01.10.2021 13 199 VAZ 2110

Author: Ivan Baranov

Any modern car is equipped with many different sensors that allow the driver to know about the condition and performance of certain components. And the VAZ 2110 car is no exception; in this article we will talk about what sensors are used in it and what their location is.

As you know, the VAZ 2110 injector with 8 or 16 valves is significantly superior to the carburetor version in many ways. At least because in this case the supply of gasoline, as well as the combustible mixture, is regulated by electronics. Accordingly, the use of electronics implies the use of many different regulators and controllers. Their breakdown can lead to certain consequences, so the car owner should always know what certain regulators are responsible for. Below we consider almost all VAZ sensors that are in the top ten.

[Hide]

A little history

The VAZ 2110 was produced from the end of the 20th century until the middle of the first decade of the 21st century. During its existence, the top ten managed to gain a huge number of fans and underwent a large number of changes.

The tenth VAZ family was initially equipped with 8-valve carburetor engines that had common roots from the G8 engines. Time moved forward and AvtoVAZ needed to develop further, and at the end of the 90s, an injection engine was installed on the top ten for the first time, which was distinguished not only by a new injection system, but also by the number of valves; some new engines received a doubled number of valves from 8- mi to 16.

To operate an engine with an injection system, you need a huge number of different sensors responsible for the operation of the internal combustion engine, and the VAZ 2110 is no exception; the dozens of injection engines have many different sensors installed that ensure correct and smooth operation of the engine.

In this article we will talk about VAZ 2110-12 sensors, their symptoms of malfunction and installation locations.

Mass air flow sensor (MAF)

It is one of the most important sensors. The mass air flow sensor is responsible for the formation of the air-fuel mixture. It measures the volume of air supplied to the intake receiver and transmits the readings to the electronic engine control unit, which in turn supplies the right amount of fuel in relation to air. The failure of this sensor affects many different functions of the internal combustion engine.

It should be noted that the “CheckEngine” lamp will light up only if the sensor fails completely. Most often, the sensor undergoes aging, but very rarely fails completely. You can read how to check this sensor in our article.

Signs of malfunction:

- Increased fuel consumption;

- Uneven idle speed;

- Difficulty starting the internal combustion engine;

- Loss of dynamics;

- Jerks when moving;

What is a mass air flow sensor and where is it located in the VAZ 2110

Mass air flow sensor is one of the devices involved in controlling an injection engine. The abbreviation stands for: mass air flow sensor. It is entrusted with the task of measuring the volume of air directed into the power unit. The mass air flow sensor works in conjunction with two other sensors: atmospheric pressure and air temperature.

In its modern version, the mass air flow sensor is a hot-wire flow meter. The working element is a thin platinum wire to which voltage is applied. The more air passes through the sensor, the more the wire cools. Therefore, to maintain a constant temperature, it is necessary to increase the voltage, by the value of which the ECU judges the volume of air entering the engine.

The mass air flow sensor notifies the electronic control unit about the amount of air directed into the engine

The serviceability of the device affects the optimal operation of the naturally aspirated engine. The mass air flow sensor is a small device. It is mounted on the air filter housing of the VAZ 2110. From the device there is a pipe to the throttle valve.

The MAF sensor is located on the air filter housing

Speed sensor

This sensor is designed to transmit readings to the engine ECU about the speed of the vehicle. It is involved in adjusting the engine speed when driving, namely, if the car is rolling in neutral, you will notice that the speed is slightly higher than the idle speed when the car is standing still. The DS is also responsible for the performance of the speedometer and odometer.

Signs of malfunction:

- Inoperative speedometer or odometer;

- There are no increased speeds when driving in neutral gear;

Air flow control

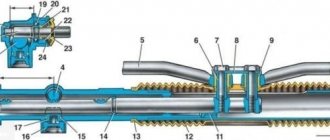

The location of the mass air flow sensor (MAF) is on the air duct running from the filter to the throttle valve. The device consists of 3 elements located inside the air flow. The first one measures the temperature of the incoming stream, and the other 2 heat up to a certain degree. The stronger the flow passing through the air sensors of the VAZ-2110, the more intensely they are cooled. The controller that supplies the voltage determines the air flow by the energy spent on heating the 2 elements in relation to the temperature of the first meter.

There is another design of the MAF device with a silicon mesh and two elements; it operates on the same principle. The marking of the first type is 2112-1130010, the second - 21083-1130010. Receiving signals from these devices, the processor makes a calculation and changes the duration of fuel injection for the VAZ-2110. The following signs indicate a sensor failure:

- the engine stalls when switching from high speed to idle;

- unstable operation at idle;

- difficulties arise when starting the engine;

- increased fuel consumption.

Replacing the mass air flow sensor control device is not difficult; you need to disconnect the wires, remove the old sensor from the air duct and install a new one.

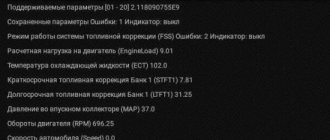

Coolant temperature sensor (DTOZH)

The DTOZH is installed in the thermostat housing and transmits readings to the ECU about the temperature of the engine coolant. Based on these readings, the engine control unit increases or decreases engine speed for more stable operation of the internal combustion engine. The operation of this sensor is noticeable on a cold engine; when starting the engine in the cold season, you can notice increased speed, which decreases over time as the engine warms up to operating temperature.

Signs of malfunction:

- Increased fuel consumption;

- Poor starting on a cold engine;

- Lack of warm-up speeds;

Coolant temperature sensor

Removing the fan regulator on a VAZ 2110 On a VAZ 2110, sensors can be used for different purposes, but most of them are mounted in the engine compartment. On an 8 or 16 valve engine, the fan sensor is a device designed to activate the fan. We are talking directly about a fan designed to cool a hot engine.

The controller turns on automatically when the power unit reaches a certain temperature. But it can also turn on when the engine is off. At first, this fact may be alarming for many owners of the “ten”, but there is nothing wrong with it, so there is no need to worry.

It is necessary to highlight the advantages of this controller:

- As practice has shown, the fan sensor is one of the most reliable vehicle devices, since its design is based on a solid filler. When the ambient temperature increases, this filler begins to expand.

- The design of this device also includes a special spring-loaded lever. Thanks to this component, no defects occur during the operation of the regulator.

- The device prevents sparks from appearing, which is especially important for ensuring vehicle safety.

- In fact, this type of regulator itself is reliable. If you buy a high-quality device, then in the future you will notice that it will function for quite a long time; you can forget about the need to replace it for the next few years.

Crankshaft position sensor (CPS)

DPKV is a sensor that counts crankshaft revolutions. Just like most sensors, it participates in the formation of the fuel mixture. If it malfunctions, the car will not start.

The sensor is installed on the rear of the engine under the oil filter. Works in tandem with the crankshaft pulley (generator drive).

Signs of malfunction:

- The car does not start (no spark);

- Jerks when moving;

- Spontaneous engine stop;

Other control devices

The remaining sensors are also connected to the controller and perform important functions. Failure of any of them leads to an increase in fuel consumption, loss of acceleration dynamics or unstable operation of the power unit. Here is their list:

- throttle position detector;

- knock sensor;

- speed meter;

- oxygen sensor;

- phase detector.

The element that determines the angle of rotation of the throttle valve is installed on its body and is directly connected to the axis. The task is to facilitate the supply of excess fuel to the cylinders when the accelerator pedal is pressed sharply. The principle of operation is similar to the accelerator pump in a carburetor, only of the electronic type. The device often fails, especially after washing the engine.

The knock sensor located on the front side of the cylinder block functions much more reliably. Unlike other devices, it generates a signal independently, acting on the principle of a piezoelectric element. The stronger the detonation flashes in the cylinders, the more voltage is supplied to the controller, and it regulates the ignition angle, trying to extinguish detonation. If necessary, change with a wrench.

The oxygen sensor (otherwise known as a lambda probe) monitors the content of free oxygen in the exhaust gases, indicating that the fuel mixture is enriched or lean. Participates in the formation of this mixture and is very reliable in operation. It is afraid of leaded fuel and quickly breaks down when used. It is located in the first part of the exhaust tract, at the convergence of the exhaust manifolds.

The speed meter also works on the principle of a Hall sensor and takes readings from the speedometer drive shaft located near the gearbox. The task is to transmit information about the speed of the car to the processor.

Additional information about the operation of the timing belt is transmitted to the controller by a device that determines the phases. It is installed on VAZ-2112 cars with 16 valves in the upper part of the cylinder head. This device tells you when the fuel valves are opening by monitoring the position of the intake camshaft. This helps to synchronize the complex process of gas distribution and injection of the fuel mixture at the right time.

Phase sensor (PF)

This sensor is necessary for counting camshaft revolutions; its functions are similar to those of the DPKV. Designed for phased fuel injection; without this sensor, the internal combustion engine will operate in emergency mode and the fuel supply will switch to pairwise mode.

It is installed under the timing cover on 16-valve engines, and on 8-valve engines on the end of the cylinder head on top of the thermostat.

Signs of malfunction:

- Increased fuel consumption;

- Unstable work at XX;

- Loss of dynamics;

VAZ 2110 sensors

In this section I will provide an overview of the electrical sensors that are installed on injection engines. As well as their location and the cause of failure.

Mass air flow sensor (MAF)

The air flow sensor is one of the most vital organs. It is located in a visible place, right behind the air filter.

Measures the amount of air entering the cylinders. And transmits readings to calculate the required amount of gasoline. Quite reliable and rarely fails, but over the years it can begin to produce information that is not entirely correct. In this case, the engine begins to work unstably, but the “ check engine ” indicator does not light up. Since the part works and the signal is received, the car may behave differently:

- Difficulty starting;

- Floating idle speed;

- Jerks and dips when starting and moving;

- Increased consumption;

- Decrease in dynamics.

Crankshaft position sensor (CPS)

DPKV is also vital. Installed at the bottom of the engine on the oil filter side. On the generator drive gear.

Reads the crankshaft torque and provides information to the unit. He, in turn, sees that the shaft rotates and regulates the fuel supply. It is quite reliable and rarely fails, but due to its location it often gets clogged with dirt. That is, it stops responding to movements. But it is very easy to treat; we dismantle it and clean it of dirt. Signs of malfunction:

- The engine stalls during operation;

- The engine does not start at all.

Oxygen sensor (OS)

DC or as it is also called “lambda probe”. Installed in the exhaust manifold. That is, it serves to measure the level of exhaust gases. Thanks to it, the ECU controls the dosage of gasoline and air. In other words, without increasing gas pollution. Since it sometimes becomes covered with soot, it may give incorrect readings. In this case, it is necessary to dismantle and clean with phosphoric acid. Signs of malfunction:

- Decrease in dynamics;

- Increased consumption;

- Black smoke from the exhaust pipe;

- Floating speed when warming up.

Idle speed sensor (IAC)

The DXH is mounted on the rear of the throttle body. Consequently, it regulates the air supply at idle speed. That is, when you press the accelerator pedal, the DHW is turned off. It also has the ability to become clogged and fail. I've heard from many people that it can be cleaned, but I've never done it myself. Since its price is not very high. It seems easier to me to replace it with a new one. Signs of malfunction:

- Floating idle speed;

- Difficulty starting;

- The engine stalls when idling.

Throttle Position Sensor (TPS)

The TPS is installed on the rear of the throttle valve, next to the DHX. It transmits information about the position of the throttle valve, as it is directly connected to the accelerator pedal. That is, pressing the accelerator pedal opens the air supply. Meanwhile, the ECU sends a signal to supply fuel. Unfortunately, the TPS very often fails and requires replacement with a new one. Because it cannot be repaired. Signs of malfunction:

- The speed increases randomly;

- Difficulty starting;

- Increased consumption.

Coolant temperature sensor (DTOZH)

The DTOZH is installed on the thermostat in the area of the air filter, under the mass air flow sensor. Firstly, it is responsible for cold starts. That is, it sends a signal about the state of heating of the coolant to the ECU, which in turn regulates the fuel supply. Secondly, it controls the temperature, preventing the motor from overheating. Because the signal turns on the cooling fan. Signs of malfunction:

- Increased consumption;

- Difficulty starting;

- Floating speed when warming up.

Speed sensor (DS)

The DS is installed on the rear side of the engine in the throttle valve area, at the bottom, at the gearbox. It is responsible for speed, that is, it sends a signal to the instrument panel. Signs of malfunction:

- Speedometer malfunction.

Phase sensor (PF)

The DF is installed in the front part of the engine, in the timing belt area above the generator. Since it is responsible for the camshaft speed. That is, if the timing belt breaks, the fuel supply is stopped by the DF signal. If it fails, the system goes into emergency mode. Signs of malfunction:

- Increased consumption;

- Decrease in dynamics;

- Floating idle speed.

Knock sensor (DS)

The DD is installed in the front part of the engine on the block, between the second and third cylinders. Designed to control detonation. That is, the ECU receives a signal and doses the combustible mixture, thereby reducing detonation. Signs of malfunction:

- Decrease in dynamics;

- Floating idle speed;

- Jerks and dips when starting and moving.

Idle air control (IAC)

This sensor is installed on the throttle valve and regulates the air supply when the car is running at idle. In other operating modes of the internal combustion engine, the idle air regulator is not involved. The sensor performs mechanical functions, so if it malfunctions, the “CheckEngine” warning light does not light up.

If the regulator breaks down, you can wash it and try installing it again. If washing does not help, the sensor must be replaced with a new one.

Signs of malfunction:

- Unstable idle;

- The engine stalls when coasting;

- Difficulty starting the engine;

- Low speed XX;

Checking the functionality of the idle speed sensor

You must identify the breakdown manually - there is no self-diagnosis. The idle speed regulator of the VAZ 2110 is located in the intake after the valve (throttle body).

First, analyze the electrical part with a multimeter:

- The pinout of the IAC VAZ 2110 is being studied (available in the product instructions or on the Internet).

- They check whether the sensor is powered normally, for which it is disconnected and the block is removed.

- They take measurements of the two outer terminals on block A and D: Turn on the ignition, turn the multimeter to “continuity”, the black probe to ground (on the body itself) of the internal combustion engine, touch the positive (red) contacts one by one. A value within 12 V is normal. If not, the circuit is broken, the ECU is broken, the battery is discharged. This means we check the integrity (contacts, wires), the ECU (at pins 4 and 54 the norm is also 12 V), and the battery. If they are working properly, the problem is in the valve;

Throttle Position Sensor (TPS)

TPS is designed to transmit indications about the position of the valve in the throttle assembly. The received readings are transmitted to the ECU for further regulation of the fuel mixture. This sensor fails quite often. Located on the throttle valve above the IAC.

The sensor cannot be repaired and if it breaks, it is replaced with a new one.

Signs of malfunction:

- Spontaneous increase and decrease in speed;

- Difficulty starting the engine;

- Increased fuel consumption;

- Low speed XX;

Injectors

Nozzles or “injector” are the main part of the body. It is a solenoid valve and atomizer, it is activated by a signal. Hence, which comes from the block. First of all, collecting information from meters. Due to this, a combustible mixture is created, but due to the poor quality of gasoline, the nozzle often fails. That is, it gets clogged with dirt.

If it fails, the operation of the machine becomes incorrect. That is, there are jerks and dips when starting and moving, detonation, difficult starting and a decrease in dynamics. Therefore, cleaning the nozzle is the first priority in repairs. And due attention must be paid to this process.

Firstly, the easiest way to clean it is to pour liquid into the tank and mix it with gasoline. Secondly, you need to remove the fuel rail. I would like to draw your attention to the fact that on 8 valve engines the ramp is located in the rear of the engine, but on 16 valve engines it is in the front. When removing the ramp, you will have to dismantle the air manifold. Because he just gets in the way. Then disconnect the injectors from the ramp. Next, apply 12 volts to the nozzle to open the valve and blow it out with a cleaning spray.

Oil pressure sensor (OP)

This sensor signals the condition of the oil pressure in the engine. When it decreases, a lamp on the car’s dashboard lights up in the form of a red oil can. The sensor is completely mechanical and is only responsible for turning on the low oil pressure indicator.

Signs of malfunction:

- The oil pressure lamp does not light up;

- The oil pressure lamp is constantly on;

Where are the valve and temperature sensors on the VAZ 2110?

The owner of a modern car, stuffed with various electronics, inevitably has to figure out where the VAZ-2110-2112 valve sensors are located. After all, the car enthusiast himself can change any of them; for this, he does not always need to go to a service station, waste time and pay money. Most drivers only know the coolant temperature gauge sensor and the device that monitors oil pressure. But there are much more of these devices in modern VAZ cars.

Oxygen sensor (OS)

The VAZ 2110 oxygen sensor is installed in the exhaust manifold. The DC measures the exhaust gases and uses their readings to determine the ratio in which the fuel mixture is formed. If the readings exceed the permissible values, the ECU adjusts the air-fuel mixture in such an amount that the exhaust gases do not exceed the permissible values.

Signs of malfunction:

- Increased fuel consumption;

- Loss of vehicle dynamics;

- Black smoke when driving at high speeds;

Mass air flow sensor

The power unit of the "tens" is controlled using the ECM - an electronic system. This system must always know how much air needs to be supplied for a certain volume of gasoline. These two parameters are closely related to each other, since with their help a combustible mixture with the required density is formed in the engine power unit.

After the system determines the required volume of air, it begins to select the appropriate amount of gasoline. As for the regulator, it is responsible for the suction volumes.

Air controller for the “ten”This controller has certain disadvantages, in particular:

- its performance may be impaired if the controller is exposed to moisture;

- if the car is moving at lower speeds, the controller can produce higher readings;

- as practice shows, at idle the air regulator does not work entirely correctly;

- when starting the power unit, certain difficulties may arise;

- the power unit may stop abruptly for no reason after an increased power mode;

- Gasoline consumption during vehicle operation may increase.

We've dealt with the shortcomings, now let's talk about how the device functions:

- The controller design consists of several sensitive elements installed directly in the line itself through which the air flow passes. One of these components is designed to fix the temperature of the air flow, and the other two are always heated to the required parameters.

- To correctly determine the air flow rate, the principle of measuring electrical power is used to maintain the desired temperature level.

- The air regulator controller has a special mesh installed in the line, designed to filter the air flow.

- Thanks to this, the sensor can transmit the necessary data to other regulators designed to activate certain modes. Subsequently, these regulators either change or support the loads.