23.06.2014

Engine assembly

Let's look at the reasons why the engine won't start. What are the solutions and what should a person who finds himself in this situation do? We will talk about Samaras with an injection engine, since there are few carburetor ones left today.

If we are talking about the cold season - you did not start in winter, then there are several nuances regarding the engine starting algorithm. Perhaps your candles have flooded or something else. To study this issue more specifically, read the article: How to start a car in cold weather? Where the algorithm is described and, again, possible causes of the malfunction.

Now we will talk more deeply about the technical part, since “winter factors” are no longer needed.

We will describe the problems in the order of the actions taken: that is, starting from the inserted key and ending with the operation of the engine.

The starter works, the engine turns, but the car does not start

So, the starter, like the engine, the pistons move, but the engine still won’t start. There is already a problem here, most likely in the fuel-air mixture, perhaps the marks have come off, etc.

Before you sin on this, the first thing you need to pay attention to is the crankshaft sensors:

DPKV - if it malfunctions, it is very difficult to start the engine, and once it is running, it runs unevenly, intermittently, and the power drops noticeably.

Next you should pay attention to the labels:

- Mark on the timing camshaft gear (photo).

- Markings on the flywheel under the thermostat (photo).

If the marks do not match, most likely the belt has simply slipped by one tooth. The camshaft gear itself may be worn. It needs to be adjusted and installed correctly!

Next we will talk about the air-fuel mixture.

I warn you in advance that the easiest way is to do computer diagnostics of the engine or look at the errors on the on-board computer.

The air-fuel mixture is the combination of air, gasoline, and the spark needed to ignite it.

Air supply

As a rule, a malfunction in the air supply should not affect the engine starting problem. At the very least, the engine should still run. Nevertheless, let's not bypass the air system.

The following sensors are responsible for air metering and supply:

- Mass air flow sensor is the most expensive sensor. If it fails, then the car simply begins to consume liters of gasoline, then this sensor can simply die “to zero”, but it indirectly affects the starting of the car. This means, no matter how it fails, the car should start.

- The IAC should not affect the engine starting problem. If it malfunctions, problems arise from idle.

Spark

Here may be the real reasons for our problem:

- First of all, we look at the candles. We turn them inside out (How to remove candles?) and look at their condition. Normal ones should have a slightly brick color, if they are wet, the candles will flood accordingly. It is necessary to clean and bleed the cylinders by idling the engine with the starter with the spark plugs turned out. If one cylinder is flooded, the problem is local (high-voltage wires, faulty spark plug, injector), all cylinders are flooded - a general problem (ignition coil, brains, oxygen sensor, fuel pressure in the rail).

- Next, check for the presence of a spark. To check it, check out the following article: How to check the spark?

Examination:

- If there is no spark on one cylinder, there is a faulty spark plug or high-voltage wire.

- If it is missing on two adjacent cylinders (1-4 or 2-3), then the problem is in the ignition coil or in the ECU.

- If there is no spark anywhere, the problem may lie in the ignition coil or ECU, in mismatched timing marks, or inoperative DPKV.

- If there are no problems with the presence of a spark, then the cause of the malfunction lies in the fuel supply.

Fuel supply

Two points are very important here:

- normal fuel pressure;

- working injectors.

If, when you turn the key into the ignition, you do not hear the fuel pump pumping, then that is where the problem lies. First of all, we measure the pressure in the fuel rail (How to measure pressure?) and draw the appropriate conclusions.

High pressure coupled with a malfunctioning fuel pressure regulator can instantly flood the engine.

Ignition problems

Most often, the reason lies precisely in one component of the ignition system. Weaknesses that are the first to come under suspicion are:

- egnition lock;

- induction coils;

- starter and ignition relay;

- lack of voltage at the battery terminals.

Most often, the problem lies in a banal lack of voltage at the ignition switch contacts. It is supplied directly from the battery to the starter.

If, after turning the key, the dashboard goes out or does not light up at all, it may be a problem with the cylinder.

Checking the functionality of the ignition switch is relatively simple:

- it is necessary to dismantle the larva;

- Using a multimeter, the contacts are called in different positions.

If there is no contact, then you should simply purchase a new lock. It simply doesn't make sense to repair it.

You need to pay attention to the behavior of the car immediately after turning the key. If there is no characteristic clicking sound from the side of the door from under the panel, the relay has probably failed. It is located above the clutch pedal.

Like the ignition switch, it simply does not make sense to repair such a relay. You need to purchase a new one and install it in place. You also need to check the ignition coils. Often the spark on the spark plugs disappears due to their failure. The test must be carried out by removing the coil and connecting it to the tester. You should ring the windings - a break in one may be the cause of the malfunction.

We recommend: Oils for Nissan

If you have problems starting the engine in cold weather, you should make sure that the battery is working properly. Often it simply fails.

It is not difficult to check the condition of the battery using a conventional tester - you need to switch it to the constant voltage measurement mode and set it to the 20 V limit.

The voltage between the terminals should be 12.6 V. It would also be a good idea to measure the density of the electrolyte using a hydrometer.

Replace the mass air flow sensor

The mass air flow sensor regulates how much air needs to be added to the gasoline mixture for optimal ignition of the fuel. The sensor constantly reports data to the car's computer about the amount of oxygen supplied. A faulty mass air flow sensor increases fuel consumption, increases CO2 levels in the exhaust gas, and reduces engine power and smoothness. Also, if the sensor is faulty, poor acceleration dynamics are observed. In cold weather, a car with a faulty sensor has difficulty starting.

What are the reasons for the failure of the mass air flow sensor: Most sensor failures occur due to improper installation of the air filter during its scheduled replacement. Also, if you do not regularly change the air filter, as required by the vehicle maintenance regulations recommended by the manufacturer, the mass air flow sensor may fail.

What you need to do: Theoretically, you can drive for a long time with a broken mass air flow sensor (several weeks or months). But you will notice that the longer you drive, the more your fuel consumption increases. Replacing the sensor in a car service is not that expensive, since the work itself does not take much time and is quite simple. The main costs are related to the cost of the sensor, which for some car models can be 11,000-14,000 rubles if it is an original sensor or up to 6,000 rubles if it is an analogue substitute. Replacing the sensor yourself is very simple. But due to the low cost of replacing the sensor, you can entrust this work to a mechanic at a car service center. Remember that you need to regularly change the air filter, observing the vehicle maintenance regulations!

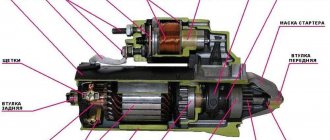

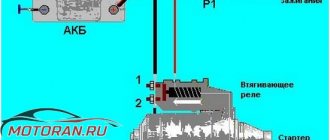

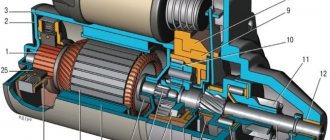

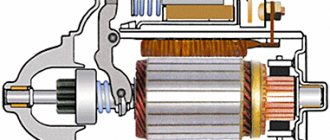

Starter failure

If all other system components are in order, then the reason for the inability to start may lie in the absence of a starter. Typical problems:

- poor contact at the terminals;

- the starter shaft bearing has failed;

- The solenoid relay has stopped working.

It should be noted: the location of the power terminals on the starter suggests the presence of moisture. Therefore, often the contact simply oxidizes, which leads to problems in the operation of the device. That is why you need to carefully examine the contacts. Then clean them and check the voltage. If it is missing, there may be a break in the wiring.

We recommend: Easy replacement of the timing belt on the Opel Astra H 1.6 Z16XER

When there is voltage, but the starter does not turn, it is often a problem with the bearings. To replace it, you will need a clean garage, as well as a special puller. This is the only way to dismantle it.

A little more often than a bearing, the solenoid relay fails. Sometimes it just jams - just tap it lightly with the key.

It is very simple to check the functionality of the retractor - just place the starter on the engine block and then touch the contact of the wiring relay connected to the positive terminal. If the starter starts spinning, it means the solenoid relay is in working condition. All of the problems listed above are typical and do not require any major repairs.

The starter turns, but does not start: VAZ carburetor

A common failure on classic models. There may be three reasons for this:

- ignition;

- air and fuel lines;

- carburetor.

However, during repairs it is necessary to check both branches.

Ignition failures

Failure to supply a spark is one of the causes of failure. The sequence of actions looks like this.

- Checking the spark on the spark plugs. The element is unscrewed from its socket. Next, without removing the cap from the stud, you need to attach the spark plug to the engine block and crank the starter. If at this time a powerful spark appears on the electrode, the part is in good condition. The procedure must be repeated for all pistons. If there is no breakdown, the element is replaced with a new one.

- Circuit breakers. Burnout of fusible links is common among carburetor cars.

- High voltage cables. If replacing the spark plug does not help (there is still no spark), the armored wires need to be checked. The ideal option would be to diagnose by replacing the cable with a known good one.

Note! Checking armored wires and spark plugs is carried out in a dark room. If the cable or spark plug body is broken, the electric arc can jump anywhere in the line.

- Distributor. It is necessary to remove the top cover of the part and inspect the ember, contact points for the presence of carbon deposits and melted areas. For systems with electronic ignition, the coil and Hall sensors are checked.

- Ignition timing. From time to time, carburetor models require adjustment of the distributor angle. You can set it correctly yourself. There are corresponding notches on the body of the mechanism and the engine block. For accurate positioning, you must read the instructions for the car.

In some cases, the car may not start due to loose starter wiring, battery or battery discharge.

Air and fuel supply

The next reason why the starter turns, but the car does not start may be due to a malfunction in the supply of the combustible mixture. The sequence of actions looks like this.

- Initially, the filter elements, air and fuel, are checked. Interruptions in the supply of gasoline or air are the primary source of the problem, when the starter turns, seizes, but does not start - clogged inserts prevent the free flow of fluid.

- The next stage is the fuel pump. When cranking the starter, you need to listen to the details. If the unit does not pump fuel, starting the engine will be impossible.

Note! In some car models (VAZ 2101/06), a common cause of breakdown, when the starter turns but the car does not start, is overheating. To eliminate the defect, simply moisten a rag with cold water and wrap it around the pump. After cooling, the car will start.

- Air leaks are also a common cause. The user is required to check all hoses and pipes for loose clamps, cracks or abrasions. Damaged elements are replaced with new ones.

- Line blockage. Sediment rising from the gas tank can clog the thin tubes, preventing the free flow of gasoline.

Carburetor

If all manipulations with the lines and the fuel supply system have not brought results, the next step is to check the cleanliness and accuracy of the carburetor settings.

The mechanism is riddled with thin passages and bypass valves. If low-quality gasoline gets in, the channels quickly become clogged and block the movement of liquid. During repairs, the carburetor is completely disassembled and the jets are cleaned - this is best done with compressed air or thick fishing line. It is also necessary to blow out all the holes, after rinsing the structure with clean gasoline. After cleaning, the mechanism is assembled in the reverse order.

Note! During repairs, special attention must be paid to the throttle valve and jets - these elements are most often the source of trouble.

Replacing spark plugs and high-voltage wires

Spark plugs in a car are the main components for igniting the fuel mixture. If the spark plugs are faulty, the spark will not be supplied correctly to ignite the gasoline mixture. Faulty spark plugs often result in a lack of spark or an incorrect spark interval, which results in the engine not running properly. If the spark plugs do not work properly during acceleration, especially from a standstill, you may feel slight jolts.

What are the reasons for spark plug failure: Most spark plugs in cars produced before 1996 need to be changed every 25,000-30,000 kilometers. In newer cars, spark plugs last more than 150,000 km. However, these scheduled spark plug replacement intervals may be reduced by various factors related to fuel quality and driving style.

What needs to be done: If your spark plugs have not been changed for a long time, or you feel failures in the engine operation associated with ignition, then you must immediately replace them with new ones without delay. Do not try to save money by untimely replacement of spark plugs, since the cost of spark plugs is not very expensive, as well as the work of replacing them. By replacing old spark plugs, you will improve engine performance and reduce your vehicle's fuel consumption. Changing spark plugs yourself is quite easy. Basically, they are easily accessible under the hood of the car. You need a regular spark plug wrench to remove the spark plugs from the engine. It is also advisable to monitor the condition of high-voltage wires, since over time they can become unusable and allow electricity to pass through, which is transferred to the spark plugs, which will reduce the strength of the spark. Remember that regularly replacing spark plugs, in accordance with your car’s maintenance schedule, protects your exhaust catalyst from breakdowns and also improves engine performance!

Didn't find the information you are looking for? on our forum.

Check the fuel filler cap

Many drivers, in most cases, when the “check engine” indication appears, will think about serious problems in the car’s engine, but will not even think about checking the tightness of the fuel system, which may be compromised due to a defect or an insufficiently tightened fuel tank cap. This is a very common reason for the appearance of the “Check” engine icon.

Reason for the error: Leakage of the fuel system due to the passage of air through the filler cap of the fuel tank will increase the vehicle's fuel consumption, to which the vehicle's diagnostic system will generate an engine error by turning on the "Check engine" indication on the vehicle's instrument panel.

What needs to be done: If, when the “Check” indication appears, your car has not lost power, and there are no audible signs of engine damage (engine knocking, humming, creaking, etc.), then first check the gas tank for leaks. Your gas cap may be cracked or not tightened enough. If the cap was not tightened enough, then after tightening it all the way, continue driving the car for a while to see if the engine error disappears. To prevent a check engine light from appearing for this reason, check your fuel filler cap regularly. Remember that the cover must be replaced with a new one periodically!