Classification by operating principle

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. According to its principle of operation, an electric machine tachometer resembles a regular one class=”aligncenter” width=”448″ height=”412″[/img]

Repair of VDO tidy — Lada Kalina Sedan, 1.6 l., 2005 on DRIVE2

In general, friends, I had the following problem: one day the battery charge light stopped lighting, as it later turned out that the cause was poor contact between the device and the connector. As a result, I soldered the contact legs going to the connector. But that’s half the trouble after assembly, the light is on, everything seems to be fine, but it was not there, the bottom line of the tidy display stopped showing, but not completely, but partially in the photo you can see how

This is how the temperature was shown

After that, the search for a solution to the problem began: the Internet, friends, relatives. But it didn’t give anything. There was nothing on the Internet except how to find out errors or a non-working switch. I disassembled the device, cleaned the contacts between the board and the conductive rubber band of the display, but nothing. I already I resigned myself to the idea of buying a new one, but decided to try again; I completely disassembled it and removed the scales in order to clear them of the blue glow at night.

cleaned with nail polish remover

I decided to completely pull out the display, there’s nothing complicated, I just need to remove the clamping bracket

this is with a bracket

with bracket removed

I decided to clean the contact between the display and the rubber band and cleaned it with regular cologne. The main thing is not to forget which way is up and which way is down, otherwise I got confused after assembly and they showed hieroglyphs)) Then I took it apart again and hurray! The display shows everything completely, I would have known to have cleaned everything earlier.

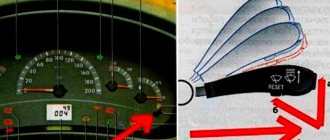

And when I bought the car, the tachometer didn’t work, but it turned out that a gear just jumped out

This is the gear, it needs to be corrected

and everything works.

And finally, a photo after assembling and cleaning the scales. I am pleased with the result, as well as with the savings. All the best!

I forgot when removing the hands, use tweezers like this, it will protect against breakage

Tips for motorists

On the left side of the instrument cluster of the Lada Kalina passenger car, there is a tachometer, from which the driver can determine the engine speed. Malfunctions in the electrical circuit of this device can lead either to a complete cessation of its readings (the tachometer needle is at zero when the engine is running), or to jumps in the needle on the scale, which does not allow determining the exact number of crankshaft revolutions.

The first thing drivers do in this case is open the hood and remove the negative terminal of the battery for a couple of minutes, thus trying to clear errors from the controller’s memory. If this does not help restore the tachometer to working order, then it is necessary to conduct a diagnostic test to identify error numbers. To do this, use your finger to press the button, which resets the daily mileage in the instrument cluster odometer. And without releasing it, turn the key in the ignition switch to the “ignition on” position.

All instrument needles must begin to move from the zero position to the final position and back. If the tachometer needle does not start moving or starts moving but does not return to its original position, this will indicate that the malfunction is located inside the instrument cluster. Considering that the stepper motors, with the help of which the tachometer needle moves, and circuit boards are not available for retail sale, the entire instrument cluster assembly will have to be changed.

If the tachometer passes the test, then the fault will have to be looked for outside the instrument cluster. On their own, most drivers can only check the condition of the terminals in the tachometer electrical circuit blocks, since this can be done visually. First of all, you need to check terminal No. 30 of the low-voltage tachometer input, which should be connected to the brown-red wire coming from the electronic control unit (ECU). To do this, you will need to remove the instrument cluster by disconnecting the wiring harness block from it. Terminal No. 30 should not be bent or show signs of corrosion.

Tachometer failure. — Lada Kalina Hatchback, 1.6 l., 2007 on DRIVE2

Yesterday I started the engine, and the tachometer needle is at zero. The EUR also did not work due to the inability to count engine speed. After about five minutes of driving, the tachometer and power steering came to life again. After I turned off the engine, I started it - again the ESD and tachometer did not work, again drove for about five minutes and everything came to life, then it turned off and did not turn on again. During the tidy test, the tachometer functions. In addition, I noticed today that the BC does not show fuel consumption.

I will try, following the advice, to change the speed sensor, although the speedometer works. This is the second day in our city of rainy weather, crawling under the hood is not an option, but we need to move around. To prevent the power steering from turning on unexpectedly when taking a turn, I removed fuse F31.

EUR fuse. F31. The largest fuse in the mounting block.

Without an EUR, it’s bad when parking and at low speeds, but on the highway without it, the information content of the steering wheel has increased.

Addition: As it turns out, it’s still not a speed sensor issue, I’ll look into it further.

Addendum 2 In the afternoon I had to take my wife to work. I started the engine and the tachometer surprised me, it works. Miracles... I haven’t put the EUR fuse back in place yet.

Mileage: 93272 km

Causes of malfunction

So, basically the malfunction appears due to disassembling the instrument cluster. On many forums, car owners complain that after disassembling the panel, this defect appeared.

But this may not be the only reason . Let's consider the main ones:

- The tachometer control motor burned out.

- The tachometer controller has failed.

- Error in the electronic control unit.

- Part of the instrument cluster board was burnt.

Thus, the main problems have been found.

Disassembling the dashboard

Treatment methods

In order for the tachometer needle to return to its place, it is necessary to eliminate the causes of this effect. So, let's look at how to treat various malfunctions with your own hands:

- The motor burned out. It is necessary to unscrew the panel and unsolder the element contacts. Check the resistance, which should be 300 ohms. If necessary, clean the contacts and solder the motor back. If this does not work and there is no resistance, then you need to install a new motor.

- Tachometer controller . If the motor is sealed and the tachometer does not return, then you need to find the control controller and check it. Replace if necessary.

Now we know how to eliminate the causes of the malfunction.

Car maintenance and repair: VAZ TACHOMETER DOES NOT WORK

Each car has its own dashboard.

They all differ in style and design, but what they all have in common is that they all show the same data. As a rule, this is data on the speed of the car (speedometer), as well as the number of engine revolutions per minute (tachometer). Today we will talk about tachometer malfunctions. You will learn why the tachometer does not work, as well as about the main malfunctions of the VAZ tachometer.

WHAT IS A TACHOMETER AND WHY IS IT NEEDED?

A tachometer is a device that, as I already said, shows the number of engine revolutions per minute (thousand rpm). The tachometer readings are necessary to make it easier for the driver (usually a beginner) to navigate and correctly select the desired gear (up or down). A tachometer is also necessary in order to monitor the correct operation of the engine by the number of revolutions. For example, when the speed fluctuates or is too high, a fault can be detected in time.

The first tachometers were analog (they are also called dial gauges). Analog tachometers have a dial with numbers and an arrow. One division of the analog tachometer is equal to 1 thousand revolutions. A little later, digital (electronic) tachometers began to appear on mostly Western-made cars. Data in electronic tachometers is displayed on a display (LCD or LCD display). In modern cars, digital tachometers look like analog ones because, like older tachometer models, they display information in the form of a dial and an arrow that indicates the number of revolutions.

SIGNS OF A TACHOMETER MALFUNCTION

- The idle speed is floating (the tachometer needle twitches even when the car is standing still and your foot is not on the gas pedal).

- The arrow does not respond to the gas pedal (it is at the zero mark or in another extreme position).