Replacing the front wheel bearing of a VAZ classic model

Wheel bearings facilitate the rotation of the wheels, they account for part of the car's support, while they fix its axles and bear a high load. This part is an important element of the chassis, and if it breaks, the front wheel bearing of the VAZ classic models will need to be replaced. If this is not done in time, an unpleasant hum will appear, the vehicle's rolling will worsen, and fuel consumption will increase. If the bearing fails, the machine will be unusable.

Sign of a faulty VAZ classic wheel bearing.

A faulty bearing usually produces extraneous sounds in the form of a hum or grinding sound, and the wheel can also hang on such a bearing due to wear or due to a poorly tightened wheel nut.

To diagnose a bearing, it is enough to hang the wheels (or each separately) and rock the wheel in different directions. If there is play when rocking in all planes (wheel rotation left and right and tilt up and down), the wheel bearing may need to be replaced. But the backlash can also be due to tired silent blocks or ball bearings. To exclude a suspension malfunction, you need a second person who will check whether the wheel wobbles together with the steering knuckle or walks separately from it. If the wheel moves separately from the steering knuckle, then the wheel bearing is definitely faulty (in this case, tightening the wheel nut may briefly save the situation).

A sign of a malfunction may also be extraneous sounds when the wheel rotates (usually a hum, sometimes a grinding sound) or its uneven rotation.

You can also determine a faulty bearing by an excessively heated wheel (for example, if the front right wheel disc is much warmer than the front left one). But you can’t compare the temperature of the rear and front wheels because... They have brakes of different designs.

And so, let’s summarize everything we’ve read. The wheel bearing is replaced if:

- The wheel dangles separately from the steering knuckle.

- A hum and grinding noise is heard when the wheel rotates.

- The wheel does not spin evenly.

- The wheel rim gets very hot.

Replacing the wheel bearing on a VAZ 2101-VAZ 2107

Welcome! Wheel bearing - why do we need a bearing at all, we think you know, but for those who don’t know, in a nutshell let’s say that in order for any parts to rotate, spin, etc., there are several types of bearings, namely plain bearings and rolling bearings (This is based on the type of friction), bearings are also classified according to where they will be used, for example, take a sliding bearing, classification “Radial” - it takes a radial load and is designed to work in difficult conditions, its maximum temperature can reach as much as 400 °C, and the speed of relative movement of the surfaces can be a maximum of 40 m/s,” there are also bearings classified as “Support”, “Self-aligning” and others.

Note! To replace the hub bearing, you will need to purchase: A repair kit for the hub (There will be bearings and lubricant), as well as stock up on hammers, screwdrivers and all the necessary keys, and of course, choose a free day and get to work!

Summary:

Where is the wheel bearing located? Having read the name itself, you can already understand that the bearing is connected to the hub, and so it is located in its inner part, usually when replacing this bearing, people remove the brake disc together with the hub, because separating the brake disc is only a waste of time, but changing the bearing on the installed hub will not work at all, so it will need to be removed (without removing the brake disc) and then replaced.

When should you replace a wheel bearing? When will it start to hum, but the whole point is that it is very difficult to determine when you drive a car all the time, because the bearing will start to hum strongly only when it has actually all broken down and become unusable, so checking this way is not an option to carry out more For an accurate check, you will first need to hang the wheel (First the right front, then the left, it doesn’t matter, both wheels need to be checked) and after that, turn it by hand, it should spin without any jamming and hum (extraneous sound), there should be no (Only the pads can touch the brake disc, but this sound will be completely different, you can distinguish how the bearing hums and how the pads rub), for more details on how to check it, see the video below, it will be said about this hum, and more about how to determine by rocking whether the bearing has become unusable or not yet.

What bearings to put

When a wheel bearing requires replacement, the question immediately arises of which part to install. Many people advise using original components. However, today the quality of parts leaves much to be desired and the issue of choice remains quite relevant.

Table: type, installation location, and size of bearings

| Installation location | Bearing type | Size, mm | Quantity |

| Front wheel hub (outer support) | Roller, conical, single row | 19,5*45,3*15,5 | 2 |

| Front wheel hub (inner support) | Roller, conical, single row | 26*57,2*17,5 | 2 |

| Rear axle shaft | Ball, radial, single row | 30*72*19 | 2 |

Manufacturer's choice

When choosing a manufacturer of a wheel bearing for a VAZ “Seven”, we can recommend SKF , SNR, FAG, NTN, Koyo, INA, NSK. The companies listed have many locations around the world. These products are of high quality and meet the most stringent requirements.

Among the domestic manufacturers that supply bearings for cars of the Togliatti plant, we can highlight:

- CJSC "LADA Image" - manufactures and sells original Lada wheel bearings through secondary markets;

- Saratov plant - produces parts under the SPZ brand;

- Volzhsky Plant - uses the Volzhsky Standard brand;

- Vologda plant - sells products under the VBF brand;

- Samara plant SPZ-9.

Wheel Bearing Adjustment

The main parameter when carrying out a replacement is setting the correct hub clearance. The procedure is performed in two ways: using a dial indicator or by touch.

- Prepare an indicator stand.

- Place the device on the brake disc and secure with bolts.

- Place the end of the indicator against the end of the trunnion, as shown in the figure.

- Rotate the hub to measure the play.

- If the value is more than 0.15 mm, it is necessary to loosen the nut and tighten it with a torque of 9.6 N*m. Spin the disk several times. Loosen the nut (approximately 20-25 degrees), tighten with a torque of 6.8 N*m.

- Check the backlash value.

- Lock the nut.

Setting the gap without an indicator:

- Put on the wheel.

- Evenly tighten the nut while rotating the hub.

- Rock the wheel in a vertical plane to “feel” for play. To do this, place your finger on the end of the trunnion. A barely noticeable gap should be felt when the wheel rocks.

- If the play is caught, tighten the nut to a torque of 19.6 N*m. Don't counter.

- Rotate the assembly several times in both directions (to self-install the bearing). Check the gap.

- Lock the nut.

The rebuilt unit should rotate easily, without wedging.

Front wheel bearing for VAZ-2107

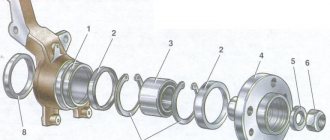

After removing the consumable, it is necessary to inspect and, if necessary, repair the bearings. To do this, do the following:

- It is necessary to remove the bearings for inspection and lubrication. To do this, it is worth fixing the hub with a vice.

- Perform gentle blows on the outer part of the bearing race to knock it out of the hub without damaging it.

- Remove the oil seal by prying it with a screwdriver. Underneath there is a spacer sleeve that also needs to be pulled out.

- Using careful movements, knock out the inner bearing.

How to replace and adjust

Because bearings wear out over time, they must be replaced. When disassembling, you need to take them out and carefully inspect them.

To do this, you need to clean the bearings and hub from old grease and contaminants. They are first wiped with a rag, then washed with kerosene. After these parts are completely cleaned, they need to be inspected.

At the same time, check the degree of wear and the presence of mechanical damage. If necessary, they replace the wheel bearings on the VAZ-2107. The new ones will also have to be lubricated and installed in place - in the hub. After this, the wheel is assembled and installed.

If the parts are suitable for further use, they are installed in place after cleaning and lubrication.

How to repair a car

In this article we will look at how to change the rear wheel bearing of a VAZ-2101, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic and how to check the rear wheel bearing of a VAZ.

It was time to change this bearing a long time ago, but for some reason I only got around to it now. On the highway the car still behaves normally, but on the off-road the rear of the car began to wobble, and it began to creak when cornering.

The easiest way to check the rear wheel bearing is to press the outside of the wheel with your foot to wiggle it (you will hear a distinct thud). The wheel will simply dangle.

You can buy bearings for about 260-300 rubles. There are more expensive ones, but who cares, we take those that are cheaper.

One thing can be said, if you drive carefully, these spare parts will last a long time, if you don’t drive carefully, you will gouge everything, even those spare parts that cost 100 rubles more. The most important thing to understand is that careful driving extends the life of any part and the car as a whole. The bearing must be well filled with grease.

Now let's start removing the wheel and see how to change the rear wheel bearing of a VAZ-2101, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic. Changing the rear bearing is very easy, not like the front wheel bearing.

1. We begin to remove the wheel. We tear off the bolts when the wheel is on the ground, it’s more convenient. And there is no need to put it on the handbrake, since you will have to remove the brake drum.

2. When you lift the car with a jack, be on the safe side. The picture shows that the car rested against the jack and the safety stump. If the jack falls out, the box will rest against a stump. Even if the box bends, it’s okay, but you will remain alive.

We knock out the bearing (the blows should fall on the inner race, since the outer race is very thin and will crumble).

6. All that remains is to hammer in the new bearing. In order for the bearing to seat well, lubricate the walls of the cage with oil. Align the wheel bearing as level as possible. And carefully hammer the bearing evenly, the main thing is that it does not warp. If the bearing is installed level, it will easily go into place. Install the retaining ring and screw it back on.

If you hit the hub, the inner part of the bearing race will come out, this cannot be allowed. Therefore, we score with light blows using a pipe. All that remains is to tighten the nut so that nothing dangles. The bearing must be tightened, the tighter the better. Tighten tightly and loosen a little, and seal.

Repair of VAZ 2101, 2106, 2107 hub

Maintenance-free front hubs on VAZ 2107 (bushing drawing)

This time we will talk about maintenance-free front hub bearings. Having changed 3 bearings over the winter (sometimes they didn’t last, sometimes they overtightened them, sometimes they fell apart during maintenance), I got tired of all this, surfing the Internet and DRIVE came across articles about maintenance-free bearings on the front. There are several options: 1. Buy a ready-made kit. There are people who sharpen hubs and axles for them. 2. hub with axle from Izh od (also suitable) - I couldn’t find it 3. Rear hub from 08 VAZ + bearing also rear and + adapter sleeve - that’s what you need and in terms of cost.

Replacing the wheel bearing of a VAZ 2107

The chassis of the VAZ 2107, like all classic models, is not distinguished by its design complexity, but at the same time it fully complies with the somewhat inflated endurance requirements that road surfaces impose on us. The 7 has a reliable and simple wishbone suspension, but it does not last forever, and can remind you of itself from time to time with tapping and creaking.

Content:

Signs of a worn out bearing

We immediately pay attention to the knocking of the suspension and play in the steering, and try to find and neutralize the tired part as soon as possible. The front wheel bearing behaves completely differently. As a result of wear and tear, it does not immediately show its fatigue, but gradually. When turning right, the left wheel bearing begins to hum, and when turning left, vice versa.

It is quite possible that the bearing adjustment nut has become loose, but then the hum should be accompanied by a knocking sound. This can be easily determined by checking the play on the front wheel. To do this, hang the car on a jack and grab the wheel by the lower part and the upper part with your hands, then rock it. If there is play, then it will be enough to tighten the adjusting nut with a torque of 2 kg/cm and tighten it with a blunt chisel. If the hum continues after this, it means the bearing has worn out and needs to be replaced.

Removing the front hub of a VAZ 2107

Before starting work, place the car on a level surface, secure the rear wheels with wheel chocks and tighten the handbrake. After this, we jack up the front wheel with a jack, but it is advisable to place a stand under the lower arm after we remove the wheel. We loosen the jack, the bulk of the car falls on the stand, and now the car is securely fixed.

- Using a blunt chisel or screwdriver, remove the hub protective cap.

- Remove the front brake caliper. To do this you will need to remove the brake pads. We unpin the pad pin, take it out, and then you can use a pry bar or a large screwdriver to press the pistons into the caliper. After this, you can remove the brake pads.

- The front brake caliper is attached to the axle with two bolts that need to be unscrewed. In order not to disconnect the caliper from the brake system, we hang it on a wire so that the brake hose is not stretched.

- Let's move on to the hub. Using a 27mm socket, unscrew the hub adjustment and fastening nut. To avoid any surprises, let us remind you that the right wheel has a left-hand thread, and the left one has a right-hand thread. It's hard to confuse. Having oriented towards the cardinal points, unscrew the nut.

- Remove the hub from the axle and place it on a horizontal surface.

Replacing the Wheel Bearing of a VAZ 2105

Vas 2105 . hubby

front wheel

bearing replacement August 11, 2013

If the adjustment is unsuccessful, create a fake hub bearing on a VAZ 2105

.

We also replace if grease leakage is detected under the hub nuts, indicating a seal failure. Replacing silent front manual blocks with classic ones \ VAZ 2105. Duration: 11:24. VAZ 2101-2107 and others. Do-it-yourself VAZ repair 2. VAZ 2105. replacing the front wheel bearing. VAZ 2105. Removing and replacing steering rods. It's also worth remembering to replace

the bearings are paired on each side. For repairs, prepare standard tools and perform the following steps:

- Remove the wheel from the repair side. Volkswagen Golf II | Replacing the front wheel bearing. The VAZ repair has been completed. Replacing the hub bearing with another front wheel VAZ-2105, VAZ-2106. Next, remove the brake caliper and hang it on a wire so it doesn't hang on the brake hose.

- Then, using a twenty-seven socket wrench, they first loosen and then completely unscrew the nut. hubby

and remove it with the washer underneath it.

Then remove the outer wheel bearing spacer . - Now you can remove the hub from the brake rotor, gently pull them towards you and it will come off the stud.

READ Changing the oil in a Nissan Almera n16 box

replacing bearings front hub VAZ 2107

Replacing bearings

front

Hobby VAZ

2107, repair kit

front

bearings hubby

.

replacing bearings hubby VAZ. (All details)

ADJUSTMENT Wheel bearings

HERE: DIAGNOSTICS

Wheel bearings

HERE:.

- Remove the pliers or any other handy grip hubby

first the oil seal and then the inner cage

bearing

.

- We then proceed to replace the bearings. To do this, knock out a flathead screwdriver and remove the retaining ring, that is, the cutting sleeve, from its place.

- Place the brake disc on a vice and use a deep-head screw wrench to unscrew the two idler pins.

- Remove the spacer ring and brake disc the hubby Removal and installation of the VAZ 21099 stabilizer, removal and installation of VAZ 2108 supports, replacement of the VAZ 2109 wheel bearing, replacement of the ball joint and suspension repair. Replacing the front axle bearing of a VW Golf 3. Replacing the front axle bearing of a UAZ Patriot. Now we begin to squeeze out the carrier cells.

- We make a small impact and apply light blows with a hammer around the entire circumference of the frame, knocking out the outer and inner rings.

- Now that the bushing is disassembled, thoroughly wash off the old grease and begin installing new ones.

- First of all, we install the inner race of the outer bearing . We then install a separator, which also lubricates the spacer ring.

- Similarly, press on the new oil seal, outer ring bearing

, and then install the brake disc and outer spacer.

READ Replacing Intake Manifold Gaskets Renault Megane 2

This is repair work to remove and replace wheel bearings, front wheel

completed for VAZ

2105 Reassemble in reverse order. After assembly, adjust the bearing

.

Instructions for replacing the wheel bearing on a VAZ-2107 with your own hands

Removal

Put the car on the handbrake. Place a shoe under the wheel to prevent the machine from rolling away. Loosen the front wheel nuts.

Raise the car and place a support under the body. Remove the wheel. Unscrew the caliper mounting bolts located on the inside and remove the caliper. To avoid damaging the brake hose, it is better to tie up the caliper.

Using a screwdriver, pry up and remove the hub cap. Unscrew the hub nut. After removing the nut and washer, pull out the outer separator. Pull the brake disc towards you and remove it together with the hub. After unscrewing the two guide pins, remove the brake disc from the hub.

Using a screwdriver, pull out the oil seal and separator, and then the spacer ring. Now you need to knock out the clips. Using a mandrel of the required diameter or a drift, knock out both clips with a hammer.

Installation

Before assembly, wash all components with any grease-cleaning liquid. Remove the races from the new bearings and, holding them in a vice, press them into place through spacers (it is best to use the old race as a mandrel).

Lubricate the inner bearing cage and install it in place. Insert the spacer ring, press the oil seal through the spacer, being careful not to damage it. We put on and secure the brake disc with studs.

We install the unit in place. Having pre-lubricated, insert the outer bearing separator into place and, having installed the washer, tighten the nut until it stops. We put on the wheel. We turn it several times to ensure complete seating. Then slowly unscrew the nut until a small amount of play appears. Lock the nut in this position.

We clean the hub cap of old grease, fill it with new one and install it in place.

Having examined how the wheel bearing is replaced on a VAZ-2107, we can conclude that this repair is not so complicated. And if desired, almost every car enthusiast can do this.

Timely maintenance and the use of high-quality spare parts will extend the life of your car. It is important not to forget that the serviceability of the car’s front suspension is a guarantee of your safety.

Elements protecting hinges on front-wheel drive VAZ vehicles

The boot is a hinge protection element on front-wheel drive Zhiguli cars, made of special corrugated rubber. It is installed on the internal and external drive joints and protects them from external factors. It also holds the lubricant necessary for operation inside the joint.

Power Torque: Front Wheel Bearing Replacement

Basic concepts on how to replace a defective front wheel bearing. The list of main transitions will allow you to independently carry out this operation.

Replacing bearings yourself

Modern drivers often encounter such a problem as the occurrence of hum and various extraneous noises in the car suspension. The main reason for this is usually the presence of faults in the bearings. This means it's time to replace them. To carry out repair work

Determining the causes of a windshield wiper malfunction on a VAZ car

wipers If suddenly the wipers on your car stop working, this is not a reason to panic. This device is quite simple and, if desired, anyone can independently eliminate the cause of the malfunction by following the further instructions. And so, let's find out why the wipers on your VAZ-2105 do not work.

How to independently replace CV joint boots on a VAZ 2109.

The CV joint boots are a front-wheel drive unit, which is popularly called a “grenade”. The reasons that lead to their damage can be different: aging of the material, hitting an obstacle, as well as careless operation of the car.

Replacement features

The front hub of the VAZ 2107 car has a pair of roller bearings, one of which is called internal, and the second external. The manufacturer recommends replacing these products in pairs, on both front wheels of the car. We will find out further what the replacement of the parts in question is.

Algorithm for replacing a faulty bearing

The work is performed in almost the same sequence. As for many other VAZ models (classics):

The vehicle is fixed;

Hanging out;

The wheel is dismantled;

The caliper is removed (it is possible without disconnecting the brake hoses);

Use a bayonet screwdriver to pry up the protective cap that covers the hub nut, remove it;

Unscrew this nut, remove the separator and washer, dismantle the hub along with the brake disc;

Remove the oil seal;

Remove the separator;

Remove the ring placed between the outer and inner bearings;

Using a suitable size drift and hammer, knock out the clips.

Now you can proceed to installing a new bearing and assembling the hub. The operations are performed in reverse order.

Before starting assembly, it is imperative to remove dirt and old lubricant residues and wash the parts (using special cleaning fluids).

The outer races are removed from the new bearings in a vice. Internal ones, using special spacers (for example, an old clip), are pressed into place.

Installing new bearings

The inner bearing cage is lubricated and installed in place. Then, the spacer ring. Next, the oil seal is pressed in (be careful not to damage it during installation).

Apply lubricant

The brake disc is put on and secured with studs.

The assembled unit is put in place. Then the separator of the second bearing (external) is lubricated and installed, the washer is inserted, and the nut is tightened until it stops.

Read, it may come in handy: How to independently restore the effectiveness of the handbrake

The wheel is put on and the nut is unscrewed until slight play occurs. Then it is locked in this position.

We put new grease into the previously cleaned cap and put it in its original place.