Let's start with the fact that my typewriter is one year old. This year there have been few pleasant things and many not so pleasant ones. Ran 31 thousand kilometers. Main mileage: Kashira, Stupino, Moscow, several trips to Tula.

I have long been tormented by a strange knocking sound from the engine when cold. It didn’t cause any particular panic, as the engine warmed up and the knocking noise disappeared. And at 29,000 kilometers, the tapping stopped disappearing after warming up and even brought with it a crackling sound when starting off. Alternator, exhaust system, CV joint, front bumper and this is not a complete list of what I checked. There was still a pump and an automatic timing belt tensioner pulley, I opened the casing, but didn’t see anything suspicious. I went to a friend's service center to look at it with a more experienced eye. Based on the sound they said the pump, they opened the timing case and, sure enough, the timing belt was running along the pulleys. What I was most afraid of was this diagnosis because there are no spare parts for the Lada Grant at all. I surfed the forums and Drive2, found a couple of cases where a pump from a Priora was installed, it was said that the difference was only in the width of the pulley, and even then not by much.

Engine Cooling Water Pump

Here it is, a mine - a water pump. Refers to the cooling system, but is driven by a timing belt. If the pump wedges due to the death of the bearing, it will cut off the teeth on the belt, and then there will be destruction in the motor. And they “forgot” to mention this detail in the routine maintenance section of all service books.

New VAZ engines are now equipped with high-quality timing belts from well-known brands. I believe that if no oil gets on it, it will cost 180 thousand. But is the difference in components really so great that on the 8-valve VAZ-11186 for Granta the belt must be changed at the 75th thousand, and on its closest relative VAZ-11189 at the 180th?

Let's continue the research. The pulleys are not demolished at all. Pressure roller bearing up to 180 thousand? Let's admit it, although it's hard to believe. But why change all this equipment at the 180th thousand, if the estimated life of the engine is 220 thousand km? Refresh before demise or major overhaul? If you don’t believe me, look at the photo taken in the workshops where VAZ engines are produced.

Timing belt

How would you act on your own without clear instructions in the service book? On both an 8-valve and a 16-valve engine, I would change at least the pump, and better yet, the belt and tensioner between the 60th and 70th thousand kilometers. According to the period, if the mileage is small, for the sixth year of operation.

hi guys))) please tell me when to change the pump on a Priorika 16 cl? I changed the belt, and now I regret that I didn’t replace the pump... what is its service life? When replacing the belt, I twisted it without jerking, there is a small play but it doesn’t leak ) mileage 61000

Now that I'm tired of washing the gray insert

by Adminrive · Published 10/07/2014

In general, who is from Moscow

by Adminrive · Published 07/30/2015

Replacing parts on different types of engines

How to change a pump on a Grant with an 8-valve or a 16-valve, there is not much difference. The algorithm described above remains unchanged, taking into account one nuance: on the “eight” the crankshaft is equipped with one pulley, on the “sixteen-valve” - two. The replacement procedures will be identical, but when working with a 16-valve engine, the car enthusiast will need more time to complete the work.

It should be noted that when purchasing a pump, you need to pay attention to what type of engine the product is intended for. The packages are marked so that the car enthusiast can select the right part for an 8-valve and 16-valve engine, respectively.

Procedure for replacing the pump on 8 valve engines Grants VAZ 11183 (82 hp) and VAZ 21116 (87 hp)

To begin, we disconnect the battery as standard and drain the coolant. You will need keys 10 and 17 and 2 screwdrivers.

Also, replacing the pump on a Grant 8 valve is slightly different from the 16 valve versions. These are differences in the dismantling of protective covers; in general, dismantling occurs according to the principle of removing the crankshaft pulley and the rear timing cover.

When replacing or removing the pump to check, it is necessary to notice the gasket that connects the pump to the engine block. This is a prerequisite for the tightness of the cooling system.

If you have wondered what kind of gasket is on the Lada Granta pump, the answer is simple - it is mainly a paranitic gasket for the tightness of the system. Many craftsmen and car enthusiasts are sure that it should be lubricated with sealant. Don’t be lazy and compare pumps when purchasing and choose only high-quality, albeit expensive, products.

Korean-made coolant pump for VAZ-21179 engine

The owner of any elderly foreign car with a timing belt will confirm that repairmen insist that during a scheduled belt change, they replace both the pump and the pressure rollers with bearing assemblies. And these parts are often sold as a set. Moreover, at a discount - the whole set is cheaper than the belt, rollers, and pump separately.

I don’t want to once again convince you that the stingy pays twice, but over the years I have come to the conclusion that Western manufacturers include in the regulations changing the belt not because of the belt as such, but because of the pump and tensioner bearings. They just needed a reason to reliably replace the entire set of parts associated with the camshaft drive, and they found it.

I propose to do the same with our engines. Why? Formally, at each maintenance it would be necessary to remove the cover and inspect the timing belt and water pump. You can see a tear in the belt, as well as a leak on the pump. In both cases, the part is changed without delay. But this is a malfunction. And if everything is outwardly normal, the ideal option is to include preventive replacement in the regulations.

Symptoms of malfunction

- Noise from the pump when the engine is running. Extraneous sound appears due to bearing wear. It is recommended to replace the cooling system pump after one or every replacement of the timing belt kit. If you neglect service intervals, wear appears on the rolling elements, inner and outer races, which leads to noise and whistling. Often the cause of accelerated wear is antifreeze, which, due to a leak in the oil seal or rubber cuff, gets to the rubbing vapors.

- Antifreeze leak. Like the pump bearing, the oil seal and rubber seal have a limited service life. The appearance of play due to bearing wear will significantly increase the risk of seal leakage.

- Misalignment with respect to timing gears and rollers (the pump becomes askew). Uneven tension distribution leads to accelerated wear of not only the bearing, but also the oil seal. Incorrect installation or a manufacturing defect, in which the pulley rotates misaligned, leads to accelerated wear of the loaded part of the belt. Such a defect, even with low mileage, can cause the timing belt to break and the valves to meet the pistons.

- Engine overheating. When the impeller blades break off, the pump's performance decreases, as a result of which less coolant passes through the small circulation circuit.

Often a decrease in performance is noticed after using a sealant to repair a radiator leak. The poured mixture clogs the cooling system channels and sticks to the pump impeller.

If the liquid has not clogged the coolant drain channel in the housing, then pouring sealant will not lead to a malfunction of the water pump. But you can’t do without removing the pump and flushing the system.

Signs and causes of failure

You can identify a broken part by the following signs:

- insufficient circulation of coolant and, as a result, frequent overheating of the engine;

- presence of smudges at the pump mounting location.

hum of bearings at the pump mounting location;

These markers indicate the most likely causes of malfunctions in the Grants pump:

- bearing wear or damage;

- damage to the seal;

- worn sealing gasket;

- broken pump impeller.

In most cases, the part becomes unsuitable for major repairs and requires a complete replacement. Ignoring pump problems leads to replacing the timing belt and replacing components of the connecting rod and piston group. Valves and bearings may also need to be replaced.

Why do you need a pump in a car?

The power unit of any vehicle works in close connection with the cooling system. Constant circulation of antifreeze (or antifreeze) through the system ensures proper cooling of the engine and protects the rubbing parts of the engine from overheating. Accordingly, if there were no cooling system, the motor could not be considered a working unit - at the first load it heats up to a critical temperature and boils.

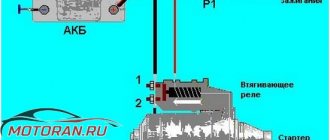

The operation of the cooling system fits into a simple scheme:

The driver pours antifreeze into the expansion tank.

After the engine starts, antifreeze begins to flow into the pump cavity.

From there, the fluid under pressure is directed to the radiator device and to the cylinder block.

Accordingly, the pump in this scheme plays the role of pumping equipment, which ensures the continuous supply of coolant to the engine.

The device is made of hard metal alloys, which allows you to extend the service life of all moving and rubbing parts of the pump

On the Lada Granta, the pump starts when the engine is ignited. The pump itself is part of the gas distribution mechanism: its impeller blades will rotate as long as the pulley rotates through the timing belt.

How to choose a pump for a VAZ

There are several signs that determine the correct choice of pump for a car. Moreover, each parameter is taken into account individually - there is no universal method.

The pump impeller can be:

- plastic;

- metal.

The first option has the advantage of having no inertial load, which makes it easier to unwind when the motor starts. The downside is the short service life and changes in the geometry of the wings under the influence of high temperatures - this reduces the efficiency of the pump. New foreign cars are equipped with impellers made of expensive materials that can withstand overheating and cavitation abrasion.

The second type is made of metal. Such impellers are heavier, take a long time to spin, but do not change geometry when heated. On the other hand, steel parts quickly become corroded when the wrong antifreeze or water is used in the cooling system, which critically reduces their performance.

According to the design, you should choose impellers with a minimum gap between the housing and the blades. This combination minimizes idle rotation of the mechanism and increases the efficiency of the unit.

The manufacturer recommends using parts of the same brand. If such pumps are not available, you should study reviews of the available company in advance and choose the best one at your own discretion.

Signs of a pump malfunction on a Lada Granta car

"Lada Granta" continues the best traditions of the automotive industry of the domestic plant, and therefore its design does not cause any particular difficulties in diagnostics. To identify a pump malfunction, you do not need to look at the instruction manual or contact the services of a service station specialist. There are only three signs of a water pump failure that the driver can identify on his own.

The engine started to get very hot

If the Granta, even in winter, starts to get very hot while driving, and the fan can no longer cope with cooling the engine, then this is a clear sign that the pump has failed. The thing is that the presence of coolant in the system does not yet guarantee engine cooling, since if there is no pressure, then the liquid simply will not flow to the cylinder block.

You can confirm your suspicions in a fairly simple way:

Wait until the engine warms up to its operating temperature.

If only cold air begins to come out of it, then the circulation of antifreeze in the system is disrupted. Most likely, the problems are associated with severe wear of the pump impeller blades, and therefore you need to replace the pump with a new one as soon as possible.

Instrument readings in the cabin indicate that the engine is very hot - this is a reason to look under the hood and check the condition of the pump

Timing belt wears unevenly

Often drivers, having decided to change the timing belt, are surprised to notice that it is worn out on only one side. Of course, this is not normal for the operation of a rubber product - the timing belt design is designed for uniform planned wear of each part.

The timing belt rubs on one side due to the fact that the bearings on the pump shaft are loose . Accordingly, if there is asymmetrical wear on the timing belt, this indicates that the pump is about to fail. Usually, if the bearings become loose, the driver hears a loud crunching or banging sound from under the hood while driving.

Even after a short period of operation, the belt will begin to wear out on only one side if the pump bearings are worn out.

Pump leaking

Even a high-quality water pump cannot last forever. Therefore, over time, the pump seal (the most vulnerable component of the pump) will begin to wear out and, as a result, leak. And an antifreeze leak in the timing belt area clearly indicates that the pump has lost its tightness and is no longer performing its function to the required extent. Of course, if the leak is small, then the car can be used for now, since the system will still provide engine cooling. However, at any moment the oil seal can completely break through, and all the antifreeze will flow out of the crankcase.

In some cases, water pump leaks are observed not only due to the wear-out of the oil seal, but also due to improper installation of the rubber seal when replacing the pump.

Abundant release of antifreeze in the timing belt indicates depressurization of the water pump

Replacing the water pump on Grant (8 valves)

The driver can change the pump on an 8-valve Lada Granta without going to a service station. The main thing is to follow the replacement instructions and, upon completion of the replacement, set the crankshaft and pulley values correctly. Usually, along with the water pump, it is customary to change the timing belt.

Where is the pump located?

Since the pump is put into operation by a gas distribution mechanism, it is quite obvious that it will be built into the timing system. That is, you need to look for the location of the pump on the Lada Granta on the right side of the engine.

It is impossible to visually see the pump before removing the timing belt - only the pump pulley is visible, which is what starts the impeller into operation.

The water pump is included in the timing belt assembly

Preparing tools

To work, you will need several wrenches, standard auxiliary tools and materials:

wrench 10;

socket head 10;

wrench 17;

a screwdriver with a flat and thin blade;

container for draining coolant (at least 10 liters);

Replacing the pump on a Lada Grant does not require special tools - a standard set of tools is enough

How much coolant should be drained and refilled when replacing

Regardless of the availability of time or desire of the driver, you will still have to drain the antifreeze when changing the water pump. This is necessary in order to relieve the existing pressure in the cooling system and protect yourself from possible risks. However, the main question is how much liquid needs to be drained.

Traditionally, when replacing a pump, the entire volume of antifreeze is drained, since the new water pump will need new coolant. However, if new antifreeze was recently filled in, then there is no point in replacing it. It is enough to drain 4–5 liters of liquid to reduce the pressure, and then pour the same liters back.

Antifreeze is completely drained in 10–15 minutes

Draining can be done in two ways:

Disconnect the pipes from the radiator and place a container under the drain holes. This method allows you to remove almost all liquid from the cooling system.

Unscrew the plug from the expansion tank housing - no more than 5 liters of antifreeze will leak out.

New coolant should be added only after all installation work has been completed. It is recommended to make sure that the antifreeze supply and discharge hoses are tightly connected to the fittings.

Pump replacement procedure

On an 8-valve Lada Granta, changing the water pump is somewhat easier than on a 16-valve one. All actions of the owner fit into the following scheme:

Characteristics of the differences in the procedure for Lada Granta 8 and 16 valves

In general, there are no significant differences in the design of engines with 8 and 16 valves in the Lada Granta. However, the procedure for replacing the water pump will differ in only one way: the 8-valve model has one crankshaft pulley, and the 16-valve model has two.

Accordingly, dismantling and installing the water pump on 16-valve versions will take more time, but the replacement scheme will be identical for 8-valve models.

On a Lada Granta car with a 16-valve engine, two crankshafts are installed, and therefore the time required to replace the pump increases significantly

When choosing a new pump, you need to be careful: water pumps of various designs are installed on Lada Granta with 8 and 16 valves. That is, they cannot be considered interchangeable, as is usually the case with other modifications of VAZ cars.

Identifying a faulty pump on a Lada Grant and replacing it yourself is a completely accessible procedure for any driver. The work does not require special equipment - a standard set of tools that can be found in any garage will be used.

Pump replacement completed

Note that 8-valve Lada Granta units suffer from a risk of belt breakage due to jamming of a lately diagnosed and replaced pump. On these units, the pump life is close to 80 thousand runs, having a warranty of one year. Here you should be careful and choose only high-quality spare parts.

There is disagreement among Lada Granta owners regarding the need to cover the new gasket with a sealing compound, or the lack of need for such an action. Pump manufacturers claim that it is not necessary! Many craftsmen neglect this postulate, and they add sealant, explaining this by better sealing the cooling channel where the pump is located.

We focus on some important aspects during replacement:

- do not allow the camshaft pulley key to pop out;

- We stop the motor shafts after removing the belt, preventing them from turning.

How long does it take to change the pump on a grant?

To avoid being blown up by a mine, it is enough to know where it is laid. Let's play sapper and find out when you really need to change coolant pumps and timing belts on VAZ engines.

Domestic engines for Grant, Kalin, Prior, Vest and Iksreev, with the exception of VAZ-11183, belong to the “plug-in” category. What this means is that when the timing belt breaks, the pistons meet the valves. Read - it exploded and led the engine to destruction, which was expensive to repair.

With Vesta and Xray, progress is obvious - at 45, 75, 105, 135 and 165 thousand we adjust the gaps in the gas distribution mechanism. And for the first time we plan to remember the timing belt along with the rollers for 180 thousand kilometers! This is for 16-valve engines VAZ-21129, 21179 and 8-valve Vesta VAZ-11189. I can’t do without the quote: “2.11. Replace the timing belt along with the rollers. 2.12. Replace the crankshaft and camshaft sprockets. Replace the toothed belt, tensioner and support roller (for the VAZ-11189 8-cl. engine, only the tensioner) of the engine gas distribution mechanism drive. Adjust the tension of the toothed belt." Not only is the oil oil (we change the same belt twice), but of all the parts, they didn’t remember the most vulnerable one - the pump!

New VAZ engines are now equipped with high-quality timing belts from well-known brands. I believe that if no oil gets on it, it will cost 180 thousand. But is the difference in components really so great that on the 8-valve VAZ-11186 for Granta the belt must be changed at the 75th thousand, and on its closest relative VAZ-11189 at the 180th?

Let's continue the research. The pulleys are not demolished at all. Pressure roller bearing up to 180 thousand? Let's admit it, although it's hard to believe. But why change all this equipment at the 180th thousand, if the estimated life of the engine is 220 thousand km? Refresh before demise or major overhaul? If you don’t believe me, look at the photo taken in the workshops where VAZ engines are produced.

I don’t want to once again convince you that the stingy pays twice, but over the years I have come to the conclusion that Western manufacturers include in the regulations changing the belt not because of the belt as such, but because of the pump and tensioner bearings. They just needed a reason to reliably replace the entire set of parts associated with the camshaft drive, and they found it.

I propose to do the same with our engines. Why? Formally, at each maintenance it would be necessary to remove the cover and inspect the timing belt and water pump. You can see a tear in the belt, as well as a leak on the pump. In both cases, the part is changed without delay. But this is a malfunction. And if everything is outwardly normal, the ideal option is to include preventive replacement in the regulations.

Replacing the pump (water pump) on a Lada Granta is done in two ways: if the pump “hangs” on the timing belt, then by replacing the timing belt, if separately from the belt, then without removing the timing belt. Replacing the pump on a Lada Granta can only be entrusted to a motor mechanic at a car service center. It is strictly not recommended to change it yourself.

Along with replacing the pump on a Lada Granta, it is necessary to change the gasket of the pump (water pump). When purchasing a pump, pay attention to whether the pump gasket is included. In cheap pumps, the gasket is sold separately. When replacing the pump on a Lada Granta, it is better to immediately replace the antifreeze. You should not decide to replace the pump yourself. Do a diagnostic of the cooling system, the mechanic will be able to accurately determine whether it is the pump or not and will guarantee that replacing the pump will correct the problem.

Cost of replacing a water pump (water pump) on a Lada Granta:

| Replacement options | Replacement | Pump price |

| Replacing the Lada Granta pump, without timing belt | from 2,000 rub. | from 1,100 rub. |

| Replacing the Lada Granta pump, with timing belt removed | from 4,500 rub. | from 1,100 rub. |

In terms of time, replacing the pump on a Lada Granta takes from 2 to 12 hours, depending on the engine size.

Pump replacement warranty

- 180 days.

Rating of Lada Granta pump manufacturers based on owner reviews: 1. Graf (Italy) 2. Airtex (Spain) 3. SKF (Sweden) 4. Luk (Germany) 5. Ruville (Germany)

When you need to change the pump on Lada Granta:

— backlash of the pump drive pulley; — extraneous sounds from the pump; - leaks on the pump; — the antifreeze leaves, but no leaks are visible.

Engine Lada Granta

The main defects of the Lada Granta water pump are coolant leaks and bearing wear (determined by increased noise and hum during operation). Repairing a water pump, as a rule, does not lead to the desired result, so it is recommended to replace the pump assembly.

You will need: keys “10”, “17”, two screwdrivers.

Let's sum it up

Now you know which pump is best to choose. Try to timely diagnose and replace the coolant pump on your LADA Granta. Use only high-quality products, which will allow the components of the unit to serve for a long time and properly. Don’t be lazy to compare different products from among the offers, because this is a reasonable action in terms of selecting the optimal option.

Lada Granta 2012

- Greetings to all! I am sure that this article will be very useful for owners of Lada Granta with engine 21116 installed on cars with the “norm” configuration. There were 3 before this article, I deleted them and decided to write this one so as not to confuse the chronology of events!

Let's start with the fact that my typewriter is one year old. This year there have been few pleasant things and many not so pleasant ones. Ran 31 thousand kilometers. Main mileage: Kashira, Stupino, Moscow, several trips to Tula.

I have long been tormented by a strange knocking sound from the engine when cold. It didn’t cause any particular panic, as the engine warmed up and the knocking noise disappeared. And at 29,000 kilometers, the tapping stopped disappearing after warming up and even brought with it a crackling sound when starting off. Alternator, exhaust system, CV joint, front bumper and this is not a complete list of what I checked. There was still a pump and an automatic timing belt tensioner pulley, I opened the casing, but didn’t see anything suspicious. I went to a friend's service center to look at it with a more experienced eye. Based on the sound they said the pump, they opened the timing case and, sure enough, the timing belt was running along the pulleys. What I was most afraid of was this diagnosis because there are no spare parts for the Lada Grant at all. I surfed the forums and Drive2, found a couple of cases where a pump from a Priora was installed, it was said that the difference was only in the width of the pulley, and even then not by much.

And so it was necessary to buy:

— Water pump 2170;

— Automatic timing belt tensioner roller 2190;

— Timing belt 2190;

To my surprise, the timing belt for the Granta was in almost every store, with a roller and pump for the Granta ambush, as expected, no, I called all the stores in the south of the Moscow region and Moscow, they all got the same picture, in the database there is in stock no, on order delivery time unknown.

I asked the store to show the pump from the nine and the Priora, I didn’t immediately notice the difference except the width of the pulley and took it to my grief from the nine.

Why you can’t install a pump from a nine on the 21116 Lada Granta engine:

If you look at the VAZ-21116 and VAZ-210914 pump with a superficial glance, I assure you you will not notice the difference, on the VAZ-210914 pump there will be a slightly different impeller and there will be no small threaded hole for attracting the timing case, but this is not a problem, the most important difference is in the teeth pulley On the VAZ-21116 engine, the pulley migrated from the VAZ-21126 priors, only it became a little narrower. On the Prior, the pulley comes with rounded teeth, and on the VAZ-210914 with rectangular ones, and even more so they are a couple of millimeters higher; by installing this pump on the VAZ-21116 engine, you will push through the timing belt and it will last ten times less. At the time of purchase I did not know this and bought from nine.

Why is it not recommended to install an automatic tensioner pulley on the VAZ-21116 engine from Priora VAZ-21126

I bought the roller from a Priora Pilenga PT-P 1570. By eye it turned out to be the same except for the bolt hole on the engine mounting side. When I shot my own video, I realized that there was a big difference! Firstly, the original roller 21116 is larger in diameter, and secondly, it is narrower. The plastic body of the Priora roller is wider and it clings to the engine, this is solved by grinding off the excess with a grinder or, as I did, with a grinding machine. There is a difference in one more detail, the thickness of the metal body of the roller grants is wider than that of the Priora and therefore if you are planning to install from the Priora it is necessary to place a washer. My conclusion is not optimistic: since the roller from the Priora is smaller in diameter than that of the Granta, when tensioning the roller it is necessary to pull it further than the mark and thereby actually deprive it of the range of automatic adjustment.

Replacing the timing belt, roller and pump. Attempt No. 1

I collected all the purchased parts in a package:

— Automatic tensioner roller 21126 (2170) Pilenga PT-P 1570;

— Timing belt VAZ 21116 (2190) Original 5670XS

— Water pump VAZ-210914 TZA 21091307010-75

The total was 2540 rubles.

Previously, I never had to change the timing belt myself; I didn’t have time to study, so I decided to take it to a service center. The whole thing was sorted out there. We took out the pump, there is some play, but not that critical! Why did the timing belt slip? It's still not clear.

The bearing is also in excellent condition, as is the belt! I put the original parts in the trunk and installed new ones. I start the car and hooray! The knocking is gone, the belt fits like a glove! I paid 2,000 rubles and went home happy.

In total, it cost me 4,500 rubles to change the timing belt consumables, thanks to the guys from AvtoVAZ.

You probably thought that everything is fine, the pump has been replaced and the car is now like new. No, no, no.

I arrived home and decided to inspect the engine compartment, everything was fine except for the alternator belt being overtightened, well, there was nothing, I adjusted the tension, checked it and went home (remember this moment).

In the morning I started to start it and the knocking noise appeared again, I tried to start, and the crashing noise also came next! I went to work upset. At work I have a lot of thoughts on this topic and then I come across a forum and photos on the Internet! It shows pictures of water pumps and pulleys for Priors and Nines and shows what the difference is! I just have a hurricane of thoughts in my head. After work, I fly home, open the timing belt, and yes... the belt is clearly crushed. There are teeth marks on the front side...change it again.

Operations to replace the water pump (pump) Lada Granta

1. Disconnect the wire from the negative terminal of the battery.

3. On VAZ-21116 and VAZ-111 engines, remove the four bolts securing the upper part of the front cover of the timing gear drive.

5. On the VAZ-11183 engine, remove the three bolts securing the front cover of the gas distribution mechanism drive.

7. On the VAZ-21126 engine, using a 5-point hex key, remove the five bolts securing the upper front cover of the timing belt

9. Set the piston of the 1st cylinder to the TDC position (see “Installing the piston of the 1st cylinder to the TDC position of the compression stroke on a Lada Granta car”).

10. Remove the tension roller (see “Replacing the timing belt and tension roller”).

After removing the timing belt, it is prohibited to turn the camshaft and crankshaft.

11. Remove the camshaft timing pulleys (see “Replacing the cylinder head gasket”).

12. On VAZ-21116 and VAZ-11186 engines, remove the crankshaft pulley mounting bolt.

Service life of the timing belt and generator, pump, as well as Kalina tension rollers

How long do factory timing belts, alternator belts, as well as tension rollers for both timing belt and alternator last? Mine are personal.

How to replace a part on an 8 and 16 valve unit?

For the repair process, that is, when the pump is replaced, you should acquire the simplest tools, namely:

- screwdrivers in assortment;

- keys whose sizes are “10” and “17”.

- Disconnect the on-board network from the battery.

- We install the piston of the first cylinder in the traditional TDC position on the LADA Granta model.

- We dismantle the tension roller in combination with the timing belt, having previously deactivated its tension.

- Remove the pulley on the crankshaft.

- We remove the cover protecting the timing drive unit.

- Unscrew the bolts that hold the pump. Don't forget to drain the liquid first!

- We remove the pump from the mounting cavity of the motor block (with a screwdriver).

- Don't forget to replace the gasket!

- We install the new product in place, observing its correct orientation (number up).

Important! We do not rotate the motor shafts (camshaft and crankshaft) in order to avoid mark failure.