01 April 2020 Lada.Online 32 574 0

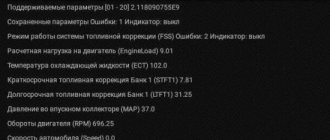

The fault indicator (Check Engine) on Chevrolet Niva cars is located in the instrument cluster. When the warning light turns on, it signals to the driver that the on-board diagnostic system has detected a malfunction of the ECM and the vehicle continues to move in emergency mode. To determine the cause, you should use a diagnostic tool, with which you can read error codes and decipher them according to the table below.

Trouble P0328 Knock Sensor 1 Bank 1 Input High

Code P0328 is entered if the following conditions exist:

engine crankshaft speed is more than 1300 rpm; coolant temperature above 60°C; the amplitude of the knock sensor signal is above the threshold. If a permanent malfunction occurs, the “CHECK ENGINE” lamp lights up after 2 drive cycles.

1. The existence of conditions for the occurrence of code P0328 is checked.

2. The serviceability of the screen of wires 2 B and 88 G is checked.

1. Connect the adapter cable to the diagnostic connector. Start the engine and warm up to a coolant temperature of 60°C. Set the engine crankshaft speed to more than 1300 rpm.

Code P0328 is intermittent. If it is currently inactive and there are no other codes, analyze the conditions under which the code occurred. Check by ear the operation of the engine for the presence of extraneous metallic noises and knocking (valves are not adjusted); if found, eliminate them. Make sure that the sensor wiring harness is not routed near high voltage wires. See the “Checking the Knock Control System” card.

2. Check the serviceability of the screen and the connection between the screen and engine ground. Check the tightening torque of the knock sensor mounting nut.

If comments are found, the sensor or controller is faulty.

If there are no comments, fix the problem.

After repair, start the engine, reset the codes and make sure there is no signal from the “CHECK ENGINE” lamp.

The error is entered under the following conditions - in forced idling mode: 1. The amplitude of the DD signal is below the threshold value 2. The computer is operating in detonation control mode. Parameter BK_R is “NO”. 3. crankshaft rotation speed in the range of 2250 - 2350. It is necessary to check the condition of the DD connector for the presence of dust - dirt and engine oil... The error is entered into the ECU memory on the third drive cycle. On cars of the first production, the DD fastening was observed to be tightened with insufficient torque. Check procedure: 1. Turn off the ignition, connect the diagnostic tool, warm up the engine to a temperature of 90 degrees. We are trying to reproduce the conditions under which the error occurred. If the error is not active at the moment, check the tightness of the DD, the correct connection and the integrity of the wiring harness. 2. If the error is active, turn off the ignition, disconnect the wiring harness block from the engine control unit and the computer. We measure the resistance of the wires connecting the ECU and the DD. If the resistance is more than 1 ohm, we eliminate the break. 3. If the resistance is less than 1 Ohm, the motor control unit or ECU is faulty, or there is a weak contact in the wiring harness blocks.

Error 0328 - high signal level of the knock sensor The error is entered under the following conditions - in forced idling mode: 1. The amplitude of the DD signal is above the threshold value 2. The computer is operating in knock control mode. Parameter BK_R is “NO”. 3. The crankshaft rotation speed is in the range of 2250 – 2350. The error is entered into the ECU memory on the third drive cycle. Error 0328 may indicate deterioration or engine malfunction. It is necessary to check the condition of the engine hardware, especially the condition of the timing belt and timing gear. On cars of the first production, tightening of the motor drive fastening with insufficient torque was observed. Check procedure: 1. Turn off the ignition, connect the diagnostic tool, warm up the engine to a temperature of 90 degrees. We are trying to reproduce the conditions under which the error occurred. If the error is not active at the moment, check the tightness of the DD, the correct connection and the integrity of the wiring harness. 2. If the error is active, check the condition of the screen and its connection to engine ground. Check the tightening torque of the DD fastening. 3. If a fault in the wiring screen is not detected, the engine control unit or ECU is faulty; if a fault in the wiring screen is detected, eliminate the fault.

Self-diagnosis

To carry out repair and maintenance work on the vehicle's engine management system, a diagnostic tool should be used. In service centers this can be DST 2M (DST-10, DST-12), for self-diagnosis an OBD-II scanner ELM327 (price about 200 rubles, see the AliExpress catalog) and a smartphone with installed software (for example, OpenDiag) are suitable. or an on-board computer installed in the car.

| Error code | Description |

| P0030 | Oxygen sensor heater before the converter, control circuit open |

| P0031 | Oxygen sensor heater before converter, control circuit short to ground |

| P0032 | Heater of the oxygen sensor to the converter, short circuit of the control circuit to the board, network |

| P0036 | Oxygen sensor heater after the converter, control circuit open |

| P0037 | Oxygen sensor heater after converter, control circuit short to ground |

| P0038 | Heater of the oxygen sensor after the converter, short circuit of the control circuit to the board, network |

| P0102 | Mass Air Flow Sensor Circuit Low Signal |

| P0103 | Mass Air Flow Sensor Circuit High Signal |

| P0112 | Intake Air Temperature Sensor Circuit Low Signal |

| P0113 | Intake Air Temperature Sensor Circuit High Signal |

| P0116 | Coolant temperature sensor circuit, signal out of range |

| P0117 | Coolant Temperature Sensor Circuit Low Signal |

| P0118 | Coolant Temperature Sensor Circuit High |

| P0122 | Throttle Position Sensor Circuit Low Signal |

| P0123 | Throttle Position Sensor Circuit High |

| P0130 | The oxygen sensor before the converter is faulty |

| P0131 | Oxygen sensor circuit to converter, low output level |

| P0132 | Oxygen sensor circuit to converter, high output level |

| P0133 | Oxygen sensor circuit to the converter, slow response to changes in mixture composition |

| P0134 | The oxygen sensor circuit to the converter is inactive |

| P0135 | Oxygen sensor to converter, heater faulty |

| P0136 | The oxygen sensor after the converter is faulty |

| P0137 | Oxygen sensor circuit after the converter, low signal level |

| P0138 | Oxygen sensor circuit after the converter, high signal level |

| P0139 | Oxygen sensor circuit after the converter, slow response to changes in mixture composition |

| P0140 | The oxygen sensor circuit after the converter is inactive |

| P0141 | Oxygen sensor after converter, heater faulty |

| P0171 | Fuel system too lean |

| P0172 | Fuel system too rich |

| P0201, P0202, P0203, P0204 | Cylinder 1 injector (2,3,4), control circuit open |

| P0261, P0264, P0267, P0270 | Cylinder 1 injector (2,3,4), control circuit short to ground |

| P0262, P0265, P0268, P0271 | Cylinder 1 injector (2,3,4), control circuit shorted to on-board network |

| P0300 | Random/multiple misfires detected |

| P0301, P0302, P0303, P0304 | Cylinder 1 (2,3,4), misfire detected |

| P0327 | Knock Sensor Circuit Low Signal |

| P0328 | Knock Sensor Circuit High Signal |

| P0335 | Crankshaft position sensor circuit is faulty |

| P0336 | Crankshaft position sensor circuit, signal out of range |

| P0337 | Crankshaft Position Sensor Low Signal |

| P0338 | Crankshaft Position Sensor High Signal |

| P0339 | Crankshaft position sensor, no signal |

| P0340 | Camshaft position sensor is faulty |

| P0341 | Camshaft position sensor, signal out of acceptable range |

| P0342 | Camshaft Position Sensor Circuit Low Signal |

| P0343 | Camshaft Position Sensor Circuit High Signal |

| P0422 | Neutralizer efficiency below threshold |

| P0441 | Gasoline vapor recovery system, incorrect air flow through the canister purge valve |

| P0444 | Canister purge valve, control circuit open |

| P0458 | Canister purge valve, control circuit short to ground |

| P0459 | Canister purge valve, control circuit shorted to on-board network |

| P0480 | Fan relay 1, control circuit open |

| P0481 | Fan Relay 2, Control Circuit Open |

| P0500 | Vehicle speed sensor is faulty |

| P0506 | Idle system, low engine speed |

| P0507 | Idle system, high engine speed |

| P0508 | Idle speed control, control circuit short to ground |

| P0509 | Idle air control control circuit faulty |

| P0532 | Air conditioning pressure sensor, low signal |

| P0533 | Air conditioning pressure sensor, high signal level |

| P0560 | On-board network voltage is below the system operability threshold |

| P0562 | On-board voltage, low level |

| P0563 | On-board voltage, high level |

| P0601 | CUD controller, ROM checksum error |

| P0615 | Additional starter relay, control circuit open |

| P0616 | Additional starter relay, control circuit short to ground |

| P0617 | Additional starter relay, control circuit closed to on-board network |

| P0627 | Fuel pump relay, control circuit open |

| P0628 | Fuel pump relay, control circuit short to ground |

| P0629 | Fuel pump relay, control circuit shorted to on-board network |

| P0645 | A/C compressor clutch relay, control circuit open |

| P0646 | A/C compressor clutch relay, control circuit short to ground |

| P0647 | Air conditioning compressor clutch relay, control circuit shorted to on-board network |

| P0691 | Fan Relay 1 Control Circuit Short to Ground |

| P0692 | Fan relay 1, control circuit shorted to on-board power supply |

| P0693 | Fan Relay 2 Control Circuit Short to Ground |

| P0694 | Fan relay 2, control circuit shorted to on-board power supply |

| P1386 | SUD controller, detonation detection channel error |

| P1570 | Immobilizer, circuit faulty |

| P1602 | Court controller, power supply loss |

| P1640 | COURT controller, EEPROM memory read-write error |

| P2187 | Fuel system lean at idle |

| P2188 | Fuel system rich at idle |

| P2195 | Oxygen sensor to the converter, stuck in a lean mixture |

| P2196 | Oxygen sensor to the converter, stuck in a rich mixture |

| P2270 | Oxygen sensor after the converter, stuck in a lean mixture |

| P2271 | Oxygen sensor after the converter, stuck in a rich mixture |

How does a mechanic diagnose a P0328 code?

When diagnosing this error code, a mechanic will do the following:

- Connects the OBD-II scanner to the vehicle's diagnostic connector and reads all stored data and error codes

- Clear error codes from the ECM and test drive the vehicle to see if P0328 appears again

- Find out if the engine makes a lot of noise during operation

- Inspect the knock sensor for damage

- Check the cooling system as well as the engine for damage

- Checks the octane number of the fuel, as well as the fuel system

- Check the knock sensor voltage

- Checks engine coolant temperature and fuel pressure

- Will check the ECM according to the manufacturer's procedure

How to replace a faulty knock sensor on a Chevrolet Niva

From time to time, malfunctions occur on any car. One of the causes of malfunctions that cause problems may be the occurrence of detonation. This can be seen by the engine running for a long time after the ignition has been turned off. It usually occurs due to explosive ignition of fuel in the cylinders.

There is a general principle of operation of an internal combustion engine:

- The fuel-air mixture enters the cylinder and is ignited by a spark from the glow plugs at the moment when the piston remains a few degrees before reaching top dead center. Complete combustion occurs at the moment when the piston reaches the top point, creating maximum pressure.

- If a detonation effect occurs, then ignition occurs much earlier, when the piston is still in the middle of the compression stroke. Therefore, during combustion, a force acts on it in the opposite direction, reducing engine power and leading to increased wear of parts.

Also interesting: Chevrolet Niva pinouts. Wire diagrams

If an indication of errors in engine operation appears on the instrument panel, this does not mean that the problem lies precisely in a faulty sensor. But if corresponding problems also arise when driving, then its urgent replacement is necessary. It should be done in accordance with the table.

· Switch the multimeter to DC voltage measurement mode

Connect the connectors to the sensor output

· tap the sensor with a small hammer. In this case, the voltage should change.

· If the voltage does not change, then the sensor is most likely faulty

The cost of a knock sensor on a Niva is 500-600 rubles, so you shouldn’t delay replacing it so as not to spend much more on engine repairs.

Priora knock sensor

A knock sensor is a device that detects the knock levels of internal combustion engine processes. The installation location of such a device is the cylinder block. Maintaining it makes it possible to obtain high power, as well as achieve good fuel economy without causing damage to the engine.

The detonation process is the main defect of an internal combustion engine, since the force is considerable and it is impossible to ignore it. Among several different devices that are used as performance optimizations, the knock sensor is used to prevent knocking fuel combustions. Fuel detonation can be controlled thanks to the main indicator - the manifestation of high-pitched and ringing metallic sounds, which, according to indicators, are sometimes mistaken for the clicking sounds of the cylinder-piston group. If the process is strong enough, with faulty knock prevention systems the engine begins to fail.

Is it possible to avoid detonation?

Pay attention to where the knock sensor is located on the Chevrolet Niva. It is located in the center of the engine block. The distance from the sensor installation location to the 1st and 4th cylinders is the same, thanks to this it allows you to capture all detonation knocks that appear in the internal combustion engine.

And in order to eliminate the possibility of detonation, it is enough to follow a few simple rules:

- When you drive your car uphill or off-road, you need to downshift. It is desirable that the engine operates at a frequency of 2500..3500 rpm.

- Monitor the condition of the spark plugs - the quality of ignition of the mixture depends on them. It is better to occasionally check the compression in each cylinder.

- It is not recommended to use gasoline with a low octane number. It is advisable to fill the tank only with fuel recommended by the car manufacturer.

Pay attention to where the knock sensor is located on the Chevrolet Niva. It is located in the center of the engine block. The distance from the sensor installation location to the 1st and 4th cylinders is the same, thanks to this it allows you to capture all detonation knocks that appear in the internal combustion engine.

- When you drive your car uphill or off-road, you need to downshift. It is desirable that the engine operates at a frequency of 2500..3500 rpm.

- Monitor the condition of the spark plugs - the quality of ignition of the mixture depends on them. It is better to occasionally check the compression in each cylinder.

- It is not recommended to use gasoline with a low octane number. It is advisable to fill the tank only with fuel recommended by the car manufacturer.

Additional comments for troubleshooting P0328

When diagnosing the P0328 code, it is very important to follow the diagnostic protocol to ensure all checks and repairs are performed correctly.

To make a proper diagnosis, a mechanic will need a professional scanner that can not only read stored error codes, but can also view data from various sensors, such as fuel pressure and engine coolant temperature, in real time.

Need help with error code P0328?

The company - CarChek, offers a service - on-site computer diagnostics; specialists from our company will come to your home or office to diagnose and identify problems with your car. Find out the cost and sign up for on-site computer diagnostics or contact a consultant by phone

How to Troubleshoot or Reset Trouble Code P0328

Some suggested steps to troubleshoot and fix error code P0328:

- Visually inspect the electrical wires and connectors leading to the sensor.

- Check the continuity of the wiring from the PCM to the knock sensor wiring connector.

- Measure the resistance of the knock sensor and compare with factory specifications.

- If necessary, replace the knock sensor.

Please note that there are two types of knock sensors, resonant in the form of a barrel and broadband in the form of a ring-washer.

How to remove and check the sensor?

Access from above to the Priora DD is difficult due to the intake module located above it. The easiest way to get to the sensor is from below, first removing the engine protection or at least unscrewing and folding its front part. When working from above, you will have to do everything by touch. In any case, before starting work, it is necessary to disconnect the ground wire attached to the “negative” terminal from the battery.

To remove the crankcase protection, you need to:

- unscrew 5 nuts with a 10mm head;

- unscrew the 2 19 nuts installed on the back of the shield;

- remove protection.

- by pressing the metal latch of the DD connector, disconnect the block of wires going to the controller;

- using a 13mm wrench, loosen the bolt securing the sensor;

- Unscrew the bolt and remove it from the threaded hole, removing the sensor.

Photo of dismantling the knock sensor

- We connect a multimeter to the DD terminals. We set the device to voltmeter mode, choosing a measurement limit of up to 200 mV.

- We take a metal object - pliers or a bolt - and lightly tap it on the DD.

When you tap on a working sensor, the voltmeter will show voltage surges. A faulty DD will not react in any way. A more accurate diagnosis of a removed sensor can only be done using a special stand.

In the photo - diagnostics of the knock sensor

Installation of a new DD is carried out in the reverse order of dismantling. Experts recommend installing a similar Bosch instead of the “native” one. Before going to the store for a new sensor, you should write down the markings of the removed sensor. The bolt securing it to 13 must be tightened with a slight force - 10.4–24.2 Nm (1.1–2.5 kgf). Tightening too tightly will affect the operation of the sensor.

Replacing the sensor

The procedure for replacing the knock sensor on a Chevrolet Niva is quite simple. You need to adhere to the following sequence:

- Find the location of the element on the engine block. And it is located in the middle part of the block; a wire made of a corrugated tube is connected to it.

- Prepare your tools. A 13mm wrench and a screwdriver will be enough.

- For convenience, you need to unscrew the bolt securing the front tube strut in the gun. After carrying out the necessary manipulations, this spacer must be moved to the side.

- Press the latch to disconnect the block from the sensor.

- Using a 13mm wrench, unscrew the bolt that secures the sensor to the engine block.

- Install the new element in reverse order.

It is advisable to check the integrity of the electrical wiring before installing a new sensor to ensure that it is working correctly. Depending on where the knock sensor on the Chevrolet Niva is purchased, its price may vary between 450-650 rubles.

What does it indicate?

The appearance of error P0325 indicates incorrect operation of the knock sensor, or more precisely, the presence of faults in its circuit. The device is installed on the cylinder block or intake manifold. It is designed to detect engine detonation using a piezoelectric element located in it.

The sensor perceives vibration of the cylinder blocks as an oscillatory movement. The pressure is then converted into a voltage signal and transmitted to the engine control module. Error code P0325 occurs when the sensor voltage level is too low or, conversely, too high. This does not have a critical impact on the operation of the engine as a whole, and the driver has time to safely get to the service station.

Often, along with the P0325 error, related errors appear, which also indicate problems with detonation. All of them occur due to damage to the sensor or the use of low quality fuel.

- P0326 – the sensor signal is outside the permissible limits.

- P0327 - decrease in the signal level of the knock sensor.

- P0328 - signal level exceeded.

Engine operating principle

Detonation very often occurs when going uphill. In this case, the car is moving slowly, and the speed is increased. But do not worry, since this phenomenon is called glow ignition, and it does not indicate that the engine is not working properly.

Any internal combustion engine works according to the following principles:

- A mixture of gasoline and air is supplied to the combustion chamber of the cylinders, where it is ignited by a spark on the spark plug. Moreover, the piston should be literally a few millimeters from top dead center. As soon as the piston reaches the top position, the greatest pressure is generated in the cylinder. At this moment, the entire air-fuel mixture will completely burn.

- During normal operation of the knock sensor on the Chevrolet Niva, signs of this phenomenon will not appear. This device will help get rid of the manifestation of detonation. And it appears when the mixture begins to ignite much earlier than it should. This usually happens halfway to top dead center. And when the air-fuel mixture burns, a force is exerted on the upper part of the piston, which pushes it in the opposite direction. At the same time, the engine power is reduced, and significantly, and its parts wear out.

Signs of a malfunctioning knock sensor

Resistance that should be in the sensor in good condition

Before considering the causes, it is necessary to look at the symptoms of the malfunction. So, let's look at what could be a warning sign that the knock sensor has failed:

- The engine is losing power.

- Overclocking potential drops.

- Fuel consumption has increased.

- The CHECK light came on on the instrument panel.

- Smoky exhaust.

- Presence of detonation.

- The engine started to stall.

Of course, an important reason for the failure of the knock sensor is the fuel mixture, namely the quality of gasoline itself. The lower the octane number, the lower the resistance to detonation. If the fuel detonates, it will not completely burn through the engine and you will hear the muffler firing.

Knock sensor diagnostics

The sensor is checked with a multimeter. In this case, the sensor is “knocked” with a screwdriver

To diagnose the knock sensor, it is removed from the engine and a voltmeter with a measurement limit of up to 200 mV is connected to it.

Next, they “knock” the sensor on a hard surface and look at the voltmeter readings. When tapping, the readings should change. If they do not change, this means that the sensor is not working. If they change, then the sensor readings change, but whether they are correct is in question!

ECU signal about malfunction

Failure of the sensor will be immediately obvious by a characteristic knocking sound. Many motorists simply reset the “minus terminal” to reset the readings of the electronic control unit, but it is worth understanding the very reasons for the effect and eliminating them. Let's look at the ECU error codes that signal a failure of the knock sensor:

- code-0325 hints at network problems. For example, a break in the wiring or acidification of the plug contacts. In this case, we call the electrical circuit connecting the sensor, clean the electrical contacts ;

Error 0325 on the BC STATE screen (Open circuit of the knock sensor)

Type of knock sensor

ECM error codes for Niva Chevrolet cars and their interpretation

To extract more specific and accurate data about the vehicle's operation, it is recommended to use third-party diagnostic devices or a computer connected via a diagnostic connector.

While control panel error codes can be retrieved using self-diagnosis, ECM error codes are retrieved using external devices.

The received error data is transmitted via the diagnostic connector to an external device in four-digit code format. The task of the external device is to read and decrypt this data.

List of fault codes recorded by the controller

P0102/103 - a low or high pulse is received from the mass air flow sensor, this indicates damage to the circuit or the device itself;

P0112/0113—increased or decreased pulse levels of the intake manifold temperature sensor were received;

P0116 - the pulse from the coolant sensor exceeded the standard values. Reason: failure of the dozh device;

0117/0118—DTOZH warns about too low/high impulse; it is necessary to verify the functionality of the sensor;

P0122/123—receipt of a low or high signal level from the throttle position sensor; sometimes it is enough to clean the mechanical part of the device or check the working condition of the touch device itself; weak/strong signal

P0130-0132—signal transmission error of the oxygen sensor located before the catalytic converter, you can clean the part itself or replace it;

P0133 - there is slow feedback on depletion or enrichment of DC No. 1 to the neutralizer;

0134/0135 – no data from DC No. 1 to the neutralizer. Source of error: there was a violation of the integrity of the wires in the power circuit, unreliable contact, heater DC No. 1 failed;

P0136—open circuit supplying pulse DC No. 2 after the neutralizer. Reasons: short circuit to the electrical wiring that controls the heater, controller malfunction;

P0137/0138 - The signal voltage of the oxygen sensor No. 2, located after the exhaust gas converter, is below or above the permissible range. Reasons: unreliable connection of contacts in the ignition system harness block, sensor and controller, incorrect harness routing;

P0140—no signal is received from DC No. 2 after the neutralizer. Causes: damage to the contacts of the sensor connector or poor-quality connection, open circuit or controller malfunction;

P0141—DC heater No. 2 after the neutralizer is faulty, poor-quality connection in the harness and sensor blocks or DC requires replacement;

P0171/0172 - the code indicates a malfunction of the fuel supply device (exceeds or falls below the lower limit of the permissible range). An error may occur due to damage to the harness, its incorrect route, unreliable grounding of the controller, poor connection of contacts, malfunction of the fuel pump, degradation of the UDC;

P0201-0204—there is a break in the injector control circuit of cylinders 1-4;

P0217 – the permissible engine temperature has been exceeded. Source of error: thermostat malfunction, low coolant level, fan not working, poor connector contact or faulty relay, short to ground in the voltage supply wiring or its break;

P0261/0264/0267/0270—a short to ground control circuit was detected in the cylinder injector (1,2,3, 4). Malfunctions may include an open circuit, short to ground or power supply of the injector control circuits, a malfunction of the controller or ignition system harness;

P0262/0265/0268/0271—Short circuit of the electrical control circuit to the on-board network of cylinder injectors (1,2,3,4). Reasons: turn-to-turn short circuit in the corresponding injector, controller malfunction;

P0300—the system has detected misfires that affect toxicity, it is necessary to check the fastening of the ground terminals in the ignition system harness, the absence of mechanical damage to the pistons, valves, camshaft, the integrity of the vacuum hoses and their connections;

P0301/03102/0303/0304—in cylinders 1-4, the fuel-air mixture ignites partially or does not ignite at all. Reasons: malfunction of ignition and fuel supply system elements, air leaks in the intake system after the mass air flow sensor, unreliable connection of vacuum hoses, mechanical failure of engine parts, radial runout of the disk;

P0327/0328—deviation of the knock sensor signal from the permissible threshold to the lower or upper part. Reasons: sensor malfunction, wiring damage, failure of engine parts;

P0335-00328—The absence of a pulse from the DPKV occurs even if there is a signal from the crankshaft position sensor. Causes: damage to the teeth on the crankshaft pulley drive disk, damage to the electrical wiring, short to ground, broken contacts of the DPKV block;

P0340—Phase sensor circuit malfunction. Source of error: breakdown of the controller, sensor, damage to the harness or pad locks;

“Camshaft position sensor is faulty (Phase sensor error).”

P0342/0343—low or high level of the DPRV pulse.

P0422—the efficiency of the converter is reduced, the controller detects an increased oxygen content after the converter. Possible reasons: the wrong type of neutralizer is installed; presence of metal-containing additives in fuel; leakage of the exhaust system between the exhaust pipe and the converter, the converter and the main muffler;

P0441/0443—error in the flow rate through the canister purge valve. The causes of the error may be: jamming of the canister purge valve, squeezing, clogging or incorrect connection of the hoses between the canister and the engine, vacuum leak in the fuel vapor recovery system;

P0480/0481 - open circuit in the control wiring of fan relay No. 1/2 of the cooling system, short to ground or short to ground. Source of error: faulty harness, controller or fan;

P0500/0503—there is no pulse from the speed sensor. Reasons: violation of the integrity of the harness, possible breakdown of the sensor or controller;

0506/507 – blocking of the XX regulator due to low/high XX speed;

P0560—voltage drop in on-board systems due to battery discharge;

P0562/0563—the controller's on-board power supply voltage is below 10V, or above 17V. It is necessary to check the battery, generator relay and the integrity of the wiring harnesses;

P0615—no load in the starter relay control circuit. The fuse and wiring need to be checked;

P0616 - short to ground in the additional starter relay circuit. The cause of the code may be an incorrect connection of the alarm system;

P0617—short to +12V in the starter relay control circuit.

P1135 - malfunction or interruption in the circuit of the heater DC No. 1 to the neutralizer. Source of error: short to ground or +12V, lack of load in the circuit, installation of a different type of sensor;

P1140—difference between the data obtained from the mass air flow sensor by measurement from the calculated value by the threshold value. Reasons: failure of the controller, poor contact in the controller and sensor block, installation of intake system parts that does not comply with the ECM;

P1141—a malfunction was detected in the DC heater circuit after the neutralizer. Source of error: installation of the wrong sensor, open circuit;

P1386—the permissible limits of test pulses coming from the mixture detonation channel length sensor have been violated. If the error occurs again after clearing the error codes, the controller must be replaced;

P1410—the purge valve control line has a short to the source of the on-board control circuit network;

P1425—short to ground in the canister purge valve control circuit;

P1426— there was a break in the control line for the canister purge valve;

P1501/1502—short to ground or to +12V in the power and control lines of the main fuel pump;

P1509—XX regulator circuit overload. Cause: electrical wiring fault;

P1513/1514—short to ground or +12V in the IAC control circuit;

P1541—no load in the fuel pump relay circuit. Reasons: incorrect alarm connection, open circuit;

P1570—No positive response from immobilizer. Reason: the immobilizer unit may have become unusable;

P1602—data from the RAM about a loss of voltage in the on-board circuit disappears in the controller. Reasons: malfunction of the power supply circuit from the battery to the controller;

P1606—incorrect signal detected from rough road sensor. Reasons: sensor failure, defective wiring harness, unreliable connection of contacts in the sensor block;

P1640—Electrically reprogrammable memory read or write test error;

P1689—violations have occurred in the controller error memory; the controller needs to be replaced.

2188 - a frequently occurring error warning of an excessively rich fuel mixture at idle; the contacts of the injection system harness pads, sensor and controller are not reliably connected.

Common errors when diagnosing code P0332

The most common mistake made when diagnosing the P0332 code is not performing a thorough check to properly determine the cause of the problem. This often results in the mistaken replacement of the knock sensor when the problem is, for example, worn or damaged electrical wires or connectors or a fault in the engine cooling system or exhaust gas recirculation system. Before replacing the knock sensor, it is necessary to perform a thorough diagnosis and consider all possible causes of the error.

Under what conditions is it diagnosed?

To diagnose error P0325 as accurately as possible, a number of conditions must be met.

- First of all, the possibility of false positives should be eliminated. Using a diagnostic scanner, reset the error and perform a test drive. If the P0325 error code appears again, go to the next step.

- Perform a performance check of the knock sensor (knock sensor). For these purposes, a multimeter is used, which determines the voltage level of the sensor under pressure. Then the circuit of the electronic control unit is checked for breaks.

- If you do not have a multimeter, the test can be performed mechanically. It's very simple. To do this, it is necessary to lightly hit the engine at idle speed as close as possible to the location of the knock sensor. If this device is working properly, the ignition angle will automatically change and the speed will decrease.

- Test the performance of the engine control module by contacting a dealer service center.

Engine operating principle

Detonation very often occurs when going uphill. In this case, the car is moving slowly, and the speed is increased. But do not worry, since this phenomenon is called glow ignition, and it does not indicate that the engine is not working properly.

Any internal combustion engine works according to the following principles:

- A mixture of gasoline and air is supplied to the combustion chamber of the cylinders, where it is ignited by a spark on the spark plug. Moreover, the piston should be literally a few millimeters from top dead center. As soon as the piston reaches the top position, the greatest pressure is generated in the cylinder. At this moment, the entire air-fuel mixture will completely burn.

- During normal operation of the knock sensor on the Chevrolet Niva, signs of this phenomenon will not appear. This device will help get rid of the manifestation of detonation. And it appears when the mixture begins to ignite much earlier than it should. This usually happens halfway to top dead center. And when the air-fuel mixture burns, a force is exerted on the upper part of the piston, which pushes it in the opposite direction. At the same time, the engine power is reduced, and significantly, and its parts wear out.

Purpose and location of the knock sensor

A knock sensor (DS) is a device that is installed on the outside of the cylinder block wall to monitor the appearance of abnormal vibrations caused by detonation in the engine, that is, explosive self-ignition in the combustion chamber of the working mixture. The DD produces an alternating current signal, the voltage amplitude and frequency of which depend on the vibration parameters of the cylinder block.

Photo of Priora knock sensor

Each level of intensity and frequency of oscillations of the engine walls corresponds to its own signal. The engine control controller constantly analyzes the data received from the engine. When detonation occurs in the cylinders, the amplitude of vibrations of the corresponding frequency increases, and the DD generates a signal, after processing which the controller adjusts the ignition timing, making it later, which leads to the suppression of detonation of the working mixture.

The Priora DD consists of a washer-shaped plastic body, which has a hole in the center for a bolt with a 13-head head, and on the side there is a two-pin connector for connecting wires from the controller. The main part of the DD is located inside the case - a sensitive piezoceramic disk element, which, in fact, generates voltage (signal) when exposed to vibration.

The DD Priora is installed on the cylinder block, namely: on its front wall under the intake module, next to and slightly above the dipstick socket for monitoring the oil level in the engine. It is not visible from the top of the hood. It can only be seen from below, for example, from a pit, when the lower engine protection is removed.

P0328 knock sensor circuit high signal level

Detonation, metallic ringing, clanking when you press the gas pedal, or “knuckle knock” can occur during sudden acceleration or when the engine is running under load.

This ringing means that the fuel is detonating (the combustible mixture spontaneously ignites). Detonation is very harmful to the engine and can lead to its destruction. To detect detonation on cars, a special sensor is installed on the cylinder head - knock sensor . This sensor measures the engine noise level and, if the noise level is exceeded (the moment detonation occurs), it adjusts the internal combustion engine parameters (ignition angle) to reduce detonation.

There are two types of knock sensors: resonant and broadband.

Photo 1. Wideband knock sensor

Let's consider the design and principle of operation of a broadband knock sensor, since it is the most common.

Vibration affects the inertial mass 3 (seismic mass) made of high-density alloys. The seismic mass, in turn, with a certain vibration affects the piezoceramic sensitive element and when a piezoelectric effect occurs, an alternating signal is removed from contact pads No. 1 and No. 2 and is supplied to the engine control unit. Thus, the ECU measures the engine noise level and, if minimal detonation occurs, controls the ignition timing.

Let's give an example of a knock sensor signal and the process of adjusting the ignition timing.

When the engine is running, the ECU tries to set the optimal ignition angle, but at the same time prevents it from entering the detonation zone. When detonation occurs, the ECU adjusts the ignition timing to a late value until detonation passes.

Why is detonation so harmful to the engine?

Detonation occurs before a spark forms on the spark plug; the mixture ignites ahead of time, i.e. spontaneously, under certain conditions. Detonation is wave-like and similar to multiple explosions, and these explosions can cause serious damage to your engine: burnt pistons and valves.

More and more fake knock sensors are appearing on the market. These are simply “blank” dummies, inside of which there is no sensitive measuring element. How can you avoid falling for a fake and check the knock sensor?

1. It is necessary to measure the resistance of the knock sensor. As a rule, all imported cars have sensors with a shunt resistor of 500. 600 kOhm . If you have measured this resistance, then take the detonation sensor and tap on its lower part with a metal object, simulating detonation. Is it best to tap the valve from the block head? The resistance when tapping will vary from 500 . up to 800 . 1300 kOhm, depending on the force of tapping. If you didn’t see any resistance, then there may not be a shunt resistor inside, as on most Russian cars. To check such a sensor, you need to install a shunt resistor parallel to the sensor terminals and repeat the test by tapping the sensor.

Knock sensor from a Nissan car, serviceable, resistance - 0.562 MOhm = 562 kOhm.

2. Measure the capacity of the knock sensor. Setting the multimeter to capacitance measurement mode, we check the knock sensor. When checking, remember that the wires from the sensor to the multimeter should be at least 1.5 cm. After all, the wires themselves may show a minimum capacity. The knock sensor capacitance should be between 800 and 1500 picofarads (pF) . Small deviations can be taken as an error, but if you suddenly measure a capacitance of 100 pF, then such a sensor can be considered inoperable.

3. Measure the voltage of the knock sensor. Set the multimeter to AC voltage measurement mode with a measurement limit of up to 2 volts and hit the sensor several times. The voltage of a working sensor will fluctuate from 30.60 mV , or even reach 100 mV. Let's repeat, we got the maximum effect by knocking on the knock sensor with a valve from the cylinder head, tapping with a regular key, the effect was minimal.

4. How else can you check the knock sensor? You can assemble a test circuit using an old car alarm, namely a shock sensor , by removing the seismic sensor from the board and soldering a wire with a chip under the knock sensor on it. Sensitivity can be adjusted using a standard trimming resistor.

unsolder the seismic sensor and in its place solder a shielded wire with a connector for connecting the knock sensor

We connect the knock sensor, connect the +12 volt power supply and ground, turn the trimming resistor to the maximum and tap the knock sensor body with a metal object. The LED will light up. You can also connect the actuator to the blue wire; a “minus” appears on it when detonation occurs. You can simply connect the LED probe. Let's watch a video on checking the KNOCK SENSOR.

What are the most common knock sensor malfunctions?

If the knock sensor malfunctions, the following errors are entered into the ECU memory: P0325 – malfunction of the knock sensor circuit P0326 – the sensor signal is outside the normal range. P0327 – low signal level of the knock sensor P0328 – high level of the knock sensor signal. Error P0328 may appear when the vehicle is refueled with low-quality fuel. These errors can also occur due to the destruction of the knock sensor itself. Photo below.

There are also situations when an initially defective knock sensor is installed on a car, inside of which there is an ordinary metal blank without a sensitive measuring element. In such cases, errors appear - P0326, P0325

Let's look at a video in which there was exactly that same dummy. Computer diagnostics and sensor defects were carried out.

Read on.

Date added: 2017-01-10

Author of the article: Alexander Dmitriev (AlastaR)

© AutoService | Online store, Ekaterinburg

The structure of the flat engine knock sensor (non-resonant type) allows vibration detection over a wide frequency range: approximately 6 to 15 kHz. Knock sensors are installed on the cylinder block and are designed to detect engine knock. The sensor consists of a piezoelectric element that generates voltage when deformed. Voltage is generated when the cylinder block vibrates due to detonation. The occurrence of engine knock can be eliminated by delaying the ignition timing.

HINT: When one of DTCs P0327 and P0328 is detected, the ECM will go into limp mode. During operation in emergency mode, the value of the ignition timing angle is assumed to be equal to the maximum retardation. Emergency operation continues until the ignition is turned off.

For reference: Check using an oscilloscope.

The signal shape should correspond to that shown in the figure.

| Parameter/Device | Content |

| Contacts | KNK1–EKNK |

| Hardware settings | 1 V/div. 1 ms/div. |

| Conditions | Maintain engine speed at 4000 rpm when engine is warm |

How to fix

Fuel detonation, that is, its spontaneous combustion, can ultimately lead to engine destruction. Therefore, it is important that the sensor works correctly. To do this, it is highly recommended to resolve the P0325 error as soon as possible.

There are several effective solutions to this problem:

- Thoroughly clean the contacts or replace damaged wiring (depending on the actual cause of the error).

- Replace or repair the wiring in the area from the knock sensor to the engine control unit.

- Replace the damaged knock sensor, as this element is not repairable.

- Update the control unit software or replace this device.

Error P0325 is called Knock Sensor 1 Circuit Malfunction, that is, “a malfunction in the knock sensor circuit.” For its accurate diagnosis, a special device is used - a multimeter. There are several ways to solve this problem, depending on the specific cause. Typically, for these purposes, the contacts are cleaned, the wiring between the sensor and the control unit is changed, or the sensor or control unit is replaced, depending on which device is not operating correctly.

Error P0325

Error code P0325 has an official name - “malfunction in the knock sensor circuit.” In English it sounds like: Knock Sensor 1 Circuit Malfunction. It signals to the driver that the engine control unit does not receive a signal from the DD. Due to the fact that some problems have arisen in its power supply or signal circuit. The cause of this error may be very low or very high voltage coming from the sensor due to a break or poor contact in the wiring harness block.

Possible causes of the error

There are several reasons why error p0325 may occur. Among them:

- broken knock sensor wiring;

- short circuit in the DD wiring circuit;

- malfunction in the connector (chip) and/or contact DD;

- high level of interference from the ignition system;

- malfunction of the knock sensor itself;

- malfunction of the engine control unit (abbreviated as ECM).

Conditions for recording error code 0325

The code is installed in the ECU memory on a warm engine at a crankshaft speed of 1600-5000 rpm. if the problem does not go away within 5 seconds. and more. The archive of fault error codes itself is cleared after 40 consecutive cycles without fixing a fault.

To find out exactly what problem caused the error, additional diagnostics must be performed.

External symptoms of error P0325

External signs of this error may include the following situations. However, they can also indicate other errors, so you should always perform additional diagnostics using an electronic scanner.

- The Check Engine light on the dashboard is activated;

- the engine control unit operates in emergency mode;

- in some cases, engine detonation is possible;

- loss of engine power is possible (the car “does not pull”, loses its dynamic characteristics, accelerates poorly);

- Unstable engine operation at idle.

In general, the symptoms of failure of the knock sensor or its wiring are outwardly similar to those when the ignition is set late in the car (on carburetor engines).

Error diagnosis algorithm

To diagnose error p0325, it is necessary to have an electronic error scanner (for example ELM 327 OBD-II). The error detection algorithm will be as follows:

- First, you need to make sure that the alarm was not false. To do this, you need to reset the error using the scanner (if there are no others, otherwise you need to deal with them first) and perform a test drive. If error p0325 occurs again, then we continue further.

- You need to check the functionality of the knock sensor. This can be done in two ways - using a multimeter and mechanically. Using a multimeter, you first need to measure the voltage of the sensor when pressure is applied to it. And also check its circuit to the ECU for an open circuit. The second, simpler method is to simply hit the engine at idle speed in the immediate vicinity of the sensor. If it is working properly, then the engine speed will drop (the electronics will automatically change the ignition angle), which is true that this algorithm does not work on all cars and in some cases, reading the BC signal from the DD works under other additional conditions).

- Check ECM functionality. In rare cases, the program may crash. It is unlikely that you will be able to perform the check yourself, so it is better to seek help from an official dealer of your car manufacturer.

How to get rid of error p0325

Depending on what exactly caused the p0325 error, several options are possible to solve this problem. Among them:

- cleaning contacts or replacing wiring connectors (chips);

- repair or replacement of wiring from the knock sensor to the engine control unit;

- replacing the knock sensor itself, most often this is what is done (this unit cannot be repaired);

- flashing or replacing the engine control unit.

Error p0325 itself is not critical, and the car can get to a car service center or garage under its own power. However, there is a risk that if detonation occurs in the engine, the ECU will not be able to react properly and eliminate it. And since detonation is very dangerous for the power unit, you need to get rid of the error and carry out the appropriate repair work as quickly as possible after its occurrence.

How to check the knock sensor?

Unfortunately, the knock sensor can also fail. In this case, a person without special knowledge will be able to notice this only by the lit indicator. No other obvious signs will be noticed. The car will continue to operate in the same mode and start without any signs of breakdown.

At this point, it is necessary to remember that this device is not mechanical, it is part of an electronic system, and therefore the breakdown is considered electronic.

A knock sensor malfunction can happen for a number of different reasons, including:

- There has been a breakdown inside the sensor itself.

- Closure.

- The signal wire or braided shield is broken.

- Damage to the engine control unit.

Thus, it will not be difficult to identify the breakdown. In order to determine it, it is necessary to conduct a test.

The easiest way to check is to go to a car service center. There, experienced craftsmen will open the engine protection and identify the breakdown in just an hour.

But those who are not looking for easy ways can always carry out this simple process on their own. Self-checking occurs according to the following scheme:

“Code 0328 is entered if: - the engine is running at speeds above 1300 rpm - the coolant temperature is above 40°C - the amplitude of the DD signal is above the threshold The “CHECK ENGINE” lamp lights up 2 drive cycles after a permanent malfunction occurs “

Now comes the crux of the problem. An extraneous sound was noticed at 3000 rpm. Something was cracking loudly. Moreover, it could be caught at certain speeds. I somehow didn't pay attention. But over time it began to progress and the error rarely appeared. Now 2 times a week. After reading the shnivo forum I still don’t understand where to dig. Gasoline consumption is normal. The spark plugs worked 41t. km. and were in good condition, but replaced them just in case. The dynamics have not worsened. Maybe someone can listen to the engine and make a diagnosis? Or tell me who had something similar?

error 0328 (Knock sensor signal high)

Yandex. Direct

error 0328 (Knock sensor signal high)

MURTAZA Mar 10, 2010, 11:58

error 0328 (Knock sensor signal high)

av 10 Mar 2010, 14:53

error 0328 (Knock sensor signal high)

crocodile 13 Mar 2010, 12:24

error 0328 (Knock sensor signal high)

av Mar 14, 2010, 9:23 pm

I thought too. What should we do with it? Should I change or tighten the bolt?

Last year, in the spring, such a sound also began. but was significantly quieter and did not cause an error. Then I sank the car and when I changed the hydraulic compensators, I checked the chain and the damper. After assembly the sound disappeared.

Apparently I'll take it apart and see what's there

error 0328 (Knock sensor signal high)

MURTAZA March 14, 2010, 21:35

error 0328 (Knock sensor signal high)

crocodile March 14, 2010, 10:32 pm

error 0328 (Knock sensor signal high)

av Mar 21, 2010, 12:02 pm

What could it be from? The valve seems to be moving well. When replacing the camshaft and valve levers with new ones. The error does not appear and the engine does not make such a sound, it runs smoothly and smoothly, but knocks a little at idle. Will it work in? Or is something wrong somewhere?

error 0328 (Knock sensor signal high)

Flanger Mar 21, 2010 12:38 pm

error 0328 (Knock sensor signal high)

crocodile March 21, 2010, 12:49

error 0328 (Knock sensor signal high)

crocodile March 21, 2010, 12:50

error 0328 (Knock sensor signal high)

Wasilih Mar 27, 2010, 03:58 pm

error 0328 (Knock sensor signal high)

-Alexandr — 28 June 2010, 17:46

error 0328 (Knock sensor signal high)

Igyr 28 June 2010, 19:12

Now on 4×4.tomsk. ru

This forum is currently viewed by: no registered users and guests: 0

Reg.: 12/06/2004 Threads / Messages: 4031 / 23190 From: Moscow Age: 65 Car: 21214M, 2013

Reg.: 09.13.2008 Threads / Messages: 3 / 597 From: Ivanteevka Age: 37 Car: was VAZ 21214 2008, now 3151 UAZ

First, look at the wires from the control panel to the controller. You obviously have either a bad contact or a non-working sensor (or incorrectly tightened).

There is no signal from the DD controller, it overestimates the OZ, so it shoots at you.

Reg.: 12/10/2010 Messages: 82 From: Omsk region. Age: 35 Car: CHEVROLET NIVA 2008

Reg.: 04/09/2013 Messages: 24 From: Russia, Moscow Age: 40 Car: Niva 212140, 2012

I'll raise the topic with a question.

Once I cleaned the DD contacts, error 0327 no longer popped up. But detonation at low speeds in traffic jams remained. Tell me - how can I eliminate it?

Name: Yaroslav Reg.: 03/21/2012 Threads / Messages: 3 / 8260 From: Taganrog Age: 28 Car: VAZ-21214-50-120 (06/01/2012), SHTAT UniComp 400L (firmware 3.3.1), VAZ-11173 2012, VAZ-21112 2006

Reg.: 04/09/2013 Messages: 24 From: Russia, Moscow Age: 40 Car: Niva 212140, 2012

Nope, the situation is the opposite. When standing in a traffic jam for more than 30 minutes, when starting off smoothly, the engine begins to shake and shoot noticeably (I don’t know how else to say it in Russian), and if you give it some gas, the detonation disappears. When driving in Moscow traffic jams, you can’t press the gas too hard. And driving in mode - you drive 10 meters slowly and you stop)))

I refueled until June 95, and now I switched to 92. I don’t see any difference in terms of driving, but I don’t want to overpay. I only refuel at Lukoil.

Name: Yaroslav Reg.: 03/21/2012 Threads / Messages: 3 / 8260 From: Taganrog Age: 28 Car: VAZ-21214-50-120 (06/01/2012), SHTAT UniComp 400L (firmware 3.3.1), VAZ-11173 2012, VAZ-21112 2006

Reg.: 04/09/2013 Messages: 24 From: Russia, Moscow Age: 40 Car: Niva 212140, 2012

Ok, I'll try. If it still shakes, I’ll ask again. ;)

Name: Alexey Reg.: 03/05/2005 Threads / Messages: 61 / 4064 From: Moscow, Northern Administrative Okrug Age: 39 Car: Shniva 2021 70 tkm

Epigraph “Don’t you, priest, chase after cheapness” (c)

I decided to install Boshevsky DD 0261231046, because sometimes the valves were knocking like on a carb one. I bought a DD in existential at a bargain price (250 rubles). Immediately error 0327. Resetting does not help. I went online, read that there are a lot of fakes, and realized that what I have is a fake. I went to Rus' and bought a second Bosch sensor, but it was more expensive (650 rubles), but it came in a box and with a 1/2 year warranty card, which they filled out in front of me. I changed it - everything is fine. I decided to see what was inside the fake sensor.

In principle, I’m not surprised that I ran into a fake, it happens to everyone. But for me to run into a “dummy” - this is the first time this has happened to me:

If it’s hard to see, the “knock sensor” consists of a bushing cast in plastic and two washers to increase the total mass of the sensor.

Description of detonation Niva Chevrolet

Engine operation is often accompanied by various types of failures. One of these failures is detonation, which involves prolonged engine operation when the ignition is turned off.

From the technical side, this occurs as a result of explosive ignition of the combustible mixture in the engine cylinders.

Drivers encounter this phenomenon when driving uphill in a car at low speed and in high gear, resulting in a glow effect. This phenomenon is abnormal and does not bring any benefit.

The internal combustion engine operates according to the following principle:

- When a combustible mixture enters the cylinder, it ignites when the piston is several degrees below top dead center. Complete combustion of the mixture is completed when the piston reaches the top point. This is how the normal operation of any internal combustion engine is carried out.

- The phenomenon of detonation occurs when the piston reaches the middle of the compression stroke. At this moment, the piston receives a counterforce, resulting in reduced engine power.

Problems with engine detonation on a Chevrolet Niva car

The problem of detonation is also familiar to the Chevrolet Niva. Coming from an SUV family, the Niva has the peculiarity of frequent trips not only off-road, but also in hills and mountainous areas. Therefore, when climbing at low speed and in high gear, you sometimes hear the sound of a metallic clatter. This phenomenon can lead to the following types of problems:

- Engine failure resulting from the action of a destructive force on the cylinder head and crank mechanism;

- Burnout of the cylinder head gasket (cylinder head), which occurs when the temperature rises to critical values during detonation. Often the first one to become unusable and requires immediate replacement;

- Piston burnout. Corrosion of the piston crown appears and with frequent exposure to this phenomenon, it leads to burnout.

Therefore, it is necessary to control the operation of the engine when moving up at low speeds and in high gear. Detonation can contribute to the failure of the cylinder block, pistons and crankshaft of a Chevrolet Niva, which can only be corrected by replacing them with new ones, which will be practically very expensive.

To reduce fuel consumption on a Shnivy you just need...

All cars are susceptible to this phenomenon. The main reasons that lead to this effect are:

- Circumstances under which the Chevrolet Niva is operated. This is exactly the case when climbing a steep hill at a speed below 40 km/h and in fourth gear;

- Quality of the fuel mixture. If the octane number is low, then detonation is guaranteed. A high number ensures detonation resistance;

- Design characteristics of the motor. These include: the condition of the spark plugs and their location, the shape of the combustion chamber, the compression ratio and the shape of the piston.

What methods of protection are provided in Shnivy against detonation?

Chevrolet Niva is equipped with a knock sensor. It is designed to protect the motor from this effect, as well as to display the process of its occurrence in the form of a light alarm. The sensor is a sensitive element made of piezoceramic material. On the Chevrolet Niva it is located in the area of the cylinder block. The operating principle of the sensor is as follows:

- When the phenomenon of engine detonation appears, the amplitude of its vibrations increases;

- The built-in controller on the instrument panel corrects the ignition timing, which helps to dampen the phenomenon;

- The signal to the controller is supplied by a sensor, which generates an incoming voltage signal that occurs under certain engine vibration parameters;

- The controller is also capable of displaying a sensor malfunction in the form of a light alarm on the instrument panel. The alarm is represented by the inscription “CHEK ENGINE”, familiar to all drivers, which is highlighted in red.

in our VKontakte group

DIAGNOSE YOUR CAR YOURSELF!

Code P0328 is entered if the following conditions exist:

engine crankshaft speed is more than 1300 rpm; coolant temperature above 60°C; the amplitude of the knock sensor signal is above the threshold. If a permanent malfunction occurs, the “CHECK ENGINE” lamp lights up after 2 drive cycles.

1. The existence of conditions for the occurrence of code P0328 is checked.

2. The serviceability of the screen of wires 2 B and 88 G is checked.

HOW TO CHECK:

1. Connect the adapter cable to the diagnostic connector. Start the engine and warm up to a coolant temperature of 60°C. Set the engine crankshaft speed to more than 1300 rpm.

Code P0328 is intermittent. If it is currently inactive and there are no other codes, analyze the conditions under which the code occurred. Check by ear the operation of the engine for the presence of extraneous metallic noises and knocking (valves are not adjusted); if found, eliminate them. Make sure that the sensor wiring harness is not routed near high voltage wires. See the “Checking the Knock Control System” card.

2. Check the serviceability of the screen and the connection between the screen and engine ground. Check the tightening torque of the knock sensor mounting nut.

If comments are found, the sensor or controller is faulty.

If there are no comments, fix the problem.

After repair, start the engine, reset the codes and make sure there is no signal from the “CHECK ENGINE” lamp.

What does it indicate?

Error code P0327 stands for “Low signal from the knock sensor” (Knock Sensor 1 Circuit Low Input in English). The occurrence of this error is not always indicated by the Check Engine light on the dashboard - for it to light up, at least two trips must be made with a low sensor signal level. Sometimes the meter itself can function properly, but a low signal level from the sensor to the electronic control unit leads to engine malfunction.

Knock protection

The engine management system contains a knock sensor - it allows you to determine the presence of knocks, as well as evaluate their strength. If detonation suddenly appears and the sensor is faulty, the electronic engine control unit will generate an error signal. On the contrary, when the sensor is working properly, it will begin to produce a signal.

The design of the device is based on a piezoelectric element, which generates energy under the influence of impacts. And after that, the electronic control unit processes the signal and analyzes its level. After this, it sends a signal to change the ignition timing.

The engine management system contains a knock sensor - it allows you to determine the presence of knocks, as well as evaluate their strength. If detonation suddenly appears and the sensor is faulty, the electronic engine control unit will generate an error signal. On the contrary, when the sensor is working properly, it will begin to produce a signal.

Signs of an error

The error manifests itself when the engine is warm - in order for fuel detonation to occur, the fuel must be warmed up and able to detonate. Problems with the sensor lead to deterioration in vehicle behavior:

- dynamic characteristics deteriorate;

- fuel consumption increases;

- the engine is unstable at idle;

- dips in engine speed appear.

The reason for the deterioration in performance is a command from the electronic control unit to switch to emergency engine operation when the signal from the knock sensor is low. The ECU specifically limits the engine's capabilities to avoid burning out valves and pistons as a result of excessive detonation. On some vehicles, emergency operation may limit the maximum speed to 3-5 thousand rpm and the maximum speed to 50 km/h.

When is it diagnosed?

The conditions for the error to occur may vary for different car models, but general symptoms can be outlined:

- crankshaft speed level over 1300 RPM;

- warm car engine (coolant temperature exceeds +60 °C);

- The knock sensor signal level is below the limit values.

The sensor comes into operation only when fuel detonation occurs, so the absence of a signal from the meter is recorded at high speeds and a warm engine. As already mentioned, the error does not appear immediately - it is entered into the ECU memory only after the second trip in a row with the specified values.

Reasons for the error

The cause of error code P0327 may be:

- failure of the sensor itself (quite rare);

- contact failure in the electrical circuit;

- malfunction of the sensor wiring as a result of a short circuit, breakdown or break;

- incorrect installation of the sensor itself;

- malfunction of the electronic control unit.

The problem can occur on any gasoline vehicles equipped with an electronic control unit and a knock sensor, respectively.