How to properly grind valves using the example of a VAZ 2109

Valve lapping - why is it necessary?

The main task of the lapping procedure is to organize the correct functioning of the valves.

If grinding is ignored on an ongoing basis, then you cannot count on high-quality operation of the valves. Air and fuel will not be introduced into the cylinders quite correctly, but the consequences of this discrepancy will not be long in coming: the engine will begin to malfunction, and after a certain period of time, it is very likely that the engine will please you with a banal failure. By grinding in the valves, the maximum possible sealing of the mechanism is achieved. The valves are ground in both after the introduction of new elements and during prolonged operation of the power unit. As an example, you can take the jerking of a car at idle, which occurs due to a difference in compression. After grinding in, such a misunderstanding should inevitably disappear.

Spare parts and tools for work

Before starting work on replacing valves on a VAZ 2110, high-quality new parts are purchased, the names and original articles of which are as follows:

- Set of gaskets: valve cover (art. 2108-1003270/77) and cylinder head (art. 21083-1003020), intake and exhaust manifolds (set art. 21083-1008081), exhaust gas intake pipe (art. 2103-1203020-04) , as well as an oil seal (art. 2108-1005034) and oil flinger rings (art. 2108-1007026-86) (the so-called cylinder head repair kit)

- New valves for the fuel mixture intake system 4 pcs. (art. 21083-1007010)

- New exhaust system valves 4 pcs. (art. 2108-1007012)

- Valve guides 8 pcs. (art. 2108-1007032-87)

- Engine coolant

- New bolts securing the cylinder head to the cylinder block (art. 2108-1003271Н/О)

- Timing belt (art. 2108-1006040-86) and generator drive belt (art. 1000012562)

- Engine oil and oil filter

Repairs to replace worn-out parts are carried out using a standard set of tools, which are usually sold as a set, namely:

- a set of open-end wrenches marked from 8 to 21 mm;

- set of internal hex keys;

- a set of sockets with a diameter from 8 to 24 mm;

- valve desiccant;

- screw valve guide puller;

- torque wrench (needed for proper tightening of the camshaft, cylinder head and camshaft gear bolts);

- Screwdriver Set;

- electric drill;

- specialized lapping paste of two types (for rough lapping of valves to their working surface of the combustion chamber and for finishing grinding);

- gloves to protect hands from possible damage.

The presence of tools, parts and a covered room will allow you to carry out troubleshooting work yourself, since the price of replacing 8 valves on a VAZ 2110 in non-certified services in the fall of 2021 varies from 30 to 45 thousand rubles. At a certified service station of official dealers, such work will cost more than 50 thousand, which will greatly affect the financial situation of the car owner.

Problematic seals

In addition to adjusting the valves, it is extremely important to check the current condition of the seals.

Valve seals are designed to prevent excess engine oil from leaking through. In ideal operating condition, they seal tightly against the valve and allow only the amount of oil to flow through to provide effective lubrication.

Valve seals

They sometimes have to be changed, since the rubber used to make oil seals ages over time and loses its elasticity. As a result, the oil seal leaks more oil than required. Engine oil consumption increases, problems arise in the lubrication system and more.

Therefore, we offer you instructions on how to replace them.

- The work begins with the obligatory removal of the negative terminal from the battery.

- Disconnect the contacts from the ignition coil and move them aside. It is better not to unscrew the spark plugs, otherwise you risk providing the cylinders with an impressive amount of dirt during the repair process.

- Disconnect a pair of rubber tubes from the valve cover. Loosen the valve cover mounting screws and unscrew them. Subsequently, put all small parts, nuts, bolts in a separate jar so as not to lose anything.

- Remove the valve cover and a pair of gaskets. It is best to replace these gaskets immediately.

- In order not to remove the cylinder head side cover, which covers the camshaft chain and sprockets, you can move the sprockets into the cover as far as it will go and remove the shafts from them.

- Remove the spark plugs. First, insert the oil dipstick into the spark plug hole until the end touches the piston. After this, carefully rotate the pulley until the dipstick stops before lowering.

- Using a marker or paint, make marks on the sprockets and chain, fixing the required position of the teeth in the chain. This way, when reassembling, you will be able to correctly return the chain to the teeth on which it was located before dismantling.

- Unscrew the sprockets using an open-end or socket wrench. To prevent the cylinders from turning, secure the large pulley below the wheel with a key.

- Remove the shaft mounting yokes. The one next to the stars is removed first. Next, all the others are removed, adhering to the order of weakening. Place all the elements on a rag in the order in which you removed them. This way you won't get confused when reassembling.

Replacement procedure

- Remove the stars from their nests. The first one is easily removed in the area of the cylinder head side cover, if you remove the shaft position sensor first. It is held on by one bolt, so there should be no problems here.

- Having freed the shafts from the yokes, lift them a little using a flat-head screwdriver, and then remove them from the sprockets.

- After removing the shafts, remove the near sprocket and secure the chain with a slight tension.

- Next, the valve cups are dismantled. They are shiny, so it is difficult to confuse them. Although no cup holders are used, removing them can be a problem. They stick from the inside. Try using a powerful magnet.

- Remove the springs. To do this, you will need to loosen the valves on cylinders 1 and 4. This is due to the fact that on them the piston is at TDC. Secure the outer bracket with a bolt using a suitable hole in the block head. Using the second bracket, jerk the washer until it stops. The crackers should come free, after which you carefully remove them from their seats with a magnetized screwdriver.

- Remove the springs along with the washer. Place them on the table in the order in which you removed them. That's it, we finally got to our oil seals.

- Use pliers to remove the old seals. This can take quite a long time.

- Put on new oil seals, treating them with engine oil first.

- Press into place using a washer or tube of the required diameter.

- Put the springs back in place and dry them. Here you need to be as careful and attentive as possible. We recommend covering the engine with a rag. Having dried the valves of cylinders 1 and 4, move the pistons of cylinders 2 and 3 to TDC, then repeat the operation.

- Having dried the last valve, proceed to reassemble the unit. Here, strictly follow the reverse sequence.

Preparatory work

Replacing the timing belt requires some prep work to get to it. To do this, lift the hood and remove the air filter pipe by unscrewing the fastenings of the retaining clamp with a wrench. Next, the belt protective cover is removed, for which you need to unscrew the three bolts that hold it in place. This is done with a regular open-end wrench. In the opened space, the timing belt will be visible, which needs to be replaced.

The front right wheel and the protection under it are first removed to get to the crankshaft pulley, which drives the gas distribution mechanism via a belt. In the cab, put the lever in the fourth gear position and ask the assistant to press the brake pedal. We install the head 19 on a long wrench so that it is convenient to get to the crankshaft pulley, which we unscrew, which will require some effort. After the bolt is broken, you can put the gear in neutral and not hold the brake pedal.

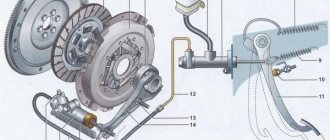

Important feature! To replace the timing belt on a VAZ 2109 8-valve injection engine or a similar VAZ 21099 model, when removing the crankshaft pulley, you need to hold the flywheel, which is best done with a screwdriver. Otherwise, it will rotate along with the pulley. In carburetor engines this problem does not exist; the pulley is held independently.

From the top of the open hood, the nut that holds the tension of the generator belt is loosened; this is best done using a special cardan on which to place the head of the key. The generator pulley is moved so that the belt can be removed without interference. After this, remove the crankshaft pulley so that the gear is visible.

The procedure for adjusting the thermal clearances of valves on VAZ 2109-21099

Attention! The car engine must be cold and its temperature at the time of adjustment should not be higher than 20 degrees.

Video tutorial on how to do the job

In order to clearly demonstrate the procedure for adjusting thermal gaps, it was decided to record a special video clip that shows everything in detail.

If from the guide presented above there is something still unclear to you, then below everything will be presented in a form familiar to everyone.

Photo report of the performed maintenance

So, before proceeding with this operation, you first need to remove the valve cover, as well as the casing under which the timing mechanism is located.

After this, you need to set the gas distribution mechanism according to the marks. To do this, jack up the front right part of the car so that you can turn the wheel by hand to set the valve timing marks.

Then we turn the wheel until the marks on the camshaft sprocket and the marks on the rear timing cover align, as clearly demonstrated in the picture below:

At the same time, make sure that the mark on the flywheel also coincides with the cutout. You need to look through the window, which is located to the right of the fourth cylinder on the gearbox housing. You must first remove the rubber plug:

When the camshaft is in this position, you can begin to measure the thermal clearances between the cams and pushers of the 1st, 2nd, 3rd and 5th valves (counting from the left):

For intake valves, the nominal clearance should be 0.20 (+-0.05) mm, and for exhaust valves 0.35 (+-0.05) mm. If you don’t know the location, I can say: from left to right in order: exhaust-inlet, inlet-outlet, etc.

If, when measuring the gaps, they go beyond the maximum permissible values, they must be adjusted by installing new shims. To do this, we put the bar on the valve cover studs and secure it with nuts.

Now we bring the mechanism lever to the desired valve, and direct it as if between the pusher and the camshaft cam, and recess the valve to the very end:

And when the pusher is pressed down as much as possible, you need to insert a clamp between the camshaft and the pusher:

It is worth noting that the cutout on the pushrod should be facing towards you so that you can conveniently remove the shim. It is very convenient to use long-nose pliers for this:

After that, look at its size, which is indicated on its back side:

Now we calculate, based on the measured gap and the thickness of the old washer, what the thickness of the new washer should be in order to achieve the optimal gap.

Now you can insert the new washer into place and make further adjustments. When the first 4 valves are ready, you can turn the crankshaft one revolution and carry out a similar procedure with the remaining 4, 6, 7 and 8 valves.

Good day. Tell me how to estimate the required thickness of the washer under the following conditions: after assembling the cylinder head in the garage, a mechanic and I were forced to cut off the thickness of the standard washer on the 1st and 3rd outlet valves to a gap of 030+005. Engine 21083 injector with a mileage of 170 t.km. The positions of the service technicians have changed to a worse position for the car enthusiast whose car is not a luxury. The latter are drawn to old-school craftsmen and production areas with mechanical processing of the cylinder head. The event of milling the surface of the cylinder head abutment to the block and replacing valves one or two valves with lapping creates a situation: at the mechanical processing area there is no equipment for adjusting the valve with the cylinder head dismantled. And during the assembly of the cylinder head into the engine, the assembly mechanic involuntarily cuts off standard washers for a large 030 -040 thermal gap on the repair valve in order to allow the car, under its own power, without damaging the same valve from a heated engine, to reach the point of adjusting the thermal clearance of the valves using washers.

one revolution is 360 degrees, the valves will return to their original position

No, they won't get up! One revolution of the crankshaft is only half a revolution of the camshaft!

So now I’m setting the gaps, first measured, do 1 revolution of the crankshaft and the shafts return to their original position, what the fuck

Egor, learn the material part or open the 9th grade Physics textbook and read FOUR STROKE internal combustion engines and you are talking about two-stroke engines. In short, like a peasant, when turning the crankshaft by 180 degrees, the mark on the camshaft gear is installed opposite the original one, but the gearbox does not match the gearbox and that’s all. In the initial position when the mark on the camshaft gear matches and in the gearbox hatch, adjust valves 1-3 and 2-5, and when turning 180 degrees, when the mark is opposite the original one but does not match, in the gearbox hatch you adjust 4-7 and 6-8

How to determine if the valve is tightly seated on the seat?

If you have removed the head, be sure to pay attention to the valves; at first glance, it may seem that the valves are good, but there is one sure sign that the valve definitely needs to be changed or ground in. Valves can be of different colors, white, brown, black, etc. This is normal, it all depends on the carburetor settings and engine oil consumption. But if the valve has different shades as shown in the photo below, this is a sure sign that the valve is poorly ground to the seat. This valve must be ground in or replaced with a new one, but it must be ground in.

Photo. Valve showing signs of burnout.

The valve in the photo can still be ground in, but if there is a blue tint, it is better to replace such a valve with a new one.

When to change valve stem seals

Replacing the valve stem seals is necessary if:

- Engine oil consumption has increased, but no leakage is visible. This is the most deceptive sign, since most often the owners think that the problem is somewhere else and fill in the oil, not wanting expensive repairs.

- The engine consumes more than 1 liter per 1000 kilometers traveled.

- Smoke with a blue tint often comes out of the exhaust pipe.

- Motor oil appeared on the spark plug electrodes. This is a sign by which faulty valve stem seals can be accurately identified, since oil does not appear on the electrodes for other reasons.

Candles in oil

If at least one sign of the above is noticed, then replacement is already necessary.

How to make a replacement

Replacing oil seals in a VAZ 2109 engine is a relatively labor-intensive procedure that requires special skills and certain tools. It is advisable to carry it out in a garage or workshop. Allow enough time for work so as not to rush. Replacing oil seals in a VAZ 2109 engine requires care, precision, and attentiveness.

Prepare everything you need

Successful replacement of valve stem seals can be done with your own hands. But this will require more than just a simple set of keys. You will have to take care of preparing special devices. Before starting work, you must equip:

- tin (or soft metal) rod with a diameter of no more than 8 mm;

- desiccant;

- tweezers;

- hammer;

- set of keys, socket heads;

- pliers;

- collet (puller) for removing oil seals;

- flat screwdrivers;

- press-fit frame.

Step by Step Actions

You can change the valve seals by removing the cylinder head (cylinder head). Some experts claim that this is the only and most reliable way. However, in practice, most car enthusiasts ignore this belief and change oil seals without dismantling the cylinder head.

First, preparatory work is carried out:

- disconnect the negative terminal;

- remove the gear from the camshaft by carefully pulling out the key;

- by unscrewing the bolts located around the perimeter, dismantle the cylinder head cover (front);

- remove the back part of the cover (ignition distributor plug);

- remove the camshaft with oil seal.

- turn the crankshaft so that the piston under the cap being replaced reaches top dead center; having unscrewed the spark plug, insert a tin rod into the hole to prevent the valve from falling out;

- using a desiccant, the springs are removed from the valve;

- remove the crackers using tweezers;

- take out the upper spring plate, inner and outer valve springs;

- put the collet on the cap, dismantling it; craftsmen carry out this operation with pliers or screwdrivers;

- before installing a new cap, remove the spring from it;

- the prepared cap is dipped in engine oil and inserted into the mandrel;

- carefully press the cap until it rests on the bottom plate;

- return the spring from the cap to its place;

- the remaining valve seals are changed in the same way;

- replacement ends with the assembly of components and parts in the reverse order of removal;

- the rod is removed from the spark plug hole;

- after installing the crackers, substituting a metal rod, hit the valve ends with a hammer - the crackers are seated in place;

- when installing the camshaft, monitor the direction of the cams of the 1st cylinder - they should “look” in the direction opposite to the valve tappets;

- When reinstalling, all rubbing parts are lubricated with engine oil.

For better clarity, you can watch a video showing the replacement of valve seals in a VAZ engine. The demo video will present all the steps, after going through which you can change these important details yourself.

How to drive a valve guide into a head

First you need to choose a valve bushing before hammering it in, there is a large selection of valve bushings in stores, ask the seller for factory guide bushings, and naturally he will answer yes (he needs to sell it and the sellers know how to hang noodles). And then you get a headache, the bushing is clogged and the valve won’t fit, but for this the mechanic has a special rubber that you don’t have. I’ll explain how to distinguish a high-quality valve bushing from the left (underground) ones. Take the valve with you and when buying valve bushings, try to put it on the valve, the factory bushing will fit easily and will move freely along the valve and the outer wall of the bushing will be polished to a shine, and the place where it is stuffed The valve seal will be matte in color. The left valve sleeve will not fit onto the valve or will fit tightly and its color will be completely dull. The valve sleeve should fit easily onto the valve, since when it is hammered into the head, it is slightly compressed and the valve fits in as it should.

Before hammering the valve sleeve into the head, put a retaining ring on it, remove it from the old sleeve, lubricate the hole in the valve head where you will drive the sleeve, the sleeve is driven from top to bottom until the retaining ring (do not overdo it.).

Zhiguli valve bushings must be driven in carefully, do not hit the place where the valve seal is packed, this place is very fragile, find a tube with an internal diameter of 12 and maximum 13 mm, place it on the bushing so that the place where the seal is packed is inside the tube, and also carefully hammer it into the head with a sledgehammer.

Drive the valve bushings onto the head of the UAZ or GAZ in such a way that on the edge on which you will hit, place a piece of tin or a thin piece of wood, place a bolt or round timber with which you knocked it out, and also hammer it into the head with a sledgehammer. If you suddenly accidentally slightly bend the edge of the bushing hole, you can level it with a drill or a file.