Earbuds

No adjustment operations should be performed on the liners. If there are scuffs, marks or peeling, replace the liners with new ones.

The gap between the liners and the crankshaft journals is checked by calculation (by measuring the parts). It is convenient to use a calibrated plastic wire to check the gap. In this case, the verification method is as follows:

- thoroughly clean the working surfaces of the liners and the corresponding neck and place a piece of plastic wire on its surface;

- Install a connecting rod with a cap or a main bearing cap on the journal (depending on the type of journal being tested) and tighten the fastening nuts or bolts. Tighten the connecting rod bolt nuts to a torque of 51 Nm (5.2 kgf m), and the main bearing cap bolts to a torque of 80.4 Nm (8.2 kgf m);

- remove the cover and use the scale on the package to determine the size of the gap by flattening the wire (Fig. 2-38).

The nominal design clearance is 0.02-0.07 mm for connecting rods and 0.026-0.073 mm for main journals. If the gap is less than the limit (0.1 mm for connecting rods and 0.15 mm for main journals), then these liners can be used again.

If the gap is greater than the limit, replace the liners on these necks with new ones.

If the crankshaft journals are worn and ground to repair size, then replace the bearings with repair bearings (of increased thickness).

Weaknesses of the VAZ 21214 engine

In addition to the weak points of the base 21213, the motor has the following weak points:

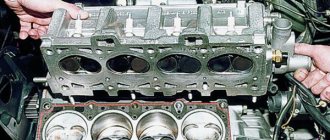

Cylinder block. This weak point appears on various models of Nivov engines, including the previously discussed 21213. Due to insufficient quality control, the assembly unit is manufactured with a high percentage of factory defects. In short, the drilling depth of the intake manifold stud holes is not maintained, causing the holes to meet the camshaft stud holes.

In this way, L-shaped through channels are obtained. After installing the studs at the factory, the connections remain sealed for some time and the problem is not identified when the quality control department employees accept engine tests. After the sale of new cars with low mileage, during sharp braking, oil begins to seep through the studs onto the hot intake manifold, so much so that smoke from the oil burning in the manifold pours out from under the hood, and accordingly, there is nothing to breathe in the cabin.

The most interesting thing is that AvtoVAZ knows about this problem and, in response to questions in correspondence with car owners, advises eliminating it according to the following technical specifications:

A sketch for the technical specifications for eliminating oil leaks from under the exhaust manifold studs.

- Remove the GC cover;

- Unscrew the two studs securing the bearing housing (see sketch) and remove oil from the threaded holes;

- Thoroughly degrease the holes and stud;

- Apply sealant UG-10 or its analogues to the lower threads of the studs;

- Place the studs in place;

- Tighten the bearing housing nuts;

- Install the cylinder head cover;

- Wait at least 30 minutes for the sealant to set.

Also interesting: Technical characteristics of the Chevrolet Niva - 1.7 engine, fuel consumption, body dimensions

Thrust half rings

Just like on the liners, no adjustment operations can be performed on the half rings. If there are burrs, marks or peeling, replace the half rings with new ones.

Half rings are also replaced if the axial clearance of the crankshaft exceeds the maximum permissible - 0.35 mm. Select new half rings with a nominal thickness or increased by 0.127 mm to obtain an axial clearance in the range of 0.06-0.26 mm.

The axial clearance of the crankshaft is checked using an indicator, as described in the chapter “Engine Assembly” (Fig. 2-14).

The crankshaft axial clearance can also be checked with the engine installed in the vehicle. In this case, the axial movement of the crankshaft is created by pressing and releasing the clutch pedal, and the amount of clearance is determined by the movement of the front end of the crankshaft.

Weaknesses of the power unit of the VAZ 21213

- Water pump;

- Engine, manual transmission and transfer case oil seals;

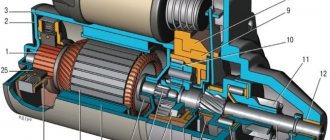

- Generator;

- Starter;

- manual transmission;

- Valve cover gasket;

- Cooling system pipe connections;

- Radiator;

- Thermostat;

- Expansion tank;

- Vacuum brake booster.

The water pump (pump) is characterized by frequent failures on new cars after 2,000 km.

Due to poor quality, oil seals require more frequent replacement than required according to the operating manual.

The generator has a high probability of failure. As a rule, it burns out even on new cars that have not reached 4,000-10,000 km.

The starter has a low service life without repair.

On a gearbox, one of the common defects is the fifth gear slipping out. In addition, the gears are not fully engaged.

The valve cover gasket loses its properties over time and allows oil to leak out.

The connections of the cooling system pipes in the places where the clamps are installed are not reliable and lose their tightness very early, which is fraught with loss of antifreeze.

The radiator is leaking. The problem occurs due to the appearance of cracks in the radiator pipe package, accompanied by loss of coolant. This defect has become widespread.

The thermostat does not provide thermal conditions for the coolant in the engine cooling system. The manifestation of this problem is no exception. The cause of the defect is a failure of the valve mechanism inside the thermostat. To check that the thermostat is working properly, after starting the engine, simply place your palm on the lower (outlet) hose, through which hot antifreeze circulates into the radiator for cooling. If the thermostat is working properly, after some time the hose should become hot; if the hose remains cold, the thermostat must be replaced.

The expansion tank cracks and antifreeze leaks out. The appearance of cracks occurs due to the failure of the steam-air valve in the tank plug due to increased pressure.

Vacuum brake booster (VUT). Manifested by a stiff brake pedal. The speed may fluctuate when the brake pedal is pressed, as well as hissing. The problem is solved by replacing failed rubber products and replacing clamps in connections.

Read news about the new Niva

- What you need to know about the VAZ 21214 engine before buying a Niva | Weak engine

- Niva VAZ 21213 engine: characteristics, malfunctions and tuning

- What you need to know about the VAZ 21213 engine before buying a Niva | Weak engine

- Interchangeability of the Zhiguli and NIVA gearboxes (is it possible to install a Zhiguli gearbox on a Niva)

- Do the valves bend in the field?

- Niva Pickup VAZ-2329 lada 4×4 – review

- Togliatti.RU (c) - Everything for the VAZ Lada 4×4

- Niva Chevrolet and Niva 2121: the main differences between owning these cars

Product added to bookmarks!

- Description

- Reviews

Standard crankshaft from the VAZ 2130 1.8L engine (OPP VAZ).

A crankshaft with a stroke of 84 mm (cast iron) is installed in the VAZ 21213 (Niva) and VAZ 2123 (Niva-Chevrolet, CHEVROLET NIVA) block together with

TDMK pistons (82.0 mm - 82.4 mm - 82.8 mm - 84.0 mm), with standard or lightweight connecting rods.

This crankshaft can be installed in the block of a VAZ 2103 (1.5L) and VAZ 2106 (1.6L) without replacing connecting rods and pistons (an accurate calculation of the compression ratio and adjustment of the combustion chamber will be required).

You can increase the engine displacement by: replacing the crankshaft with another one with a larger stroke, increasing the cylinder diameter, or both at the same time. We must not forget that when changing engine volume, it is necessary to increase the volume of the combustion chamber - to compensate for the increase in cylinder volume.

When installing a crankshaft with a long stroke, it is necessary to replace the pistons.

Boring the block cylinders by a significant amount (2 mm) must be approached with caution. For example, when a serial VAZ 21083 block is bored from 82 mm to 84 mm, the engine experiences increased oil consumption. This occurs due to the loss of block rigidity. In this case, it is better to use a special thick-walled block casting. VAZ produces such blocks in small batches.

An increase in engine displacement leads to an increase in maximum torque , but at the same time there is a decrease in maximum power speed. This is due to a decrease in mechanical efficiency. If the increase in volume occurs due to an increase in the diameter of the cylinders, then the contact area between the cylinder walls and the piston with piston rings increases. As a result, friction increases. If the increase in volume occurs due to an increase in the crankshaft stroke, then the average piston speed increases, which leads to the same results.

In any case, an increase in volume leads to a drop in the overall efficiency of the engine.

VAZ engine volume (in cubic cm) depending on the cylinder diameter and piston stroke.

Diameter Stroke, mm cylinder, 80 84 86 88 mm 76.0 1451 1524 1560 1596 76.4 1466 1540 1576 1613 76.8 1476 1556 1593 1630 79.0 1568 1646 1685 17 25 79.4 1584 1663 1702 1742 79.8 1600 1680 1720 1760 80.0 1608 1688 1628 1768 82.0 1689 1774 1816 1858 82.4 1706 1791 1834 1876 82.8 1722 1808 1851 1894 84, 0 1772 1861 1905 1950

Description of the motor device 21213

The basis of the VAZ 21213 engine includes:

- cast iron cylinder block (BC) 21213-1002011;

- block head 21213-100301*;

- crankshaft 21213-1005015;

- connecting rod and piston group 21213-10040*.

The main difference between the 21213 engine and its predecessors was the increased cylinder diameter - 82 mm versus 76 and 79 mm. The center-to-center distance of 95 mm remains the same, and allows the block to be bored to a diameter of 82.8 mm. The design of the water jacket has changed. The working volume has increased by 100 cm3, but the engine dimensions have remained the same.

To install the crankshaft in the BC there are 5 supports: one each on the front and rear walls, 3 more on the ebb. The crankshaft parameters provide a piston stroke of 80 mm. The crankshaft is cast from cast iron and consists of 4 connecting rods and 5 main journals. The connecting rod journals have oil channels. The necks are separated by cheeks with counterweights. In previous VAZ engines, balancing counterweights were found only in the outer and central cheeks. The axial movement of the shaft is limited by thrust half-rings.

The piston group for the 21213 engine was developed anew. Pistons 21213-1004015 are cast from aluminum and reduced to a single mass of 347 g. The piston class (A, B, C, D, E) is determined by the outer diameter in increments of 0.01 mm. The shape of the piston is conical in height and oval in cross section. The hole for the pin is 22 mm, offset by 1.2 mm from the piston axis. The finger is locked with rings. There are 3 rings installed on the piston skirt:

- upper compression barrel;

- medium oil scraper with expansion coil spring;

- lower compression scraper type.

The connecting rod 21213-1004045 is forged from steel and processed together with the cover. A steel-bronze bushing is pressed into the upper head of the connecting rod. To fasten the connecting rod, M9x1.0x56 bolts are used.

The aluminum BC head is designed for the VAZ 21213 engine and is designed for compression from 10 bar. Installing a head from other motors may cause it to break. Cast iron seats and guide bushings for 4 intake and 4 exhaust valves are pressed into the head. The valves operate from the camshaft cams. The gap between the valve stem and the cam is adjusted with a bolt.

Similar article M273 Mercedes engine: main problems and reviews on the engine

timing belt

The camshaft 21213-1006010 is made of cast iron and rests on 5 journals. The jaws are bleached to increase wear resistance. Axial movement of the shaft is limited by a thrust flange.

The timing belt is driven by a double-row bush-roller chain. In addition to the camshaft, the chain drives the oil pump. The drive is regulated by a semi-automatic tensioner with a shoe and damper. To prevent the chain from falling off when removing the camshaft sprocket, a limiter is provided next to the crankshaft drive sprocket.

Systems

The power supply system in the Niva 21213 engine is a 21073 Solers carburetor. The carburetor unit is two-chamber, the throttle valves operate sequentially. When the first chamber is 2/3 open, the throttle of the second chamber is engaged. At idle, the economizer turns on. The carburetor device includes:

- float chamber;

- 2 dosing systems;

- crankcase gas suction system;

- heating the throttle zone of the first chamber;

- blocking the second camera;

- economizer;

- econostat;

- diaphragm accelerator pump.

The ignition system in the 21213 engine is non-contact. The system is controlled by a switch using distributor signals. In general, the system is classic, without any special features.

Cooling of the motor occurs according to a typical scheme: liquid circulates through the water jacket in the BC and the block head. The pressure is created by a centrifugal pump connected by a belt drive to the crankshaft and generator. The radiator fan impeller works on suction, so in winter the radiator has to be covered with cardboard.