The IAC needs to be cleaned, and if that doesn’t help, then change it. If it is necessary to replace the idle speed sensor of a VAZ 2107, then even a novice car enthusiast can cope with this procedure.

Tools and materials

For the procedure you will need the following tools:

- socket wrench set to “13”;

- Phillips and flathead screwdrivers;

- tape clamps for pipes;

- pad.

To check the functionality of the regulator, you will need a voltmeter. The IAC is located on the throttle valve. The voltage is measured at the contacts. If it is below 12 V, then there is a malfunction in the control unit or in the power circuit. If the voltage is 12 V, then the regulator is faulty.

Regulator position XX

Stages

The idle speed regulator on the VAZ 2107, located on the DZ, changes along with its body.

The procedure itself consists of the following steps:

- First of all, the car is de-energized by disconnecting the negative terminal on the battery.

- Next, you need to disconnect the cable with which the remote control is controlled.

- Next, you need to disconnect the wire block from the TPS and from the IAC.

- We loosen the clamps on the coolant inlet and outlet pipes, and disconnect them from the control valve.

- After loosening the clamp, disconnect the crankcase ventilation pipe.

- Next, you need to loosen the clamp on the hose that supplies fuel vapor to the remote control and disconnect the hose.

- After unscrewing the fastening nuts, remove the DZ housing from the studs and take out the gasket.

- Next, unscrew the fastening bolts and remove the IAC.

- On the removed regulator, check the O-ring; if it is worn out, replace it.

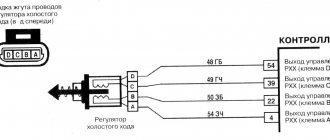

- Then we check the IAC voltage at the terminals of its windings. Between outputs AC and BD it should be infinite, between AB and CD - about 53 Ohms. If the readings are not the same, the device needs to be changed.

- Before installing a new IAC, you need to check that the needle does not protrude more than 23 mm, otherwise we replace the valve with a new one.

- Before replacing the device, lubricate the seal with engine oil.

- Installation of the DXX is carried out in the reverse order.

Thus, replacing the idle speed sensor on a VAZ 2107 is completed (video author - Ovsiuk).

Idle speed regulator VAZ 2107 injector

There may be several reasons for this unpleasant problem:

The IAC idle speed controller is malfunctioning

The idle speed of the engine changes by itself and it may even stop; often the engine does not want to start without pressing the gas pedal. And the “Check Engine” lamp may not light up. At medium and high speeds, the engine keeps its speed evenly, and no loss of power is noticeable.

Problems with the mass air flow sensor (mass air flow sensor)

If the mass air flow sensor is faulty, the speed may change not only at idle speed, but also at any other throttle opening, even when driving under load. A car can put its owner in a very dangerous situation by suddenly losing traction while overtaking. The check engine light is usually on. If you notice these signs, you will need to replace the faulty sensor. Read how to do this here

Air leaks through cracks in hoses and seals

Excess air that enters the engine intake tract bypassing the mass air flow sensor depletes the combustible mixture. The speed and power of the motor changes, the controller tries to correct this. As a result, the speed and “traction” change. But unlike the case with a faulty mass air flow sensor, this does not happen so abruptly. The Check Engine light does not come on.

Carefully inspect all tubes and hoses that extend from the throttle body, gaskets, the throttle body itself, and the intake manifold for cracks. Pay special attention to the hose going to the vacuum brake booster, as it often cracks. It also happens that the vacuum booster itself begins to “poison” the air and then when you press the brake pedal, the engine speed will change. Eliminate all these faults and the engine will start running smoothly again.

Other reasons

A car is a very complex system and it is simply impossible to describe the incredible variety of possible combinations of breakdowns. The engine may “jerk” when driving and change speed due to a malfunction of the ignition system, injectors, bad gasoline, water getting into the tank, dirty filters, etc. In each specific case, you need to carefully analyze all the signs and draw conclusions. If all else fails, you can always undergo verification diagnostics with a motor tester.

What is idle air control

When we release the gas pedal, the throttle valve closes completely, blocking the path of air into the intake manifold. In this case, engine operation is ensured by a small cross-section bypass channel, through which air flows for idle operation. A device is installed in the channel that has the ability to change its flow area and even completely block it. This mechanism is the idle speed regulator. With its help, the ECU controller can maintain and change engine speed at idle. For what? For example, when we start a cold engine and it runs unsteadily, when we turn on the heating or air conditioning, thereby adding to the load. Having received information from the crankshaft speed sensors, throttle position, speed sensor, and temperature, the controller processes it and sends a command to the idle speed controller - “add air” or “reduce air.” As a result, we have stable and smooth engine operation when the gas pedal is released.

How he does it? A stepper motor is hidden inside the housing. Short pulses are applied alternately to its two stator windings and the rotor shaft rotates to a certain angle. A screw connected to the rotor acts on the throttling element (needle), pushing it out or pushing it into the hole. The flow area of the channel changes, and the idle speed changes accordingly.

Idle air control - device, connection, general view

The regulator may stop working for various reasons. Most often, the mechanical part fails - the needle drive parts break or jam. Idle air regulators bought in stores “on the cheap” are especially prone to this because of their low quality. Failures of the electrical part occur less frequently - burnout of windings, wire breaks, wear or corrosion of the contact block.

Before replacing the regulator, we need to make sure that the reason is in it, and not in the power supply wires and connectors. To do this, turn on the multimeter in the mode up to 20 volts, check the voltage at contacts “B” “D” with the ignition on. It should be about +12 volts. If the voltage = 0 or is much lower, then the cause of the malfunction is somewhere else. It is necessary to check all circuits from the controller to the regulator and the controller itself.

Operating principle of IAC.

SPVT (Forced fuel injection system) has its own “brain”, which receives all the information from the sensors, processes it and issues commands to the actuators for the optimal functioning of the internal combustion engine (ICE). This “brain” is called a controller or ECU (Electronic Control Unit). IAC refers to the actuators controlled by the controller.

At the moment of start-up, the regulator opens a hole in the bypass. Air enters the suction manifold through it. The engine starts running. As the engine warms up, the valve closes, reducing the air supply. The speed is stabilized to a minimum.

When the throttle valve is opened, the main flow of air is supplied to the engine through the main channel. In this case, the regulator closes the hole in the bypass. To smoothly control the idle air control, the ECU receives additional information from sensors: throttle position, air flow, crankshaft position and tachogenerator.

When additional loads on the engine arise (turning on a radiator fan, heater, etc.), the regulator opens a hole in the bypass. This makes it possible to maintain power and prevent engine failures.

How to replace idle air control

To replace the regulator, you can go in three ways:

- with complete disassembly of the throttle valve;

- partial;

- without removal.

I changed the regulator with complete disassembly, as I discovered clogged tubes, and a dropped plug rattled inside the receiver. When disassembling and cleaning I used carburetor cleaner. Although this is the same acetone and could have been saved.

Carburetor cleaner, if it is not needed under pressure, can be easily replaced with simple acetone

In the second option, the replacement is made without removing the tubes, but with removing the throttle. In this case, the air duct clamp is loosened, the throttle is unscrewed and, by moving it a little, removed from the studs. You need to turn it a little, this will give access to the sensor mounting bolt.

In the third option, you need a special screwdriver capable of unscrewing the sensor mounting screw. Typically, this is a flexible screwdriver for hard-to-reach places or an angled attachment for a screwdriver.

Necessary tool

To replace the sensor you will need:

- Flathead screwdriver.

- Crosshead screwdriver.

- Socket or open-end wrench size 13.

Replacing the idle speed sensor

To avoid getting burned, carry out the replacement on a cool or warm engine.

- disconnect the damper control cable;

- remove the block from the throttle position sensor;

- remove the block from the XX regulator;

- disconnect the coolant supply pipes from the throttle body;

- remove the crankcase ventilation pipe.

- disconnect the air supply pipe;

- pull the fuel supply hose to the throttle valve;

- unscrew the screws and remove the IAC.

Removed VAZ regulator

Removing the faulty regulator

Remove and replace the plug

Cleaned throttle body

Assembly is carried out in reverse order.

After replacing the regulator, do not start the engine immediately. Simply turn on the ignition, wait 10 - 30 seconds and turn off the ignition. After that you can start it. This time is necessary to calibrate the new idle air control ECU.

Ideally, when starting on a cold car, the speed should rise to 1500 rpm and drop to 800 as it warms up.

The preparation operations are not complicated and standard for any repair, but your personal safety, the time spent on maintenance and repair, as well as the quality of the work largely depend on their implementation. We prepare our VAZ2107 car for replacement as follows:

- We do car washing

- If possible, it is advisable to wash the outside of the car before work (you will get less dirty while working), including the bottom if necessary

- If the work (as in our case) is to be done in the engine department, then it should be washed there too

- The operation associated with washing the engine compartment is best performed in a non-automated car wash.

- Here, the engine compartment of your car will be washed by hand, having previously treated the outside of the body and the engine compartment with specific cleaning compounds.

- They will also remove dirt stuck in the wheel arches, as well as from the bottom of the body, using a directed jet of water under pressure, with drying completed.

Warning: When washing the engine compartment, you should protect the pads, sensors and other actuators of the fuel injection system from getting water. You should also avoid getting water on the starter and alternator. The sensors and contacts are wrapped with insulating tape or tape, the generator and starter are covered with plastic bags and the bags are secured so that they do not fly off. In any case, washing the engine compartment involves disconnecting the terminals from the battery. After washing, the above components and parts must be thoroughly dried; to do this, blow them with a stream of compressed air.

Carburetor adjustment

Adjusting the carburetor involves several steps:

- Adjust the position of the float as described above.

- Check and set the “quality” and “quantity” screws to the initial state. Screw them all the way and unscrew them 2-3 turns for the “quality” screw and 3-4 for the “quantity” screw.

- Connect a tachometer or auto tester to the “K” terminal of the ignition coil, and the second probe to the housing.

- Start and warm up the engine to a temperature of 90°C

- Use the “quality” screw to set the maximum idle speed. The gasoline supply increases when the screw is rotated counterclockwise.

- Use the “quantity” screw to set the speed higher, approximately 80-90 rpm.

- Using the quality screw, we determine whether these speeds are maximum; if not, then we repeat the procedure.

- If the position of the quantity screw does not affect engine speed, tighten the quality screw so that the speed drops by 800-900 rpm.

This carburetor adjustment may not be entirely accurate, but does not require special equipment.

Checking the idle air control circuit

Before moving on to diagnosing the regulator itself, it is necessary to check its circuit, because the reason that it stopped working could be a simple break in the wires or a malfunction of the electronic control unit. To diagnose the circuit, you only need a multimeter with the ability to measure voltage. The procedure is as follows:

- Raise the hood and find the sensor wiring harness on the throttle assembly.

- Disconnect the wiring harness block.

The voltage between ground and each of the terminals must correspond to the voltage of the on-board network, i.e. approximately 12 V. If it is less than this indicator, or is absent at all, you need to diagnose the wiring and electronic control unit.

Unstable operation of the injection engine.

Engine instability can be due to a failure in any system. Either:

- ignition;

- fuel supply;

- electronic control unit

- wear of moving parts and engine components.

To understand this, it is necessary to check the performance of systems using the elimination method. Let's look at an ECU as an example.

The engine is warmed up, but vibration and increased speed are felt during operation. Perhaps this is an accumulation of errors in the controller memory. To reset them, you need to turn off the engine and turn off the “mass” for 15 minutes. After that, start the engine. If there are no changes in engine operation, then the reason is in the ECU sensors.

When any of the sensors does not work, the ECU has to rely only on the data from the working devices. This is not enough for normal management of SPVT. The engine does not work correctly:

- Unstable crankshaft speed.

- Increased gasoline consumption, highly enriched mixture.

- There is black smoke on the exhaust.

- Soot or soot on spark plug electrodes.

This occurs due to a lack of data entering the control unit, such as:

- air flow;

- amount of oxygen in exhaust gases;

- throttle position;

- crankshaft position;

- temperatures;

- speed;

- or IAC failure.

To check the functionality of the sensors, you need to disconnect the wire connectors one by one and observe how the internal combustion engine operates. If there are no changes, then the device that is turned off has failed.

Replacement

Diagnostics, cleaning and replacement of the throttle body is carried out after removing the throttle unit from the car.

The sensor is carefully removed from the dismantled unit and inspected. To check the performance of the dhx, use a tester switched to ohmmeter mode. Step by step diagnostic procedure:

- Set the measuring range on the tester to 0-200 Ohm.

- Attach the probes to the terminals, first on “A” and “B”, then “C” and “D”. The working element will show a value within the range of 50-53 Ohms.

- Take measurements between opposite pairs: “A” and “C”, then “B” and “D”. On a working unit, the instrument readings should tend to infinity.

If the electrical parameters are normal, the rod is measured - the overhang length should not exceed 22 mm.

If the rod is jammed, its size is increased, there are no optimal indicators of the multimeter, the part is changed. It is not advisable to repair the sensor.

Self-replacement of DZH

Before changing the device, you should first check that the light bulbs may have burned out, bad contacts, a blown fuse, or damaged wiring. If the reason is a malfunction of the device, then it needs to be replaced. Checking the bulbs and wiring is done with a multimeter.

Tools and materials

To replace the idle speed sensor on a VAZ, you should prepare the tools and necessary materials:

- key on “22” and a key on “24” may be required;

- multimeter;

- screwdriver;

- pliers;

- container for oil;

- electrical tape;

- chisel;

- hammer.

IAC breakdowns

If you have a VAZ 2107 with an injection engine, then pay due attention to the condition of the vehicle systems.

If the speed on an injection engine fluctuates, then you need to look first at the idle speed control. The fact is that the breakdown of such a mechanism as the IAC can lead to very sad consequences, including a traffic accident. Here are the main signs by which you can independently determine whether the regulator is broken:

- The engine begins to “live its own life” - the crankshaft rotation speed is constantly changing, sometimes decreasing, sometimes increasing. Consequently, the tachometer needle constantly floats.

- When you start a cold engine, the crankshaft speed does not increase, it fluctuates within a certain range.

- If you turn on powerful electrical appliances (for example, a car radio, low or high beam), the speed decreases and does not return to the set level.

- When you engage the neutral gear, the engine begins to stall if you do not apply the gas pedal from time to time.