What kind of device is this?

Such an element is present in any modern car, since the era of carburetor engines has passed and an electronic control unit (ECU), or controller in other words, is responsible for many operations. Many drivers even call him “the brain.”

The mass air flow sensor is used to measure the amount of air supplied to the engine. However, this device does not measure its volume, but only determines how much mass passes per unit of time, sending data to the ECU. In turn, the controller “understands” how much air has entered the cylinders at each moment of time, and depending on this, adjusts the fuel supply. As a result, the engine runs smoothly and without interruption.

Beginners may be interested not only in whether the mass air flow sensor can be cleaned, but, in fact, where it is located. Typically, this device is located in the area between the air filter housing and the pipe that goes to the throttle valve. It is equipped not only with gasoline, but also with diesel power units.

Sensor diagnostics

There are several ways to test the performance of a flow meter; let’s consider the easiest and fastest one. To carry out diagnostics, you will need to disconnect the power connector from the mass air flow sensor, but the engine must be running. When the contact is disconnected, the control unit will begin to operate in emergency mode. Accordingly, as a result of this, the fuel dosage will be carried out according to the parameters that were received from the throttle.

It must be taken into account that in this case the speed of the power unit can increase sharply to 1500 per minute. However, this does not happen in all cars. With the flow meter turned off, you need to drive the car a little. If you notice that the performance of the power supply has improved, then most likely you need to change the mass air flow sensor (video author - Xie Dan).

When is it time to clean?

But regardless of the type of sensor, over time it begins to function incorrectly due to contamination - the platinum measuring elements become covered with dust. Therefore, the question of how to clean the mass air flow sensor will always be relevant.

Why does this happen? The main reason for sensor contamination lies on the surface - the unsatisfactory condition of the air filter. If the filter element is of poor build quality, then it is not able to trap microscopic particles of dirt and dust that settle on the sensing element of the mass flow sensor.

As a result, the device is not able to accurately measure the amount of air and sends incorrect data to the ECU. It's not hard to imagine what this might lead to. Here we gradually approach some characteristic signs that may indicate that the sensor is clogged and needs to be cleaned:

- The need to clean the mass air flow sensor on a VAZ or other cars arises when the engine idles intermittently, in some cases they are too high - up to 1500.

- The car may jerk and have difficulty accelerating.

- Sometimes the engine does not start at all.

- Increased fuel consumption - sometimes up to 15 liters per 10 km.

- Check Engine light on the dashboard.

However, the above signs do not always accurately indicate contamination of the air flow sensor. A variety of situations can arise, and among them is one when the sensor itself is fine, but the fault lies in the hose that connects the device to the module.

In other words, although there are many obvious signs that a particular part of the car is faulty, they can indicate any other problem.

MAF sensor on a diesel engine, signs of malfunction

DMVR began to be installed on diesel engines recently. This is due to the improvement of the latter and the introduction of more complex but effective monitoring systems into their work.

The air meter performs several important functions:

- Limits smoke on turbocharged engines.

- It monitors not only the amount of air in the intake pipe, but also the volume of crankcase gases.

In the first case, when the gas pedal is sharply depressed, a certain volume of diesel fuel is formed, for which a corresponding volume of air must be formed.

But since the turbine spins up late (a turbo lag forms), the required amount of air does not have time to form. The mixture is over-enriched, fuel is not completely burned, soot is released into the exhaust system, and short-term smoke is observed from the exhaust pipe. The DPF filter partially solves the problem, but if it exists.

To solve this problem and limit excess fuel during sharp acceleration, the mass air flow sensor is activated. It transmits information to the controller about the actual amount of air pumped by the turbine.

The electronic control unit, having received this data, limits the cyclic supply of fuel, adjusting its amount to the volume of air.

This solution made it possible to reduce diesel fuel consumption while maintaining the power characteristics of the engine, but provided that the MAF sensor works correctly.

Secondly, the mass air flow sensor on a diesel engine works in conjunction with the crankcase ventilation system. It monitors how much exhaust gas enters the intake system through the EGR valve when it opens and transmits this data to the ECU. The latter, based on the information received, controls the opening and closing of the EGR valve.

This solution reduces both fuel consumption and the amount of harmful emissions into the atmosphere.

Based on this, the main signs of a breakdown of the flow meter on a diesel engine may be:

- Brief appearance of smoke (soot) from the exhaust pipe during acceleration.

- Unstable operation of the motor in transient modes, reduction in power.

- Increased consumption of diesel fuel.

Diagnostics of mass air flow sensor on a diesel engine is no different from the methods described above.

Sensor check

To accurately verify that the sensor is faulty and understand whether the mass air flow sensor on the VAZ-2114 needs to be cleaned or not, whether it needs cleaning or whether you will have to go to the store for a new mass air flow sensor, you will need a multimeter known to all radio amateurs:

- The device is switched to voltage measurement mode (voltmeter).

- Set the limit to 2 V.

- There are two wires in the sensor connector - yellow (it goes to the ECU) and green (connects to ground).

- The voltage is measured between these wires, and only the ignition should be turned on.

- Now all that remains is to look at the instrument readings.

If the measurement result is 0.99-0.02, the sensor is working. If the upper threshold is exceeded to 0.03, the mass air flow sensor needs cleaning and the sooner the better. In the case when the measurements are less than the lower limit (0.95) or the upper limit is very high (0.05), then the chances of a successful outcome are 50/50. That is, either cleaning will help and the sensor will function properly again, or you need to buy a new device.

In addition to this, you can understand whether to clean the mass air flow sensor on a VAZ-2110 or not by using one more method when you don’t have a multimeter at hand. Disconnect the sensor, then start the engine, raise the speed to 2000 and drive for a while. If at this moment there are obvious changes, the car has become more dynamic, then the sensor is definitely dirty.

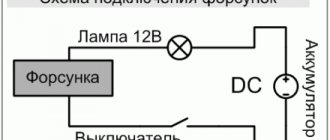

Lada 2110 ツɐʞdiҺツ (FORMER) › Logbook › Checking the air flow sensor with your own hands VAZ.

How to wash injectors without removing them from the engine? two methods for cleaning the injector yourself

Mass air flow sensor

(MAF) is located near the air filter to determine the amount of air flow passing through the air filter.

Malfunctions of the mass air flow sensor negatively affect engine performance. checking the mass air flow sensor

first .

Other symptoms of a faulty mass air flow sensor:

1)Check Engine error appears;2)Increased fuel consumption;3)Poor starting when hot;4)The car began to accelerate slowly;5)Engine power lost.6)Etc.

How to check the mass air flow sensor Method No. 1: Disable the mass air flow sensor.

Disconnect the sensor connector and start the engine. If you turn off the MVR, the controller switches to emergency mode and prepares the fuel mixture only according to the throttle position. The engine speed should be more than 1500 rpm. Let's try for a ride. If the car feels “faster”, then we can say that the mass air flow sensor is not working. By the way, for ECU Y7.2, M7.9.7. The speed does not increase when the chip is turned off!

Method No. 2: Alternative ECU firmware.

If the standard firmware of the controller was replaced with another, then it is unknown what is built into it in case of emergency mode in method No. 1. Try sliding a 1mm thick plate under the damper stop. The revs will rise. Pull out the chip from the mass air flow sensor. If it doesn’t stall, it means the problem is with the firmware, or rather with the IAC steps in emergency mode without a mass air flow sensor.

Method No. 3: Checking the mass air flow sensor with a multimeter.

This method works on Bosch sensors with catalog numbers: 0 280 218 004, 0 280 218 037, 0 280 218 116. Turn on the tester in the DC voltage measurement mode, set the measurement limit to 2 Volts.

MAF pinout: 1) Yellow (closest to the windshield) - MAF signal input; 2) Gray-white - sensor supply voltage output; 3) Green - sensor grounding output; 4) Pink-black - to the main relay. Wire colors may change, but the pin locations remain the same. Wire colors may change, but the pin locations remain the same.

We turn on the ignition, but do not start the engine. We connect the multimeter with the red probe to the yellow mass flow sensor, and the black one to the green one (to ground). Thus, we measure the voltage between the specified terminals. The tester probes allow you to penetrate through the rubber seals of the connector, along the specified wires, without disturbing their insulation.

The use of needles and other additional connections is not recommended, because they introduce some error in measurements

. We take readings from the multimeter. The voltage at the output of the new sensor is 0.996…1.01 Volts. During operation, it gradually changes and, as a rule, increases. The greater the value of this voltage, the greater the wear of the mass air flow sensor.

Mass air flow sensor voltage: 1.01...1.02 - good condition of the sensor. 1.02...1.03 - not a bad condition. 1.03...1.04 - mass air flow sensor resource is coming to an end. 1.04...1.05 - dying state, if there are no negative symptoms, then we operate further. 1.05... and higher - It's time to replace the MAF.

By the way, the same readings can be obtained without a tester, using the on-board computer (group of parameters “voltage from sensors”, Udmrv)

Cleaning products

Since the sensing element of the air flow sensor is made of platinum, therefore, it is necessary to choose the right means to clean it. And first of all, it’s worth understanding what you absolutely cannot use:

- Any liquid that contains acetone, ketone, ether.

- Products used to clean carburetors.

- Cotton wool wound around a match, toothpick, etc.

- Compressed air.

What then remains to be used? Well, there are plenty of options here too.

Cleaning DMRV VAZ 2114

Since purchasing a new mass air flow sensor is far from a cheap pleasure, you should first try to restore it by cleaning it. If it doesn't help, you'll just have to buy a new device. True, before you start repairing the VAZ 2114 DMRV with your own hands, you should firmly understand that the sensor is a very sensitive and fragile device. That is why when cleaning it (and any other manipulations with it), maximum care should be taken.

For the same reason, it is PROHIBITED to use the following substances and compositions to clean it:

- containing acetone;

- synthetic solvents;

- petrol;

- liquids intended for flushing carburetors based on ketones/acetone;

- esters, as well as compositions based on them.

Cleaning the air flow sensor

In addition, it is strictly forbidden to clean the air flow sensor using mechanical means - cotton swabs, rags, or blowing with compressed air. Any of these methods will lead to immediate failure of the device without the possibility of further repair.

The best option for cleaning the air sensor is to briefly apply WD-40 to it, followed by rinsing with a solution of ethyl alcohol.

Liqui Moly

How to clean the MAF sensor? One option is cleaning fluid from Liqui Moly. The company is known to many car enthusiasts as a manufacturer that makes only high-quality products for cars. In addition, the ratio between reliability and price is at an optimal level. As for the use of liquid for cleaning the mass air flow sensor, most vehicle owners have already become convinced of its effectiveness. This has not been proven by a single procedure. And if the sensor is in working condition, then even after cleaning it will last no less.

The liquid can be used for both diesel and gasoline engines.

How to use?

Cleaning the air flow sensor must be performed whenever the air filters are changed. The sensor itself is located in the air channel between the filter box and the throttle body. Using a special tool, the device is carefully disconnected from the electrical connectors.

Some brands of cars are equipped with mechanical flow meters. They do not have measuring wires, and therefore are less sensitive to the thoroughness of dismantling.

Next, 10 to 15 sprays are applied onto the wire or sensor plate. The composition is applied to all sides of the sensor, including terminals and connectors. Platinum wires are very thin, so they cannot be wiped. After the composition has completely dried, the device can be returned to its original place. A good spray should not leave marks or streaks on the surface of the air flow sensor.

Alcohol

We can say that this is an old-fashioned method, which at the same time will never lose its relevance. Alcohol can effectively break down dirt and blockages. About 20 years ago, the question of how to clean the mass air flow sensor was mainly solved with the help of alcohol, and this method was held in high esteem by many drivers, but now they are trying to resort to it less and less.

Nevertheless, it is relevant in cases where the car owner needs to invoice for washing with special means. Unfortunately, such disappointing practice is not uncommon at many service stations.

Cleaning

Quite often you can avoid replacing the mass air flow sensor by simply cleaning this engine element.

You should do the cleaning yourself in this way:

- Remove the pipe from the mass air flow sensor;

- Now remove the sensor from the pipe. Otherwise, high-quality washing will not work;

- To remove the sensor, arm yourself with sprocket keys in advance. Finding such kits is not a problem;

- Unscrew all the fasteners, remove the sensor from the pipe and assess its external condition;

- Often there are traces of oil deposits on the sensor. The purpose of cleaning is to make the device as good as new;

- Carburetor cleaner is often used to clean the air flow sensor;

- Inside the film there are sensors, which are small wires attached to a special resin. These elements must be carefully sprayed with cleaner so as not to damage the devices;

- Wait a while for the surfaces to dry. To speed up the process, use a can of compressed air;

- It is not uncommon to use alcohol instead of carburetor cleaner, which also works quite effectively;

- Proper cleaning of the mass air flow sensor involves treating the pipes from accumulated debris, dirt and dust;

- Having carefully processed all the components of the removed mass air flow sensor, wait until it dries, and then reassemble it. Cleaning is complete.

Spray cleaning

Statistics show that in about 80% of cases, simple cleaning can return the mass air flow sensor to its previous functionality.

Price issue

80% is not 100. Therefore, sometimes you have to change the sensor. And to replace it, you need to buy it.

There are three price categories for air mass flow sensors:

- Cheap. These are predominantly Chinese products, the price of which is up to 1000 rubles. It is strongly not recommended to purchase such regulators;

- Average. These include sensors from AvtoVAZ, domestic and some foreign analogues. These cost from 1500 to 2500 rubles;

- Expensive. High-quality, reliable, imported air flow sensors, the price of which can reach 5.5 thousand rubles. It’s hard to say how rational it is to buy them. But they will definitely last a long time.

When choosing a new mass air flow sensor, focus not only on the price, but also on the manufacturer. Today, the most popular devices are from Siemens and Bosch. Average in price, excellent in quality.

WD-40

Absolutely every car enthusiast is familiar with this product, regardless of experience. In addition, all other people who are not directly related to cars know about it. Over the course of its existence, WD-40 has proven itself to be excellent, and there is no doubt about its effectiveness.

For this reason, it is used not only to remove “deposits” from bolts, but also to clean the mass air flow sensor.

Cleaning products

You can clean the regulator with different preparations and liquids:

- Liqui Moly . This is a company that produces cleaning products, oils and various types of liquids. According to the manufacturer, the products are of high quality, but cleaning the air flow sensor with its help will be expensive. The product is suitable for gasoline and diesel engines;

- Alcohol . An old but effective method of cleaning the mass air flow sensor. The chemical properties of alcohol allow it to combat contaminants on sensitive sensor components. The method works, but it is used less often than others;

- Liquid for carburetor engine . Effectively copes with any contamination;

- "Liquid Key" . This cleaner cleans not only the mass air flow sensor, but also other transport components;

- WD-40 . A universal product that cleans, removes rust, neutralizes squeaks, and so on.

In Moscow and other large cities, finding a suitable liquid is not difficult.

How to properly clean the air flow sensor

Let's consider the procedure for cleaning the mass air flow sensor using the example of a car of the 10th family - VAZ-2110:

- Turn off the ignition.

- Disconnect the connector from the mass air flow sensor.

- Remove the sensor itself by unscrewing the bolts that secure it to the air filter housing. Depending on the car model, disabling the mass air flow sensor may vary.

- The sensor is removed from its place, otherwise its cleaning will not be effective.

- On the device itself there is an area with two bolts - these should also be unscrewed.

- The selected cleaning agent is drawn into a syringe and then sprayed onto the sensitive element. At the same time, if necessary, you can wash the block with contacts.

- Give time for everything to dry.

- Assemble the sensor and install it in place.

To make drying faster, you can use a compressor only at minimum pressure. If the sensitive element is heavily soiled, the procedure should be repeated several times.

But even in this case, washing does not always give the desired result, and you just have to go to the nearest store for a new mass air flow sensor.

Cleaning instructions

As practice shows, cleaning the mass air flow sensor is one of the most effective methods of restoring the functionality of the controller. Therefore, if the sensor breaks down, it is not necessary to change it, especially since such a pleasure today is not cheap. This procedure is necessary because over time it becomes dirty and shows other parameters.

So, how to clean the mass air flow sensor at home with your own hands:

- You will need a Phillips head screwdriver; use it to loosen the clamp securing the line from the air intake.

- Next, dismantle the corrugation and visually assess the condition of the system. You may see condensation or traces of engine fluid under the corrugation.

- Carefully inspect the inside of the controller. If everything is normal with the system, then there will be no traces of leaks or contamination. As practice shows, the sensitive element often breaks precisely due to an excess of contamination. In order not to avoid problems of this kind in the future, it is necessary to periodically replace the air filter. This procedure is carried out in accordance with technical regulations. Engine fluid may enter the controller as a result of an increased level of consumables in the crankcase. Accordingly, this occurs as a result of a clogged oil separator in the ventilation system.

- The regulator itself is fixed with two bolts on the line. The removal procedure is carried out using an open-end wrench. At this stage, if you are sure that the device has failed, you can replace it.

- You can see the entrance on which there will be a sealing rubber band designed to protect the device from the suction of dirty air flow. If you do not have a seal, it may have caught on the filter element. Accordingly, this will lead to the regulator input grid being contaminated.

- Clean the mesh using available materials. To do this, you can use a regular toothpick or toothbrush. After cleaning, the seal can be put back and the regulator can be put back in place.

Additional manipulations

It is now clear how to clean the mass air flow sensor, but this procedure alone does not end everything; it is necessary to perform a number of additional and necessary manipulations. And you need to do this before installing a clean device. And while the cleaning agent is drying, it’s time to work on the air pipe. It is worth carefully inspecting it for integrity. And if the condition is unsatisfactory - there are cracks and other damage, then it should be replaced.

As experts note, before installing the mass air flow sensor, it is advisable to replace the filter element. You should also check the condition of the rubber seal. Here it is important to pay attention to how tightly it fits, otherwise it will not be possible to avoid the suction of outside air, which is flooded with various contaminants. As a result, cleaning will be required again, and in a fairly short time. Or it will lead to its failure altogether.

When should you clean the sensor?

The condition and degree of wear of the air filter on which the first one is installed is of great importance for the long and proper operation of the sensor. So, if the filter is in good working order and does a good job of filtering dust particles and small abrasive particles in the air, then the sensor will last a long time. If the filter wears out, the sensor quickly becomes dirty and stops working correctly.

You can find out that the VAZ 2114 DMRV needs to be cleaned by one of the following signs:

- the car is poorly controlled when accelerating, there are sharp drops in speed, acceleration and jerking;

- engine speed at idle is extremely high or, on the contrary, intermittent;

- fuel consumption has increased sharply (in the case of the 14th model it can increase even by 50%);

- the engine stopped starting.

Clogged air flow regulator

Cleaning the air flow sensor using mechanical force or a jet of compressed air is strictly prohibited - such a procedure will instantly lead to its breakdown.

In most of these cases, it is not necessary to immediately run for a new sensor - simply cleaning it will help.

Symptoms and troubleshooting

Since the mass air flow sensor is electronic equipment, and a very complicated one at that, most car owners do not dare diagnose it themselves and take it to a car service center the old fashioned way. But quite often, having just connected the diagnostic device to the sensor, the auto repairman declares that the device is completely faulty, it cannot be repaired, and its place is only in a landfill. Rest assured, if you bring in a completely new sensor, the technician will tell you the same thing.

But any disinterested expert will say that the mass air flow sensor is an almost indestructible device. It may malfunction, sometimes seriously, but this is a completely fixable problem, something that will take no more than an hour. But how to check the mass air flow sensor for performance? Very simple. If, after installing a new sensor on your car, you notice that it works perfectly, then that is where the problem lies. If the situation has not improved at all, then there is no point in wasting your energy, time and money on the empty hassle of replacing a completely “healthy” sensor.

Just above we mentioned such a device as a multimeter. You can understand whether the sensor is working or not by finding out the voltage of the device. If everything is normal, then the multimeter produces 1-1.2 W. If there are any problems, then the scale goes down, the critical mark starts at 0.99 W. If, on the contrary, the voltage is higher than normal, for example 1.037, then this indicates one thing: the sensor is very clogged, and therefore makes errors in the readings. If you clean it, it will work again at the same rate.

If there is neither a new sensor nor a multimeter, then you can check the condition of the part in the old-fashioned way. At engine idle speed (870-910 rpm), the sensor in good condition produces 9.6-10 kg of air per hour. If the revolutions reach two thousand per minute, then this figure increases to 20 kg/h. We looked at ideal indicators. When they become higher or lower, the need for repair is obvious. What are the well-known symptoms of a sensor failure?

First of all, this is a sharp increase in fuel consumption. Here you should not blame the car for its large “appetites”: it is not to blame, and the manufacturer is not to blame, here you just need to “treat” your “iron horse”. Of course, this can happen not only in the case of a sensor failure, but from this fact alone you can come to the right idea: most likely the problem lies in the tiny device.

Also, when the engine loses power, a hot engine will stop starting. The car, previously dynamic and controllable, turns into some kind of monster on wheels, which is constantly lost in control and “freezes”. And finally, if you see a simple Check Engine sign on the instrument panel, then there can be no doubt: this sensor is asking you for an ambulance.

Testing and diagnostic methods

Shutdown

Pulling out the sensor is fairly easy. It is located in the air filter.

This method involves starting the motor with the sensor removed - we need to disconnect its connector. When turned off, the controller starts emergency mode, and new portions of the mixture are calculated based on the position of the damper. We need to drive a little, the speed should be above 1500 rpm. If the car behaves more dynamically without a mass air flow sensor, then the diagnosis is complete - it’s time to change the consumable.

Checking with a multimeter

This test requires that you have skills in using a multimeter (tester). The method is suitable for almost all VAZ models, including 2110. We need to take a multimeter and set it to a mode that measures constant voltage, which is usually designated DCV or only V. To work with the mass air flow sensor, you need to understand its pinout, it is as follows:

- Yellow, closest to the windshield, supplies current to the signal input;

- Green indicates ground;

- The pink or red-black wire comes from the main relay;

- The white-gray wire is responsible for the voltage output.