Car repair sable.

In this article we will examine the topic of poor engine starting in as much detail as possible. In this article we will talk about 4216 engines, but don’t worry if you have, for example, a 406 engine, we have no doubt that our article will also help you.

If your car has stopped responding to turning the key and does not even try to “wake up” somehow, do not rush to tow your vehicle to a car service center, read our article to the end and most likely you will eliminate the cause yourself. Just follow our advice.

So, let's look at the main symptoms.

The car is trying to start, but something is missing.

The engine “clicks” and doesn’t even try to start.

The car does not respond at all to turning the ignition key.

1) First of all, you must make sure how much power your battery has. (Well, here every motorist will understand this, by the characteristic sound, whether the battery is pulling or not. Elementary, press the sound signal, if the beep is heard, as usual, without “hoarseness,” then the battery is in perfect order.)

2) The next step, as trivial as it may sound, is to check the presence of gasoline in the tank. In a sable booth car, this can be done using an ordinary branch, lowering it into the tank. After you have confirmed the presence of gasoline, turn the ignition key and listen to your fuel pump; it should make a sound. Then find the fuel pipe under the hood, and at the end there is a cap, unscrew it and press the core with a screwdriver. The gasoline in the injectors must drain. Don’t worry, it won’t use up a lot of gasoline, the main thing is don’t light a cigarette. If you get a “pop”, then the pressure in the fuel system is good, therefore, the fuel pump is in working condition.

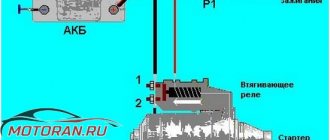

3) We look at the picture and continue to look for the reason for the poor starting of our engine. Now check the condition of your terminals; it often happens that a huge layer of plaque forms on them, and as a result, poor current flow. Remove the terminals and clean them with a metal brush, ideally lubricate them with a special paste. You can buy the paste at any auto parts store, the price is not astronomical. Next, put on the terminals and tighten them well so that they do not rotate under any circumstances. Believe me, even such a seemingly trifle can cause an unpleasant surprise and loss of your time. We try to start the engine, if nothing has changed, we move on.

4) In the picture to the right of the battery there is a box, we have circled it in red. This is the main fuse. If your box is closed, as in our image, then unscrew the top cover. There are two metal jumper plates there. They should be, like any other fuse, in good condition. Take a ten key and make sure that all these plates are well tightened. If you ride with an open block, then it’s better to unscrew it halfway and use a valve, then tighten it well.

(Believe my experience, I have two sable cars, a booth and an all-metal one, and sometimes such a little thing helps solve a problem in a matter of minutes.)

We try to start the engine. If the car does not start on the first try, do not torture it further and do not “finish off” your battery. Let's move on. In any case, now clean terminals and the main fuse block are only a plus.

5) Before you start inspecting the spark plugs, answer yourself this question: did the car start normally before the breakdown?! Were there any clicks before the breakdown?! Perhaps your starter is just “tired”.

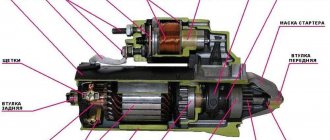

Let's check it before you buy a new one. It would be great if they took you in tow; if the car starts with a push and does not stall, then it is 100% the starter. If towing is not possible at the moment, then you need to check our starter yourself. To do this, turn on the ignition, be sure to remove the car from speed and arm yourself with a regular screwdriver. Now we find our starter (bottom right), find the two main contacts and bridge them with a screwdriver. You should try to do this quickly, touching both contacts at the same time. You should hear exactly the same sound if you were sitting in the driver's seat and trying to start your car. By 70 percent, this “screwdriver method” helps start the engine. If nothing works on the first two attempts, stop and don't drain the battery. There is one more point: perhaps the retractor has become “stuck”. Take a larger key or a small hammer and knock on it. But of course not very much. Try launching.

(I have done all of the above myself more than once, and 90% of the time I always started my sable.)

If you have all these symptoms, you are convinced that the starter has broken down, and you cannot start the engine with your own hands, then of course only replacing the starter will save you. Changing it yourself is not difficult, just unscrew a couple of bolts.

6) How long ago did you change the spark plugs?! Don't be lazy and unscrew the first two spark plugs. What is their condition?! Is there a lot of carbon deposits?! If yes, then you need to buy new spark plugs anyway. Their ability to work has already ended.

7) Check the high voltage wires. First of all, they should be a little soft. If they are “oak” and it’s winter outside, they definitely need to be changed. Carefully remove a couple of wires from the spark plug and move away the upper protective capsule; inside the wire there is a fairly thin core that often breaks. If everything is in order there, also carefully put the wires back on the spark plugs. In general, spark plugs and wires, even if they are in poor condition, they should start your engine, it will just groan, trip, etc., but work.

For those who have an alarm system installed. I once had such a story, when the protection system “got wrong”, I examined everything that was written above, checked every wiring, and only an electrician could understand that the protective function of my “miracle” alarm had worked. In such a situation, the engine turns over, but cannot start. You can try to solve this problem yourself, as a simple example, this is to press the door lock and unlock button, and then try to start it. The second option is to find the alarm button itself, this is the so-called error reset, usually located under the steering part. Press and hold the button for 20 seconds. Try it.

For those who have an alarm system installed. I once had such a story, when the protection system “got wrong”, I examined everything that was written above, checked every wiring, and only an electrician could understand that the protective function of my “miracle” alarm had worked. In such a situation, the engine turns over, but cannot start. You can try to solve this problem yourself, as a simple example, this is to press the door lock and unlock button, and then try to start it. The second option is to find the alarm button itself, this is the so-called error reset, usually located under the steering part. Press and hold the button for 20 seconds. Try it.

9) If even now your sable does not want to start, then we climb into the cabin and to the right of the steering wheel open the cover of another fuse box. It is advisable to check everything. Let's try to launch.

10) We return to the hood, and behind the engine we feel for the wire, the engine ground, everything should be well tightened. I had a situation where the mass almost unscrewed, how, it’s a mystery.

Dear readers, if you have followed all our advice and there is no result, which is of course possible, but rare, then the only thing to do is tow your car to a car service center, it is better if it is a specialized technical center.

All the best, good luck on the roads.

?Subscribe to our information channel. Every day we publish many useful and informative articles for you.

Source

Gazelle business does not start well when hot 4216

Skip to content

Useful for car enthusiasts - everything about cars

Why is the engine difficult to start when hot?

The question is often raised on car forums: why is the engine difficult to start when hot? Moreover, this problem exists in carburetor, injection, and diesel engines. For example, a person drove a car for some time, then stopped and turned off the engine, but after a couple of minutes he could no longer start it again. The engine seems to catch and then immediately stalls. So the driver has to stand and wait until the engine cools down. When cold - everything is fine, it starts as expected. Let's try to find out what's the matter?

If a carburetor engine has difficulty starting when hot, this is understandable. When the engine is running, a lot of air circulates through the carburetor, thereby cooling the carburetor. At the same time, the gasoline entering the carburetor is cooled. As a result, when the engine is running, its temperature remains much higher than the temperature of the carburetor. But this is while the engine is running. As soon as it is turned off, the air circulation immediately stops; accordingly, the cooling of the carburetor stops, and it begins to heat up sharply from the hot engine.

During the rapid heating of the carburetor, the gasoline remaining in the float chamber, at such a high temperature, also begins to evaporate very quickly, and these vapors begin to fill all the existing voids. Thus, air pockets appear in the fuel system - in the float chamber, air filter and in the carburetor itself.

This process can last from 5 to 30 minutes, depending on how long you decide to start the engine again. If you start it earlier than 30 minutes, the air-fuel mixture will be over-rich, fuel will flood the spark plugs, and such a hot start will not be easy.

In connection with the above, in a situation where you need to start a hot carburetor engine, you first need to lean the air-fuel mixture. To do this, you first need to depress the gas pedal once, fully or only halfway (depending on the situation). If you press on the gas several times, often, the proportion of the mixture will be further disturbed towards over-enrichment, and then the fuel mixture will completely flood the engine. If necessary, repeat this single press on the gas. After starting the engine, you need to press the gas several times, and then you can continue moving.

Injection and diesel engines

If the reason why a carburetor engine does not start well when hot is quite simple and understandable, then with injection and diesel engines everything is much more complicated. There may be several reasons for this problem. Here are the most common:

1. Malfunction of the JOT (coolant temperature sensor) - happens on both injectors and diesel engines. A faulty sensor sends the wrong signal to the ECU, and as a result, the fuel also flows incorrectly. The solution to the problem is to replace the JOT.

2. Fuel injectors are leaking. Gasoline flows through the injectors and evaporates. The result is an over-enrichment of the air-fuel mixture. To check the injectors, you need to unscrew the spark plugs and check if they are wet. To start a car with an injection engine when hot, you need (by analogy with a carburetor engine) to first let the gasoline vapors escape - to do this, open the throttle slightly. Fuel injectors can also leak due to wear on the seals on them. The solution to the problem is to replace the faulty injector.

3. Malfunction of the high-pressure fuel injection pump (for cars with diesel engines), due to the failure of: a) the plunger pair, b) the bushings and oil seal of the drive shaft. The solution to the problem is to replace worn parts.

4. The control injector temperature sensor has failed (for cars with diesel engines), as a result of which the injection angle changes and the car has difficulty starting when hot. The solution to the problem is to replace the temperature sensor.

5. The pump drive is stretched, as a result of which the injection angle also changes. The solution to the problem is to turn the pump one or two degrees to adjust the injection angle.

6. The fuel pressure regulator diaphragm is torn. Dripping gasoline enters the intake manifold, as a result, the mixture becomes over-rich and does not burn. The solution to the problem is to replace the fuel pressure regulator.

This is not a complete list of reasons why a car with an injection or diesel engine has difficulty starting when hot. In addition, a malfunction can lead to this problem:

– crankshaft position sensor (CPS),

– mass air flow sensor (MAF) (How to check the MAF),

– pressure sensor in the fuel drive,

Thus, if a hot injection or diesel engine is difficult to start, then there can be quite a few reasons for this, and it is best not to suffer yourself, but to carry out high-quality diagnostics at a car service center.

In addition to malfunctions of the UMZ-4216 engine itself, malfunctions of the engine control systems also occur during operation. The electronic engine control unit (fuel supply and ignition) is capable, to a certain extent, of diagnosing malfunctions of the UMZ-4216 engine control systems. In this case, sensors installed on the engine are used to obtain information about the operation of the engine and the systems controlled by the unit.

Typical possible malfunctions of the power and ignition control systems of the UMZ-4216 engine with electronic fuel injection

To launch the self-diagnosis system (as well as to connect a special diagnostic tester ASKAN 10), there is a special 16-pin plug connector in the wiring harness of the UMZ-4216 engine control system. When a malfunction in the control systems is detected, the control unit turns on the diagnostic malfunction lamp (yellow lamp on the vehicle's instrument panel with an image of the engine circuit), and a code reflecting this malfunction is entered into its memory.

Gazelle starts and stalls 406 carburetor

In this article we will take a closer look at the situation when a carburetor engine of a passenger car (VAZ 2108, 2109, 21099, 2105, 2107 and their modifications) starts and stalls due to a carburetor malfunction. Malfunctions of carburetors 2105, 2107 Ozone, 2108, 21081, 21083 Solex and their modifications will be considered. — The engine starts, runs for a few seconds and stalls, repeated starts are unsuccessful. — The engine starts with difficulty, after running for a short time it stalls, after restarting it starts and runs.

— The engine starts and immediately stalls, starts again and stalls again, and so on several times, but then it still starts working.

Causes of malfunction

There is no fuel in the float chamber

Pump it up using the manual pump lever on the fuel pump.

The fuel pump or power system may be faulty. Remove the hose from the carburetor fuel supply fitting and press the manual primer lever on the fuel pump several times. A strong pulsating stream of gasoline should come out of the hose hole. If it is missing or weak, check the fuel pump or power system.

VAZ fuel pump check

The strainer at the carburetor inlet is clogged

Remove it by unscrewing the cap, clean it (you can use a toothbrush), rinse with acetone or gasoline and blow with compressed air. At the same time, clean the filter seat in the carburetor cover.

details of mesh filters for fuel purification of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

The solenoid valve is faulty or the fuel jet of the idle system is clogged

Check whether the solenoid valve or the idle air system fuel nozzle holder has become loose due to any circumstances. Turn it on. Remove the wire from the valve and then put it back on. You should hear the click of the valve being activated. If it is not there, we connect a piece of wire plus the battery and the valve outlet. There is no click - we change the valve. There is a click - we check the EPH system.

carburetor solenoid valves 2108, 21081, 21083 Solex, 2105, 2107 Ozone

Check the serviceability of the valve itself by unscrewing it from the carburetor and removing the fuel jet from it. The jet should be carefully inspected for contamination and deformation. We also check the ease of movement of the valve shut-off needle, the presence and integrity of the rubber O-ring on the valve body.

carburetor solenoid valve device

Unscrew the idle air system fuel nozzle holder (on carburetors with a holder instead of a solenoid valve), rinse, clean the fuel nozzle and blow with compressed air.

“Suction” of foreign air into the carburetor

In this case, the fuel mixture is lean. If the engine starts and immediately stalls, it is most likely very lean. The image shows probable places where foreign air is “sucked in” on the 2108 Solex carburetor.

places where foreign air is likely to “suck” into the carburetor 2108, 21081, 21083 Solex

Read more about the “suction” of foreign air in the article “Suction of foreign air into the carburetor.”

Why does a gazelle start and stall?

During the operation of a car, a common situation is that after turning the ignition key, the car starts, the engine starts to work and stalls after a few seconds. As a rule, 3-5 seconds pass from the moment of starting to stopping the internal combustion engine. Before the engine stops completely, engine vibrations are also noticeable, the power unit shakes and operates very unstable.

This happens as a result of a decrease in speed, the resonance effect of a rotating crankshaft, etc. When you try to start the engine again, the engine may no longer start, or the situation described above may repeat again.

The reasons for this problem vary. The main thing is that if the car starts and stalls, this indicates that in-depth diagnostics are needed. Next we will talk about what to do in such a situation, as well as how to find the reason why the engine stalls after starting.

Read in this article

The engine stalls regularly - the throttle position sensor is broken

Regular stopping of the car engine may indicate that the problem is a malfunction of the throttle sensor. This sensor measures the force when you press the gas. The data goes to the ECU (electronic control unit) of the propulsion system. The volume of fuel that should be injected into the combustion chamber of the engine is calculated.

This operation is carried out unnoticed by the driver, in a split second.

If the damper sensor provides erroneous information, injection of the required amount of fuel may not occur. This moment can often be observed when the driver presses the gas pedal. Only a mechanic can perform a quality check of the functioning of the sensor. This requires special knowledge.

As an additional signal, you can pay attention to the “Check Engine” indicator. If it lights up, then it can be assumed that there is a breakdown of the throttle sensor.

How does the ZMZ 405 idle speed sensor work?

In carburetor engines, the problem of enriching the mixture when starting the internal combustion engine was solved by a starting handle and shims. With the advent of electronic ignition, this is done by the idle air regulator in conjunction with other sensors and the computer. Its operating principle is as follows:

- IAC calibration is performed by the ECU controller automatically after detecting this sensor in the system;

- in fact, the IAC is a stepper motor with a conical needle in a special hole in the throttle valve bypass channel;

- The IAC contact does not transmit any signals to the “brain” of the machine, but receives them from the controller, therefore it is not a sensor, but an actuator - an electric valve;

- in turn, the on-board computer “sees” that there is not enough air in the fuel mixture based on the signals from the mass air flow sensor, compared with the signals from the air flow sensor;

- Voltage is applied to the XX regulator, the needle leaves the channel, and the missing amount of air enters the mixture for mixing.

Gazelle won't start: reasons, how to fix it - AutoExpert

Faulty injectors tend to have a negative effect on the Gazelle engine. And the sooner the car owner identifies the cause of problems with the injector, the sooner he will be able to eliminate it, protecting the engine from major repairs. What kind of malfunctions can happen to the injector?

Signs of trouble

There are three main symptoms of problems with the injector (injector malfunction) of a Gazelle car.

- A characteristic sign of a malfunction can be considered detonation, which is unpleasant to the driver’s hearing. It destroys the motor, which is why it is so important to find the fault in time and fix it.

- If the engine stalls for no reason on the road, and subsequent attempts to start it lead to the goal only after many repetitions, this is a clear sign of a faulty injector.

- The power of the power unit does not inspire approval as before. In common parlance, the car does not “pull”. When climbing a hill, the movement turns into a real test of the driver’s nervous system and can be detrimental to the engine.

Doesn't start when the injector is hot

3 main factors for inconsistent injector operation

Experts identify 3 main factors influencing the unstable operation of the injection system.

- The time that has its effect on the injectors. The longer the service life, the higher the chance of their failure.

- Low-quality fuel filled at gas stations in post-Soviet countries is considered the most common cause.

- Repair procedures carried out at questionable service stations.

The last factor of injector malfunction is the most dangerous, as it can affect overall performance. It is better to entrust all adjustment operations to experienced professionals. As a last resort, you can try to repair this or that part yourself rather than handing over your car to be “torn to pieces” by amateurs.

Gazelle injector won't start

There are many reasons for the negative operation of the injection system, but it is worth highlighting the most dangerous and common ones. They occur on various power units; reviews regarding their prevention are almost the same.

Typical faults

Let's look at the most classic injuries.

- Increased fuel consumption may indicate clogged injectors. Their nozzle has a small diameter, and even the slightest contamination can lead to disruption of the mixture formation process. Thus, the percentage of efficiency decreases.

- Lack of fuel fluid in the system. The presence of this symptom indicates that the problem is not only in the injectors themselves, but also in other elements working in tandem with them.

- The XX injector mode is unstable. This sign may indicate many problems.

- Difficulty starting the engine.

- Trouble in the system resulting from a faulty cylinder/s.

- Fuel overflow in the system.

A clogged injector nozzle is unable to inject the required amount of gasoline or diesel fuel. As a result, a significant amount of fuel burns out in the manifold, and this leads not only to an increase in consumption, but also to other malfunctions - loss of power characteristics, increased load on the electronics, failure of the ignition module, spark plugs, armor wiring, etc.

Normal and clogged injector nozzle

When little fuel enters the system, this may indicate a failure of the fuel pump. The latter, in many cases, is simply installed crookedly in the process of amateurishly carried out repair work. In many cases, the fuel pump simply becomes clogged and needs to be cleaned.

The most compelling reason for unstable operation of the idle mode is a malfunction of the IAC sensor. In some cases, the throttle surface may become clogged.

Engine starting problems are usually caused by a lack of spark. To quickly check this, it is recommended to use a spark gap. Experts do not recommend checking the spark for a break, as this may negatively affect the operation of the ignition module and controller.

Trouble on the injector occurs due to poorly functioning cylinders of the power unit. The problem is resolved only after identifying non-working elements. Then you need to disassemble the motor and replace the required parts.

Fuel fluid in the Gazelle injector overflows, as a rule, due to a faulty sensor responsible for the position of the damper.

Thus, all the problems listed above need to be fixed quickly. As mentioned above, it is worth doing self-adjustment only in two cases: if you have a lot of experience and if there are no normal specialists nearby. Do-it-yourself repairs can be carried out using competent instructions and master classes. There are a lot of them on the Internet today.

The advantage of high-quality service stations, in addition to the high professionalism of the workers, is that they have high-tech equipment. In addition to helping to clean the injectors, the equipment makes it possible to conduct comprehensive diagnostics. For example, using the device, you can easily identify needle wear and the actual performance of a particular injector.

Diagnosis of IAC

How can you diagnose a faulty idle air control valve?:

- You stopped for 5 minutes after a long trip, naturally the engine is hot. After this, you try to start the engine, but the engine does not start or starts and immediately stalls. Even if the engine starts, the normal idle speed is not set immediately, but only after pressing the gas pedal more than once.

- The same situation can occur on a cold engine. The first time the engine starts and immediately stalls, but the second time it runs fine.

- Whatever the engine, hot or cold, it starts only when the gas pedal is depressed.

- The situation is the same as in point 3, but the accelerator pedal must be held constantly until the engine warms up or the car starts moving.

- You braked sharply and the car suddenly stalled; when you restart, the idle speed remains within normal limits.

- The idle speed hangs in an inflated range from 1500 to 2000 revolutions and only after revving it returns to normal values. Therefore, if your car’s engine starts and immediately stalls, try immediately flushing the throttle assembly and idle air control. If this doesn't help, just replace the IAC and that's it.

What does IAC look like?

Injector malfunction

The next reason that the engine starts and immediately stalls is a malfunction of the injector. Since most modern cars have a forced fuel injection system, this malfunction is very common.

Don't make mistakes.

What should not be allowed when operating fuel-injected cars:

- Do not disconnect the battery while the engine is running.

- Try to play with lighting as little as possible, and in general, handle food as carefully as possible. Injection cars are very sensitive to such manipulations.

- Try not to disconnect the ground on the car. Although I turn off the mains in my car in winter if I don’t drive for a long time, and so far I have not noticed any discomfort in operation, although many experts say that it is possible to erase information in the computer. I just try to let the car idle for up to 3 minutes when starting the engine.

- Injector-injected cars are not very fond of charging and starting devices, since when they are used, the voltage jumps significantly and the ECU can burn out.

The engine starts and stalls: troubleshooting

So, if a similar problem appears, then it is necessary to take into account a number of features. First of all, the operation of the internal combustion engine after startup will be influenced by the following factors:

- fuel supply;

- air supply;

- spark on spark plugs (for gasoline internal combustion engines);

- correct operation of glow plugs (for diesel engines);

- proper operation of the ECM and electronic sensors;

With that said, you should first start by checking the main possible causes:

- Quite often, malfunctions in the operation of the alarm system and the anti-theft system can cause the engine to fail to operate after starting. In other words, the immobilizer does not turn off and continues to block the start of the internal combustion engine, which is its main function to prevent vehicle theft. If the alarm blocks the engine, then you need to check the operation of all elements, try to reset the error, turn off the anti-theft system, etc.

- Problems with the IAC and idle air valve often arise due to contamination of these elements. You should also pay attention to the cleanliness of the throttle valve. As for the crankshaft sensor, incorrect data that it transmits to the ECU can cause the engine to stall immediately after starting.

- Poor quality fuels and lubricants can also cause problems. As a rule, problems begin in cases where low-grade fuel was filled or the engine uses motor oil that does not meet the recommendations/has lost its properties.

- A faulty fuel pump, air leaks in the fuel line, the formation of air pockets and dirty fuel filters do not allow creating the required pressure in the power system or supplying fuel in the required volume.

- The air filter and its contamination leads to the fact that the working mixture is significantly over-rich. In other words, the engine does not have enough air to burn fuel, and the spark plugs flood.

- Problems with ECM sensors (EGR sensor, oxygen sensor, DPKV, etc.) can lead to both unstable engine operation at idle and a complete engine stop after starting.

Now let's look at the most common problems and how to fix them, looking at them in detail.

- First of all, the culprit may be the low level of fuel in the gas tank and its quality. If gasoline or diesel fuel runs out, then the engine will start using the remainder in the power system, but further operation will be impossible.

Moisture accumulation on the distributor cap

Sometimes in the mornings or during rainy weather and heavy fog, the driver notices that his car runs absolutely smoothly at idle, but when the engine is pressed, the engine suddenly stalls. In this case, the reasons for this behavior of the motor are due to the accumulation of moisture (condensation) on the distributor cap. This can only happen in certain machine models that have a specific design that retains condensation.

After pressing the gas, the distributor speeds up its operation and begins to pass more current through itself. With high humidity, the chance of misfire increases significantly when the engine does not have enough spark. and as a result it stalls.

It is quite simple to detect this reason - you need to carefully monitor whether this problem occurs in dry weather and on a warm engine. If not, then to eliminate this problem, make sure that the car is in a garage in wet weather and warms it up well before driving, as it is important to prevent moisture from getting on the distributor cap. If possible, it is better to replace the cover itself with a suitable one, but of a different configuration.

The fuel pump screen is clogged

For cars of the VAZ family with an installed injector instead of a carburetor, it is typical that the car starts and stalls. Sometimes the reasons for the engine stopping on its own are due to a malfunction of the fuel pump. If the car stalls immediately after starting, but then starts, the problem lies in a clogged fuel pump cleaning screen. In this case, you need to replace the mesh with a new one and enjoy the further movement of the car.

Recommendations

And how did the epic end? I have similar syndromes =(

remove the chip from the mass air flow sensor and start it! If it doesn’t help, then put it back on and take it off. Even if the pump dies, then at xx it will create the necessary pressure, but in power mode it will not work! pull the chips and look!

So, I’ll check with the MAF tomorrow morning, but if I reset the MAF, it generally stalls immediately after starting, but sometimes it lasts for 5-20 seconds, but then it dies immediately. What else to watch? I installed the new phases, for some reason they are shorter than the old one, by 0.2 cm somewhere, +- 0.1. Rxx seems to be working, I checked it as a direct plus, according to the book it was written to check the central socket and the side ones (in turn), it closes, I check the two outer ones, it also closes, although nothing is written about the outer sockets... The mass air flow sensor is also intact, it seems like it gives out 2.80 ohms and not the norm of 2.6 as it should be...what is the reason?

according to IAC - everything depends on the ECU firmware! DPRV - question to the manufacturer DMRV - it is still a sensor and it also has brains!

filter, there’s nothing else, and maybe a fuel filter, but then it won’t work

I changed the filter, the old one was spinning the same way, they blamed it, but it didn’t turn out that way...

Guys, I’m sorry that it’s not much on topic, but I hope that there’s nothing wrong with it, on the contrary, at idle it works for me, when I press the gas pedal, it feels like there’s either not enough fuel, or it’s terribly overflowing, periodically this overflow or The lack of fuel disappears and the car drives quite normally. What could be, where to go? Thanks for understanding. Machine 3102 with ZMZ 406.

I had this happen because of the injectors.

Do you think it's worth cleaning? Or should I change it anyway?

Cleaning didn't help me, I changed it

Thank you. I'll try to clean it tomorrow

I agree with what was said above on my own - after replacing the filters, if that doesn’t help, try to measure the pressure of the fuel line. 1 the pressure of the pump without a fine filter (in front of the ramp) should be at least 4.5 kgcm 2 at idle, the pressure in the rail should be at least 2.5 kgcm3 most likely The check valve on the fuel rail failed, I replaced about a dozen at one time until I found an old model - a dismountable one - all the problems with idle were gone, good luck

really? because if I give it gas, everything is perfect, it doesn’t hold idle even for 5 seconds, it stalls...

It was due to a clogged filter in the tank (pyramid)

if the fuel pump makes a lot of noise, it means it will soon grunt, I had this happen, you can last a month on this, but apparently it needs a replacement

Gas 3110. ZMZ 406 (injector). Doesn't hold idle, starts normally, if you press the pedal it's also OK. The fuel pump is humming, you can hear how good it is humming. Compression is 12 points, all sensors have been checked and replaced, the injectors have also been checked and blown out. The camshafts are honestly as they should be, and needless to say, they have jumped a tooth. What is the reason? The idle speed sensor works. The damper also seems to say everything. Where should I go? We haven't looked at the phase sensor yet. And could this be due to the pump? Should it make a loud noise?

And how did the epic end? I have similar syndromes =(

remove the chip from the mass air flow sensor and start it! If it doesn’t help, then put it back on and take it off. Even if the pump dies, then at xx it will create the necessary pressure, but in power mode it will not work! pull the chips and look!

So, I’ll check with the MAF tomorrow morning, but if I reset the MAF, it generally stalls immediately after starting, but sometimes it lasts for 5-20 seconds, but then it dies immediately. What else to watch? I installed the new phases, for some reason they are shorter than the old one, by 0.2 cm somewhere, +- 0.1. Rxx seems to be working, I checked it as a direct plus, according to the book it was written to check the central socket and the side ones (in turn), it closes, I check the two outer ones, it also closes, although nothing is written about the outer sockets... The mass air flow sensor is also intact, it seems like it gives out 2.80 ohms and not the norm of 2.6 as it should be...what is the reason?

There may be several reasons why the car engine stalls when you press the gas after idling. But the good news is that each reason that the engine stalls when you press the gas has its own conditions, additional symptoms, so each of these reasons is not difficult to determine. Therefore, it is important to understand the situation when this problem occurs. Therefore, let's take it in order, in order of prevalence, of the reasons for the engine stopping while trying to start!

The engine stalls when you press the gas only in the morning or in humid weather. Cause: Moisture on the distributor cap

If the problem occurs only in the morning, when the engine is still cold, or in rainy or cloudy weather, then this means that the cause is moisture on the ignition distributor cap. This happens because at night, especially when it rains, condensation occurs inside the distributor cap. And the shape of the ignition distributor cap of your car model may be such that it allows the electric current inside the distributor to misfire, as a result of which the electricity simply does not reach the spark plugs.

Can weather affect engine performance?

If the engine stalls when you press the gas pedal, then pay attention to the weather. If this situation occurs in humid air or rain, then a lot of moisture may have accumulated on the distributor. When there is high humidity or rain, water gets on the ignition distributors. This happens because when the car sits for a long time, a damp environment forms inside the distributor cap.

Often the shape of the distribution cap allows the vehicle to misfire. As a result of this misfire, electricity stops flowing to the spark plugs. At idle speed this problem may not occur. This situation occurs mainly when you press the gas pedal.

The fact is that if you press the pedal, the distributor starts working much faster. Much more current begins to flow through it. If the environment is humid, then the likelihood of misfire becomes greater. As a result, the engine does not receive the required amount of “spark” and stalls.

It is not difficult to confirm the presence of just such a reason for the car’s failure. To do this, you need to pay attention to whether this problem occurs when the engine is warm and the weather is dry.

If the weather is still damp and you need to check the machine’s functionality, you can simply put the car in the garage for a certain period of time.

Complete sabotage

The most deplorable situation, the engine does not start at all.

First of all, you need to maintain composure and not scold the car itself. Only after this, we calmly begin to find out the reason why the engine does not start.

Do not allow the battery to be severely discharged by pointlessly rotating the engine crankshaft, the energy will still be useful to you, but where you will charge the battery if you are far from home is the question. Although for the electronic unit itself 8 Volts will be quite enough. But, of course, they won’t be enough for the starter.

When you have calmed down, be sure to check:

- How does the fuel pump work and is there any fuel in the tank?

- Is there ignition?

- Is the engine crankshaft timing sensor functioning?

- Have the injectors failed, although the failure of several injectors at once is too much, this happens very rarely.

- The ECU is working. But this device also fails very rarely.

Vacuum leak as a possible cause of engine stalling

If, when you press the gas pedal, the car refuses to move regardless of weather conditions, then the problem may be more serious. The car's fuel system has probably failed. There is often a vacuum leak. With this problem, the engine starts to stall occasionally, then the problem becomes more frequent.

Vacuum leakage negatively affects the state of the air-gas mixture. Therefore, the engine stalls when a person presses the pedal.

A vacuum leak can also be identified by looking at the Check Engine Light. However, such diagnostics can only be carried out by a highly qualified specialist. It is necessary to take the car to a service center, asking them to check the vehicle for leaks.

Car service to help

Read:

If you decide to contact a car service, first of all carry out engine diagnostics. Few inexperienced drivers understand the cause of the breakdown. At the same time, the Gazelle 405 may not start for various reasons, and some of them can be resolved on the spot.

When you finally take your car to a car service center, at least consult with its employees; most likely they will tell you what the problem is.

It is very important to know absolutely everything about your car.

to protect yourself on the road and do extra work. Sooner or later, any part can break, but it will be better if you are prepared for this.

What's the result?

As you can see, there are quite a few reasons why the engine starts running and stalls after starting. However, most of them are usually associated with the fuel system, ignition system and electronic control system.

In this case, it is appropriate to talk about low compression in the cylinders due to the fact that the engine has exhausted its service life (the cylinder walls, rings, etc. are worn out), that is, the unit needs major repairs. Compression can be measured at a service station or yourself using a compression meter.

The engine stalls at idle: what to check. Possible causes of malfunction on engines with a carburetor, injector, and diesel power plants.

At idle the speed “floats”: why does this happen? The main malfunctions associated with idle speed on gasoline and diesel engines.

The main reasons why the engine starts to stall after warming up. Frequent problems of carburetor and injection engines, fault diagnosis.

The reasons why, after pressing the gas pedal, dips occur and the engine begins to choke. Gas engine failures when switching from gasoline to gas.

Why the engine may not pick up speed: gasoline engine, diesel unit, car with LPG. Fault diagnosis, useful tips.

Reasons why the engine may stall when you press the brake. The power unit stalls during sudden braking, when the clutch and brake are depressed, etc.

Why doesn't the injection Gazelle 405 start? Main reasons

There are various difficulties with cars, unfortunately the Gazelle 405 injector won’t start

for some reason in most cases. Drivers begin to rack their brains, but from time to time it is impossible to find a solution to the problem in any case.

At the moment, several more possible breakdowns will be considered, during which the car will not start.

When this happens, the first thing our client needs to do is look at the wires, spark plugs, rail pressure and injectors. In most cases, the Gazelle 405 injector will not start specifically because of the spark plugs, so just change them. Alas, when problems arise that are more serious than candles.

see also

Comments 13

This happened when there was a problem with the phases! But no gases go into the coolant reservoir?

3828 number of the TOZh sensor for the 406 engine

100 poods, the temperature sensor is dead, which on the thermostat housing faces towards the radiator.

To check it, I think you need to screw in the same one, only a new one.

The owner of this motor says that it was installed new. I don't think it's about him.

but the engine won't start after you turn it off

It starts after it cools down to 55 degrees.

Then without a doubt, this is the sensor I'm talking about, I had the same thing. You just need to take it from the 406 motor, the price is 200 rubles. Sometimes from 405 or 402, but they do not work correctly.

The owner of this motor says that it was installed new. I don't think it's about him.

So what if there’s such a new percentage of marriages, mom, don’t worry. Yes, and look for 406, because... available on 405 and 409.

To check it, I think you need to screw in the same one, only a new one.

You just need to turn it off. Mosk will work according to average indicators and if it is successful, then the problem has been found.

Replacing the sensor

Replacing the sensor is possible in a garage, but if the driver does not have the proper skills and knowledge of how the car works, you should entrust the replacement of the IAC to a car service center to avoid making mistakes.

Replacement occurs as follows:

- It is necessary to completely turn off the ignition and remove the key.

- Then remove the negative terminal from the battery.

- Using a thin flat screwdriver, unclip the block clamp and disconnect the regulator connector.

Ignition system

Spark plugs and high-voltage wires directly affect engine starting. Accordingly, breakdowns in the elements will cause a failure of the entire system. To check spark plugs, a special stand is used, although you can check it the old fashioned way:

- We unscrew the candle from the well.

- We connect the armored wire.

- Connect the spark plug body to ground.

- We try to start the engine.

If everything is in order with the spark plugs, then there will be a spark between the contacts. If the part is faulty, then there will be no spark, and accordingly, the element must be replaced. Checking armored wires is quite simple. All elements are removed from the car and measured by a tester. The resistance on each high voltage wire should be 5 ohms.

Ignition problem

If the car has ignition problems, the spark is very weak. If you press the gas sharply, the spark plugs are filled. The spark plugs are lit and the spark fades.

It is not difficult to test this hypothesis. When unscrewing the spark plug, it will become noticeable that it is wet. If there is a suspicion that there is a problem with the ignition, it is necessary to check the entire system.

Long-term service of spark plugs can lead to problems such as penetration into the housing.

Checking high voltage wires can be done using a spare kit. If it is missing, you can start the engine at night by looking under the hood. If the wires are damaged, current discharges may occur.

If a breakdown such as the car stalling when you press the gas is a frequent occurrence, then it is better to seek help from professionals.

Failure Traits

If the engine malfunctions, the following characteristic features will occur:

- The car stalls when you turn on devices or other equipment powered by the on-board network.

- The operation of the BC is disrupted due to voltage surges.

- When a load is applied, the engine stops immediately.

- You can hear the sounds of the alternator belt spinning.

- If the operation of the generator is disrupted, then as the speed increases, the headlights begin to burn better and brighter.

Sometimes these problems are not related to the malfunction of the generator, but to other problems of the car.

see also

Comments 23

shoots into the launcher when the mixture is still lean

The valve timing marks were set incorrectly

YES, IT STARTED, but it runs on gasoline and on gas it shoots into the intake manifold. and the car quickly heats up and gases go into the exhaust tank. although the head was milled along the plane and measured...

also won't start after repair, only 402

and after starting the engine, dial from 1000 to 2700 rpm in 15 seconds, 3-4 times, to expel the air from the hydraulic compensators, then the engine will start to whisper, well, if you assembled it well))) on the first start there is usually noise

The high voltages may not have been attached correctly

look at the correct connection of the armored vehicles to the kateshkoh, it was like this

if there are pops, check the phases. They were right about the damper. and are all sensors connected?

and the wires are the same as 406 1-4 and 2-3

This can happen even if the car has been parked for a long time, it’s a fact

pull it in tow, the hydraulic compensators have lost oil and the clearance on the valves is completely different, or even there is no compression at all, pull it in 2nd-3rd gear for 700-1000 meters, the compensators will pick up oil and everything will fall into place, compression will appear in time

very good advice! There are no words for it!

pull it in tow, the hydraulic compensators have lost oil and the clearance on the valves is completely different, or even there is no compression at all, pull it in 2nd-3rd gear for 700-1000 meters, the compensators will pick up oil and everything will fall into place, compression will appear in time

Read more: Lamps in the headlights of a Polo sedan

+1 There was exactly the same situation, with the same engine, we took it in tow, drove it for 300 meters, everything worked.

One day the Gazelle stopped starting? The reason lies in engine malfunctions. The problem may be related to both the mechanical part and the electrical part. To fix the problem, you will have to diagnose a number of parts.

Gas distribution mechanism (GRM) and breakdown of internal parts of the power unit

The gas distribution mechanism consists mainly of a crankshaft with a group of pistons and camshafts with intake and exhaust valves. Driven by belt or chain drive.

Each of the shafts must have a certain position during engine operation, but it also happens that a large wearout of the belt, chain or gear with sprockets leads to the fact that any shaft begins to either advance or be late in performing its functionality.

This is called incorrect ignition timing adjustment.