From this small guide you will learn how to replace the clutch on a VAZ-2112. This car has earned popularity among young people and older generations. Yes, the car is still far from being comparable to prestigious foreign cars, but it has everything you need: a very playful and powerful engine, a comfortable interior, and a rather attractive appearance. And this is all that is necessary for an unpretentious person. And the most important thing is the low cost of maintenance. Spare parts for a 12 Series car cost much less than for foreign cars. In addition, many components from older “nines” and “tens” are suitable for it.

What is clutch?

Before you go to a car service center in Moscow or another city, try to figure out how to properly replace the clutch on a two-wheeler. As you can see, there is nothing complicated in the work procedure. You can complete all repairs yourself in a few hours.

The clutch is a mechanism that allows you to disconnect the engine crankshaft and the primary gearbox. As a result, the engine can work, the gearbox lever can be in a gear position, and the car will stand still.

A clutch is needed in order to change gears while the car is moving. If it were not there, then changing gears would be problematic - the lever is very difficult to move from one position to another. And all because the engine crankshaft and the wheels of the car are rigidly connected. And it is the clutch that allows for a kind of disconnection of the power units.

When repairing a car in a car service center in Moscow or any other city, you need to carefully ensure that the technicians complete all the work to the highest possible quality.

Basic clutch elements

Now let's look at what main elements are included in the design:

- VAZ-2112 clutch drive disc (usually called the “basket”). It is installed on the flywheel and secured with bolts.

- Driven disk. It stands inside the “basket” and is connected to the gearbox input shaft using a splined connection.

- The release bearing is an element that allows you to act on the petals of the basket. With its help, the slave disk is disconnected from the master disk.

- Clutch cable - allows you to transmit force from the pedal to the release bearing.

- The clutch pedal, which the driver operates with the force of his foot.

These are all the basic elements that are present in the design of a car clutch. It is worth noting that the “two-piece” uses a cable drive system, which is much cheaper than a hydraulic one. But it is much worse in terms of convenience - the pedal is tight, this is especially noticeable on older cars. And if you want the clutch on your car to be as soft as possible, change the cable in a timely manner, do not wait until it breaks.

Clutch adjustment

After installing a new or repairing a clutch, it always requires adjustment; our instructions will help you. There is nothing complicated here and, after reading this article, everyone will be able to adjust it independently. So:

Symptoms of a node malfunction

Before replacing the clutch on a VAZ-2112, you need to figure out whether it needs to be done at all.

Among the signs of malfunctions are the following:

- When you press the gas pedal, you can hear the engine picking up speed, but the car does not go faster. This indicates that the clutch is slipping, there is practically no connection between the driven and driving discs.

- Extraneous sounds are heard when the car moves - this may indicate the destruction of some system components. As a rule, at the same time as these sounds, the system also fails.

- A hum is heard when you lightly press the pedal - a clear sign of a faulty release bearing.

- The pedal falls through - most likely the VAZ-2112 clutch cable has broken. This is the most harmless thing that can happen.

- If the cable is intact, but the pedal falls and the clutch does not release, then the release bearing has collapsed. Unfortunately, this also happens sometimes.

Knowing all the signs of breakdowns, you can begin repairs. Replacing the clutch on a VAZ-2112 with your own hands is not difficult. You just need to know the order of the work.

VAZ 2110 clutch: replacing the disc with your own hands

It should be immediately noted that replacing the clutch on a VAZ 2110 is a drastic measure to repair the unit. In some situations, it is quite possible to get by with repairs that will extend the life of the existing clutch. Today we will look at these issues in more detail in our material.

Coupling problems

Actually, this is where the description of the purpose can end.

How it works and what it consists of

Device diagram

The factory clutch system for the VAZ 2110 is called VIS. Many people complain about it because it doesn’t work very effectively, although others are sure that there is no more worthy alternative for the “ten”. So opinions differ on this matter.

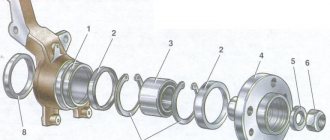

The main components of the system include:

- casing;

- Crankcase with a cover and supporting planes with which the unit is attached to the frame;

- Driven and pressure plate;

- Release bearing. It disengages the clutch;

- Flywheel;

- Shutdown plug;

- The cable wire that goes to the pedal (far left in the car interior).

Choice

Kit

Today the market is represented by an extensive list of alternatives made in Europe and China. We strongly do not recommend using Chinese spare parts, but European analogues should be considered as a replacement for VIS.

According to a study conducted among VAZ 2110 owners, the five best kits for the domestic “ten” were determined:

- Kraft Tech.

- LUK.

- Valeo.

- Sachs.

- VIS.

As we have already noted, VIS is installed as standard and works quite well. An important advantage compared to European counterparts is financial accessibility. But if your wallet allows it, replace the old clutch with a better and more expensive one.

In defense of the VIS system, we note that repairs often require simply adjusting the pedal and tightening the cable . And if you are going to completely change VIS to VIS, it will not cost you a pretty penny.

Popular problems and their solutions

There are several characteristic faults that occur on the VAZ 2110. Let's try to understand the reasons for their occurrence, and also consider ways to solve the problem.

- The clutch drives. The reasons may be: The pedal has insufficient travel, the tension is too tight. To eliminate this, you need to adjust the drive;

- The driven disk is deformed. Only replacement will help here;

- The driven disc hub sometimes gets stuck. If so, try washing it and lubricating the input shaft splines. If the element or the shaft itself is worn out, then replace them;

- The friction linings are broken and the rivets are loose. The best solution is a complete replacement of the casing, which includes a spring and a disk;

- The pressure plate is warped or warped. Replace the linings, but first make sure that there are no deviations in the end runout of the disk;

- There were problems with the cable. Pull it up. If there is no result, replace with a new one.

- The friction linings on the driven disk often burn or wear out. There is only one solution - replacement;

- Oil has reached the surface. We have already described how to solve the problem above;

Dismantling, repair and replacement

It is possible to replace the clutch on a VAZ 2110 without removing the gearbox, but the method most often used is to dismantle it. It is not necessary to remove the box if you just want to adjust the clutch. And during repairs there is no need to drain the transmission oil.

The procedure for dismantling and repair is as follows:

- Disconnect the battery;

- Remove the air filter;

- Disconnect the wiring harness;

- Raise the car;

- On the right, loosen the clutch drive nut and unscrew completely on the left;

- Remove the lever from the car suspension, and also remove the ball joint;

- Unscrew the lower protection of the power unit;

- Disconnect traction from the gearbox;

- Remove the clutch housing and inspect it. Most often, the crankcase has cracks, the threads wear out, or the “grip” of the paws holding the crankcase is lost. To correct the situation, the cracks are welded and the threads are renewed. This way the crankcase can last for many more years;

- Raise the engine with a jack, remove the gearbox, which will allow access to the clutch assembly;

- At this stage, repairs are performed or the clutch system is completely changed. It all depends on the current state of the units.

As you can see, the clutch for the VAZ 2110 plays a vital role, and keeping it in good condition is the direct responsibility of every car owner. You can fix problems that arise with the clutch on your own, without going to a service station. But if your personal experience, skills and knowledge are not enough for such work, it is better to immediately contact specialists.

Dismantling the gearbox

The most important thing is to remove the gearbox. Therefore, it is best to carry out all work on an inspection hole or overpass - it’s really more convenient. Procedure:

- Remove the left wheel, unscrew the nuts from the ball joint and the tie rod end. You will need to move the box to the side; the drive on the left should come out without any problems.

- Loosen the nut securing the rocker and remove it from the gearbox shaft.

- Remove the starter, having first disconnected the battery and all wires from it.

- Unscrew the fastenings of the pillows holding the box. It is recommended to place a jack or reliable support under the gearbox housing before doing this.

- Disconnect the speedometer cable, disconnect the wires from the reverse sensor, as well as the ground bus.

- Unscrew the three bolts and nut that secure the gearbox housing to the engine block.

- Carefully move the box to the side; the right drive must be removed.

A little about how to properly remove the box:

- Firstly, you cannot remove both drives at once - replace one with a tube that will hold the differential.

- Secondly, it is imperative to drain the oil from the gearbox crankcase. By the way, why not replace it?

Clutch installation and assembly

Replacing the clutch on a VAZ-2112 is carried out according to the following algorithm:

- Unscrew all the bolts that secure the basket to the flywheel. If you plan to install it again, then you need to unscrew the bolts evenly, crosswise. The main thing is not to damage the basket.

- Remove the basket and disk, install new elements in their place.

- Tighten all the bolts (be sure to use new ones, since the old ones are threaded) and install the guide sleeve.

- Tighten the bolts evenly, crosswise.

- Remove the old release bearing and install a new one.

- Reassemble everything in reverse order.

This is a short tutorial, but the hardest part is lifting and lowering the box, as it is quite heavy.

Replacing the clutch cable

The price of replacing a clutch on a VAZ-2112 is quite high - you will have to pay about 3,000 rubles for more or less high-quality spare parts, and at least the same for labor. But if you do everything yourself, you can save a lot of money.

Replacing the cable is much easier. The old one needs to be dismantled, and the new one needs to be fixed on the pedal and fork. The most difficult thing is to stretch it from the engine compartment into the cabin: the hole is quite small, and there are no amenities. But everything is doable, and all the work will take you, including preparation, no more than half an hour.

Operating principle of the cable

VAZ models 2112 are equipped with a standard mechanical clutch drive for Volzhsky Automobile Plant products. Its distinctive features:

- structural simplicity;

- cheapness;

- ease of maintenance;

- decent endurance.

The main element connecting the clutch with the control mechanism is the cable discussed in this article. It is enclosed in a protective shell, which ensures the preservation of the lubricant placed inside and a number of other auxiliary functions.

The pedal is located in the cabin itself, and pressing it moves the clutch fork. The force is transmitted precisely by our cable.

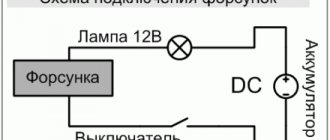

At the end opposite from the foot drive there is an extremely simple adjustment device that allows you to set the pedal stroke length. It consists of two nuts screwed onto the end of the cable. It is not difficult to find - look at the area where the clutch fork is located. The upper nut is responsible for the actual adjustment, and the lower one prevents it from spontaneously unwinding.

The principle of operation of the mechanism is as follows: the person sitting behind the wheel presses the VAZ pedal, which pulls the cable, which, in turn, pulls the fork along with it. The latter moves the release bearing, causing it to press on the basket. As a result, the clutch disengages.