09/30/2021 8,010 VAZ 2115

Author: Ivan Baranov

Russian-made cars today are equipped with a variety of electronic devices that make it possible to ensure the normal operation of many components and assemblies. In this article we will talk about the controllers and regulators that are installed on the VAZ. Where are the sensors located on the VAZ 2115, what is their purpose, what malfunctions can occur in the operation of the devices - read below.

[Hide]

Sensor layout

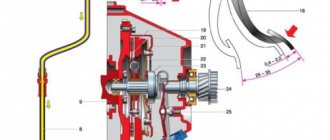

The sensors under the hood of the VAZ 2115 are located as follows.

1. Phase sensor; 2. Coolant temperature sensor; 3. Knock sensor; 4. Oil pressure sensor; 5. Oxygen sensor; 6. Crankshaft position sensor; 7. Speed sensor; 8. Idle speed sensor; 9. Mass air flow sensor; 10-11. Gasoline level sensor; 12. Antifreeze level sensor; 13. Throttle position sensor

Electronic engine control unit

The engine control unit is a kind of head control center for the entire car. This device processes all the readings provided by the vehicle’s sensors, regulates the engine control process, determines the required fuel and air ratios, generates a spark supply to the desired cylinder, and much more. The ECU is located inside the car, under the dashboard.

Mass air flow sensor

Mass air flow sensor is one of the most expensive sensors in a car. It is responsible for counting the air passing through it. These readings are necessary for proper mixing of air and fuel. The flow meter can fail if the air filter is not replaced for a long time, as well as with strong ventilation of crankcase gases due to the high content of oil combustion products in the internal combustion engine. It is located on the air filter housing and is attached to it with two bolts.

Signs of malfunction:

- Uneven idle speed;

- Increased fuel consumption;

- Long start of the internal combustion engine;

What needs to be done before replacing the DPKV

When symptoms of a malfunction appear, you need to check several points due to which the control unit is not receiving proper information.

If nothing was found during a visual inspection, then it is necessary to dismantle the device. How to change the camshaft sensor on a VAZ 2114?

Dismantling any sensor or repairing electrical wiring should always be carried out only with the battery disconnected, otherwise you can complete the repair not only by replacing the burnt circuit, but also by purchasing a new vehicle.

Dismantling on an 8-valve engine is not difficult. Where is the phase sensor located on the VAZ 2114? It is located on the right, on the top of the engine, near the air filter. It is secured with one 10mm wrench bolt. With a few simple movements, the bolt is unscrewed and the sensor is removed. After the unit has been removed, it is necessary to close its structural socket from accidental entry of foreign objects.

Location of the phase sensor on the VAZ 2114

Once the camshaft sensor is in your hands, it is important to visually inspect it. There may be cases of metal dust sticking or magnetizing. Use a cotton rag to wipe it dry and put it in place. If the error occurs again, it must be replaced.

There are rare cases when the phase sensor on a VAZ 2114 is replaced, but the symptoms and errors are not eliminated. An error in the phase sensor may occur due to a shift in the pressed control gear. This defect is extremely rare, but it does occur. Can only be corrected in a specialized workshop. Also, a more common problem with an error on the phase sensor is excessive stretching of the timing belt or incorrect installation.

For engines with a system of two camshafts and 16 valves, removing the sensor is a little more complicated. It is installed under the air manifold on the front side, next to the first camshaft pulley. To dismantle it, you must:

When replacing the camshaft sensor, under no circumstances should sealing agents such as sealant or sealing materials be used. The sensors themselves are located in an aggressive environment and at constantly changing temperatures. Therefore, excess fluid can damage the entire engine or its oil system.

Phase sensor

It is responsible for adjusting fuel injection only into the cylinder that is in the compression stroke, that is, fuel is supplied only through one injector to one cylinder. It is oriented along the camshaft, which is why it is called the camshaft position sensor. It works according to the Hall principle, producing an electrical impulse when a magnetic field is excited. If the VAZ 2115 phase sensor fails, fuel is supplied according to the principle of carburetor engines - into two cylinders at once. The result is a set of faults.

Symptoms of malfunction

The DPRV is located in the same place as the camshaft gear, on the cylinder head. The main symptom of the malfunction is high fuel consumption and loss of power. In addition, the computer displays error 0340 (sensor error) or 0343 (pulse level too high).

Examination

The malfunction of the DPRV can be judged by the error code and the burning CE lamp, but you can verify its functionality by checking the voltage at the power terminal A (12 V). The remaining terminals must not be live.

Sensors, their purposes and malfunctions

Let's now talk in more detail about each of the sensors, let's look at where they are and what they look like.

Idle speed (IAC)

The device is located in the throttle assembly. It is a small induction coil with a needle inside. Depending on the controller readings, one or another voltage is applied to the coil winding and the needle extends a certain distance into the throttle pipe, regulating the air supply. With this, the idle speed is adjusted.

Idle speed control

There is no indicator responsible for this sensor. Therefore, if this node fails, then this can be understood by the following “symptoms”:

To replace the sensor, you must turn off the power to the machine's wiring, completely disconnect the throttle assembly, and then remove the sensor from it, after first disconnecting the terminals that supply electricity to it. In place of the old sensor, you need to install a new device and place the throttle assembly in place.

Detonation (DD)

The knock sensor is located between the cylinders on a car engine and reacts when the fuel detonates inside the cylinder. In essence, it is a piezoelectric element. When gasoline detonates, the sensor converts the resulting vibrations into electricity. Current is supplied to the on-board computer and signals a fuel explosion. After this, the ignition timing is automatically adjusted.

If this type of sensor breaks down, the fuel begins to detonate in the engine. To check the device for functionality, you need to disconnect it using a key from its mounting location, connect it to a voltmeter and knock on it. If voltage was applied to the voltmeter, then the unit is working; if not, it is faulty.

To replace a device, you need to unscrew it from the seat using a key, disconnect the terminals from it and install a new device.

Oxygen (Lambda probe)

The oxygen sensor, also known as a lambda probe, is installed on the exhaust pipe close to the cylinders. It measures the amount of oxygen contained in exhaust gases and the environment. It only works when the engine is on, as it must be heated to function. When oxygen molecules hit the sensor, electricity is generated, which is supplied to the control unit. The on-board computer, based on sensor readings, regulates the supply of oxygen to the engine cylinders.

If the sensor fails, the following consequences occur:

- Unstable gasoline consumption: sometimes more, sometimes less;

- “Walking” speed at idle;

- A sharp drop in power when accelerating.

Crankshaft Positions

The VAZ crankshaft sensor is an element that allows you to transmit signals to the on-board computer about the position of the crankshaft. The performance of the combustible mixture supply systems, as well as the ignition system, depends on how this element works. And if we are talking about an injector, then the DPKV determines the functionality of the injectors.

This element is often called a synchronization regulator, since the control unit, having received data from it, detects the required moment of gasoline injection into the engine cylinders. If the device breaks down, the on-board computer will begin to transmit incorrect data, which will subsequently lead to malfunctions of the gasoline supply system. Accordingly, normal operation of the injectors will be impossible. The regulator itself is located next to the camshaft and the generator belt.

Throttle Positions

The throttle position sensor (abbreviated as TPS) is one of the main components that ensures the normal operation of the fuel system. From the name you can guess that the VAZ throttle controller transmits data to the on-board computer about what angle the throttle is currently at. The symptoms of the breakdown and the process of replacing the device are described in more detail in the video (author - Ivan Vasilyevich).

Pulse frequency is one of the key characteristics of the throttle sensor. Taking into account changes in this parameter, the engine ECU detects the required degree of pressure on the accelerator. Ultimately, the on-board computer selects the most optimal cooling mode for the power unit, as well as the volume of gasoline supplied. Since the controller itself is part of the throttle, it is located on the body of this unit, not far from the idle air control.

DPKV

This sensor tells the ECU the current position of the crankshaft. It is inductive, that is, when the above node rotates, it produces certain impulses, the frequency of which allows the computer to make the necessary calculation. If the signal is lost, the power unit stops. That is, its malfunction will not even allow you to get to a car service center. Otherwise, it breaks very rarely.

In this situation, the ECU will show an error code - 0335. However, this does not always mean that it is the DPKV that has become unusable. Sometimes the same combination appears if the mass air flow sensor is not working properly.

Sensors for VAZ 2114 injector 8 valves: location and functions

For the efficient operation of the injection power unit, the VAZ-2114 car system includes a large number of different mechanisms and automated devices.

You can’t say that the “fourteenth” car is filled to capacity with electronics, but if you look under the hood, you can find all kinds of VAZ-2114 8-valve injector sensors. The main purpose of electronics is to monitor the condition of vehicle components and assemblies. The received data is transmitted to the main “brain” center of the car. Thanks to this approach, the driver no longer needs to spend a long and exhausting time looking for reasons for deviations from the operation of a particular system. The ECU will provide all the information. What sensors are involved in the operation of the VAZ-2114 and where are they located?

Fuel level sensor

Indicates the remaining amount of fuel in the tank. Installed directly in the tank on the fuel pump glass. It fails when the graphite contacts on the electrical board are rubbed. When replacing, you should pay attention to its type number, which is indicated on the board, since all types of FLS have different resistance. If an unsuitable sensor is installed, large errors in readings may occur.

Signs of malfunction:

- Incorrect readings about the presence of fuel in the tank;

Idle air control (IAC)

The IAC is installed on the throttle body of the car and serves to adjust the idle speed by opening and closing the air channels. This sensor is involved in the operation of the internal combustion engine only at idle. It is unreliable and often malfunctions. Subsequently, with the transition to the E-GAZ system, the idle air control was removed.

Signs of IAC malfunction:

- The internal combustion engine stalls at idle;

- High speed at idle;

- High fuel consumption;

Knock sensor

Responsible for capturing noise from the engine and transmitting readings to the ECU. The principle of operation of a piezo element is reminiscent. When detonation occurs in the internal combustion engine, it generates a small voltage and transmits readings to the head engine control unit, thereby adjusting the fuel mixture. Installed on the cylinder block between the two middle cylinders.

Signs of malfunction:

- Clattering of fingers under load;

- Increased consumption;

What engine sensors are on the car?

The first injection 14s appeared in 2000-2001. After their appearance, and indeed injection machines in general, everyone actively began converting to a carburetor system, they say, “the carburetor is more reliable,” and the number of specialists in injectors could be counted on one hand.

Now this situation is observed with the conversion of the electronic gas pedal into a cable pedal.

But it is worth noting that some specialists have already learned how to configure and flash e-gas, roll out a turbo engine, compressor, not to mention the evil shafts.

As for the sensors, they all serve to structure the operation of the engine.

Coolant temperature sensor

It is installed in the thermostat housing and is responsible for automatically turning the cooling fan on and off. The sensor is also responsible for adjusting the fuel mixture during a cold start; this can be noticed when starting the car in cold weather, with increased idle speed.

Signs of malfunction:

- The fan does not work;

- There are no warm-up speeds;

What happens if the mass air flow sensor is faulty

The ECU controller will stop receiving or receive distorted air mass data, resulting in the fuel-air mixture being formed incorrectly. The result is a loss of power and torque (in VAZ cars these parameters are not too high anyway), as well as an increase in fuel consumption.

Signs of a malfunction of the mass air flow sensor - absence or incorrect value of the information signal from contact No. 5 of the sensor connector. If the sensors break down, an overestimation of indicators is first observed (up to 25%), then a complete cessation of information output. This leads to the following symptoms:

- on a cold internal combustion engine, the speed is increased by at least a third;

- with a sharp release of gas, the speed first remains at the same level, then slowly decreases;

- fuel consumption increases significantly;

- the car may stall immediately after starting;

- lacks acceleration dynamics and traction under load.

Oil pressure sensor

Oil pressure is an important indicator in engine operation; if it is absent, the internal combustion engine will not be lubricated, which will lead to engine failure. This sensor informs the driver about the presence or absence of pressure in the internal combustion engine lubrication system. The sensor is installed on the cylinder head housing and is mechanical.

Signs of malfunction:

- No oil pressure;

- The oil pressure indicator does not light up;

Crankshaft sensor VAZ 2115

DKPV is a device that supplies the electronic unit with information about the position of the crankshaft. The correct functioning of the injection engine injectors, the ignition system and the fuel mixture supply system depends on the operation of this unit.

This device is often called a synchronization sensor, since based on the data received from the DCPV, the electronic unit determines the moment of fuel injection into the cylinders of the power unit. If this sensor breaks down, incorrect information will be supplied to the “brains” of the car and the power unit will lose its functionality, since malfunctions will occur in the fuel supply system, and the injectors will not be able to function correctly. The DCPV is located near the camshaft, not far from the alternator belt.