VAZ models received one unpleasant feature: with age, backlashes appear in some parts of the car. We are talking about the transmission, engine, and gearbox. There is no need to wait until all the parts of the unit wear out, since a complete replacement will cost more than modernization. In this article we will talk about tuning the gearbox, or more precisely, about installing a short-stroke shifter (SC) instead of the standard one. Here, VAZ 2114 owners have three options: installing a freelance rocker, making the part with their own hands, and also adjusting the standard unit.

Important! Defects in the operation of the gearbox may appear due to the oil seal, the “symptoms” of which are similar to the rocker. A visual inspection is enough to determine whether the seal is working or not. The analysis can be performed according to the scheme from this article.

The short-throw rocker reduces gear shifting time, which is why this part was originally only found in sports cars. Subsequently, almost all automakers included a short-throw rocker in the design of their cars. AvtoVAZ lagged behind foreign cars a little, so the first model of the company with this part was the Lada Kalina, so if you install a freelance element, then it’s from the Kalina.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

To replace the “ten” cardan you will need a pit, keys for 10 and 13:

- The gearbox control rod joint is hidden under the boot.

- We remove the boot and move it to the gearbox.

- Loosen the clamp bolt to 13, loosen it a little and pull the link off the hinge. Then unscrew the 10mm bolt that secures the hinge on the gear selector rod and remove the hinge.

- We install a new hinge without play on the gear selector rod and secure it with a 10-point bolt. To prevent it from turning away from vibrations, we lubricate it with a thread locker.

We put the boot and the drawstring in place and adjust it.

After that we do a test drive. If everything is good, then tighten the clamp. There is an opinion that before installing the glass you need to saw off its tip a little, in fact, everything installs perfectly without sawing. After adjustment, the gearshift lever is located exactly in the middle.

Impressions from the backlash-free driveshaft of the Lada Kalina on a VAZ 2110

It seems that the lateral travel of the lever has decreased. The difference is especially noticeable while driving than when parked. Gear changes have become clearer, there is no “yaw” movements of the lever.

However, do not forget about gearbox vibration . If previously these vibrations were transmitted to the rocker and were partially damped by the play of the standard cardan, now they are transferred in full force to the gearshift knob, which causes rattling, which has to be dealt with over time.

The replacement process is quite simple

- To do this you will need keys for 13 and 10

The “cardan” is not visible from the outside - it is located inside the boot, so the latter will have to be removed.

- After this, the clamp bolt is unscrewed, the clamp is unclenched and the rocker slides off the hinge.

- It is also necessary to unscrew the bolt securing the hinge on the gear shift unit. Now the hinge can be easily removed from its original location.

- The new hinge from Kalina is secured with a 10mm bolt. To prevent the bolt from unscrewing while driving, it is lubricated with a special substance that acts as a lock. After this, the boot and the rocker are put in place and adjustments are made.

- When everything is assembled, you need to make a test drive. Once you are sure that no problems have arisen after replacement, you can finally tighten the clamps and enjoy the result.

Some motorists recommend sawing off its tip a few centimeters before installing the hinge. This is not at all necessary - the hinge can be installed quite easily and without sawing.

The gear knob must be adjusted so that it is exactly in the middle of the rocker. When performing a test drive, you can immediately see that the lateral travel of the lever has noticeably decreased. This is noticeably felt during the ride. In the corresponding section of our website you can find

Short-stroke rocker for VAZ 2110: installation, replacement of cardan

The gearbox in VAZ 2110 cars is one of the most involved dynamic elements. Because of this, the unit often becomes loose, which makes operating the car inconvenient. A shaking gear shift lever is a fairly common occurrence in domestic cars. There are two ways to combat this defect: constantly adjust the gearbox or make the rocker short-stroke - the process can be done independently. You can also purchase a gearbox repair kit from another VAZ model, which initially comes with a short-throw driveshaft.

What is so good about a short-stroke rocker? Firstly, it guarantees reliable operation of the gearbox over a long period of time. Secondly, the short-stroke version helps to increase the clarity of VAZ gear changes, including in the 2110 model. This is quite enough to make the operation of the power plant more comfortable, because smoothness, stroke and clarity of gear shifting are important for the gearbox.

Short-throw slides for "nine"

Such designs were developed exclusively for sports models, but are widely used in production ones. Advantages of the VAZ-2109 short-stroke rocker over the standard one:

- Easier gear shifting.

- The backlash of the gearshift lever is reduced, especially when using a cardan from Kalina.

Disadvantages:

- You need to either buy it or make it yourself.

- It takes a lot of force to change gears. Despite the smaller stroke, this type of backstage is more suitable for people who are not only strong in spirit.

But you don’t have to buy a VAZ-2109 rocker in stores; you can make a short-shifter from a regular one with little welding skills.

To do this, cut the old rocker in two places and weld pieces of a metal plate to lengthen the arms. The main thing is for the new drawstring to fit into place, so first carefully study the drawing, which shows the locations of the cuts.

In this article we will talk about how to install a backlash-free cardan for the gearbox from the Lada Kalina on the “ten”.

Why is this detail needed?

This hinge has zero play, which allows the lateral travel of the lever to be minimized. In addition, the clarity of gear shifting is significantly increased.

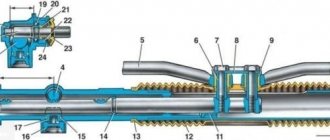

Among motorists, this element is called the “cardan”, and this part is correctly called the gearbox control hinge. Its catalog number is 1118-173160. Among some motorists, another name for this part is common - “glass”. Its cost is several hundred rubles.

Differences between a short-stroke link

The main differences can be seen even in photographs. We see that the short-stroke rocker has smaller dimensions, namely length. To reduce the stroke length at startup, the length of the transmission under the hinge should be increased. Due to this, we can not only get shorter gears, but also maintain the traction axis in its original position.

It is worth understanding that after such tuning, you will need to put more effort when changing speeds. After upgrading, switching will resemble joystick control, which is undoubtedly a plus. In addition to the rocker, you can install a backlash-free cardan, which will also have a positive effect on the smooth operation of the gearbox.

Making a short-stroke slide with your own hands

So, let's begin the modernization process:

- We raise the place of attachment of the piece of iron that goes from the gearbox to the lever inside the VAZ 2110 interior.

- You can do without dismantling the rocker, the main thing is to disassemble the ball joint.

- Now we need to ensure that the plastic paws release the ball. To do this, you need to unclench the metal ring. We disconnect the rod and carefully drag it inside through the cover, which is responsible for protecting it from dirt. It will be much more convenient to work if the clamp near the gearbox is loosened.

Replacement is carried out according to the same scheme. Only instead of welding, a freelance short-stroke rocker from another car is installed. Replacement is a more expensive solution, so doing it yourself is problematic. If you have experience working with gearboxes, then replacing and purchasing a new part will cost about 1,000 rubles.

Installing a short-stroke cardan

The first step is to purchase the cardan itself. The best choice would be a part from Priora or Kalina. Usually it is included in the repair kit with a boot, so the standard boot from a VAZ 2110 will not fit here.

Work is performed only if there is an overpass, inspection hole or lift. It is also recommended to call an assistant for help, since at the end of the process it will be problematic to independently adjust the position of the gearshift lever.

The work proceeds according to the following scheme:

- Armed with two 13 keys, we need to loosen the clamp on the drive rod and then pull it off the rod.

- The next step is to dismantle the boot. Next, use the 10th key to unscrew the bolt, which is a lock on the standard cardan. Now you can remove the cardan with gentle blows of a hammer.

Important: it is necessary to check the condition of the oil seal. If this is the first intervention in the gearbox, then it is most likely in a worn condition, so it is recommended to change the boot.

- We install the driveshaft from the Priora in the reverse order: put on the boot and install the new driveshaft, securely tighten the fixing bolt, and then tighten the boot. All that remains is to put the drive rod on the cardan rod, but the clamp should not be tightened.

- Now the assistant gets behind the wheel and places the gearshift lever in the optimal position. At this time, the clamp is tightened. Done, the replacement is complete, all that remains is to test the switching.

How to replace the universal joint

In most cases, it is not the rocker itself that fails, but the cardan. Due to its displacement, even a small one, a failure occurs in the gear shift mechanism.

Standard VAZ-2109 scenes are rarely installed during repairs; similar parts from Lada Kalina are used. The replacement looks like this:

- Using two keys set to “13”, unscrew the clamp securing the cardan to the rod.

- Using a screwdriver, pull the boot towards the box housing. If desired, you can remove it completely, and if it has cuts or other damage, replace it with a new one.

- Unscrew the fixing bolt with a “10” key.

- Knock down the cardan with a hammer, strike carefully so as not to damage anything.

- The Kalinovsky universal joint is much more durable and reliable, so install it instead of the standard one.

- Reassemble the entire structure in reverse order. But do not rush to tighten the bolt on the clamp - adjustment is necessary.

Lada 2110 PhiX › Logbook › Installing a transmission cardan from a viburnum on a VAZ 2110

Hi all! This time I will tell you about another experiment. This time we will do another stupid thing, we will replace the tuning gearbox driveshaft with a Kalina driveshaft driveshaft.

I have long had a hard, backlash-free gearbox drive unit installed; such driveshafts are made from the steering shaft and are popularly called tuning drives. In principle, he suited me with everything, but there is no limit to perfection.

Let me remind you that I previously conducted an experiment with installing a stock cardan, and then the result did not particularly impress me. www.drive2.ru/l/4779423/

So, I bought a KK for 320 rubles, the boot fits from the stock driveshaft.

Comparison of standard, tuned and viburnum cardan shafts.

The first thing that catches your eye is that the tuning cardanic is fixed on the gear selection rod, not like stock and KK, which allows you to move it forward and backward one at a time, i.e. adjust the depth of the slide more flexibly. This is of course not much use, but maybe someone will need it.

The Kalina has longer strokes (compared to the tuning one) and in theory the longitudinal stroke of the lever should have increased, but since it fits onto the rod with a turn (we will return to this later), the stroke of the gearbox lever will be slightly shorter than that of the tuning one.

The Kalina cardan is a little longer than the stock one, and in order for everything to be even, it should be shortened a little, which means that there is work for the grinder. I measured how much to cut by eye, placing two cardan joints next to each other.

To make an even cut, I marked the cut area with electrical tape.

After using the grinder, the edges of the cut turned out to be razor sharp; I had to grind the sharp edges on a sharpening machine.

By the way, don’t forget that safety comes first.

When sawing, KK felt the heat from the stream of sparks, it turned out that the sparks burned through his pants.

I am always amazed how many people work with an angle grinder without protection. In my memory, there are a couple of cases where failure to comply with safety regulations led to tragic consequences. In one case, a piece of metal shavings hit a friend in the eye and required urgent surgery. An acquaintance from the emergency hospital told me about the second case; a flying disc from an angle grinder cut the skull and got stuck in it, going halfway through; by some miracle the patient remained alive and conscious. He said that he sawed with a grinder without a protective cover.

Enough of the lyrics, let's get back to business. The driveshaft should be properly lubricated; I used CV joint grease. I stuffed as much as I could into the crosspiece.

Since this is not the first time I’ve done the installation of the cardan and adjusting the backstage, everything became easy and fast.

Conclusions:

I didn’t notice much of a difference between the tuning and viburnum cardan. The gearshift knob began to rattle a little less. And the longitudinal travel of the lever decreased slightly. The Kalina cardan, unlike the tuning one, is completely protected by anther. On the tuning one, the boot did not completely cover the cardan, which is why dirt could get into it, but it is worth noting that it worked perfectly for fifteen years and would have worked for the same amount of time.

PS

After installing the CC, I still have one question. The KK stands on the gear selector rod at an angle, i.e. rotated relative to the axis of the rod, which significantly reduces its working strokes. In this case, the working stroke of the KK is quite enough, but perhaps it would be better to place the universal joint evenly. To make it clear, look at the following photos, I have placed the moving elements (crosses) of the cardans in one plane, and now we look at the screw that secures the cardan to the rod.

As you can see on the CC, it is located in a different place, i.e. After installation, the QC turns out to be rotated on the axis of the rod.

Question for the Kalina drivers, is the cardan on Kalina installed just as crookedly or is it still straight? If you have any thoughts on this matter, I would be happy to listen. Likes and reposts are welcome. )

VAZ 2110 gearbox linkage and its repair

For front-wheel drive car models, the designers developed a gearbox speed shifting system using a special mechanism called the VAZ 2110 gearbox rocker. This design for moving the gear lever is designed to ensure good performance of the gearbox. On a VAZ 21101, the gearbox link can be easily replaced on your own.

VAZ 2110 gearbox link

When operating a vehicle, the rocker, like other systems, must be adjusted. The reason for the adjustment may be due to incorrect movement of the gear shift lever. When you engage the desired gear, you have to tilt it strongly back or vice versa, it rests against the instrument panel:

- The location of the scenes is under the body of the vases.

- It connects the lever to the gearbox.

Why change the backstage?

There are situations when it is necessary to intervene in the gear shift mechanism due to the failure of a component. But there are times when an extreme measure is required - replacing the VAZ-2109 rocker. In these cases, replacement is required:

- An oil leak appeared due to damage to the oil seal. Only the oil seal can be replaced.

- Complete failure of the scenes.

- You have realized the advantages of a short-stroke design and you have the funds for this kind of tuning.

Symptoms of gear shift mechanism failure:

- Increased gearshift lever play. Please note that this behavior may also be caused by a loose cardan. Sometimes the bolt securing it gets screwed out, so to reduce the backlash it is enough to tighten it, and first apply a drop of thread locker.

- Difficult to shift into gear. Sometimes extraneous sounds are heard.

- Gear shifting is not possible.

- Inconsistency between the position of the lever and the selected speed. For example, the back one disappears, and the first one is in its place.

If a slight play appears, it is advisable to carry out diagnostics and identify the breakdown of the unit. Make repairs immediately, otherwise one or more speeds will disappear at the most inopportune moment.

Adjustment

Adjusting the VAZ 2110 gearbox rocker

It is recommended to carry out the adjustment work together with a partner. To do this you need to prepare:

- regular set of tools;

- you will need a metal brush to clean the joints;

- cotton gloves;

- Just in case, buy a repair kit at a car store.

- Place the car in a garage with an inspection hole.

- Engage reverse gear.

Note. There are problems with inclusion - then first gear is engaged.

- Go down into the viewing hole.

- Clean the places where the fastening bolts are installed for the rocker clamp using a wire brush.

- Wipe with a rag for easy rolling.

- Unscrew the bolts.

- Turn the drive to the left until the lever stops in the plastic lock of the reverse gear.

- After this, tighten the bolts.

- Check the lever travel with the gears engaged.

VAZ 2110 gearbox link and its replacement

If the stroke still does not meet the required parameters, then it is necessary to make adjustments in neutral:

- Place the lever in the neutral zone.

- Turn the rod drive to the left to select the speed until the adjusting pin enters the rod hole.

- Remove the trim panel from the lever.

- Secure with the adjustment bolt.

Gearbox link for VAZ 2110

The lever stroke is adjusted on each car depending on the driver’s habits. This procedure is carried out by adjusting the size of the scenes from the lever itself . The neutral position is calculated depending on the depth of the seat on the cardan shaft.

Note: after the adjustment, a rattling sound remains, then you need to install a spring to hold the lever.

The progressive, accelerated development of the automotive industry in Russia allows car enthusiasts to use new and improved spare parts for older models, which include “tens”.

Installation of the backstage from "Kalina"

Replacing the VAZ 2110 gearbox

On a VAZ 2110 you can successfully install a slide from Kalina:

- To do this, it needs to be modified a little.

- The cardan from the new model is 20 mm longer than the original “tenth”.

- Therefore, it needs to be cut, to do this, use a lathe.

Note: when cutting manually, you can ruin the part, since when the temperature of the metal increases, it loses its strength.

- The replacement of the slide must be carried out in the garage from the inspection hole.

- Remove the plastic tunnel from the car interior.

- Also remove the boot.

- Remove the old rocker, unscrew all the fasteners from under the bottom of the car.

- Install a new link and adjust it.

Note: adjustment must be carried out in order to later avoid troubles that arise during operation of the vehicle.

Why is it recommended to install a cardan from the new Kalina? On VAZ-2110 models, universal joints made of less resistant material are installed, so they quickly fail. This causes premature play in the rocker, which usually affects the quality of gear shifting while the vehicle is moving. After purchasing a new link, a visual comparison should be made of the old cardan and the purchased one. The comparison will be entirely in favor of the new acquisition. The Kalina cardan is made of better quality material, it is much more wear-resistant.

Gearbox slides for VAZ 2110

After installing a new link, the lever may rattle. Since this link completely eliminates play, that is, the vibration is transmitted completely to the lever.

Fixing lever rattling

- To do this, install a new ball joint for the lever and install a repair kit.

- The ball joint must be replaced from the inspection hole, since it is easier to change it from under the bottom of the car.

- Install the retaining spring to the gear lever.

It will dampen vibration by holding the lever in the desired position. This will not affect the application of additional forces when turning on the speeds. To get rid of the rattling of the lever, you can install additional plastic washers on the gearbox axle. To do this you will need:

- material - plastic (regular lid for jars);

- open-end wrench No. 10, No. 13;

- scissors;

- Phillips screwdriver;

- flat file, you can use a small flat file.

- remove the plastic tunnel;

- unscrew the nut with an open-end wrench No. 13;

- Unscrew the screw using a Phillips screwdriver;

- unscrew the two nuts with a No. 10 wrench;

- remove the bolt;

- carefully pull out the bushing;

- remove the washers.

Using scissors, according to the size of the sleeve, cut two washers from the prepared plastic materials:

- Lubricate all parts with graphite lubricant.

- Place an additional washer on the bushing.

- Put it in place.

- Insert another washer on the right.

- Place oil-resistant rubber rings on both sides of the bushing.

- Reinsert the bolt.

- Treat the threads with graphite lubricant.

- Tighten the nuts.

Note: when tightening the nut to 13, you must take into account the following: if it is tightened too tightly, the lever will be difficult to move.

After such painstaking work, the car enthusiast will get rid of the rattling gear lever for a long time. The lever begins to work easier, and the gears are switched on more efficiently. You need to do the work yourself after watching the video and photos. Painstaking work must be carried out after a detailed study of each stage of work, since the gearbox gate ensures good operation of the gear lever. Therefore, how professionally the repair is carried out will completely affect the provision of comfort during operation of the VAZ-2110. It is also recommended to read the manufacturer's instructions. Price of spare parts for replacing the rocker:

- gearbox driveshaft from VAZ-2114/2115 from 300 rub.,

- boot from 65 rub.,

- drawstring from "Kalina" within 500 rubles.

Do-it-yourself installation and adjustment will give the car enthusiast the opportunity to fully feel the difference in the operation of the car.

Removing the front wheel drives of a VAZ-2110 car

We remove the drives to replace them or when dismantling the gearbox. Repair or replacement of the drive is required if there are knocking noises when cornering or increased vibration that occurs when the joints wear out. Wear of the hinges is caused by sand and dirt getting into the internal parts of the CV joint, when the rubber boots rupture.

We carry out the work on an inspection ditch or a lift.

To do this, remove the engine splash guard:

Using a 10mm socket, unscrew the five nuts for the front fastening of the mudguard to the body.

Use a 10mm wrench to unscrew the screws on the front plastic shield.

Using a 10mm wrench, unscrew the screws for the rear fastening of the plastic shield

Using a 10mm wrench, unscrew the two bolts securing the mudguard to the side members

To do this, drain the oil from the gearbox, use a 17 key to unscrew the plug and drain the oil into a container (volume - 4 l).

After draining the oil, screw the plug back in

We unscrew the front hub bearing nut, to do this we remove the hub cap

Use a narrow chisel to straighten the dented collar of the nut.

We lock the rear wheels with the handbrake, engage first gear and place shoes under the wheels.

Use a 30mm socket to loosen the hub bearing nut.

Loosen the wheel mounting bolts.

We hang up the front of the car and remove the wheel.

Unscrew the two ball joint mounting bolts

Replacing the universal joint on a VAZ 2110, VAZ 2111, VAZ 2112

Welcome! The backstage cardan is what people usually call it, but in reality it is called the “Gearbox control drive rod joint”, something like this, thanks to it, gear shifting is carried out, or rather, not thanks to it, but thanks to your hands, that is, in that the moment when you grab the gearshift knob and shift it, by means of a rod that goes from the rocker itself to the box and the next gear is engaged, and the cardan is an intermediary in this matter and an assistant in shifting gears, if the cardan is severely deformed, then you simply cannot change gear You can, or you can shift, but with great effort, and it’s not a fact that that particular gear will turn on and not any other.

Note! In order to change this hinge (in the future it will be called that), you will need to stock up on tools, which will include: Wrenches and spanners (Whichever is more convenient for you), and you will also need a screwdriver and a rubber hammer (If you have this one, if not, then take the regular one)!

Summary:

Where is the rocker shaft? You can only see it if you get under the bottom of the car and move the boot (Indicated by a red arrow) that protects it to the side; for an example, see the photo below, on which the blue arrow indicates the location of this very hinge:

When do you need to change the driveshaft? It is changed as it wears out, namely, when it wears out, the gears may not engage correctly, for example, you turn on the first gear and your reverse gear turns on instead, and also this hinge, many car owners are replaced with the same hinge, but only from the viburnum, but indeed the hinge is from Kalina does not have any play, therefore the gears are engaged clearly and the gearshift lever travel itself becomes less than if we take, for example, a standard hinge from a VAZ 2110, but there is one thing!

The whole point is that the Kalinovsky joint has no play, which means it will put more force on the gearbox, in addition, due to the fact that there is no play in the joint from the viburnum, all the vibration that comes from the box will reach the gearshift knob, unlike the original one a hinge from which much less vibration will go to the handle.

Note! Let’s say something else about the viburnum hinge, if your gearbox hasn’t been repaired for a long time and from time to time it knocks out gears when driving (Gears can knock out gears due to heavily worn gear teeth and because of worn out forks that are responsible for engaging the gear), then It is not recommended to install a Kalinovsky hinge on your car, because as mentioned earlier, it transfers more load to the box and therefore it will fail very quickly, so be careful!

Backstage replacement and repair

Taking into account the fact that during the operation of a car, the rocker on a VAZ or on any other car experiences constant loads, the mechanism wears out, and the adjustments get lost. For this reason, it is important to understand what in a particular case would be the optimal solution: repair, adjustment or replacement of the link with a standard new one or a short-stroke one.

In any case, it is necessary to first disassemble the mechanism. To do this you will need:

- remove the cover on the gearshift knob;

- drive the car onto a pit or overpass/lift;

- remove the tunnel where the gearshift knob is installed by unscrewing the bolts;

- dismantle the rocker itself (on a VAZ 2110 it is secured with six bolts).

During the disassembly process, you need to carefully check the condition of each individual part, you should also bend the boot, check the condition of the support, oil seal, cardan, etc.

If, for example, the oil seal has failed, then it is enough to have a repair kit where such an oil seal is included. This kit will also come in handy if more complex repairs to the backstage are required.

If the bushing is deformed, it must be replaced. In the event that the cardan is loose, as well as in a situation where the hole in the lever axis is worn out, a complete replacement of the link will be required, that is, a repair kit will not be able to solve the problem.

We also note that a common problem that drivers note during operation is the rattling of the rocker. Typically, in this case, if there are no other complaints, the drawstring cushion is often the culprit.

At the same time, replacing the rocker cushion is not a complicated procedure, but the result is often positive and significantly increases the comfort when operating the vehicle.

- Another important procedure in the process of servicing the rocker is replacing the rocker rod oil seal. It is important to understand that the serviceability of not only the operation of the backstage, but also the gearbox directly depends on its condition.

If drops of transmission oil are visible under the car, this often indicates that the seal is leaking. As a rule, problems with the VAZ 2110 rocker seal appear in the form of a crunching noise when switching.

We also recommend reading the article on how to remove the gear shift lever. From this article you will learn about the features, subtleties and nuances that need to be taken into account when removing the gearshift lever.

As for replacing the oil seal, the car needs to be driven into a pit or raised on a lift. Next, you should inspect the rubber boot. If it is not sealed or is torn, traces of oil will be visible.

Then you should bend the boot, disconnect the cardan and thus gain access to the cuff. Now the cardan is removed from the lever, after which it is disconnected from the rocker. After removal, you can get to the oil seal and then use an awl or hook to remove the gearbox cuff.

Next, you should press in a new oil seal (in home-made conditions, installation is carried out using a stopper from a plastic bottle). If the oil seal is installed successfully, you can proceed to reassembling the entire mechanism, not forgetting to put the boot in place.

In fact, such repairs allow you to avoid oil leaks in the gearbox and improve the operation of the gear shift mechanism. Finally, we note that it is also important to carry out adjustments and settings after repairs.

The fact is that even a serviceable, but incorrectly configured rocker will not work properly. By the way, on a VAZ 2110 it’s difficult to set up the rocker yourself. To make the process easier, it is better to immediately invite an assistant.