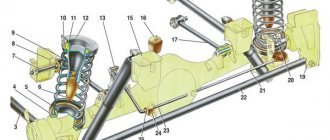

The suspension life of front-wheel drive cars depends not so much on the design features of the suspension, but on operating conditions. One of the most heavily loaded and critical components is the ball joint. Both in the double-wishbone suspension of classic VAZs and in the MacPherson spark plug, the support performs two functions at once. It connects the arms to the steering knuckle, while keeping it from moving horizontally. And if we take into account that the connection must be movable within certain limits, then the design of the ball becomes completely more complicated.

Ball joint design 2110

The service life of the suspension of front-wheel drive cars, as in the photo, depends on operating conditions

True, in the VAZ 2110 and other front-wheel drive models the unit no longer has such strategic importance as on the classics, where a loose support could lead to complete destruction of the suspension, and fives and kopecks lying teeth on the asphalt with the wheels turned out were constant attributes of bad roads. You still need to be able to bring the suspension to this state. In both front-wheel drive and classic models, the task of the support is simple - to provide an articulated rotary connection between the knuckle and the upper or lower arm, and the design of the unit has remained virtually unchanged, except for the landing planes.

A ball joint is a cone-shaped pin with a ball or mushroom-shaped end that can rotate and change angle through the range of operation of the suspension. The ball is placed in a plastic liner and pressed on both sides with a metal case with a top and bottom cover. At one time they produced supports with a collapsible body, but later this idea was abandoned. There were too many factors influencing the wear of the support - here was the quality of assembly during repairs, the quality of the liners, and the quality of lubrication. And the unit had quite a strong influence on traffic safety, and besides, it was more profitable to sell the entire support than to just replace the pins and bushings. Therefore, collapsible supports are practically never found. They are all welded, assembled at the factory, and lubricated there with lubricant, which, however, must be added immediately when installing a new part.

Video on replacing a ball joint on VAZ family cars

The quality of the support depends not only on the design. It just doesn't differ in variety. The support can be of only two types - with a metal-ceramic bearing, they are used as lower supports, and a filler one. The latter are installed on the upper arms of the front suspension and work only on compression, so there is little demand for them. And the main load falls on the lower supports with a metal-ceramic plain bearing. Visually, they differ in the shape of the hole for the finger and the shape of the boot, which protects the sliding bearing from dirt and moisture.

Ball joint life 2110

Replacing the VAZ 2110 ball joint, oddly enough, becomes relevant only after 150-200 thousand mileage. Not 15-20, but precisely 150 thousand. That's how long a quality support for ten goes. Another thing is that buying one is not so easy. The supports are falling like leaves in October, and the producers are multiplying. Therefore, choosing a human support becomes increasingly difficult. But it is possible. To do this, you need, without paying attention to the boxes and colored packaging, just carefully examine the support, and the scorched part will show itself.

After 150,000 km on the “ten” you need to think about replacing the ball joint

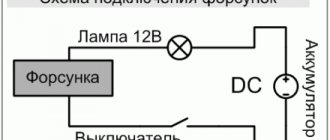

Replacing a VAZ 2110 ball joint, lubrication details

Changing the support on the ten with your own hands is quite simple. Having placed the car on the handbrake and put the gearbox in first gear, tearing off the wheel bolts, the front part is raised with a jack and installed on a stand. The wheel is removed, the pin fastening nut is unscrewed, after which the pin is pressed out of the lever using a puller. You can remove the finger without a puller; in this case, a pry bar and even tapping on the conical part will help. The support is unscrewed from the steering knuckle with two bolts; now you can install a new support, having previously coated it well.

Special attention must be paid to the lubricant, and the recipe for its preparation is special: a quarter of the transmission, a quarter of the lithol, the remaining part is the CV joint. The new support is clamped in a vice, the pin is sprayed with the transmission, and after that the required compound is filled into the boot. The consistency should not be too thick, because after 5 thousand km there will be no lubricant left in the joint. If you lubricate every 45-50 thousand, the support will come off for a very long time, regardless of the brand.

The front suspension of McPherson-type front-wheel drive VAZ cars does not cause as much trouble as in traditional 2101-2107. The design of the linkage front suspension of the Zhiguli is more vulnerable to the lack of road surface due to its design features. But even on front-wheel drive cars it is necessary to monitor the condition of the suspension components, since they are not endless. First, it goes to the ball joints.

Characteristics Ball joint boot VAZ 2110

| Factory number | 2110-2904070 |

| Manufacturer | BRT |

| Original spare part for | |

| Applicability | 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, 2115 |

| Product code | 107618 |

Accepting orders From 9:00 to 19:00 – Mon Tue Wed Thu Fri From 10:00 to 16:00 – Saturday

Delivery in Moscow

- By courier to the address

- No prepayment

- Payment upon receipt

Delivery across Russia

- Transport services

- C.O.D

- Business Line

- ZhelDor

- Post office

The ball joint is an important element of the chassis of the VAZ 2110. If it fails, the controllability and safety of the vehicle deteriorate, and the risk of getting into an emergency situation increases. Therefore, if the first signs of a malfunction appear, it is necessary to immediately check and, if necessary, replace the defective part. Repairs are easy to do with your own hands, and if difficulties arise, you should refer to the corresponding thematic video.

Checking the condition of ball joints

There are several ways to check ball joints, and we will look at all of them, because there are only three of them.

- We hang the car on a jack, having previously placed the wheel chock under the diagonally opposite rear wheel, and it is better to put the car on the handbrake. We take the wheel with our hands in its upper and lower parts. We are actively swaying and trying to catch the play.

There can be a catch here, since the wheel bearings can lead to horizontal play. Just in case, let's check the bearing. To do this, shake the wheel in a vertical plane. If there is no obvious play, then the support is still to blame.

Diagnostics of the ball joint condition

You should pay attention to the ball joint if at least one of the following symptoms is present:

- when driving over uneven road surfaces, there are extraneous sounds in the front suspension, especially noticeable at speeds close to 30 km/h;

- when the car moves on a straight road, it is pulled to the side regardless of the position of the gearshift lever;

- entering a turn by a VAZ 2110 is accompanied by a knocking sound coming from the wheel arches;

- tires wear unevenly;

- you have to apply more force than usual to the steering wheel to turn the wheels;

- the stability of the machine is partially reduced, which is most evident when driving over uneven surfaces;

- creaking and grinding noises accompany the turning of the wheels;

- turning into a turn becomes more difficult due to reduced controllability of the VAZ 2110.

The presence of the above symptoms only indirectly indicates a malfunction of the ball joint. Therefore, additional testing is required for a more accurate diagnosis. It is performed in several stages. You should start by checking the absence of backlash. To do this, you need to shake the hanging front wheel in a vertical plane to the left and right, as well as from top to bottom.

A visual inspection of the boot is important. The performance of the ball joint very much depends on the quality and quantity of lubricant under the cuff. When cracks, tears and other mechanical damage appear on the boot, moisture and abrasive particles get under it. Water dilutes the lubricant and changes performance characteristics. As a result, the friction point experiences excessive loads, leading to failure of the unit. The abrasive debris trapped under the cuff gradually moves into the work area. There it causes increased wear of the sho.

The most accurate way to check the ball joint is after removing it from the car. You need to wiggle your finger. It should not move due to hand effort. The presence of axial or radial play indicates that the shock absorber must be replaced.

Ball joint diagnostics

There are several options for this activity:

- The first option is to regularly visit your favorite service station and have the chassis diagnosed there. The diagnostic price is usually about 150 rubles.

- The second option is to do this diagnosis yourself. Here's how it's done.

- Place a jack under the car and lift it so that the wheel comes off the ground.

- Place something under the vehicle - do not work on a jacked vehicle.

- Grab the wheel from the top and bottom.

- Make sudden movements - shake the wheel. Push the top away from you and the bottom towards you and vice versa.

- When the wheel wobbles, a dull knock will be heard.

- Ask a friend to shake the wheel, and you yourself place two fingers on the connection between the ball joint and the suspension arm (see Suspension repair - how to do it correctly).

- If the ball joint is out of order, vibration will be heard at the point where the fingers are applied.

Remember. The ball joint does not necessarily change as a pair.

You can also make assumptions about ball wear for the following reasons:

- The car does not move steadily on a flat road. If the ball joints are loose, this is quite possible.

- The rubber on the front wheels shows significant uneven wear. Although it may be an incorrect alignment, it does not prevent the ball joint from wearing out.

- When a car wheel hits a hole, a dull knock is heard - this indicates that the ball joints on your VAZ 2110 have become unusable.

- The steering wheel became harder to turn.

How to diagnose a ball joint

This can be done in two ways - listening and feeling. Let's look at each separately.

Aurally:

- This method does not require any additional equipment.

- Place the car on a level surface and in as quiet a place as possible so that sounds can be heard better.

- Place your foot on top of either front wheel.

- Rock the car from side to side.

- If, when rocking, the car makes dull metal impacts on one side, then there is a possibility that the ball joint on the side of the emanating sound has become unusable.

Advice! Of course, the words “there is a possibility” only indicate a possible malfunction. To diagnose an exact breakdown, it is best to use the second method.

To the touch:

- First, the car should be raised so that the front wheel can rotate freely.

- First, lift it with a jack, then support something and lower the car onto this object.

- You can substitute bricks, a wooden block or other thing at hand.

- Rock the wheel from top to bottom.

- Again, when rocking, dull sounds should be produced.

- To be sure, you need to place your hand (two fingers) at the junction of the lever and the ball joint.

- With your fingers you will feel the knock that the ball joint pin creates.

Advice! If there is even a slight knock in the ball joint, it is better to replace it. Never delay car repairs - in the end, even your life may depend on it.

- Do the same operation with the second wheel. If any problems are found, make appropriate repairs.

Dynamic diagnostics:

- In this case, it is necessary to listen to extraneous sounds directly while the car is moving.

- The malfunction of the ball joint will be especially audible when the wheel hits the slightest hole on the road.

- A knock will be heard from the side of the faulty ball joint.

- In this way, you can determine whether the VAZ 2112 ball joints need to be replaced or not.

- But this method also does not fully guarantee that it is the ball joint that has failed!

Choosing a quality ball

You can buy any ball joint at the nearest store and drive it for quite a long time, but this is a matter of chance. Therefore, let's look at what a high-quality ball should be:

- Ball joint housing. It must be welded in two parts. The seam should be visible on one side, but not on the other.

- Ball joint pin. Must be hardened, gray in color, must have scale and no paint on it. Rolled thread.

- The ball should rotate with great effort, but not bite. It is often very difficult to turn the finger with your hands - you have to take a knob.

- The kit should include a boot and a nut.

- Remember - most VAZ 2110 owners install Track balls on their car. Also good options are BelMag, Trial-Lux and others.

Replacing the ball joint

Now let's look at how to replace a ball joint correctly with your own hands.

Removal

Advice! Don't forget to set the parking brake and install wheel chocks.

- On a VAZ 2110, replacing the ball joint begins with raising the car. This is done using a jack and stand.

- Then, using a balloon tool, unscrew the wheel mounting bolts and remove it.

- Take a metal brush and clean the area around the ball joint to make it easier to unscrew.

- Spray the ball pin with HP spray to make the nut easier to unscrew.

- Take a 19mm socket and a long wrench. Unscrew the ball pin nut completely.

- Now we need a ball joint remover. Place the connection between the suspension arm and the ball joint into the puller and unscrew the rod until the pin comes out of the arm.

Replacement of ball VAZ 2110

Advice! Tap the suspension arm with a hammer periodically - the vibration will help remove the pin.

- If you can’t get such a puller, you can remove the ball joint using a hammer and a pry bar.

- The pry bar must be placed between the lever and the steering knuckle, rest against the fist and press on the lever to create pressure.

- At this time, it is necessary to apply clear and strong blows to the suspension arm with a hammer until the finger pops out.

- Next, using a pry bar, in the same position, you need to bend the lever and move the ball pin away.

- Using a 17mm socket, unscrew the two bolts securing the ball joint to the steering knuckle.

- Remove the ball.

Ready!

Preparing a new ball

You can just install a new ball joint, but it would be better to apply some tips:

- Lubrication. Clamp the new ball joint into the planks.

- Remove the nut and boot.

- Place a wrench (a small tube of suitable diameter) onto the ball joint pin.

- Take Litol or other lubricant and fill the ball joint housing with it.

- In this case, you should make rotational movements with the finger of the ball joint so that the lubricant is better distributed in the housing.

- Lubricate the ball-to-knuckle bolts.

- Drive the threads on the bolts with at least nuts.

Remember! Do not lubricate the ball pin, because it will rotate when you try to tighten the nut directly on the car.

Installation

- First of all, clean the seat for the ball joint on the steering knuckle.

- Screw the ball back to the knuckle using a 17mm socket.

- Using a pry bar, bend the suspension arm and place the finger of the ball joint into the hole in the arm.

- Tighten the ball joint pin nut.

Attention! If the finger scrolls, then it is necessary to create a load. This is done with the same mount, only the pressure needs to be created in the opposite direction.

- Then put the car wheel back in place.

It doesn't matter on which side of the car you change the ball joint - it's done the same way. In the same way as the replacement of ball VAZ 2110 is done, it is done on other models of this family. Apply these tips from the article, look at the process in the photo and this will make your repair as fast and high-quality as possible!

Replacing a ball joint on a VAZ 2110

Instructions for replacing the ball joint on a VAZ 2110 are given below.

- Secure the rear axle with the handbrake and wheel chocks.

- Jack up the car.

- Unscrew the front wheel fastenings and remove it.

- Unscrew the bottom nut.

- Unscrew the 2 ball joint fasteners.

- Install the puller. Using a wrench, you need to screw in the bolt to press out the SHO until the lever cage loses its pin.

- Press the lever and remove the old ball joint.

- Install the new SHO and assemble everything in reverse order.

- After the car has driven about 100 km with the new ball joint, all threaded connections must be re-tightened.