How to check car suspension springs

The question of how to check a spring is often of interest to car owners only when the car “sags” even with a small load, or even without it. However, such a check of the suspension springs should have been done only when the first symptoms of their wear appeared. It is best to do diagnostics in a car service center on a special stand, but the simplest check of the condition of the springs can be done in a garage with your own hands. This does not require a special tool, and the procedure is accessible to almost everyone.

Where to buy Patron suspension springs?

Today, the market offers a wide range of auto parts from various manufacturers, which makes it difficult for consumers to decide on a brand and choose a truly high-quality product. The prices for original spare parts are quite high, and not every driver can afford to purchase them. Among the available alternatives, which are not inferior in quality to the original ones, PATRON spare parts, our own brand, stand out. You can purchase Patron suspension springs, as well as other automotive components, in the company’s stores, as well as at points of sale from official dealers of the brand.

Patron auto parts undergo strict quality control during the production process, which is confirmed by numerous certificates. Suspension springs of this brand are made exclusively from high-quality raw materials in compliance with all requirements for production technology. Car owners who purchase PATRON parts note their reliability and wear resistance.

From the outside, checking a car's suspension seems like a complex process that requires global technical knowledge and equipment proficiency. In fact, it is possible to check the suspension yourself - this does not require equipment or complex instruments. We will tell you in this article how to properly check the suspension yourself, and what conclusions you can draw after checking.

Signs of faulty suspension springs

For the need to check the fatigue of car suspension springs, one or more signs may appear. Among them:

- It is visible to the naked eye that one of the sides of the car “sank” more than the other in an unloaded state (without cargo and passengers). You need to look at one axis, that is, for example, compare the front left and front right springs. In such cases, most likely the spring has sagged or broken completely (on the sagging side). However, there is a nuance here, which consists in the fact that the subsidence of one or the other side can be influenced by the so-called glass, that is, the place where the spring rests. Often on old cars (most often VAZ “classics”) the glass falls through. When diagnosing, you will need to check both the fatigue of the spring and the cup.

- A metallic clanging sound while driving on rough roads is a clear sign of a broken suspension spring. Moreover, this clanging sound can be produced even when driving over small bumps or potholes. However, in this case it makes sense to also check the steering rack and ball. A metallic clanging sound usually indicates that one of the spring coils has partially or completely snapped.

- Low landing of the machine when loading, even lightly. Especially if everything was fine before and such a phenomenon was not observed. Typically, this problem is more common on the rear springs, and at the same time the wheels begin to scrape against the wheel arch liners, and the mud flaps begin to touch the road surface. This is a very dangerous situation, because in this way, in emergency mode, the tires wear out, and at one “wonderful” moment they can simply burst.

- Strong vibration and shaking while the car is moving, even on a flat road. In this case, the shaking increases as the speed of the machine increases. As a rule, this is a sign that the spring has burst completely.

- Reduced ride quality . This can be seen by comparing the operation of the machine before and after the problem occurred. Usually the spring stops working normally and when driving over bumps the car jumps or dives into a hole.

- Significant car roll even with gentle braking.

If at least one of the above symptoms appears, it makes sense to perform a comprehensive diagnosis of the suspension, including checking the shock absorber springs. Moreover, it is advisable to perform the check not only on the side where the car sank, but on all the others too.

Causes of spring failure

There are five main reasons why rear and/or front springs fail completely or partially.

- Metal fatigue and spring wear . This happens for natural reasons over time. During operation, the metal becomes softer and more pliable, and accordingly, the spring becomes softer. And also when the coils of the spring collide, the springs rust and microcracks appear. Particularly harmful to the rods are the strong impacts that occur when a car hits a pothole or bump at high speed.

- Constant friction of the coils of a weakened or heavily loaded spring among themselves. For this reason, the spring stiffness decreases, and the surface of the coils themselves becomes not round, as it was initially, but has a worn-out plane. Accordingly, for this reason the rod becomes thinner, and therefore the spring becomes weaker.

- Overloading a car and driving it in this condition at high speed over uneven surfaces or distances. In such conditions, all suspension elements suffer, including springs.

- Corrosion of metal springs . This is a very common reason why springs fail. Over time, the paint on their surface peels off, and water and road reagents do their job. Interestingly, if corrosion “ate” only a 0.15 mm layer on a 10 mm spring wire, then the cross-section of the said wire is reduced by as much as 6%!

- Installing the wrong spring . In particular, this can happen due to incorrect selection of parts. Another option is a factory defect. It often happens that springs with different stiffnesses are placed in one package.

Stretched spring - reasons

If the spring is faulty, this does not mean that it is of poor quality or that you have been deceived. There are a number of factors that are involved in premature spring failure, including:

- Natural wear and tear . Too frequent use in difficult conditions or simply high mileage. Nothing lasts forever, perhaps the spring has simply exhausted its resource. Each spring has its own resource, approximately 50-80 thousand km. mileage

- Incorrect operation . If you constantly load your car or carry more weight than expected, the springs will last much less than if you were driving alone or with minimal additional weight.

- Corrosion and reagents . These factors need no introduction or explanation. Once the rust penetrates under the paint of the spring, it does its dirty work, day after day, eating away at the surface of the spring, weakening it. The same is with reagents; they aggressively affect the metal, destroying its surface and worsening its properties.

How to check a suspension spring

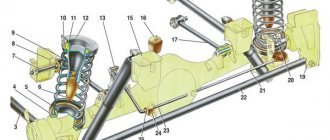

To check the condition of the car suspension spring, it must first be removed from its seat and cleaned of dirt and rust. This will allow you to visually assess its condition, check for cracks, chips and other defects.

First of all, you need to check the spring for stiffness. However, before that you need to find out what class it belongs to, as well as which springs the car manufacturer recommends installing on the part of the suspension from which it was removed.

All springs are divided into two main classes - A and B. Their differences are in stiffness and length. The length of A-springs is up to 27.8 cm, and the length of B-springs is over 27.8 cm. As for color coding, this depends on the specific car brand and spring manufacturer.

Press check

To determine the fatigue of springs using the compression method, you need to know what stiffness it should be installed in a specified location in order to know with what to compare the result obtained in the future. So, in garage conditions, spring stiffness can be checked using the following tools:

- two square bars with a thickness of at least 1.2 cm and an area slightly larger than the area of the end of the spring being measured;

- scales;

- manual press (controlled by a thread drive).

The verification algorithm in this case will be as follows:

- Using a floor scale, find out the total mass of both bars and the spring being measured.

- Place the floor scales on the lower platform of the press, place one of the pre-prepared bars on them.

- Place a spring on the block, and place a second block on top of it.

- When activating the press, it is necessary to compress the spring.

- The compression value (distance) and pressure must be pre-selected in accordance with the documentation. Accordingly, there can be no specific recommendations here.

- From the obtained force value (in kilograms of force), it is necessary to subtract the previously measured total mass of the bars and spring.

If the spring has compressed a certain distance with insufficient force, this indicates that it has weakened significantly and it is advisable to replace it. However, the decision to replace must also be made on the basis of a visual inspection, as well as information about how many kilometers the car has traveled with a given spring.

However, in practice, this method is quite problematic to implement, since the test requires considerable effort. For example, when testing the springs of a VAZ-2110 car, you need to develop forces equal to 325 kilograms of force. With this value, standard front suspension springs must have a length of at least 201 mm (for the so-called “European” spring, the same value will be 182 mm). For a rear standard spring with the same force, its length will be at least 233 mm (for a “European” spring - at least 223 mm).

Theoretical calculations

The permissible geometric change of the spring, as well as its stiffness, can also be calculated using the appropriate formulas. Thus, the geometric change is calculated as follows: X = F × L / C. Here X is the change in spring size, F is the applied force, L is the initial length of the spring, C is the proportionality coefficient, table value (depends on the radius of the coil part of the spring, material its manufacture, rod diameter).

Similarly, the stiffness of the spring is calculated using another formula - k = F / X. Here, too, F is the force, and X is the size of the compressed spring measured as a result of experiment. The complexity of such calculations is due to the fact that you need to know the proportionality coefficient, and this information can only be found in technical documentation.

Checking the manual

The technical documentation (manual) for any car contains a detailed description of the procedure for checking ground clearance, and, in particular, springs. Let's consider a similar diagnosis using the example of the popular Toyota Camry. So, for this you first need to measure four parameters:

- A is the distance (clearance) from the center of the measured front wheel to the surface on which the machine is installed;

- B - distance from the center of the bolt of the lower suspension arm No. 2 of the measured front wheel;

- D — distance from the center of the measured rear wheel to the ground (clearance);

- C is the distance from the center of the trailing arm bolt of the corresponding rear wheel being measured to the ground.

Next, you need to find the difference between the values of A and B, as well as C and D. After this, compare the minimum acceptable values with the data given in the table. If the values obtained as a result of measurement are lower than those given in it, then it is necessary to carry out additional diagnostics. You may have to use additional spacers or replace the spring with a new one. If the obtained values are greater than the minimum acceptable values, it means that everything is in order with the spring (if there are no additional symptoms of a malfunction).

How to check the rear suspension

The main part of the components and assemblies is concentrated in the front suspension, so it is easier to check the rear suspension. On most budget cars the rear suspension is dependent, its most expensive part is the struts; on medium (budget) cars they last about 100 thousand kilometers, after which they begin to “get tired”.

There is nothing else significant or critical in the rear suspension, except for the silent blocks, which are practically eternal (again, look at the condition of the rubber bands). If the rear suspension is independent, its design is somewhat more complicated, but the essence does not change - apart from the struts and silent blocks, there is nothing fatal, but in an independent suspension they wear out faster, and this is more noticeable.

It is best to check the rear suspension together with the front during a test drive; here the sounds and behavior of the car will best tell you about the situation - whether something “clunks” or not, and how it absorbs it - whether it sways on bumps or not. If the car rocks on uneven surfaces not only up and down, but also sideways, this indicates that the suspension is damaged and repairs are urgently needed. This also means that the car was not looked after or looked after at all, and it is better not to buy such a car.

Shock absorber malfunction: symptoms and what affects

Shock absorber malfunctions greatly affect the car's behavior on the road. In particular, the car body “dives” during acceleration and braking, the braking distance increases, rolls heavily during maneuvering and sways when driving over uneven surfaces.

There are obvious and hidden signs of faulty shock absorbers. Obvious ones include the appearance of oil leaks (wear of the oil seal and/or rod), but there are more hidden ones, for example, aging of the oil, deformation of the valve mechanism plates, wear of the piston seal and the inner walls of the working cylinder. To avoid unpleasant consequences, you need to identify the faulty shock absorbers in time.

Signs of faulty shock absorbers

There are two types of signs that a shock absorber has completely or partially failed. The first type is visual. In particular, they can be identified by visual inspection of the shock absorber. The second type of signs includes changes in the behavior of the car in motion. Let us first list the signs related to the second type, since first of all it is necessary to pay attention to how the behavior of the machine has changed, in particular:

- Rocking when braking and accelerating . If the shock absorbers are working properly, then even with sharp braking the car should swing back no more than once, after which the shock absorber should dampen the oscillatory movements. If there are two or more swings, this is a symptom of partial or complete failure.

- Roll when maneuvering . Here the situation is similar; after exiting a sharp roll when entering a turn, the body should not sway in the transverse plane. If so, the shock absorber has similarly failed.

- Increased braking distance . This factor is due to the same swing during braking. That is, during prolonged braking, the shock absorber does not dampen vibration, and the car periodically lowers and raises the front part of the body. Because of this, the load on the front wheels is reduced, which reduces braking efficiency. The braking distance is especially longer for vehicles equipped with an anti-lock brake system. This is because the rear end rises and the ABS reduces the brake line pressure. Also, the braking distance increases when braking on uneven roads.

- The car does not “hold” the road . In particular, when the steering wheel is installed in a straight position, the car constantly pulls to the side. Accordingly, the driver must constantly steer in order to align the trajectory of movement.

- Discomfort when driving . It can manifest itself in different ways. In particular, some drivers and/or passengers feel discomfort from the rocking of the car when driving long distances; people suffering from “sea sickness” (the official name is kinetosis or motion sickness) can feel motion sick. This effect is a typical symptom of faulty rear shock absorbers.

Please note that signs such as long braking distances, uneven tire wear and constant need to steer may indicate other problems in the vehicle, such as worn brake pads, low brake fluid levels, uneven tire pressures, problems with the ball joint or other components. pendants. Therefore, it is advisable to perform a comprehensive diagnosis. Visual symptoms of shock absorber wear include:

- The appearance of drips along the body and stem. In particular, this occurs due to wear of the oil seal (seal) and/or shock absorber rod. A decrease in oil level leads to a decrease in the operating amplitude of the device, as well as to an increase in wear of the parts included in its design.

- Wear of silent blocks. As is known, in this rubber-metal hinge, mobility is ensured due to the elasticity of rubber (or polyurethane, depending on the design). Naturally, if the shock absorber works hard, then increased forces will be transferred to the silent block, which will lead to its significant wear and failure. Therefore, when diagnosing shock absorbers, it always makes sense to check the condition of the silent blocks.

- Damage to the shock absorber housing and/or its fasteners. This can be expressed in different ways. For example, the appearance of rust on the rod (stand, support), curvature of the body, damage to the mounting bolts, and so on. In any case, the shock absorber must be carefully inspected.

- Uneven tire wear. They usually wear more on the inside and less on the outside.

That is, if there is a malfunction of the shock absorbers, then expect failure of other suspension elements, because they are all interconnected and can be influenced by each other.

Indirect signs of malfunction

To see that the shock absorber strut is leaking, just look at the suspension from below. However, it is not always possible to do this. And on some cars, due to the design of the shock absorbers, they are simply not completely visible. Accordingly, it will be useful to know about indirect signs that the rack is leaking.

This includes the following signals:

- long rocking of the car even on a flat road;

- knocking when driving over uneven surfaces;

- beating in the steering wheel;

- severe body roll when accelerating, braking or maneuvering.

This is more difficult to notice, but when shock absorbers leak, fuel consumption and braking distance increase, the car handles worse, and does not hold the road during aggressive driving.

What is the effect of a faulty shock absorber?

The use of worn shock absorbers can not only cause discomfort while driving, but also cause a real danger when driving the car. So, possible problems associated with a faulty shock absorber:

- Reduced wheel grip. In particular, when the car rocks, the clutch will have a variable value.

- Increased braking distance, especially on vehicles with an anti-lock braking system (ABS).

- Some electronic systems of the car, such as ABS, ESP (exchange stability system) and others, may not operate correctly.

- Deterioration in vehicle handling, especially when driving at high speed.

- The appearance of “hydroplaning” when driving on a wet road at low speeds.

- When driving at night, constant rocking of the front of the car can cause the headlights to blind oncoming drivers.

- Discomfort when driving. This is especially true when driving long distances. For the driver, this threatens increased fatigue, and for people prone to seasickness, this is dangerous due to motion sickness.

- Increased wear of tires, rubber bushings, silent blocks, bump stops and springs. and other elements of the car suspension.

How to check the front suspension

Most cars have a standard McPherson front suspension. The most expensive part of the suspension are the struts and shock absorbers. In terms of difficulty of replacement, the following are the silent blocks of the stabilizer and levers. The easiest and cheapest thing to change is the ball joints of the front suspension.

When checking the front suspension, first of all, inspect the anthers and rubber covers of the parts, and then proceed to inspect the silent blocks, balls and all of the above. Inspect the mounting bolts and tie rod ends. If you find a part whose cover is damaged, you will need to replace the part.

Carefully inspect all rubber seals; they should not have mechanical damage. Separately examine the parts adjacent to the body - here you need to inspect more carefully due to poorer visibility.

The shock absorber will show oil leaks - the first signs of a malfunction. They can be noticed before sounds occur when the car rocks. If the car swings instead of the vibrations being dampened, this will also mean wear on the shock absorber, but at a more advanced stage - again, replacement is required.

Causes of shock absorber malfunction

The causes of failure are usually natural factors, including:

- Aging of shock-absorbing fluid (oil). Like other technological fluids in a car, the oil in the shock absorber gradually gains moisture and loses its performance properties. Naturally, this leads to the fact that the shock absorber begins to work harder than it worked before. However, it must be understood that fluid aging does not happen overnight, with the exception of a rupture of the seal on the shock absorber body.

- Torn seal. In particular, the sealing of the piston and the inner walls of the working cylinder. The oil seal can rupture due to external factors or simply due to the aging process. It, like any rubber seal, becomes tanned over time and begins to leak liquid. Because of this, oil leaks from the shock absorber, as well as moisture from the outside entering the oil, which leads to a deterioration in its performance.

- Deformation of the valve mechanism plates. This process is also natural and occurs on an ongoing basis, albeit at different speeds. Thus, the rate of deformation depends on two main factors - the quality of the shock absorber (the quality of the metal of the plates) and the operating conditions of the machine (naturally, a significant impact load leads to premature deformation).

- Gas leak. This is true for gas-filled shock absorbers. The idea here is the same as for oil-filled devices. Gas here performs a damping function, and if it is not there, then the shock absorber will not work.

- Failure of silent blocks. They wear out due to natural reasons, losing their elasticity and performance. These components are practically not subject to repair, so if they fail, they simply need to be replaced (if possible, or the shock absorbers must be completely changed).

Why do springs break, symptoms of failure?

The spring looked almost new

The working environment of the suspension spring can be called complex, so during operation it is easy to damage the protective coating of the coiled body of the element and expose the steel, which can very quickly begin to corrode under the influence of salts. But most of all, the spring element suffers in winter, when water, salt and sand get between the coils, which leads to its damage.

Typical symptoms of a broken suspension spring:

Irregular knocking and vibration on uneven surfaces; Characteristic dull impacts when turning the wheels hard or braking heavily; There is a difference in the height of the machine along the longitudinal axis (the left side is higher than the right, and vice versa) or between the front and rear parts; Strong rolls when driving and braking

How to determine if shock absorbers are faulty

Car owners are not without reason concerned about the question of how to check an oil or gas-oil shock absorber. This is due to the fact that modern shock-absorbing devices often have a more complex design than older models, which makes diagnostic measures more complicated. Therefore, ideally, they should be checked in a car service center on a special stand. However, there are a number of “garage” verification methods.

Body rocking

The simplest, “old-fashioned” method is to rock the car body. In particular, they rock its front or rear part, or the shock absorbers separately. You need to swing it strongly, but do not bend the body elements (in practice, such cases occur!). In theory, you need to achieve the maximum possible swing amplitude, then release the body and look at its further vibrations.

If the shock absorber is working properly, the body will make one swing (or one and a half), after which it will calm down and remain in its original position. If the shock absorber has a malfunction, the body will make two or more oscillations. In this case, it must be replaced.

It is worth noting, however, that the rocking method is suitable for cars with a simple suspension system, for example, the VAZ “classic” (models from VAZ-2101 to VAZ-2107). Modern cars often use complex (often multi-link) suspension, so it will dampen the resulting vibrations even with faulty shock absorbers. Therefore, with the help of body rocking, by and large, it is possible to determine two borderline states - the damper is completely out of order, or it jams during operation. It is not easy to identify the “average” states of the shock absorber using swinging.

Visual inspection

When diagnosing a problem shock absorber, be sure to perform a visual inspection. To do this, you need to drive the car into a viewing hole or lift it on a lift. You can, of course, dismantle the shock absorber, but this can take a lot of time and effort. During the inspection, be sure to check for oil smudges on the shock absorber body. You can wipe off traces of oil with a rag and leave it like that for several days. After this period, the test should be repeated.

If the car is raised on a lift, it is advisable to check the condition of the shock absorber rods. They should not show any signs of rust or damage. If they are present, then the device is at least partially faulty and additional diagnostics need to be performed.

When inspecting, be sure to pay attention to the wear pattern of the tires. Often, when shock absorbers are broken, they wear unevenly; as a rule, the main wear occurs on the inside of the tire. There may also be isolated bald spots of wear on the rubber. However, tread wear may also indicate other failures in the suspension elements, so additional diagnostics are also needed here.

If faults in the front shock absorber (strut) are checked, a mandatory inspection of the springs and upper supports must be performed. Shock-absorbing springs must be intact and free of cracks and mechanical damage.

Machine control check

If the shock absorber/shock absorbers are faulty, then while driving the driver will feel that the car is “scouring” along the road, that is, it will be necessary to constantly steer in order to keep it in the rut. When accelerating and braking, the car will sway. The situation is similar with lateral body tilts. In this case, it is not necessary to accelerate to a significant speed; the city speed limit is quite suitable for testing. In particular, at a speed of 50...60 km/h you can do sharp acceleration, braking, and snake.

Determine the problem by eye

When the springs are heavily worn, they sag, and all that is required in this case is to inspect the car, paying attention to its fit. The car is lower than it should be - a sure sign of “fatigue” shock absorber springs. This also makes it impossible to adjust the wheel camber.

Ball joints are checked in an inspection hole; this is somewhat more difficult, as it requires the ability to look under the car, as well as the presence of a mount. Press the lower control arm bushings and check how they move up and down. If there are no backlashes, and the rubber on the parts is intact, then everything is in order and you don’t have to worry.