It is important for every driver that the car obeys him well in any situation. One of the main systems of a car is the steering system. Therefore, every breakdown of the steering system leads to a deterioration in driving quality, and possibly even to an accident.

It is for this reason that it is important to always monitor the condition of the steering system and promptly carry out its repair and maintenance. Today we will talk about the VAZ 2114, or more precisely about its steering rack.

The steering rack itself is a long rod with attachments and two outgoing parts. The steering rack is responsible for the handling of the car and also for the safety of the driver, so if it breaks down, you should immediately begin repairs.

You can understand that the rack requires replacement by the following signs: when you turn the steering wheel, you hear a knock and play appears. In this case, the knocking sound most often appears only when driving; if it is heard when turning the steering wheel while parked, then the steering rack definitely requires immediate replacement - this means that the breakdown has started and the rack is in critical condition.

Steering rack VAZ 2114 - what it consists of

Before proceeding directly to the verification process, you need to know the design features of the steering rack. Let's look at what elements it consists of:

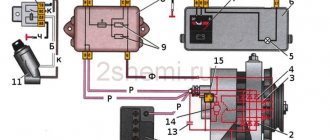

1 – protective cap; 2 – steering gear housing; 3 – rack; 4 – drive gear; 5 – inner tie rod end ; 6 – spacer sleeve; 7 – tie rod mounting bolt; 8 – connecting plate; 9 – support sleeve; 10 – steering gear support; 11 – rack support sleeve; 12 – protective cover; 13 – clamp; 14 – rack restrictive ring; 15 – sealing ring of the rack stop; 16 – nut; 17 – rack stop; 18 – roller bearing; 19 – ball bearing; 20 – retaining ring; 21 – nut sealing ring; 22 – gear bearing fastening nut; 23 – boot; 24 – lock washer

Steering wheel

The steering control of the VAZ-2109 car is built according to the following scheme:

- steering wheel;

- column;

- cardan or intermediate shaft (cardan);

- rail;

- rods and tips.

Let's look at the meaning of each element of the chain.

Steering wheel

The steering wheel - the steering wheel, the steering wheel, the steering wheel - is an important part of the control system - is in the hands of the driver. The device transmits a person’s muscular force to the wheels of a car to set them in one direction or another.

The steering wheel is the visible part of the system. The remaining components are hidden in the steering column and under the hood.

VAZ steering wheel

The steering wheel of the VAZ 2108 is a simple 2-spoke design, covered in leather. You can find the “native” steering wheel using catalog number 21083-3402012. In the fifteenth version of the Zhiguli, the steering wheel became 3-spoke, but it cannot be called modern and multifunctional.

Cardan or intermediate shaft

Cardan joint - universal joint - a movable joint between the steering rack and column. The unit ensures easy rotation of the drive wheels.

The element consists of two sliding U-shaped forks connected by a cross. At the joints there are miniature needle bearings, which are prone to souring if water gets on them.

The steering of the VAZ-2110 car has two cardan shafts. In designs with one element (the Soviet Volga), the transmission of rotation to the wheels occurs intermittently, in pulses. Cars 2108-2115 have two hinges: the upper one is located in the driver’s feet, the lower one is located near the steering rack under the bottom.

Crosspieces are considered maintenance-free. This is due to the fact that the elements operate in gentle conditions - they are not influenced by external factors. The service life of the intermediate shaft under favorable conditions is up to 500 thousand km.

But the entire mechanism bears the same loads as the transmission when driving on uneven roads. In fact, the cardan may succumb to corrosion (stop bending) or wear out (play will appear). To repair parts, buy a set of crosspieces and bearings of a suitable size.

Rail

There are no secondary components in the system. But the rack in the steering device of the VAZ-2109 car plays a special role. The part is responsible for the maneuverability of the vehicle, turning the wheels of the car in the desired direction at the command of the driver. The rack cannot be called the main element of the mechanism, but the comfort and safety of travel depends on it.

The assembly looks like this: a gear rack is placed in the crankcase. Protection from dust and dirt is in the form of anthers - rubber accordions, like on CV joints. There are two threaded holes on the bar - these are sockets for securing the end rods. There is a drive gear, support rings for smooth sliding and a stop mechanism that regulates the amount of clearance of the rack-pinion pair.

Rack VAZ

This is a loaded unit with high efficiency. Wear of the mechanism affects the controllability of the vehicle. The steering wheel turns hard, there is play, and there is a knocking sound coming from underneath when the car maneuvers.

However, the steering rack is a simple mechanism that can be easily repaired in a garage.

Traction

They transmit force from the steering mechanism to the wheels. Technically, the rod is made like a metal bar. One side of the bar is attached directly to the steering rack through a hinge. Here, special mounting sockets are provided for the rods. On the other side there is a regular thread for attaching tie rod ends.

Fingers (tips)

The steering system in a car is rigidly fixed, while the wheels are movable. The rods, in order to transmit the driving force to the wheels, are connected to the steering knuckle lever through the steering tips (fingers) - the last link in a long steering-wheel chain.

The tie rod end is an extremely simple, and therefore reliable, hinge. It consists of a housing with an axle shaft and a threaded ball pin. And also an insert for fixing the finger. The device body is closed with a lid. The cover is fixed to the finger with a ring, the latter is attached to the body with a spring.

The Teflon liner holds your finger tightly. Therefore, steering tips last a long time. But when the liner wears out, play appears. The protection (anthers) can also be broken.

A problem with the tips is indicated by kickback in the steering wheel on any bump and a dull sound when turning. The phenomenon is prevented by timely maintenance and repair of the steering control of the VAZ-2110 car. Driving with a faulty mechanism is not only uncomfortable, but also dangerous.

Shock absorber struts

In cars without springs (which is practically all modern vehicles), shock absorbers or shock absorber struts are installed. These are mechanisms of different design and functionality that inexperienced drivers confuse:

- A shock absorber is an oil pump that dampens vibrations that occur when the car is moving. The term "telescopic strut" refers to a shock absorber.

- The shock absorber strut, in addition to softening the ride of the car, sets the geometry of the suspension. Another function is to create multiple support points.

The design of the unit is complex. The key components work in pairs - the shock absorber and springs themselves. The latter are compressed when the car hits obstacles and, due to elasticity, are released. The springs then continue to oscillate up and down until they reach equilibrium.

Shock absorber struts VAZ

Vibrations are transmitted to the car body. But here a shock absorber is connected - a cylinder, inside of which a piston moves in a gas or oil environment. The strut shock absorber dampens unnecessary vibrations of the springs. If the body begins to sway strongly or the car begins to roll, you need to check the condition of the shock absorber struts.

What racks and rods were installed on 2108-2115

Modernization of Tolyatti VAZs has always been slow. Starting in 1984, there were no changes in the suspension, engines, or steering for 20 years.

The steering rack of the VAZ-2108 was under catalog number 2108-3400009-20, passed from model to model until the release of the “ten”. The article number of the VAZ-2110 part, called “old-style slats”, is 2110-3400009-20.

What is the difference between racks and rods of different models?

The factory equipped V8s with straight-toothed racks developed in the 70s with a full steering rotation of 3.7 turns.

Subsequent modifications of the car were equipped with such elements. And initially the tenth model. But then the rack was improved: it, like the drive gear, became helical. The manufacturer strengthened the VAZ-2110 steering gear housing and used a “figure-of-eight” gear-rack pair. The latter received the name “rasp” from auto mechanics. The full stroke of the new-style helical rack became 4.2 turns of the steering wheel. The catalog number has changed - 2110-3401068.

The Lada Kalina came off the assembly line with a shortened helical rack with a full steering rotation of 3.1 turns. The part number is 11183-3401068-00 (11183-3401068-01).

Are racks and rods of different models interchangeable?

The topic of interchangeability is lively discussed on automotive forums. The answer is yes, but with some nuances:

Are racks and rods of different models interchangeable?

On the VAZ 2108-2115 model from 1984 to the present day, you can install steering racks:

- manufacturer code – TRIALLI, article – CR 108;

- from AVTOVAZ the part goes under catalog number 2108-099,2113-2115. 2108-3400009-20.

Steering rods: manufacturer VIS ZAO, article number 21080-3414060-00.

Dimensions: length, width, height of rods – 370x50x50 mm.

Steering rack VAZ 2114 - the main reasons for failure

Reasons for failure

When the issue of rack adjustment has been sorted out, you can consider the reasons for its failure:

- Wear . Each car mechanism has its own running life.

- Due to uneven roads, the pressure on the rack is significantly increased.

- Inadmissible acceleration at extreme wheel position.

- Mechanical damage caused during operation.

Steering rack VAZ 2114 - signs of malfunction

Let's look at each of the signs and what can cause them to appear. It should be noted that some problems, for example knocking, may not be related to the mechanism itself.

- So, the free play on the steering wheel has increased, that is, it dangles more; the increased travel can additionally manifest itself in the appearance of a beating in the steering wheel when braking.

This problem may be associated with loosening of the ball pins to the stabilizer strut, increased clearance in the ball joints, or increased clearance between the rack and pinion.

- If play is detected in the steering wheel, first of all you should inspect the steering ball joints. It rarely happens, but it is possible that the nuts securing the tips have become loose and the pin has begun to come out of the seat, causing a significant gap to form at the mounting point. Fixing such a malfunction is simple, just tighten the nuts.

- Ball end wear is much more common, resulting in a gap between the pin and the body. This problem can be eliminated by changing the tips.

- Play in the steering wheel can be formed due to an increase in the gap between the rack and pinion. During the operation of this mechanism, these elements gradually wear out, and the gap between them increases. Repairing this problem comes down to an adjustment that just requires tightening the adjusting stop nut correctly.

- A knock in this mechanism can be caused by play in the tips, an increased gap between the rack and gear, as well as loosening of the mechanism itself.

- As for the tips and rack clearance, the repair of the mechanism is indicated above, that is, just tighten the thrust nut and that’s it.

- Regarding the loosening of the fastening, it is enough just to tighten the nuts securing the clamps that hold the mechanism, and the problem will be solved.

- Stiff rotation of the steering wheel may be due to damage to the support bearing of the shock absorber strut (the case when a problem with the suspension affects the steering mechanism), damage to the rack bushing, wedging of the steering tips, or wedging of the steering gear bearings.

- In the case of a worn support bearing, the repair boils down to removing the support and replacing the bearing.

- If the reason for the tight rotation is the support bushing, then you need to put a new one in place of the damaged one, and lubricate the mechanism itself.

- If there are problems with the tips, they should be checked and replaced if necessary. The same applies to drive bearings.

Adjusting wheel alignment with a caliper

It should be noted that after repairing many faults, adjustment of the wheel position (wheel alignment angles) will be required.

All work with the steering mechanism can be done with your own hands; there is nothing particularly difficult about it. But after work, especially on the steering tips, the toe angles will need to be adjusted, which is best left to specialists.

If a malfunction occurs, you will first need to diagnose the mechanism to identify the unit that caused it. First, the condition of the tips is checked. To do this, they are removed from the support and checked manually. With a working tip, the finger moves in its body with effort, but it should not get wedged to any position; such a tip can be put in place and continue to look for faults. If it moves freely and there is some play, then it is replaced.

Next, the gap between the rack and gear is adjusted. For this, a special 6-sided key is used. With its help, the thrust nut is tightened until it stops, and then loosened by ¼ turn. After this, the nut is fixed using punching. If the adjustment is made correctly, and the condition of the rack is still satisfactory, then the knocking should disappear. If the adjustment does not help, then most likely the wear of the main components is quite severe and a major overhaul of the mechanism is required with the replacement of the rack, which can also be done with your own hands.

Diagnostics and restoration of slats

Instead of purchasing a new rack, you can try to repair the one installed on the car. But first you need to make a diagnosis.

To do this, we completely disassemble the assembly into its component parts and carry out troubleshooting. This will allow you to determine which elements are extremely worn or damaged.

Repair kits for restoring the steering mechanism are sold on the market. Moreover, their completeness is very different.

Some include only rubber and plastic elements (oil seals, boots, bushings).

Others come with a new rack, gear, connecting elements, bearings (in general, almost all components).

With the help of repair kits, you can restore the functionality of the “native” unit, but only on the condition that the body is intact and does not have significant wear.

The use of repair kits can significantly reduce the cost of repair work. But they do not always allow you to restore functionality and problems with the steering remain even after repairs.

In this case, there is only one way out - replacing the steering rack with a new one.

Do-it-yourself self-diagnosis and check of the VAZ 2114 steering rack

So, to check the steering rack you need to measure the gaps in it.

This can be done either on a removed mechanism (which is even better) or directly on the car. Now let's move on to the process:

Set the mechanism to the middle position. It can be determined by its dimensions - ( 87±0.25 ) mm from the gear axis to the rack end. Using a special device, we load the unit to a force P = 500 ± 20 N (51 ± 2 kgf). The distance from the gear axis should be – 84 mm .

The maximum permissible movement of the rack “X”, measured through the relative movement of the pressure punch 1, should not exceed 0.12 mm . After assembly, the torque of the gear in the area of the rack stroke should be in the range of 50–200 N·cm (5.1–20.4 kgf·cm) at a rotation speed of 30 min-1 .

Work order

Replacing steering bearings on a vehicle such as a VAZ-2110 consists of a number of stages that must be carried out in the order in which they are listed below.

The whole process can be seen in the video:

First, you need to disconnect the battery on the car to prevent an electrical short circuit. It is enough just to remove one terminal where the “-” sign is indicated.

Then you need to remove the steering wheel. To do this, you will need to turn the car's ignition key, and also turn the steering wheel 90° in either direction. You will see a whole row of nuts, thanks to which the steering wheel is attached to the shaft

Using a special wrench, unscrew the nuts, and then carefully proceed to the recess to remove the steering wheel. This is done due to the fact that in some cars there is a system in the steering wheel that allows the steering wheel to be spring-loaded

If you do not take this into account, you may even get injured.

Using a special wrench, you need to unscrew the nuts where the steering column switch mechanisms are secured. Next, their bases must be moved towards the driver’s seat.

Having found the wire connected to the oil pressure sensor, you need to remove it.

How to disassemble the steering rack of a VAZ 2114 and replace worn parts

In addition to a helper and new slats, you will also need a set of tools and materials. Be sure to include in this list:

- Set of wrenches;

- Jack;

- 17mm hex wrench;

- Balloon wrench;

- Bricks or similar materials (to support the front of the car without wheels);

- Puller for steering rods (not necessarily needed, you can do without it);

- Dry rags;

- Litol type lubricant;

- The almighty WD40.

Now you can proceed directly to replacing the steering racks. We strongly recommend that you follow the established procedure for conducting operations.

- Place the car on a level surface. No, a simple floor in your garage is enough, it is not necessary to level it with cement.

- Apply the parking brake to keep the car from moving.

- Raise the car on a jack, place logs or bricks under the front, and then remove the wheels.

- Remove the negative cable from your battery for safety reasons. Nobody needs electric shocks today.

- On the driver's side inside the passenger compartment, near the pedal block, unscrew the locking fastening bolt of the cardan of your steering shaft.

- Remove the adsorber directly from the engine compartment. You can put it aside for now.

- Remove the cotter pins, which will allow you to then remove the mounting nuts from the tie rod ends.

- Using a rod puller, the ends are removed from the racks. If for some reason the puller is missing, it can be replaced by gentle, successive blows to the tips. Don't damage their threads just by doing this. They usually lend themselves, so many people do without pullers.

- Treat the rack clamp fixing nuts with an anti-rust agent. Now we are talking about the almighty WD40. Wait a while for the composition to be absorbed.

- Using a wrench, unscrew the fastening nuts. Processing with a Vedash should greatly simplify this task for you. There are four nuts in total.

- Remove the rack by pushing it through the passenger side, that is, the right side of your VAZ 2114.

- We recommend replacing the boot at the same time as replacing the racks. Over time and during the period of operation, the steering boots seriously wear out, so it is hardly worth trusting old boots to work with new racks.

- The tips are removed from the slats. At the same time, try to count the number of turns with which the nuts were tightened. This will allow you to fasten them back as close to precision as possible at the reassembly stage and, with peace of mind, go to the service station, where they will adjust the wheel alignment.

- Take your new rail, remove the plugs from it.

- Next, take Litol or a similar lubricating liquid into your hands and fill the body with this composition as much as possible.

- The ends are mounted back onto the rods. Try not to mix up the places of the nodes, although they are different from each other. However, as practice shows, this does not prevent many do-it-yourself repairmen from confusing them.

- The new rail is placed in its rightful place. To do this, the nuts are attached to the studs of the clamps.

- Now you will need your friend, comrade, assistant. Ask him to help guide the shaft drive gear to the seat located directly on the rack housing. The splines must line up exactly. Be sure to check this moment.

- A locking bolt is fixed on the cardan.

You can safely perform all other work in the reverse order of the dismantling described above. In this case, each thread must be treated with Litol. This event will allow you to more easily deal with disassembling the elements during subsequent repairs. Or it will be a pleasant surprise for the new owner of your VAZ 2114.

What kind of steering wheel can I install?

If you decide to replace your old steering wheel, it means that its appearance did not suit you in some way. Of course, the issue may be a breakdown or external damage, however, even in this case, you should consider installing third-party models. What if you like one of them much more than the previous steering wheel?

Original

2108-3400012 – original catalog number of the steering rack produced by AvtoVAZ. It fits perfectly into the seats and does not require modification of the fasteners. The average cost is 6,000 rubles.

Original steering rack made by AvtoVAZ

Analogs

In addition to the original part, there are a number of analogues that can be used for installation on a car. Let's look at which ones:

- Weber SG 2108-0012 - average cost is 4,500 rubles.

- Pilenga SR-P 1141 – average cost is 6000 rubles

Pilenga steering rack

- Trialli CR 108 — steering mechanism (rack) for VAZ 2108 (2113-2114) without tie rods (cr 108). The cost of the product is 6,000 rubles.

- Trialli CR S 708 — Steering mechanism (rack) for VAZ 2108 (2113-2114) with tie rods and ends (cr s 708). The average cost is 12,000 rubles.

What you need to know when installing

Please note that not every steering wheel is suitable for installation on VAZ 2114 and VAZ 2115 cars. You need to choose a steering wheel with the same contact group as the original part.

choose a steering wheel with the same contact group as that of the VAZ 2114 and 2115

This is quite easy to do if you plan to install a steering wheel from other VAZ models. For example, a steering wheel with a Europanel from a VAZ 2110 is ideal for these purposes.

If you have chosen a Lada Kalina car, then its steering wheel should be marked 1118–3402010. With it you will also have to install the upper casing marked 2110–3403070–30, as well as the lower casing 2110–3403072–30.

To install a non-standard steering wheel on a VAZ 2114, use the steering shaft housing 2110–12

If you like sports models, then you will have to purchase a special adapter designed for VAZ 2113–2115 cars. This adapter is installed on the steering shaft, and the steering wheel is mounted on top. An adapter model suitable for this purpose is PROSPORT RS-04282.

This is interesting: Causes of white smoke from the exhaust pipe: how to fix the problem

for installing a sports steering wheel on VAZ 2114 and 2115 cars, the PROSPORT RS-04282 adapter is suitable

VAZ 2114, is it possible to install an amplifier yourself?

The work will take no more than two hours if you do everything without haste and with breaks. There is no need to remove the VAZ steering rack; there is no need to even disconnect the rods. You will need a small set of keys: for 10, 13 and 17. The last two are needed. It is advisable to have a good set of tools, since pliers, for example, may be needed at any time.

First you need to remove the left clamp and install the amplifier clamp located on the left on the studs. Moreover, its eye should be facing upward. After this, tighten all the nuts. The clamp on the right side of the steering rack is replaced in the same way. Then you need to put the corner of the rack on a pin located on the cross beam of the car body.

If there is an adsorber tube, remove it first and then install it on top of the corner. The entire structure must be tightened by placing a large washer on the stud. Next, the cross member is installed; its two bolts must be tightened simultaneously.

If there is a gap of about 1 cm in the structure, you will need to rearrange the clamps. Most likely, you mixed them up and installed them incorrectly. This completes the installation, now you can check the VAZ power steering rack in action.

The difference will be immediately felt, the car's handling will become much better, and it will be easier for you to stay on course. If necessary, adjust the rack to minimize the backlash.