violation of its operating parameters is reported |

| 1386 | Problems in the electrical data transmission circuit from the detonation controller |

| 1606, 1616 | Malfunction of the rough road sensor. You need to check the device itself and the wiring |

| 2122-2128 | Problems with the gas pedal position controller. A detailed diagnosis of the mechanism is required. Possible damage to wiring |

| 0720 | Malfunction of the output shaft controller. The error is specific only to vehicles equipped with an automatic transmission. |

| 0717 | Damage to the turbine speed control sensor. This error also appears only on cars with automatic transmission. |

| 0711-0713 | Malfunction of the automatic transmission oil temperature controller |

User Alexander Skripchenko spoke in detail about troubleshooting the Lada Kalina, as well as reading combinations.

Description and meaning of error P0422

This diagnostic trouble code (DTC) is a generic powertrain code, which means it applies to OBD-II equipped vehicles. While general, specific repair steps may vary depending on the make/model. A vehicle's catalytic converter (catalyst) helps improve tailpipe emissions by oxygenating the exhaust gases. It helps convert carbons (HC), carbon monoxide (CO), and oxides of nitrogen (NOx) into water vapor (H20), carbon dioxide (CO2), and nitrogen (N). The PCM (Powertrain Control Module) monitors catalyst efficiency through the catalyst post oxygen sensor. This sensor is mainly used for this purpose. It should shift much slower than the front oxygen sensors. If at any time the PCM detects that the catalytic converter O2 sensor is switching too quickly (without indicating any change between the input and output of the catalytic converter), then it interprets this as the catalyst not functioning properly. Bank 1 is the side of the engine with cylinder number 1.

Decoding: Lada Granta errors

The list of possible faults is long. So we've broken it down into three parts based on the original issues. These are the error codes that it produces:

- Electronic control unit (ECU);

- If equipped - automatic transmission (automatic transmission);

- Problem with EEPROM data transfer.

Grant ECU: error codes

The largest group of faults. This includes data on internal combustion engine sensors. Code numbering from P0030 to P2501.

P0030-P0172

P0200-P0363 P0422-P0660

P0661-P1388

Р1389-Р1689

R2070-R2501

Complete list of Grant automatic transmission errors

The complete table of faults with the VAZ2190 automatic transmission is much smaller than the previous one. The whole list is below:

All automatic transmission error codes fit into one block

VAZ 2190 data transmission error codes

The smallest group of codes. There are only six of them, all starting with U - automatic transmission and internal combustion engine faults are indicated by the letter P.

All known data transfer errors on Grant