A vehicle's clutch plays an important connecting role between the transmission and the vehicle's powertrain. Sometimes this unit requires preventive measures, so adjustment of the clutch of the VAZ 2109, and other vehicles, is carried out in cases where defects associated with the operation of this mechanism appear. Such malfunctions include:

- clutch pedal adjustment;

- clutch cable adjustment;

- pedal height adjustment;

- clutch adjustment.

How to adjust the clutch on a VAZ 2109

Cars of the 09 VAZ family are equipped with a cable-operated clutch. This technology is 5 times more reliable than classic variations with hydraulic drive. However, during operation, any mechanism requires calibration and this unit is no exception.

A scheduled inspection must be performed every 15,000 km or once a year, whichever comes first. However, unexpected breakdowns occur that require surgical intervention.

The following factors are considered signs of incorrect operation of the unit.

- The car starts moving jerkily - the clutch slips, which causes uneven acceleration.

- Increase in fuel consumption by approximately 10-15%.

- Dissonance between engine speed and actual acceleration of the car.

- When shifting into gear, extraneous sounds and squeaks are heard from the gearbox.

- When inspecting the car, there is an unpleasant smell of burnt pads.

- The pedal falls or sticks.

- The drive does not operate in the middle of the pedal stroke.

Do-it-yourself clutch adjustment on a VAZ 2109

The essence of the work is to set the required pedal pressure and measure the cable tension. Figuratively it looks like this:

- pedal height measurement;

- cable tightening;

- examination.

You can also watch a detailed report on the procedure in the video:

Clutch cable adjustment

Clutch cable calibration is performed as follows.

- The necessary tools are prepared: 2 keys No. 17, a ruler or tape measure, WD-40 or an equivalent.

- The car is driven onto a flat section of the road and the parking brake is put on.

- For safety, you can disconnect the battery terminals.

- On the left as the car moves, you need to find the cable itself - the part is attached to the gearbox housing with a special bracket.

- After this, the adjustment unit itself is located (the place of fastening to the gearbox). There is a rubber casing and two nuts that are tightened on the sides of the bar.

- Threads are filled with high-pressure fluid for better unscrewing.

- Next, simultaneously loosen the nuts using two No. 17 wrenches.

- Side No. 1 rotates clockwise to loosen the cable (the pedal falls down), to tighten it, you need to turn it in the opposite direction - the lever rises.

- When the required pretension of the structure is established, all nuts are tightened until they stop.

- Then you need to get into the car, squeeze the clutch all the way 5-6 times and check that the settings are correct, and adjust more if necessary.

Note! According to the factory instructions, the correct position of the cable is when the car begins to move approximately halfway through the free travel of the clutch pedal.

Adjusting the clutch pedal free play

The position and free play of the clutch lever on the VAZ 2109 is set in this way.

- A tool is prepared - a ruler or tape measure, two keys No. 17.

- Inside the car, you need to attach a measuring tape to the side of the pedal.

- When not pressed, the height from the floor is about 180-190 mm - this is normal.

Next, you need to press the lever all the way and remember at which mark the lower part of the pad stops. For example, 50-60 mm.

After manipulating the tensioner, it is necessary to check the correct engagement of gears and the timing of the release bearing. If all standards are met, no additional calibration is required. It happens that the adjustment does not bring the desired effect, in this case it is necessary to contact a qualified technician - perhaps the problem is hidden inside the clutch unit itself.

Clutch operation diagnostics

To understand whether the clutch is working correctly, just follow the procedure.

- Take a ruler and place it on the floor. The other end of the meter should be attached to the bottom of the pedal. It should be approximately 18-19 centimeters.

- Press the lever all the way and measure the distance again - normally it will be 7-8 cm.

- It is considered normal when the difference between the readings is 13.5-14.5 cm.

If there is a deviation in the parameters from the norm by more than 20 mm, the drive needs to be adjusted.

Design and adjustment of the VAZ 2109 clutch

VAZ 2109 is the legendary “nine”. The front-wheel drive five-door hatchback was serially produced at the Volzhsky Automobile Plant from 1987 to 2004. From 2004 to the end of 2011, the VAZ 21093 modification was assembled in Zaporozhye.

Many car owners try to maintain their personal car themselves and know how to do it correctly, since they carefully study the operation of the main components and leading modules. The list of routine maintenance includes periodic adjustment of the VAZ 2109 clutch. This task is quite simple if you familiarize yourself with the operation algorithm in advance.

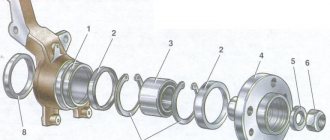

Nine clutch device

The clutch kit is one of the key components of the Nine transmission. This is a single-disc friction-type mechanism located between the engine and the gearbox (gearbox). The algorithm for its operation is as follows:

- Initially, the car is stationary, the engine is started, the pedal is released. The gearshift lever is in the neutral position, that is, the rotation of the input shaft is not transmitted to the secondary shaft.

- The driver is preparing to move forward. With his left foot he presses the pedal, and the mechanism disconnects the gearbox input shaft from the engine. The driver moves the lever to the first gear position, the mechanism ensures the engagement of the primary and secondary shafts of the gearbox. The car is stationary because the engine is disconnected from the transmission input shaft.

- The driver smoothly but decisively releases the pedal. The engine is connected to the input shaft, the task of which is to transmit power to the drive wheels through the secondary shaft, then the car will start moving.

- Switching from first gear to second, from second to third, and so on occurs in the same way.

Typical VAZ 2109 clutch malfunctions

The clutch is one of the relatively reliable units of the VAZ 2109. With normal operation and periodic adjustment, it lasts for years. The estimated resource of the unit exceeds 100 thousand km. And if the clutch pedal fails, this is a rare case. The list of typical faults includes:

| Type of problem. | What is expressed? | What is the reason. |

| The clutch drives. | Pressing the pedal all the way does not ensure complete disconnection of the shaft from the gearbox, and the engine is not disconnected from the gearbox. Pressing the pedal when the unit is faulty leads to the fact that the pressure bearing does not act strongly enough on the damper spring, and the engine flywheel continues to partially transmit torque to the gearbox shaft. | The reason for this is often poor adjustment of the VAZ 2109 clutch cable or failure of the drive disk. |

| The clutch is slipping. | When the pedal is fully released, the gearbox input shaft remains loosely pressed against the engine flywheel and slips, that is, slippage occurs. The torque is only partially transmitted to the drive wheels and sliding of the contact surfaces occurs. This effect is clearly manifested when a loaded car is moving uphill: the driver accelerates, the speed increases, but the car almost does not accelerate, the clutch of the VAZ 2109 slips. | In this case, the drive is most often poorly adjusted, the clutch cable gets stuck, the driven disc is worn out or oily, which is why the clutch slips. |

| Noise when switching off transmission. | When you press the pedal, a distinct rustling or rustling sound is heard. | This quiet sound may indicate a possible release bearing failure. Continuing to operate the car in this condition can lead to troubles: if it jams, the VAZ 2109 clutch basket will inevitably quickly fail. Change the bearing at the first sign of a malfunction, otherwise serious repairs to the clutch, including replacement of the basket, are inevitable. |

Clutch adjustment is not only included in the list of routine maintenance of the VAZ 2109, but is often a way to eliminate emerging malfunctions of this mechanism.

Reasons for replacement

Practice shows that there are several main situations that force you to change the clutch cable.

| Situation | Peculiarities |

| The clutch does not work properly | It becomes difficult for the driver to depress the clutch pedal, which causes problems when trying to move away or start the car, the clutch slips |

| Gearbox is acting up | It begins to switch with certain problems, and during operation it also makes strange, incomprehensible sounds |

| The pedal has failed | If, after pressing the clutch pedal, it does not want to return to its original position when you remove your foot, this may indicate a problem with the cable |

We recommend: How to tighten a car armrest with your own hands (using the Priora as an example)?

Such symptoms can only suggest that the problem lies in the cable. To make sure of this, you should conduct a full check of the node's condition.

All the symptoms mentioned may indicate a broken cable or a broken fork. In the case of a cable, you will have to replace it. If the fork falls off, it will need to be returned to its place and clamped in order to prevent possible repeated falls.

Between a broken cable and a broken fork, it is better to face the first situation. Buying a new cable will cost 200 rubles, and a fork costs about 2000 rubles.

Do-it-yourself clutch adjustment

Experienced car owners know how to adjust the clutch on a VAZ 2109 on their own. Indeed, there is nothing complicated about it. Two 17mm wrenches and a regular drawing ruler 30cm long are all you need for the job. There is no need to open the VAZ 2109 clutch housing; the work is feasible even for an inexperienced vehicle owner.

Motorists usually check the adjustment approximately every 15 thousand kilometers or once a year. If there is a feeling of increased pedal travel, prompt inspection and adjustment are carried out. Work should be carried out in the following order:

- Take a mechanic's ruler or a drawing ruler and measure the distance from the pedal in a free state to the floor of the car. Usually this value is about 20 cm. This will be the first size.

- Press the pedal with your hand and push it all the way down. Measure the distance from the pressed pedal to the floor. This is the second size.

- Calculate the difference between the second and first dimensions and you will get the pedal stroke. If the result is 125-135 mm, clutch pedal adjustment is not required. When the calculated number does not fall within the specified range, adjustment is advisable. But if the pedal travel is 160 millimeters or more, the mechanism must be adjusted immediately.

- To adjust the pedal travel, open the hood, turn off the power to the electrical system, and put the car in the parking brake and in first gear.

- Hold the adjusting nut with one wrench and loosen the locknut with the second. The adjusting nut is located in the engine compartment of the VAZ 2109 on the drive bracket mounted on the gearbox housing. The nut secures the drive shell in this bracket, and the locknut protects it from loosening.

- To decrease the pedal stroke, the cable must be tightened; in this case, rotate the adjusting nut counterclockwise, and to increase the stroke, clockwise.

- Achieve the desired pedal stroke and secure the new position with the lock nut.

This completes the adjustment. Pump the pedal several times and make sure the travel is within the normal range. If it exceeds the acceptable limits, repeat the adjustment process.

Adjustment can be carried out in the warm season and even in the absence of a garage.

Step-by-step replacement instructions

To carry out the procedure, the machine must be raised. It is best to use an inspection hole, a trestle or a lift, but lifting with jacks will suffice.

Tools

The procedure lasts no more than 15-20 minutes. To carry it out, there is no need for a large number of tools and materials, just prepare:

- new clutch cable (TC);

New cable for VAZ 2109

- a set of keys;

- screwdriver

Stages

Replacing a vehicle with a VAZ 2109 consists of the following steps:

- First, work is carried out in the engine compartment.

- In a VAZ 2109 car, the cable is attached to the box thanks to a metal bracket. In order to remove the part to be replaced from the bracket, you need to loosen the fasteners.

Two vehicle mounting nuts

- Then remove the lower end of the cable from the clutch release fork.

- To carry out further work, you need to move into the car interior. It is necessary to disconnect the vehicle from the pedal. To do this, you need to remove the rubber mats and move the carpet.

- Next, you need to pull out the locking bracket using a regular screwdriver, and then remove the pin that connects the vehicle to the pedal bracket.

Pull out the locking bracket from the finger

- The next step is to remove the cable. There is a rubber cushion installed on the passenger compartment side of the engine compartment. Under the steering wheel in the body partition there is a hole through which we pull out the cable sheath by pushing out the rubber cushion, after which we pull out the old vehicle.

- Next comes the installation process, which starts from the inside of the car. The new spare part must be passed through the hole under the bottom and its tip must be secured to the PS pin using a locking bracket.

- Next, you should fix the vehicle in the box so that the rubber bushing fits into the bracket. In this way, damage to the threads can be avoided.

- Then you need to put the tip on the fork.

- To make the cable more elastic, it is advisable to lubricate it with oil.

- After installing a new vehicle, it is necessary to check the operation of the mechanism and adjust all parts.

- To adjust the vehicle, loosen the locknut. This will allow the adjusting nut to move freely.

Adjusting nut 1 and locknut 2

With its help, it is necessary to pull the vehicle to the optimal distance. If you overtighten, it may tear again; if you do not tighten it as expected, it will not be adjusted.

- After any manipulations with the PS, it should be adjusted. To do this you need to do the following:

- unscrew the nut located under the pedal;

- a little lower there is a lock nut that should be tightened;

- Next you need to tighten the first unscrewed nut;

- Now you need to screw the rubber washer onto the fork as much as possible.

The clutch and brake pedal must be at the same level. If the PS is higher, it will wear out quickly.

Thus, the procedure for replacing a vehicle on a VAZ 2109 is not too complicated and can be done at home, which means the car owner will be able to save on car service costs.

We delve into the process of adjusting the clutch using the example of a VAZ 2109 car.

A vehicle's clutch plays an important connecting role between the transmission and the vehicle's powertrain. Sometimes this unit requires preventive measures, so adjustment of the clutch of the VAZ 2109, and other vehicles, is carried out in cases where defects associated with the operation of this mechanism appear. Such malfunctions include:

Why do you need clutch adjustment?

Adjustment is necessary due to normal wear and tear. Between the basket and the disc there are friction linings that are subject to abrasion. Consequently, after grinding them down, the pedal rises and the unit acts up.

The second reason is stretching of the clutch cable. As its length increases, similar defects occur.

Clutch pedal adjustment

Periodic adjustment of the VAZ 2109 clutch pedal is carried out for the following reasons:

- When driving on a non-adjustable clutch pedal, subsequent repairs are possible, because exaggerated energy costs for incorrect operation of the mechanism will cause malfunctions of other components of the car.

- Due to improper functioning, the clutch pedal periodically does not function. This leads to the fact that the pressure plate of the unit is forced into “engagement” with the motor flywheel, as a result of which they are subject to accelerated wear.

- If the pedal stroke is insufficient, the vehicle slips, i.e. the required torque of the wheel pair is lost.

To carry out diagnostic work on adjusting the clutch pedal, you need to use an arithmetic ruler to measure the length of the pedal stroke to the floor. If it does not correspond to 16 cm, then adjustments are necessary.

Signs of incorrect operation of the clutch mechanism: there is no possibility of a smooth start from a standstill, movement from a standstill is accompanied by jerks and jolts, when changing gears the transmission makes increased noise, the pedal of the mechanism falls to the lower position. In practice, it turns out this way: if the vehicle began to move from the moment the pedal began to be lowered, then the free play does not correspond to the required value. When the pedal is completely released, the vehicle does not move, which means there is no free movement in the car.

Clutch pedal adjustment:

- Unscrew the nut located under the clutch pedal.

- Tighten the locknut located below until it stops.

- Next, screw in the fasteners located under the clutch pedal.

- We tighten the rubber washer to the clutch fork as far as possible.

- To increase the pedal stroke, you need to screw the fastener onto the tip. To reduce the pedal stroke, you need to unscrew this fastener. The VAZ 2109 clutch pedal is adjusted until the limit of 12-13 cm is reached.

- After completing the pedal adjustment operations, you need to: depress the pedal three times, measure the length of the pedal stroke, adjust the operation until the required stroke length is achieved.

To adjust the hydraulics you need:

1. Remove the spring from the mountings of the working cylinder and the clutch fork. 2. Adjust the fasteners located on the clutch cylinder rod. 3. The recommended free play value is 0.5 cm.

Often, a large pedal stroke depends on the height of its location from the driver's floor, and this creates certain difficulties. To adjust the height, a series of simple plumbing operations and a wrench set to “12” are required:

- We find two fasteners on the steering column shaft, one is a thrust screw that limits the height adjustment position, the second is a lock nut that changes the movement of the pedal.

- Unscrew the stop screw.

- We give it rotation until the pedal movement normalizes.

- Screw in the locknut.

If slippage is observed after adjusting the clutch, then the following operations must be performed:

- Remove the stem locknut.

- Move it until there is no free movement.

- Return the rod one full turn.

- Determine whether the clutch has free play.

- Test the operation of the transmission gears. If there is an incomprehensible noise, you need to perform the above operations again.

- Screw in the locknut.

Adjustment instructions

The procedure itself is simple and after reading our article and watching the video, even an inexperienced car owner can handle it.

Where is?

The main element that we need is an adjusting nut, which is located in a fairly convenient place - on the cable sheath.

Tools

- tape measure or ruler;

- 2 keys for 17;

- gloves (as you will have to touch contaminated surfaces). Necessary tools

Stages

- When the pedal is released, you need to use a tape measure to measure the distance from the floor to its lower edge. It should be within 18-20 centimeters. Distance in the depressed position

- Next, you need to press the pedal with your hand all the way to the stop and measure the distance from the floor, again to the bottom edge. It should be within 6-7 centimeters. Measurement when squeezed

- From the first result obtained, 18-20 cm, we need to subtract the result of the second measurement, 6-7 cm, in the end we get 13-14 cm. This is considered to be the normal value for the VAZ 2109.

- If this value differs in one direction or another, we can talk about the need to readjust the clutch - it needs to be tightened or, conversely, loosened. Location of elements

- Use one wrench to hold the adjusting nut, and with the second, slightly loosen the lock nut.

- By rotating the adjusting nut clockwise, we increase the pedal travel, it will begin to move up. And vice versa, by rotating counterclockwise, we reduce its speed; at this moment it will begin to move down.

- We take measurements, if the results are satisfactory, then tighten the locknut and the work can be considered complete. If not, then we do it again, that is, you need to tighten or loosen the cable.

If you still have questions, then you can watch in the video we offer to see how an experienced professional handles this work.

You adjust the clutch

Survey

- On one's own

- A friend helps

- At the service station

Loading …

Adjusting the VAZ 2109 clutch

This operation is carried out in cases where there are shocks or friction when the clutch is engaged, slight slipping of the clutch when the clutch is pressed for a long time, the clutch “drives.”

To adjust the clutch, do the following:

- Place the gearshift lever in the “neutral” position.

- We dismantle the clutch housing.

- We dismantle the bearing. Repair operations should be carried out smoothly and calmly, because the bearing may be defective.

- Rotate the adjusting fastener until the pedal movement is completely adjusted.

- We test the clutch for oil leaks, otherwise the clutch mechanism may slip. To eliminate this problem, it is necessary to treat the coupling with a degreasing compound.

VAZ clutch diagnostics.

You can determine whether the clutch pedal is adjusted correctly or not independently, without the intervention of a car service center. You only need to adjust the pedal stroke if you have any signs of a problem.

How to independently determine whether the clutch pedal is adjusted correctly:

- When the car starts moving smoothly, it jerks, hits and makes noise.

- The pedal fails.

- When the speed is turned on, a noise is heard.

- If the car starts to move immediately after you start releasing the clutch pedal.

- If the car does not move at all even after fully releasing the pedal.

Adjusting the clutch cable VAZ 2109

A technological operation such as adjusting the clutch cable is considered simple and can be done independently. It is recommended to use a clutch cable with the nomenclature code 2109-1602210 for installation on a vehicle. To carry out a repair operation such as adjusting the VAZ 2109 clutch cable, you will need a set of wrenches and a new cable, which may be useful if you replace a used product.

- We check the cable for tension and, if necessary, using 2 “17” wrenches, adjust the cable with the required degree of tension, working with 2 nuts. To completely dismantle the cable, completely remove the nut fastener.

- Remove the cable from the manual transmission.

- Remove the cable from the pedal.

- We remove the cable from the engine compartment.

Important: when adjusting the VAZ 2109 clutch cable, the pedal should be of medium elasticity.

Adjusting the cable

To adjust you need:

- Loosen the locknut, which will allow the adjusting nut to move;

- Tighten the cable using the tension nut;

- You need to pull until the car shakes;

- During this process, it is a good idea to periodically press the clutch pedal;

- Do not overtighten the cable, otherwise it will soon break again;

- If you do not tighten the cable, the performance of the clutch will leave much to be desired. What to do? Find the optimal balance.

Replacing the cable, clutch disc and other manipulations with the clutch pedal require its adjustment.

Pedal adjustment

To adjust the pedal, follow the following algorithm.

- Press the clutch pedal all the way to the floor and place a tape measure next to it.

- The tape measure also rests on the floor at one end.

- Having fixed the pedal in the lowest maximum position, measure the distance to the floor in the center of the pillow.

- Release the pedal, then measure in the uppermost position. Write down the data or just memorize it.

- Now calculate the amount of free play, that is, the distance from the bottom to the top point.

- When replacing a clutch cable or disc, the indicator is usually more or less than 125-135 millimeters.

- To change the parameter, you need to adjust the length of the cable sheath.

- To do this, lift the hood and find the end of the cable. Use a wrench to loosen the tension on the locking nut that holds the cable to the lever. And tighten the second nut.

- Similar manipulations are carried out until the free play is within the range of 125 to 135 millimeters. Happened? That's it, job done.

There is nothing particularly difficult about replacing or adjusting the cable. The main thing here is to do everything consistently, carefully and not to rush. It is haste that causes most failures when repairing a VAZ 2109 yourself.

Source