The main reason for the unstable operation of the Lada Granta engine at idle is a malfunction of the regulator , throttle position sensor.

Note to the driver!

The Lada family, starting from the Priora, is equipped with an electronic throttle position control system. Previous models used a mechanical type of drive (cable).

Systematic use of equipment leads to wear and unstable operation. The process of self-prevention and replacement is simple, but requires attentiveness on the part of the master.

Using the example of a Lada Granta car, we will consider a step-by-step algorithm for replacing the idle speed sensor.

Signs of failure, need to replace IAC, TPS

- Difficulty starting the engine “cold” or “hot”;

- floating idle , unstable engine operation;

- increased fuel consumption;

- the accelerator pedal is uninformative;

- vibration in the car interior, vibration of the steering wheel;

- reduced acceleration dynamics;

- the car stalls when driving downhill;

- when you press the accelerator pedal, periodic dips and speed jumps are noticeable;

- increased consumption at idle.

Causes of breakdowns of idle speed sensors

External air leakage is the first and main reason for unstable operation of the ignition system and fuel equipment. The electronic engine control unit (hereinafter referred to as the ECU), while scanning the readings, “does not know what to do with” the excess air.

The breakdown indicator lights up on the dashboard, the car speed fluctuates, and the air consumption increases.

The second most common reason is systematic jamming of the mechanisms in the ventilation valve. As a result, the tachometer needle shows speeds from 850 to 1250 rpm, and the idle speed is unstable.

Completes the “top three”: a lean mixture entering the cylinders for subsequent ignition.

Sensor

Preparatory stage before installing the idle speed sensor

Necessary tools, materials:

- screwdriver with magnetic tip;

- calipers;

- tester;

- stationery knife;

- torque wrench;

- idle speed controller (hereinafter referred to as IAC);

- throttle position sensor (hereinafter referred to as TPS);

- rags;

- additional lighting;

- liquid for removing deposits and rust WD-40.

Location of the idle speed sensor on the Lada Granta

The Lada Granta with an electronic pedal does not have an idle speed sensor! That's why they sent you from the store to remove yours. There is only one idle speed sensor, you can’t go wrong if you have one, of course.

This is what the electronic pedal looks like

Finding out which pedal you have is easy. If you have a throttle cable under the hood, then you have a regular pedal. So, if you do not have an electronic pedal, then the sensor is located on the throttle valve assembly, or rather in its lower part.

Throttle assembly without idle speed control (electronic gas pedal)

To remove it, you must:

- remove power from the battery;

- remove the power supply from the idle speed sensor;

- unscrew the two fastening bolts;

- remove the idle speed sensor.

In the picture the idle speed sensor is indicated in red, the throttle assembly has also been removed

We diagnose the breakdown

There can be many reasons for a situation where the engine of a Lada Granta starts and immediately stalls. And this is not necessarily the idle speed sensor.

In my experience, I can say that you can still drive an 8-valve Granta with a breakdown of this sensor, since the engine is a “tractor” one. But 16-valve engines will stall, since these are high-revving engines. Therefore, if your 8-valve valve stalls, the reason may not be a breakdown of the idle speed sensor. But if it’s a 16-valve engine, then the symptoms you described are correct. By the way, Lada Prioras behave the same way, they have the same 16-valve valve.

Replacing the idle speed control is not a panacea in the fight against floating speed or a throbbing engine. Most automotive electricians have a tester in their arsenal to check the operation of the regulator. To do this, remove yours and give it for inspection. The regulator glitch may be intermittent, but the tester will show the correct picture.

Source: https://carfrance.ru/gde-naxoditsya-datchik-xolostogo-xoda-na-lada-granta/

Sequence of actions when independently replacing IAC and TPS sensors

- We place the machine on a level platform and ensure priority safety measures during repairs.

- We open the hood, an air duct with a receiver is laid above the engine. The Lada Granta with 8 and 16 valves has plastic, while in previous Lada models it is aluminum.

Air vent with receiver

- We press out the plastic clamp of the block with wires.

Plastic retainer

- Disconnect the contacts of the electronic gas pedal.

Electronic pedal contacts

- Using a Phillips screwdriver, unscrew the two screws securing the IAC to the throttle body.

- We remove the IAC from the cavity of the throttle assembly.

Removing the IAC

- Next, we proceed to unscrew the TPS, it is installed a few centimeters lower.

- We unscrew the two screws, remove the TPS, and disconnect the block with the wires.

Retrieving the TPS

Note to the driver! When removing the valve, be extremely careful not to lose the rubber bushing.

- We carry out troubleshooting of the seat of the IAC and TPS. We clean the rust deposits with a rag and use WD-40 aerosol as needed.

- Screw in each of the sensors one by one and connect the connectors with wires.

- We start the engine and check the idle speed.

of the idle speed sensor is complete.

Replacing the idle speed sensor

Cleaning Rules

It often happens that cleaning the idle speed sensor can solve the problem of device inoperability. In general, this procedure is quite simple. Therefore, almost anyone can cope with it.

So, how to clean the idle air regulator:

- First of all, the IAC must be disconnected from the wiring.

- Next, take the WD-40 liquid and apply it to a Q-tip. This stick is used to clean contacts.

- Next, take a small Phillips head screwdriver and unscrew the controller latches, there are two of them. If the fastenings are completely missing, this indicates that the IAC is mounted on varnish; if this is the case, then, most likely, the entire throttle will need to be dismantled.

- Dismantle the DXX and inspect it. If there is dirt or traces of motor fluid on the device, then in addition to the regulator itself, you will need to clean the entire throttle assembly.

- Now take a cleaning fluid (you can use carburetor cleaner instead of WD-40) and apply it to the cone needle and spring. Although carburetor cleaner is better for cleaning! Having done this, you need to dry the controller and put it in place. Before installation, make sure that the distance from the device body to the needle is 2.3 cm. If cleaning does not help fix the problem, then most likely you will have to change the DHC.

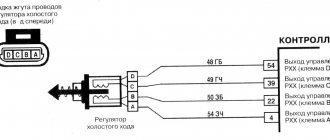

Controller connection diagram

Equipment diagnostics

- We switch the tester to resistance testing mode (ohmmeter), measure the resistance at the regulator terminals according to the diagram: A - B, C - D. Data in the range from 0.040 to 0.080 Ohm.

- Using a caliper, measure the distance between the end of the needle and the flange; it should not exceed 23 mm.

Measuring the distance

- We inspect the mounting socket for each of the sensors, clean it with a rag from dirt and dust.

- Before installation, lubricate the O-ring with engine oil.

- We tighten the screws of the regulators with a torque of 3 - 4 Nm.

Removing/replacing IAC

Let's take a closer look at the process of dismantling and replacing the idle air control. It is worth immediately noting that on different cars the process may differ in some details, but in general the algorithm will consist of the following stages:

- All work must be performed with the engine turned off. It is also advisable to disconnect the negative terminal from the battery.

- Disconnect the connector (chip) of the contact going to the regulator.

- Unscrew the mounting bolts that secure the regulator body. At the same time, make sure that the unscrewed bolts do not fall into the engine compartment.

- Remove the regulator directly from its seat.

Installing a new regulator is performed in reverse order. However, before installation, it is necessary to lubricate the flange O-ring with engine oil. The brand in this case is not important, the main thing is that it is non-aggressive towards rubber. Also check the distance from the flange to the extreme point of the cone needle. It should be 23 mm . Such a gap is needed so that when installing the IAC, its conical needle cannot rest against the seat on the throttle body. The gap value can be adjusted using a special multitester or control pulse shaper.

Addresses of companies providing installation/replacement services (Moscow, St. Petersburg, Kyiv region)

| № | Name | Address |

| 1. | "Oiler" | https://oiler.ua/ Kyiv, V. Lobanovsky Ave., 119D, Goloseevsky district |

| 2. | "AUTOKLONDAYK" | https://auto-vaz.com.ua/ TO AUTOKLONDAYK, Kyrylivska street, 60P, of. 1, Kyiv, 04080 |

| 3. | "Star - D" | https://star-d.ru/ st. Savushkina, 89, not far from the Staraya Derevnya metro station, 200 meters from the St. Petersburg - Finland highway (from Primorsky Prospekt). |

| 4. | "OSA" - Society for Assistance to Motorists" | Address: 190013, St. Petersburg, st. Vvedensky Canal, 7, BC “Farvater”, office 210 |

| 5. | "Auto Mechanic" | Address: Rostokinsky pr-d, 3с61 |

| 6. | "PaAlex" | Address: st. Ozernaya, 46k2s2 |

List of online stores providing goods (Moscow, St. Petersburg, Kyiv region)

| № | Name | Address |

| 1. | "Existential" | https://exist.ua/ |

| 2. | "Klondike" | https://autoklondayk.com.ua/ |

| 3. | "Major-auto" | https://www.major-auto.ru/ |

| 4. | "AvtoRus" | https://www.autorus.ru/ |

| 5. | "How much" | https://www.avtostore.spb.ru/ |

| 6. | "PulseCen" | https://spb.pulscen.ru/ |

Review of prices from different manufacturers

| Manufacturer article number | Price, rub.) | Resource (Thousand km) |

| Idle speed regulator 2190 KZTA1148300-02 | From 695 | 85 – 95 |

| 2190-1148300-03 | From 700 | —/— |

| Throttle position sensor 2190 VTN 05435435 | From 250 | 65 – 75 |

| Omega 465656 | —/— | —/— |

| Ricor Electronics | —/— | —/— |

| KRAFT NEW | —/— | —/— |

*prices are current as of November 3, 2018.

Location and principle of operation of the idle speed sensor

The idle speed control is located next to or on the throttle body. The location of the sensor may vary depending on the make of the vehicle. For example, on Opel and BMW models the regulator is remote, that is, located separately from the manifold.

In most cases, the IAC is secured with two bolts through a rubber O-ring and is located directly in the throttle valve. Difficulties in dismantling and installing the product may arise due to sticking of the bolts; if such a problem persists, then try the simplest method - drilling.

The main task of the IAC is to supply fuel at idle, which helps us save fuel consumption and maintain stable idle speed.

When the ignition is turned on, the sensor rod moves forward to its maximum length and rests against the hole in the throttle pipe.

After the required number of steps have passed, the valve returns to its original position. The number of steps is a constant value, which is set by the manufacturer. When you start the engine, you can watch on the tachometer how the revolutions drop as the engine warms up; this is a process that occurs due to the presence of a sensor.

The more the rod is pushed forward, the more steps are used in the work. The average stroke of the rod is 250 steps. According to this principle, the engine receives the required amount of air for its full operation, and thus the idle speed of the car is regulated. When the engine is not warmed up, thanks to the regulator, the speed increases, which allows you to start moving without fully warming up the engine.

Further work is carried out and adjusted by the mass fuel flow sensor; it analyzes the air entering the engine and gives a command to supply fuel based on the data received. Observing the engine speed, the controller begins to control the regulator. In this way, the required volume of air is monitored and further work is adjusted.

The main task of the IAC is more complete combustion of fuel due to air supply and, of course, reducing wear on the crankshaft bearings.

Recommendations for choosing components

Insufficient driver experience and a wide range of spare parts are the main factors that make it difficult to select and purchase components for the Lada Granta.

Cheapness is the first sign of low quality workmanship.

When purchasing, carefully check the catalog items and search indexes with the actual data specified in the operating instructions. If you do not have experience in servicing equipment, use the services of certified service stations and demand a quality guarantee for the work performed.

Reviews

| № | Positive |

| 1. | Vasily: I’ve been driving a car for a year and a half, I haven’t made any capital investments, except for the purchase of consumables. I regularly maintain it, buy good oils, and fill it with high-octane fuel. |

| 2. | Gennady: at 30,000 km I cleaned the idle air regulator once, and since then I forgot about the malfunctions. In winter, the car starts with a half turn. |

| 3. | Ivan: I recently went to a service station, the car started to be difficult to start. After diagnostics, the technician discovered poor contact between the block and the wires on the throttle position sensor. Now the Lada Granta works like a watch. |

| 4. | Vladlen: I have no complaints about the quality of the machine, because it is a budget option. Yes, breakdowns do occur, but they are minor and can be repaired independently. |

| 5. | Gennady: a year has passed since the purchase of the equipment, there are no comments. I tighten the fastenings in small ways, check the wiring, otherwise no comments. |

| 6. | Dmitry: for two years of operation of the car there were no major breakdowns, minor ones were fixed independently, and I did not contact the service center. |

| 7. | Valery: I am satisfied with the quality of workmanship and assembly of the machine. After the purchase, I immediately tightened all the fasteners, the interior is quiet, the plastic does not make noise. |

| Negative | |

| 8. | Victor: the first time the regulator flew 40,000 km, I contacted the service center and had it replaced. At 65,000 km the TPS began to act up. I decided to sell the car and will buy a Renault Logan. |

| 9. | Georgy: after a year of operation, the car began to crumble, I visited the service station twice unscheduled. I am dissatisfied with the quality of workmanship and assembly and plan to sell the car. |

| 10. | Vladislav: I used the car actively for six months, it started to fall apart, I had it repaired twice under warranty. I do not recommend Lada Granta for purchase. |

IAC cleaning

Do-it-yourself troubleshooting of the idle air regulator consists of simply washing it to remove carbon deposits. To do this you need to follow the instructions:

- disconnect the wire plug from the sensor;

- Unscrew the two fastening screws with a small shaped screwdriver and remove the sensor from the mounting socket;

- Clean the needle cone using WD-40 or carburetor cleaner.

Read more: KAMAZ Euro 1 crankshaft

The same means can be used to wipe the regulator contacts and the entire throttle assembly.

After cleaning, the IAC is installed back. In this case, you need to measure the distance from the end of the needle to the body - it should be approximately 2.3 cm.

Conclusion

The performance of idle speed sensors is influenced by many factors, including:

- fuel quality;

- level of dust and gas contamination of the territory;

- filter replacement frequency;

- car driving style.

In most cases, breakdowns are caused by violation of the operating conditions of the technical equipment by the driver. Purchasing cheap, non-original spare parts and unprofessional installation are the main factors that create the preconditions for premature wear of parts.