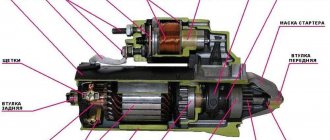

Starter device

First, let's look at how a starter works:

- when the driver turns the key to the extreme right position, current flows to the starter winding;

- the crankshaft flywheel engages with the overrunning clutch gear;

- The crankshaft, rotating, transmits torque to the pistons, the combustible mixture begins to enter the cylinders and ignite through ignition;

- at approximately 100 revolutions the clutch and flywheel are separated;

- after the circuit is opened, the key goes to the middle position, the starter shaft does not rotate.

Schematic structure of the system:

Starter device:

If the starter hums but does not turn the engine, this behavior indicates a wide range of different malfunctions. The peculiarity of the situation when the engine does not start is that there are certain difficulties in localizing the problem: it may lie in the fuel pump that does not turn on after turning the key, in the starter’s refusal to turn the crankshaft, etc. But in the general case, a common phenomenon is when the starter “turns” and turns out to be is able to rotate the crankshaft, but the engine refuses to start.

Reason #2: fuel filters

In principle, this could be attributed to the previous point, if not for the frequency with which this malfunction occurs. The starter turns, but does not engage, the car does not start, perhaps the engine does not have enough fuel as a result of a clogged fuel filter. After all, there is no need to talk about the quality of modern gasoline and the impurities in it. Even newbie car enthusiasts have heard about this.

Starter malfunction

Before you do an in-depth check of the components, you should make sure that the starter itself is in order. It should work without any extraneous sounds - clicks, hums, etc. The starter electric motor normally operates smoothly, without failures or any omissions. The malfunction is determined by ear, and if the starter clicks but does not turn the engine, the cause is most likely in the starter itself.

Of course, if after turning the key nothing happens at all, this unit also needs to be checked for serviceability. So, the absence of a click clearly indicates a breakdown of the solenoid relay.

If the starter rotates the shaft normally, but the engine still refuses to start, you should check:

- fuel system;

- ignition;

- state of sensors of the electronic engine control system;

- flywheel ring teeth or clutch gears - they may be worn out. This is a common reason why the starter turns but does not turn the engine. The malfunction may also be accompanied by the grinding sound of worn teeth.

These problems can manifest themselves in both “cold” and “hot” conditions. Another reason why the starter does not turn on a hot engine is a malfunction of the power unit: for example, the crankshaft liner is worn, which is pinched when heated, or there is an axial displacement of the shaft. The starter does not turn well on a hot engine if the piston group is faulty, the battery is discharged, the ignition is incorrectly configured and the starter elements are worn out.

It is also possible that the crankshaft cranks too slowly when trying to start. There may be several reasons why the starter turns the engine slowly:

- poorly charged battery that does not produce sufficient current;

- faulty solenoid relay;

- wiring problems;

- The oil is too thick.

How to check the fuel - air system of a VAZ 2110

Another reason why the VAZ 2110 will not start may be a faulty supply of the fuel-air mixture to the car’s engine. In the air supply system, malfunctions occur extremely rarely and boil down to either a tightly clogged air filter or a blockage of the air channel by a foreign object. Such malfunctions are unlikely to occur on a well-maintained personal vehicle. But if the car is, for example, a service car or recently purchased, it would be a good idea to make sure that the filter is intact and that there is no rag stuck in the channel after a recent repair.

The engine fuel supply system is controlled by an electronic control unit, which, in turn, regulates the fuel-to-air ratio based on readings from the mass air flow sensor (MAF) and the throttle position sensor. If both of them are faulty, it is not surprising that the VAZ 2110 does not start.

Diagram of the fuel air system of the VAZ 2110

Next, it’s worth checking the condition of the air filter, since this is the easiest thing to do. And, if none of the above steps help, you need to check the pressure in the system created when the fuel pump operates. Connect a pressure gauge to the diagnostic fitting of the fuel rail and measure the pressure. Its low level indicates a clogged pump filter, and its high level indicates a gearbox malfunction.

The normal pressure level directly depends on the type of engine installed in the VAZ 2110 car:

- the limit from 284 to 325 kPa is normal for engines of type 2111, 2112;

- the limit from 364 to 400 kPa is normal for engines type 21114, 21124.

By the way, the serviceability of the fuel pump can also be determined by disconnecting the main gas supply hose to the ramp and pumping gasoline through it into a clean container. A working pump will pump at least 1.5 liters in a minute. fuel.

Also listen to the starter. Does the main electromagnetic relay turn on with a characteristic click and does the electromechanical drive of the unit work at all? Despite the fact that the design of the starter is extremely simple, the electrical contact on it can easily be lost or the gearbox can fail. In the latter case, a characteristic creaking or whistling sound will be heard.

If the starter does not rotate, you should remove it from under the hood of the car. This process will not take much time, just like disassembling the block itself. It is worth checking the serviceability of the electrical part using a multimeter, “ringing” the windings, and disassembling the gearbox. A large amount of lubricant in it in the cold season does not allow the starter to rotate.

Failures outside the starter

Most engine failures with a working starter are due to the fact that there is either “nothing to burn” or “nothing to ignite”. Let's take a closer look at them.

Fuel system

It consists of several elements that should be checked step by step:

- fuel pump (electric or, in some car models, mechanical driven by the engine);

- fuel supply system - carburetor or injector;

- fuel line;

- filters that clean the fuel passing through the highways.

Another possible reason is a disruption in the fuel supply due to the formation of suction in the system; it should be found and eliminated.

An important note concerns diesel engines: if the owner has chosen the wrong diesel fuel in the winter, in the cold it thickens (waxes), and the fuel supply system units simply cannot pump the fuel to deliver it to the cylinders.

Owners of cars with injection engines know that immediately after turning the key you can hear the fuel pump turn on for one or two seconds. Its job is to supply fuel to the system, and if the pump is faulty, the engine will not start. The sound of its operation is a characteristic hum, and when it is not heard, then most likely the problem is in the fuel pump or its power circuits. You need to check the correctness:

- the electric fuel pump itself;

- relay;

- fuse;

- power wires going to the node.

Injection pump VAZ 2109:

Interesting: for injection cars, you should check whether there is fuel in the fuel rail. It has a special control valve, when pressed, gasoline should begin to flow. This will indicate that fuel is present in the ramp and is supplied to the injectors.

If the car is carburetor, then its pump is most likely driven by transmitting torque from the camshaft. To carry out the check, you need to remove the hose going to the carburetor inlet fitting; in addition, the hose can be removed from the pump outlet. After this, use the manual pump lever (located on the pump) to pump up some fuel. If the unit is in order, gasoline will leak out.

Note: the author has repeatedly had to deal with the situation of a fuel pump failure, when the car was driving for quite a long time with an almost empty tank, without adding fuel. The fact is that gasoline at domestic gas stations is not always of high quality; it contains impurities that settle at the bottom of the tank. When the filling of the fuel tank drops, the pump begins to “scoop up” dirty gasoline/diesel with sediment from the bottom, which clogs the pump mechanism, filters, fuel injectors, leading to malfunctions, engine tripping, and a complete inability to start it.

There are often situations when fuel filters become clogged, then the liquid can no longer pass through them normally, and the starter “turns” idle. Filters should be checked and cleaned/replaced if necessary.

How does the engine start?

The internal combustion engine only operates if the following conditions are met:

- A sufficient amount of fuel and air mixture enters the engine cylinders.

- At the right moment (and to be precise, after the air-fuel mixture is compressed), the spark plug produces a high-power spark.

- The camshaft and crankshaft rotate at the required frequency, which is strictly selected. Only in this way does the gas distribution system work correctly and the chambers are filled with a combustible mixture in a timely manner.

When the driver turns the ignition key, voltage is applied to the starter relay, thereby activating the electric motor. Its function is to engage the flywheel with the crankshaft. Then the crankshaft begins to rotate, its angular momentum is converted into reciprocating movements of the pistons.

When the cylinders begin their work, this subsequently leads to the movement of the camshaft. The latter is needed in order to promptly open the valves to fill the combustion chambers with the mixture.

Camshaft

We recommend: Do-it-yourself repair of the starter retractor relay

The internal combustion engine power system is responsible for the timely delivery of the combustible mixture. As soon as the piston moves to the upper compression point, high voltage is applied to the spark. Thus, when the mixture is ignited, a small explosion is created, the expanded gas affects the piston and it moves, moving the crankshaft. We have described the principle of starting an internal combustion engine; remember that engine modifications may be different, so the starting algorithm may differ.

Operation of an internal combustion engine

Ignition problems

So, let's assume that the starter is ok, the fuel system has been checked, but the engine still refuses to start. The reason for this may lie in ignition failures (“nothing to ignite”).

The first thing you should check is the condition of the spark plugs, coils and high-voltage wires going to them (“armored wires”). Their failure leads to the fact that the spark required for ignition does not appear on the candles.

The presence of a spark from an injection engine can be determined by unscrewing one of the spark plugs. This should be removed, then an armored wire should be put on it and the spark plug should be attached with its skirt to the cylinder block.

Important: it is advisable to perform the operation together.

After this, you should turn the starter with the key: if current flows to the spark plug and there is a spark, it will be visible to the naked eye. Spark on the spark plug:

It is important to follow safety precautions and not touch the electrodes! If the spark plug does not react in any way to the starter, it means there are problems with it, the wires or the ignition coil itself. A more thorough check of these elements should be carried out.

The coils can be checked “in the field” by simply swapping the wires. If there is a fault somewhere, such a rearrangement will quickly show them.

Important: the absence of a spark on one or more spark plugs may indicate a general failure in the ignition module, which in such a situation should also be checked.

The coil of a carburetor engine can be checked using another “field” method: remove the central wire and bring its end 5 millimeters closer to the metal surface, then “turn” the starter. There should be a spark; if it is not there, then the coil is faulty. If there is a reaction, but the engine refuses to start, you should remove the distributor cover and check the condition of this unit.

Reason #5: Battery, wiring, terminals

Actually, the serviceability of the starter itself does not mean that the rest of the vehicle’s electrical system is working. Check to see if the battery is dead or if the terminals are oxidized. Faults and breaks in the electrical wiring can also cause the engine to refuse to start. For example, the wire that goes to the generator or from the positive terminal of the battery to power the controller could come off.

Quite often such a test does not give a positive result. Therefore, below we provide a list of reasons why the engine may not start, although they occur much less frequently:

- The integrity of the fuses is broken. Not the most common breakdown, but sometimes the engine does not start for this reason.

- Corrosion of parts. Particular attention should be paid to devices related to the vehicle's electrical network, for example, the same starter. Also check for corrosion on the spark plugs.

- Pay attention to the color of the carbon deposits on the candles. During engine operation, its formation is inevitable, but carbon deposits should be light brown in color. If the carbon deposits are black, the spark plug must be replaced. It is also unacceptable to use spark plugs with damaged or oily contacts.

- There is no spark at the ignition coil. In this case, we check the high voltage wire; its integrity may be compromised. In this case, the wire must be replaced. If it is ok, the ignition coil itself is probably faulty.

- Condensation under the hood. Sometimes the presence of excess moisture prevents the engine from starting. Place the car in a dry place, open the hood and wait for the moisture to evaporate. After this, try to start the engine. If the attempt is successful, try to find out where the excess moisture under the hood came from.

- Perform diagnostics on the on-board computer. It is likely that the immobilizer is activated. In this case, starting the engine is simply prohibited.

- Check if the crankshaft sensor is working properly. It may provide incorrect information to the on-board computer about the position of the crankshaft. A flammable mixture of the wrong composition may form. As a result, the starter turns, but does not engage, and the car does not start.

For efficient operation of a car engine, careful and proper care is required. Carry out regular preventive inspections, change consumables, and monitor the condition of your car. Also, don’t put off visiting a service station if your car suddenly starts acting up. This will not only avoid more serious malfunctions, but also prevent them in the future.

We also watch a video that will be especially useful for beginners: what to do if the starter turns, but the car does not start.

Signaling

If you cannot start the engine, you should pay attention to the car alarm. Many modern cars are equipped with immobilizers that prevent the power unit from operating until the owner performs certain actions (pressing a button on the key fob, applying a “pill”, etc.). If you can’t start, it’s possible that the immobilizer protection has simply not been removed.

A car alarm can block the engine on its own if there is some kind of malfunction in its main unit.

Why does the starter turn normally, but the engine does not catch and does not start?

In half the cases when a car refuses to start, the starter is to blame. At the same time, the other half occurs in situations where the starter regularly rotates the crankshaft, but the engine starts only after repeated attempts or is completely silent. This could be due to a variety of reasons.

Driver inattention or negligence

The notorious human factor can manifest itself in the most unexpected ways. For example, a banal lack of fuel or an alarm that blocks the fuel pump. It also happens that some “well-wisher” clogged the exhaust pipe, or a careless driver, while backing up, got stuck in a pile of soil or a snowdrift. Such reasons do not fall into the category of technical malfunctions, but they can spoil a lot of nerves.

Technical problems - starter malfunctions

Every more or less experienced driver will distinguish the sound of a starter, which regularly rotates the engine, from the useless buzz of its electric motor when there is no engagement with the flywheel.

When starting to troubleshoot, you should definitely make sure that the starter is functioning normally, and that no extraneous knocks, clicks or malfunctions are observed during its operation. The starter is considered faulty in the following cases:

- The Bendix gear cannot engage with the flywheel ring gear. This manifests itself in a loud metallic grinding sound that appears when the starter is turned on. The reason for this phenomenon is wear of the mating surfaces, chipped teeth, etc. The solution to the problem is to install a new flywheel or ring. The latter can be rotated 180° and thus avoids the need to purchase a new part.

- The overrunning clutch or retractor relay mechanism is stuck. At the same time, the starter motor hums, but it makes no attempt to start the engine. In some cases, repeated attempts to turn on the starter help, but this only postpones the need for repair or replacement for some time.

- The crown is loose. A similar malfunction occurred on cars from the end of the last – beginning of this century, including the popular “nines”. In this case, the starter engages with the ring and begins to turn it, but it turns on the flywheel with a grinding noise. Only replacing the latter will help.

Video: Watch for anyone who has problems turning on the starter. Useful advice from an auto electrician.

Diesel

The most difficult thing is starting a diesel engine. The fuel in it ignites according to a slightly different principle. The chambers in which diesel fuel burns are heated to very high temperatures, after which diesel fuel is supplied to them along with air, which ignites due to compression. In cold weather, it is advisable to heat the air in the cylinders with glow plugs. If this is not done, then the car may start, but immediately stall or operate unstably until it warms up.

Even the slightest frost or zero temperature can be enough to cause starting problems. In a diesel engine, you need to start by checking the condition of the glow plugs. We start by checking the glow plug control unit. For this we need a control lamp. We connect it to ground and power to the spark plugs, and then turn the key in the ignition. If the unit is working properly, the indicator lamp will light up.