Removing and cleaning VAZ 2114 injectors

- 223 15 164k

- 151 2 127k

Injector performance calculator

Online injector performance calculator

Every car owner of an injection car sooner or later encounters problems in the fuel system and begins to think about cleaning the fuel injectors.

The task of the injector is to maintain the pressure created by the fuel pump and only at the right moment to open for a fraction of a second to allow the required amount of fuel to pass through.

There are a lot of different additives in the fuel, which during engine operation stick to the seat of the injector locking needle. As a result, the injector begins to spray fuel incorrectly or leak fuel when it should be closed. In such cases, it is necessary to clean the injectors or replace them.

The recommended period for cleaning injectors is 25,000 km - 30,000 km . Failure to properly maintain fuel injectors can lead to their complete failure, and then only replacement will be necessary.

There are several signs that indicate you need to at least remove and check the condition of the fuel injectors. Next, a decision is made to clean or replace the elements.

Pay attention to the behavior of your car and specifically the engine. They will tell you if there is something wrong with the injectors. This may manifest itself as follows:

- The engine produces less power, the same acceleration efficiency is not felt;

- If the engine performs poorly or lacks power, fuel consumption still increases;

- Poor starting is not a rare sign of injector failure;

- If the engine does not hold idle speed well, the injectors may well be the cause;

- The amount of toxic components in exhaust gases increases;

- At idle the speed increases.

Without removing the injectors, you can indirectly check them for leaks (or leaks). The video shows an example: you need to unscrew and lift the fuel rail, apply pressure and see if a leak appears. The check is the simplest and only for an obvious malfunction, however, if you suspect the injectors, it won’t hurt to do this.

Operating principle and typical failures

A fuel pump is a kind of small electric motor that pumps fuel and creates pressure in the fuel rail of a VAZ 2114 car. The pump is a component of the fuel module.

Structurally, the pump and electric motor are a single unit. Its electrical part is washed with fuel, which provides cooling, plus lubricates the surfaces that come into contact with each other.

Fuel pump VAZ 2114

There are many signs of breakdowns, which indicate a failure or malfunction in the fuel system, or more precisely the fuel pump. Almost every person is able to detect some of them:

- The engine does not start;

- When you try to start the engine, you cannot hear the electric motor;

- The engine runs intermittently;

- Jerking occurs when moving at low speed.

Causes

As for the reasons why the fuel pump fails, they may be:

- Fuse on the pump is broken;

- Failed relay;

- Failure of the pump electric drive;

- Poorly secured block masses;

- Damage to the pump itself;

- Missing or poor contacts at the motor terminals.

In fact, it is extremely rare for an electric motor to break down. This is due to the active cooling of the element by fuel, which not only cools, but also flushes all its components.

Shidron blower and mesh

But the centrifugal gate hydraulic supercharger suffers more often than others. The reason is small contaminants in the fuel, which end up inside the mechanism, rub against the structure and wear them out. The performance of the unit drops, the pressure decreases. This leads to the formation of the first signs of pump wear, operation noise increases, and the engine refuses to start. It is impractical to repair a broken pump; it must be completely replaced.

The process of removing the fuel rail (+photo)

General view of the fuel rail

Before proceeding directly to the dismantling process, you need to understand that you will have to remove the injectors, and therefore you can simultaneously diagnose and clean this unit. So, let's consider the sequence of actions that are aimed at removing the fuel rail:

- Remove the minus terminal from the battery.

- We are dismantling the receiver.

Unscrew the clamp and remove the crankcase ventilation hose

Unscrew the oil circulation pipes

Removed the oil dipstick

Having disconnected the connectors, we disconnect the ramp from the on-board network

After unscrewing the fastening screws, we dismantle the fuel pipe bracket

Unscrew the screws by 5 and remove the ramp

Unscrew the fastenings of the fuel supply regulator and remove it

Reasons for withdrawal

There are several reasons for removing the fuel rail from the car:

- Cleaning injectors.

- Replacement or repair of the ramp itself.

- Removing the valve cover.

- Carrying out diagnostic and repair operations that involve engine disassembly.

- Other operations where removal of the ramp is required.

Fuel rail mounting diagram

WHAT GASOLINE TO POUR IN THE VAZ-2114?

This topic has become overgrown with various conjectures and speculations, but we will try to put everything in its place.

The technical data sheet of the fourteenth indicates that the car engine requires AI-95 gasoline, and there is no reason not to trust the manufacturer’s recommendations.

Another thing is that many car owners, over their long driving experience, have accumulated rational doubts about the existence of any serious differences between 95 and 92 gasoline. Adding fuel to the fire was the recent statement by the chief engineer of the Moscow oil refinery, A. A. Abrosimov, that we do not make 95-grade gasoline in our country, and everything that is sold under its guise is either 92-grade or unknown fuel brought from somewhere.

As evidenced by reviews from VAZ 2114 owners who use exclusively 92-octane gasoline, there were no problems with the car during its service life due to fuel, and they see no point in using a more expensive analogue. However, the final decision about what to pour into the fourteenth is yours.

How to remove the fuel rail of VAZ 2114, 2115 injectors - step-by-step instructions

1. First, you need to relieve the pressure in the fuel system; to do this, you need to turn off the fuel pump. To quickly turn off the fuel pump, simply remove the fuse that is responsible for this device from the socket in the fuse block. Next, you need to start the engine and let it run until it stalls. If you don’t want to go to the fuses, then you can try to turn off the power to the fuel pump in another way, for example, by disconnecting the fuel pump power supply.

2. Next, turn off the ignition.

3. Disconnect the negative terminal of the battery.

4. Disconnect the air receiver hose, as well as the vacuum hose from the pressure regulator.

5. Using a wrench set to “17” (some have a wrench set to “22”), unscrew the fittings and move the tubes to the side.

6. Then disconnect the fuel rail power wires.

7. Next, remove the clamping bar securing the fuel pipes.

8. Take the hexagon at “5” and use it to unscrew the two bolts securing the fuel rail.

9. Remove the injectors from their sockets, while slightly pulling the ramp along the axis.

10. Now you can remove the fuel rail from the car. Be extremely careful and careful not to damage the contacts of the injector connectors and sprayers. Make sure that nothing, such as dirt or dust, gets into the channels or fuel lines.

11. When unscrewing the union nut, hold the fitting using a second wrench.

12. Cleaning the ramp from dirt should be done exclusively with a special liquid for cleaning fuel cells (ABRO, WD-40).

This completes the removal procedure, all that remains is to carry out repair work, replace faulty parts and reassemble everything in reverse order. Thank you for your attention, see you again at VAZ Repair!

Typically, the engine fuel rail is dismantled if it is necessary to remove injectors or in other cases of engine repair.

- First of all, relieve the fuel pressure in the fuel line.

- Then you need to remove the receiver.

Using a 17mm wrench, unscrew the fitting of the fuel supply tube to the ramp. We also unscrew the fuel drain pipe from the hose.- Then we remove the hose tips from the tubes and remove the O-rings from them. Damaged rings need to be replaced.

- Remove the hose from the fuel pressure regulator pipe.

- Disconnect the wiring harness connectors from the injectors.

- Using a 5mm hex wrench, unscrew the 2 bolts securing the fuel rail to the intake manifold.

- Remove the fuel rail assembly with injectors. There may be residual fuel in the fuel rail.

Let's disassemble the fuel rail:

- Using a screwdriver, move the injector retainer along the fuel rail.

- We remove the nozzle.

- In the same way, remove the remaining three injectors.

- We check the O-rings at the junction of the injectors with the fuel rail. Damaged rings need to be replaced.

- Remove the injector clamps from the fuel rail.

- Remove the fuel pressure regulator.

- Using a 24mm wrench, unscrew the nut of the fuel supply pipe and remove the end of the pipe and the fuel rail. Checking the O-rings.

- If necessary, use the cap from the wheel nipple to unscrew the spool of the diagnostic fitting.

- We assemble and install the fuel rail in place in the reverse order. Before installation, lubricate all O-rings with a thin layer of oil.

To remove and install the fuel rail of the K7M engine, perform the following operations.

You will need: TORX TZO wrench, flat blade screwdriver, side cutters.

1. Reduce the pressure in the supply system. 2. Disconnect the wire from the negative terminal of the battery. 3. Remove the air filter housing. 4. Squeeze the clips and disconnect the wiring harness blocks from the injectors.

5. Move the wiring harness to the side.

6. Remove the two fuel rail mounting bolts

7. Remove the ramp by removing the injectors from the holes in the inlet pipe and without disconnecting the pipeline from the ramp.

If any injector remains in the intake pipe when removing the ramp, be sure to replace the retainer for that injector. 8. To disconnect the fuel line, cut the plastic safety clamp.

9. Squeeze the retaining ring and disconnect the pipeline from the fuel rail.

If necessary, press out the fasteners with a screwdriver.

Replace rubber pipe O-rings with new ones each time the connection is disassembled.

10. Remove the fuel rail assembly with injectors.

11. Install the fuel rail in the reverse order of removal. 12. Start the engine and check the tightness of the pipe connections and injector seals.

Removing and installing the fuel rail of the K4M engine of the Lada Largus

We remove the fuel rail to replace injectors and to clean the fuel rail, as well as when repairing the cylinder head.

We prepare the vehicle for work.

Relieve fuel pressure. To do this, we tilt the rear row of seats forward (for a 5-seater configuration) or the middle row (for a 7-seater configuration).

Disconnect and lift the floor covering.

Remove the electric fuel pump hatch cover.

Disconnect block 1 of the rear wiring harness from module 2 of the electric fuel pump.

We start the engine and let it idle until it stops completely to relieve pressure in the fuel system.

Disconnect the negative terminal of the battery.

After this, connect the wiring harness block to the fuel pump module.

Install the electric fuel pump manhole cover.

We install and secure the floor covering.

Return the seats to their original position.

Using a 13 socket, unscrew the two nuts 1 (Figure 2) and remove the protective casing 2 of the fuel rail.

We press the spring clamp of the tube connector 1, and by moving along the axis of the fitting, disconnect the tube 1 from the fuel rail 3.

For vehicles with a van body, first cover the place where the fuel pipe connects to the fuel rail with a rag and prevent fuel from escaping when the fuel line is disconnected, since the pressure in the fuel line is maintained.

Disconnect the blocks 2 (Figure 3), the wiring harness from the fuel rail injectors 3.

Using a socket 8, unscrew the two bolts 4 and remove the fuel rail 3 complete with injectors.

Recommendations for cleaning injectors on a VAZ 2110

Dirty injectors

- It is recommended to remove the rubber sealing rings before the procedure and install new ones after cleaning. It is best to start cleaning each nozzle by clearing its nozzle of various deposits. Attention should also be paid to the funnel-shaped surface, on which coke-like resinous deposits can accumulate.

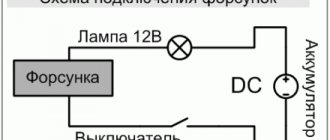

- After this, you can proceed to cleaning the fuel mixture supply channel. To open the fuel supply solenoid valve, a power source is required, preferably not exceeding 5-7V. To do this, you can use an adjustable, stabilized voltage source or a mobile phone charger. A car battery is also suitable, but in this case, voltage must be supplied to the injector through an incandescent lamp, which acts as a current damper to eliminate the possibility that the injector winding will be burned.

- The supply of electricity is carried out through two wires, in the gap of one of which it is necessary to install a button that closes and opens the network, turning it on and off, we will simulate the operation of an injector in an engine under the influence of pulsed electricity.

Cleaning

- As equipment for supplying cleaning liquid to the nozzle channel, you can use a can containing liquid intended for cleaning the carburetor.

- To tightly connect the canister nozzle with the nozzle, you can use a rubber tube, which must be securely fixed using a plastic clamp or any other available fastener on the canister nozzle and on the nozzle.

- When everything is ready, you can start applying electricity to open the nozzle, while simultaneously pressing the canister to supply the washing liquid. After some time, the jet of cleaner coming out through the fuel sprayer should become uniform and clearly visible, which indicates successful removal of carbon deposits. At this point, the cleaning procedure is considered completed.

PREVENTION OF THE FUEL SYSTEM VAZ-2114

Prevention, as a rule, comes down to regular cleaning and, if necessary, replacing the fuel pump filter and the main fuel system filter.

Also once every 25-30 thousand km. It is necessary to clean the injectors, which is performed exclusively at a service station. There are two methods for cleaning injectors, neither of which require removing them:

- Ultrasonic cleaning;

- Cleaning with a special washing liquid.

The most effective and expensive is ultrasonic cleaning, which makes it possible to bring back to life even heavily worn nozzles.

Checking diesel injectors for overflow (drain to return)

As diesel injectors wear out over time, a problem arises due to the fact that the fuel from them gets back into the system, due to which the pump cannot generate the required operating pressure. The consequence of this may be problems with starting and operating the diesel engine.

Before the test, you will need to buy a 20 ml medical syringe and an IV system (to connect the syringe you will need a 45 cm long tube). To find an injector that throws more fuel into the return line than it should, you need to use the following algorithm:

- remove the plunger from the syringe;

- with the engine running, use the system to connect the syringe to the “return” of the injector (insert the tube into the neck of the syringe);

- hold the syringe for two minutes so that fuel is drawn into it (provided that it will be filled);

- repeat the procedure one by one for all nozzles or build a system for all of them at once.

Based on information about the amount of fuel in the syringe, the following conclusions can be drawn:

Checking the return flow

- if the syringe is empty, it means the nozzle is fully operational;

- the amount of fuel in a syringe with a volume of 2 to 4 ml is also within normal limits;

- if the volume of fuel in the syringe exceeds 10.15 ml, this means that the injector is partially or completely out of order and needs to be replaced/repaired (if it pours 20 ml, then it is useless to repair, since this indicates wear of the injector valve seat ), since it does not maintain fuel pressure.

However, such a simple check without a hydraulic stand and plan test does not give a complete picture. Indeed, in fact, when the engine is running, the amount of fuel discharged depends on many factors; it can be clogged and needs to be cleaned, or it freezes and needs to be repaired or replaced. Therefore, this method of checking diesel injectors at home allows you to only judge their throughput capabilities. Ideally, the amount of fuel volume they pass through should be the same and range up to 4 ml in 2 minutes.

You can find the exact amount of fuel that can be supplied to the return line in the manual of your car or engine.

To ensure that the injectors last as long as possible, refuel with high-quality diesel fuel. After all, it directly depends on the operation of the entire system. In addition, install original fuel filters and do not forget to change them on time.

Signs of a faulty injector

As experience shows, a faulty injector can be determined by its symptoms, which, however, can also signal other breakdowns. Among the problems in engine operation that indicate that the injector nozzle is not working include:

- Unstable engine operation at idle;

- the engine is tripping, that is, one of its cylinders is not working;

- fuel consumption has increased significantly;

- a cold engine does not start well;

- jerking when driving after pressing the gas pedal;

- loss of dynamics, especially during sudden acceleration.

Checking diesel injectors for overflow (drain to return)

As diesel injectors wear out over time, a problem arises due to the fact that the fuel from them gets back into the system, due to which the pump cannot generate the required operating pressure. The consequence of this may be problems with starting and operating the diesel engine.

Before the test, you will need to buy a 20 ml medical syringe and an IV system (to connect the syringe you will need a 45 cm long tube). To find an injector that throws more fuel into the return line than it should, you need to use the following algorithm:

- remove the plunger from the syringe;

- with the engine running, use the system to connect the syringe to the “return” of the injector (insert the tube into the neck of the syringe);

- hold the syringe for two minutes so that fuel is drawn into it (provided that it will be filled);

- repeat the procedure one by one for all nozzles or build a system for all of them at once.

Based on information about the amount of fuel in the syringe, the following conclusions can be drawn:

Checking the return flow

- if the syringe is empty, it means the nozzle is fully operational;

- the amount of fuel in a syringe with a volume of 2 to 4 ml is also within normal limits;

- if the volume of fuel in the syringe exceeds 10.15 ml, this means that the injector is partially or completely out of order and needs to be replaced/repaired (if it pours 20 ml, then it is useless to repair, since this indicates wear of the injector valve seat ), since it does not maintain fuel pressure.

However, such a simple check without a hydraulic stand and plan test does not give a complete picture. Indeed, in fact, when the engine is running, the amount of fuel discharged depends on many factors; it can be clogged and needs to be cleaned, or it freezes and needs to be repaired or replaced. Therefore, this method of checking diesel injectors at home allows you to only judge their throughput capabilities. Ideally, the amount of fuel volume they pass through should be the same and range up to 4 ml in 2 minutes.

You can find the exact amount of fuel that can be supplied to the return line in the manual of your car or engine.

To ensure that the injectors last as long as possible, refuel with high-quality diesel fuel. After all, it directly depends on the operation of the entire system. In addition, install original fuel filters and do not forget to change them on time.