Every modern car owner knows about the existence of an on-board computer, which can not only indicate the basic parameters of the operating mode (speed, consumption, temperature), but also recognize errors caused by various malfunctions. Unfortunately, Chevrolet Niva error codes cannot be deciphered without additional tables, since there are too many of them. Let's consider various diagnostic methods.

We receive the first signal about the presence of a malfunction using the indicator on the “Check-Engene” panel.

After turning on the ignition, all systems are tested, and if no errors are detected, this indicator goes out. Otherwise it remains burning. Specialized centers will quickly identify the error and not for free, but the Chevrolet Niva has a built-in on-board computer that can allow you to deal with the problem yourself.

Self-diagnosis

Without going into details of the operation of all electronics, we note that the functioning of all vehicle systems is “monitored” by an electronic control unit (ECU).

It receives information from numerous sensors. Like any computer, the ECU requires software called firmware. This firmware is capable of analyzing indicators received from sensors, comparing them with normal parameters, identifying errors and storing these errors in memory.

Carrying out self-diagnosis

In the Chevrolet Niva, as in some other cars of the VAZ family, some parameters can be displayed on the VDO dashboard. It is often called an integrated on-board computer.

Testing is started by first pressing the daily mileage reset button and simultaneously turning the ignition key.

All instrument needles begin to move, which indicates the beginning of the testing process. Pressing the same button once will cause the firmware version to appear on the display, and pressing it again will give us a reading called an error code.

Panel codes should not be confused with ECU codes, which are diagnosed by external devices.

| Error code | Decoding |

| 1 | Processor faults |

| 2 | No signal from the fuel level sensor |

| 4 | Increased voltage of the on-board network (exceeds 16 V) |

| 8 | Reduced voltage on-board network |

| 12 | Control indicator malfunction |

| 13 | No signal LAMDA probe |

| 14 | Increased coolant temperature |

| 5 | Reduced coolant temperature |

| 19 | Error from HF sensor |

| 21-22 | Error with TPS |

| 24 | Error from speed sensor |

| 27 — 28 | Incorrect CO potentiometer parameters |

| 23 — 25 | Error from intake air temperature sensor |

| 33 — 34 | Error from the MAF sensor |

| 35 | Error from sensor XX |

| 41 | Error from phase sensor |

| 42 | Ignition system malfunction |

| 43 | Error from knock sensor |

| 44 — 45 | Rich/lean fuel mixture |

| 49 | Loss of vacuum |

| 51 — 52 | ROM/RAM errors |

| 53 | No signal from CO potentiometer |

| 54 | No signal from the octane corrector |

| 55 | Load on the power unit |

The operation of the on-board computer cannot be called flawless, since many errors arise as a result of software failure. You have to reset the errors by holding down the daily mileage reset button in testing mode. This diagnostic method is not entirely convenient for the reason that the error code can be the result of the sum of two codes at the same time (10=8+2).

Decoding codes

Now we suggest that you familiarize yourself with the decoding of the combinations. Why errors may occur and how to eliminate them can only be found out as a result of diagnostics.

The elm327 channel published a video showing the diagnostic procedure for a Chevrolet Niva using a special adapter and an Android-based mobile phone.

Common mistakes

First, let's look at deciphering frequently occurring problems that occur in the Chevrolet Aveo in the back of the T250, T300, Niva and other models.

| Error | Decoding |

| p1396 | Code p1396 is an error in the operation of the ABS system. If this code appears in an Orlando, Niva, Lacetti or other Chevrolet model, the car owner needs to test the performance of the unit itself, as well as the rough road controller. Often the cause of 1396 is a failed sensor, damage, oxidation or contamination of its contacts. You can try to solve the problem by dismantling and cleaning the connector |

| p0661 | The car owner is informed about problems with the solenoid or damage to the electrical circuit. A detailed check needs to be done |

| p0404 | The on-board computer received a message about violations in the functioning of the exhaust gas recirculation system. Often the reason is related to a breakdown of the controller, so it is necessary to diagnose and replace the sensor |

| p1628 | Error code 1628 indicates a problem with the locking device. It is necessary to test the operation of the immobilizer. If you do not pay attention to diagnosing and checking this error, then over time the immobilizer may block the engine and, as a result, it will be impossible to start it. You can try to disable and activate the immobilizer or reprogram its chip |

| p1661 | The Check Engine light does not work. You need to check the functionality of the indicator light in the dashboard. Often the problem can be solved if the light bulb is working by resetting the error |

| p1602 | Error 1602 literally means a loss of voltage in the on-board network. The reasons may be different. If the car starts and the engine runs normally, the malfunction may be damage or poor contact of one of the plugs of the control unit, or poor soldering of its components. Perhaps this is a firmware glitch or some relay is not working. A qualified electrician can find the cause. |

| 136 | The meaning of this code may vary for different Chevrolet models. In Orlando cars, this error means a malfunction of the second lambda probe or damage to the wiring. In Cruze models, the code indicates the need to diagnose the parking radar. Perhaps the parking sensors are simply clogged |

Engine

Let's consider the malfunctions encountered in the operation of power units.

| Error | Decoding |

| p0013 | There is a break in the circuit between the crankshaft and camshaft devices. Shaft adjustment required |

| p0171, p0172 | The control unit received a signal about the incorrect functioning of the fuel supply control system. The volume of the air-fuel mixture in the power unit is reduced or increased. We need to identify the cause |

| p0201, p0262 | Malfunctions related to the operation of the injector of cylinder 1 |

| p0202, p0265 | Problems related to the functioning of the injector of cylinder 2 |

| p0203, p0268 | Cylinder 4 injector needs diagnostics |

| p0204, p0271 | Cylinder 4 injector check required |

Diagnostics with a scanner

The information in this section is quite extensive, since there are many types of scanners.

The basic principle of their operation is that all data, including errors, is transmitted from the ECU to a special diagnostic connector, which in a Chevrolet Niva is located on the driver's side under the steering wheel.

The scanner's job is to read and decode these messages.

Note that there are dealer scanners, that is, those that are designed for a given car. For Chevrolet Niva this is BC State.

It is inserted into the panel instead of the signaling device, and the information loop is prepared from the factory.

Universal scanners should be connected to the diagnostic connector. The most popular scanners today are models that allow you to transmit information via Bluetooth.

To do this, you need to install the appropriate application on your smartphone, for example, OpenDiag, and connect it to the scanner.

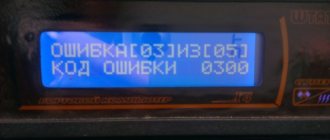

The program interface allows you not only to read the parameters, but also to manage some of them. You can also reset all errors from your smartphone. There are scanners with their own display. All error information in the form of codes is displayed on this display.

Diagnostics using third-party equipment

More precisely, errors on Chevy Niva can be identified by connecting additional equipment. The technique is more technically complex, but allows us to determine the cause of a breakdown or failure with minimal error. In this case, the sequence of actions is as follows:

- turn off the engine;

- find the contact connector under the dashboard, the connector is located at the bottom of the steering column;

- connect the configured computer to the ECU output;

- turn on the ignition;

- follow the program instructions.

If all actions are performed correctly, all available information and any errors in the form of encrypted codes will be displayed in the desktop window.

There are also specialized scanners designed specifically for Chevrolet NIVA. Dealer devices are connected to the place of the standard signaling unit through an output cable.

Separately, we should highlight modern devices designed to connect a smartphone to a car, while reading encodings and controlling operating modes occurs directly from the gadget’s display.

At the same time, you should know what the encodings displayed during diagnostics mean. The code consists of several elements.

- P – the motor electronics have failed;

- C – there are problems with the chassis;

- B – interior space, a problem has been detected;

- U – there are problems when establishing pairing of on-board systems.

The next element is a single digit:

- 0 – OBD 2;

- 1-2 – standard code of the manufacturer;

- 3 – reserve part of electrical equipment.

The following digit determines the exact serial number of the line in which the defect was detected:

- 0 – exhaust system device;

- 1-2 – violation of the fuel or air supply device to the engine;

- 3 – ignition does not work correctly;

- 4 – additional equipment control;

- 5 – monitoring the engine idle state;

- 7-8 – transmission and chassis design.

Chevrolet Niva error codes

Errors transmitted through the diagnostic connector are displayed on an external device as a four-digit code. There are special tables that allow you to decipher these codes.

| Code | Explanation |

| P0102 | Low signal level of the mass air flow sensor (MAF). |

| P0103 | High signal level of the mass air flow sensor (MAF). |

| P0112 | low signal level of the intake manifold temperature sensor (ITM). |

| P0113 | High signal level of the intake manifold temperature sensor (IMT). |

| P0116 | The signal from the coolant temperature sensor (TTOZH) is out of the permissible range. |

| P0117 | Low signal level of the coolant temperature sensor (DTOZH). |

| P0118 | High signal level of the coolant temperature sensor (DTOZH). |

| P0122 | Low signal level of the throttle position sensor (TPS). |

| P0123 | High signal level of the throttle position sensor (TPS). |

| P0130 | Incorrect signal from oxygen sensor No. 1 to the converter. |

| P0131 | Low level signal from oxygen sensor No. 1 to the converter. |

| P0132 | High level signal from oxygen sensor No. 1 to the converter. |

| P0133 | Slow response to enrichment or depletion of oxygen sensor No. 1 to the converter. |

| P0134 | Lack of signal (open circuit) of oxygen sensor No. 1 to the converter. |

| P0135 | Malfunction of the oxygen sensor heater circuit No. 1 to the converter. |

| P0136 | Short circuit to ground in the N9 oxygen sensor circuit 2. |

| P0137 | Low level signal from oxygen sensor No. 2 after the converter. |

| P0138 | High level signal from oxygen sensor No. 2 after the converter. |

| P0140 | Lack of signal (open circuit) of oxygen sensor No. 2 after the converter. |

| P0141 | Malfunction of the heater circuit of the oxygen sensor No. 2 after the converter. |

| P0171 | The fuel supply system (fuel-air mixture) is too lean. |

| P0172 | The fuel system (air/fuel mixture) is too rich. |

| P0201 | Open circuit for controlling the injector of the 1st cylinder. |

| P0202 | Open circuit in the 2nd cylinder injector control circuit. |

| P0203 | Open circuit in the 3rd cylinder injector control circuit. |

| P0204 | Open circuit in the 4th cylinder injector control circuit. |

| P0261 | Short circuit to ground in the 1st cylinder injector control circuit. |

| P0262 | Short circuit to the source of the on-board network of the injector control circuit of the 1st cylinder. |

| P0264 | Short circuit to ground in the 2nd cylinder injector control circuit. |

| P0265 | Short circuit to the source of the on-board network of the injector control circuit of the 2nd cylinder. |

| P0267 | Short circuit to ground in the 3rd cylinder injector control circuit. |

| P0268 | Short circuit to the source of the on-board network of the injector control circuit of the 3rd cylinder. |

| P0270 | Short circuit to ground in the 4th cylinder injector control circuit. |

| P0271 | Short circuit to the source of the on-board network of the injector control circuit of the 4th cylinder. |

| P0300 | Random/multiple misfires detected. |

| P0301 | Misfire detected in cylinder N91. |

| P0302 | Misfire detected in cylinder N9 2. |

| P0303 | Misfire detected in cylinder N9 3. |

| P0304 | Misfire detected in cylinder N9 4. |

| P0327 | Low signal level of the knock sensor (DS). |

| P0328 | High signal level of the knock sensor (DS). |

| P0335 | There is no signal from the crankshaft position sensor (CPS). |

| P0336 | The crankshaft position sensor (CPS) signal is outside the permissible limits. |

| P0337 | Short circuit to ground in the crankshaft position sensor (CPS) circuit. |

| P0338 | Open circuit of the crankshaft position sensor (CPS). |

| P0340 | Malfunction of the camshaft position sensor (CPS) circuit. |

| P0342 | Low signal level of the camshaft position sensor (DPRV). |

| P0343 | High signal level of the camshaft position sensor (CPS). |

| P0422 | The efficiency of the neutralizer is below the permissible threshold. |

| P0441 | Incorrect air flow through the valve. |

| P0443 | The canister purge valve control circuit is faulty. |

| P0480 | Cooling fan N91 relay control circuit malfunction. |

| P0481 | Cooling fan N9 2 relay control circuit malfunction. |

| P0500 | Incorrect vehicle speed sensor signal. |

| P0503 | Intermittent signal from the vehicle speed sensor. |

| P0506 | Low idle speed (idle speed control blocked). |

| P0507 | High idle speed (idle speed control blocked). |

| P0560 | The on-board network voltage is below the system operability threshold. |

| P0562 | Reduced voltage of the on-board network. |

| P0563 | Increased voltage of the on-board network. |

| P0601 | Controller ROM checksum error. |

| P0603 | Error writing/reading external RAM of the controller. |

| P0604 | Error writing/reading internal RAM of the controller. |

| P0615 | Open starter relay control circuit. |

| P0616 | Short circuit to ground in the starter relay control circuit. |

| P0617 | Short circuit to the on-board supply source of the starter relay control circuit. |

| P1135 | Malfunction of the oxygen sensor heater circuit No. 1 to the converter. |

| P1140 | The signal from the mass air flow sensor (MAF) is incorrect; the measured load parameter differs from the calculated one. |

| P1141 | Malfunction of the heater circuit of the oxygen sensor No. 2 after the converter. |

| P1386 | The test pulse or controller knock channel integrator is out of tolerance. |

| P1410 | Short circuit to the on-board power source of the canister purge valve control circuit. |

| P1425 | Short circuit to ground in the canister purge valve control circuit. |

| P1426 | Open circuit for controlling the canister purge valve. |

| P1501 | Short circuit to ground in the electric fuel pump relay control circuit. |

| P1502 | Short circuit to the on-board supply source of the electric fuel pump relay control circuit. |

| P1509 | Overload of the idle air regulator (IAC) control circuit. |

| P1513 | Short circuit to ground in the idle air regulator (IAC) control circuit. |

| P1514 | Short circuit to the on-board power source (or open circuit) of the idle air regulator (IAC) control circuit. |

| P1541 | Open circuit in the electric fuel pump relay control circuit. |

| P1570 | There is no response from the car anti-theft system (ATS) or the circuit is open. |

| P1602 | Loss of on-board power supply voltage in the controller. |

| P1606 | Incorrect rough road sensor signal. |

| P1616 | Low level of rough road sensor signal. |

| P1617 | High level of rough road sensor signal. |

| P1640 | Error writing/reading internal flash RAM (EEPROM) of the controller. |

| P1689 | Incorrect code values in the controller fault memory. |

The most popular Niva 21214 errors and methods for eliminating them.

Engine error codes (P0000)

Note!

Chevrolet Niva on-board computer errors found in this way reflect the most accurate state of affairs at the current time.

- 0102/103 - the pulse from the mass air flow sensor is too low or high, damage to the device or its wiring may occur;

- 0112-0113 – similar indicators from the device for measuring the actual temperature of the intake manifold;

- 0116 – the level of the DTOZh signal is outside the permissible limits, urgent diagnostics of the system is required;

- 0117/0118 – is responsible for the above element and indicates that the signal level is too low/high; it is also necessary to check the sensor itself;

- 0122/0213 – excessively weak or strong impulse from the TPS, cleaning the mechanical part of the device or replacing the sensor may help;

- 0130-0132 – incorrect data transmission from DC1 installed to the catalytic converter; the part may need to be replaced or cleaned;

- 0133 – is responsible for the above element and indicates a slow response of the device to driver commands;

- 0134/0135 – breakage of the power line/breakage of the heater DK1;

- 0136 – short circuit with contact to the negative wire of DK2;

- 0137/138 – critical drawdown/exceeding the permissible norm of the signal from the oxygen sensor installed after the exhaust gas converter;

- 0140/0141 – open circuit of the wiring or breakdown of the DC2 itself;

- 0171/0172 – malfunction of the fuel supply device; the mixture is excessively lean or rich; it is necessary to check the fuel lines for damage; the fuel pump and its relay should also be diagnosed;

- 0201-204 – damage to the injector driver control wiring for each engine cylinder in series;

- 0261/0264/0267/0270 – short circuit on the body for wiring the driver of each injector in series;

- 0262/0265/0268/0271 – similar, only with a touch to the vehicle’s on-board wiring, for each cylinder, respectively;

- 0300 – the electronic control unit has detected multiple misfires, the gasoline supply is turned off;

- 0301-0304 – similarly, misfires are observed for each working chamber, respectively, the controller cuts off the flow of fuel to the damaged module;

- 0327-0328 – the knock sensor is not working correctly, a weak or too high signal is detected;

- 0335 – DPKV is out of order or its wiring is damaged, you should immediately perform physical diagnostics of the sensor;

- 0336 – the same sensor does not work correctly;

- 0337/0338 – short circuit to the body/break in the DPKV wiring;

- 0340 - therefore, error p0340 Niva shows that there are problems in the circuit of the above sensor;

- 0342 – critical reduction in the permissible impulse from the DPKV;

- 0343 - error 0343 Niva warns that the actual impulse from the DPKV is above the permissible limit;

- 0422 – obstruction of the catalytic converter has been detected, the device needs to be replaced;

- 0441 – the actual value of the flow meter differs from the calculated values;

- 0443 – the canister purge valve is faulty or there is serious damage to the power cables;

- 0480/481 – failure or damage to the wiring of the fan relay No. 1/2 of the cooling system;

- 0500 – the speedometer sensor shows incorrect data;

- 0503 – DSA pulse is interrupted or the wiring is short-circuited;

- 0506/507 – the power plant XX regulator is blocked, a low or high speed level is detected;

- 0560 – the performance of on-board systems is limited due to a critical voltage drop, usually the cause is a deep discharge of the battery;

- 0562/563 – there are voltage surges in the on-board network, up or down from the reference value;

- 0601 – error in writing or reading information for a permanent recording device;

- 0603/604 – similar for RAM;

- 0615 – there is no power to the starter relay, you need to check the safety insert and wiring;

- 0616/617 – Short circuit on the on-board network or on the car body of the starter relay wiring;

- 1135 – interruption or incorrect operation of the control wiring DK1;

- 1140 – mass air flow sensor error, the measured value differs from the calculated value;

- 1141 – disruption of the operation of power lines DK2;

- 1386 – incorrect signal from the mixture detonation channel length sensor;

- 1410 – Short circuit of the canister purge valve lines with contact with other wires;

- 1425 – similar, only with contact on the car body;

- 1426 – complete break in the lines of the canister purge valve – no pulse;

- 1501/02 – there is a short circuit in the control and power lines of the main fuel pump touching the standard wiring or body, respectively;

- 1509 – critical overload of the power plant idle speed control relay;

- 1513/514 – short circuit of the above module with contact to the wires or car body;

- 1541 – control of the electric fuel pump is lost, there is a break in the cables;

- 1570 – APS does not respond, control elements or control lines may be damaged;

- 1602 – error 1602 Niva indicates that there is no power in the controller;

- 1606 – the rough road sensor is acting up;

- 1616/617 – too weak or strong impulse from DND;

- 1640 – error in writing or reading the EEPROM system;

- 1689 – false data in the error memory, the system needs to be reset;

- 2188 - error 2188 Niva warns the user that an excessively rich fuel mixture is supplied to the engine at idle speed (the engine choke).

Computer diagnostics

The most complete diagnosis is possible with a computer or laptop. In order to use this method, you must purchase an adapter. This adapter performs two functions at once. It is an adapter from a K-line port to a USB port or to a COM port. It also acts as a decoder, which allows you to transmit signals from the ECU to the PC. You will also need to install the appropriate software on your laptop. There are a lot of free versions on the Internet. There are universal programs, as well as programs written for a specific car. After connecting to the computer, you will need to turn on the ignition and launch the program. The connection will happen automatically.

The interface of the computer program is very convenient and allows even an inexperienced user to navigate intuitively. All functionality can be divided into several sections. These are parameters, errors and settings. If the first two sections are informational, then using the third section you can control the vehicle systems.

Video “Resetting Airbag Error”

If malfunctions are found in the operation of certain systems, then the first thing to do is to correct them. If after repair the codes remain in memory and do not disappear, then you can eliminate them yourself.

There are several options for resetting errors:

- Clear codes by disconnecting the battery terminals. Open the hood and loosen the bolts on the clamps, then disconnect the alligator clips. Wait about one minute, then connect the crocodile clips into place.

- Using the on-board computer. The device has a special function for this. To delete the code, go to the “errors” section in the main menu, then press the middle key on the panel. You will hear a beep and dashes will appear on the computer display. If they exist, then the errors have been successfully removed from memory.

- Resetting can be done using the odometer button. You need to hold it down for five seconds. About 15 seconds will pass, after which the numbers will appear on the display. We wrote about errors during self-diagnosis at the beginning of the article, but if the number 0 appears on the display, then there are no problems with the operation of the sensors, engine and other systems in the car.

If the Chevrolet car was diagnosed using the Chevrolet Explorer program, then information about faults can be deleted through the utility.

In addition, there are other options for resetting codes:

- Disconnect the battery from the power supply. To do this, you need to open the engine compartment and use a wrench to loosen the nuts on the terminal clamps. Then they are disconnected. The connection is completed in one minute.

- Resetting error information is possible through the vehicle’s on-board computer. This device has an appropriate option to perform this task. You need to go to the errors section in the main menu of the computer, and then click on the middle button on the panel. In confirmation, the device will emit a sound signal, and dashes will appear on the screen, indicating that the fault information is deleted from the memory.

- Resetting the codes can be done using the button on the odometer, it is pressed for five seconds and then released. After 15 seconds, numbers should appear on the display. If 0 lights up, this indicates that no problems were detected in the operation of the systems.

User Alex Moss talked about self-resetting an Airbag fault using the example of a Chevrolet Epica.

Loading …

Check engine error

If a check light comes on on a Niva Chevrolet car, this warns that there are malfunctions associated with the operation of the engine. The light comes on at the moment when the engine begins to detect a failure or error and writes a specific code into its memory.

Let's look at the main reasons why this warning may appear:

- The air/fuel mixture is incorrect. This problem is eliminated by filling the tank with higher quality gasoline.

- Low engine oil level

- Engine overheated

- There are problems with the ignition system, which may be due to a faulty spark plug or ignition coil

- The power system is faulty. It is possible that fuel injection into one of the cylinders has stopped.

- Lambda probe faulty

- A separate sensor in the ECM system has failed

We can conclude that in some cases, when the engine starts and the check light is on, this may indicate that the engine is operating in emergency mode and the problem is not very critical. If the engine starts and stalls, then this is most likely a problem with the fuel supply or the crankshaft sensor has failed.

In any case, it is better not to use the car until you find out the exact reason.