Developers of modern cars are constantly improving engines to improve their environmental component. The USR system is one of the mechanisms that allows minimizing toxic emissions into the atmosphere by returning part of the exhaust gases to the combustion chamber, while the operation of the diesel engine becomes “softer”. When operating a power unit with EGR, many car owners experience breakdowns or malfunctions of the recirculation system. A new replacement part is quite expensive, but it can be cleaned, repaired, or the system simply turns off.

How does the USR work on a turbodiesel?

The main function of the EGR system is the partial return of exhaust gas to the intake manifold for the purpose of afterburning. On a diesel engine, this solution allows for softer and smoother operation of the engine, which improves its performance and reduces fuel consumption, and the exhaust reduces its toxicity. The appearance of exhaust gases in the intake does not change the ratio of the main components of the combustible mixture, power is not lost in different operating modes, and fuel is saved.

The principle of operation of the USR valve on diesel engines is the connection of part of the exhaust gases with air entering through the intake manifold. Engine exhaust contains nitrogen oxides due to increased heating of gases in the combustion chamber. When the EGR system is activated, combustion occurs at a lower temperature, and the level of harmful substances in the exhaust becomes lower. On diesel engines, the valve opens automatically at idle, and closes under load and maximum power.

Operating principle of the recirculation system

The principle of operation of the recirculation system is a closed loop. The USR valve is controlled by an electrical controller or electronically and pneumatically. In the first decision, the system receives data to the internal combustion engine controller from a special sensor. In the second option, the EGR valve is adjusted based on data depending on the readings received from the intake manifold pressure sensors, mass air flow, and intake air temperature.

With an improved design of power units, where exhaust gases are intensively cooled during recirculation, the USR valve is built inside the cooling system. Moreover, despite the more complex design of the system, the amount of oxides is reduced much more effectively.

During the operation of engines equipped with an EGR valve, the following advantages are revealed:

- In gasoline engines, a reduced pressure drop is observed in the area where the throttle valve is located.

- A decrease in temperature leads to a decrease in detonations, which makes it possible to use an earlier ignition timing, which improves the torque characteristics of the internal combustion engine.

- The operation of a diesel engine with EGR becomes smoother and the noise level at idle is reduced due to the reduced oxygen content during combustion of the fuel mixture.

Why do you turn off the EGR valve?

During long-term operation of a diesel engine equipped with an EGR system, car owners often experience a decrease in power and the appearance of exhaust smoke. Fans of engine tuning claim that gas recirculation “strangles” the power unit, preventing it from displaying its full power potential. Based on similar arguments, many drivers decide to turn off the EGR system. This procedure involves turning off the recirculation system, which should theoretically increase power.

There is an opinion that the rapid formation of carbon deposits on the USR valve and the intake of exhaust gases into the intake manifold provoke increased carbon formation and coking of the combustion chamber. A malfunction of the USR system associated with valve failure leads to excessive fuel consumption and unstable engine operation. Resins and soot enter the combustion chamber, due to which diesel oil quickly oxidizes and the overall service life of the power unit is reduced.

The need to disable the USR appears after a mileage of 80-120 thousand km, because the presence of such mileage causes a certain wear and tear on the engine. Exhaust gases redirected inward have a high degree of pollution. After they are further mixed with crankcase gases, a thick layer of tarry deposits appears in the intake manifold, EGR valve and engine head valves. A clogged system causes errors to appear and can cause the car to suddenly go into emergency mode.

Consequences of removing the EGR valve: pros and cons

Advantages of eliminating EGR:

- clean intake manifold;

- reduction of exhaust smoke;

- increase in power at medium speeds;

- no need to maintain and change expensive components.

At the same time, you can programmatically disable the particulate filter and lambda probe, chip tuning the engine, and also remove the power limit imposed by the manufacturer.

The disadvantages of the method are an increase in the temperature of fuel combustion and the content of nitrogen oxides in the car exhaust. Possible consequences include the occurrence of detonation in a certain engine speed range, a decrease in the service life of the engine oil, and an increased risk of microcracks in the cylinder head.

Problems with lack of traction at low speeds, power failures and black smoky exhaust do not always arise due to the USR. You can make a 100% accurate diagnosis by performing a comprehensive diagnostic test on a bench.

USR malfunctions on diesel engines

The USR valve is a part that performs a bypass function, which either passes part of the exhaust gases from the manifold into the supply line, where they are mixed with air (if in good condition), or not. If the valve malfunctions, the ECU will display a corresponding error on the dashboard indicator. Malfunctions of the USR on a diesel engine may include the following:

- Carbon deposits in the system that affect the EGR valve and plate. Excessive carbon formation occurs when the engine is operated on low-quality fuel, incomplete combustion of the fuel mixture, or a violation of the crankcase gas exhaust system.

- The valve is clogged, causing it to jam when opening or closing, or incorrect operation in the form of untimely operation, which is noticeable when the engine is idling.

USR malfunctions manifest themselves in frequent engine stops, floating speed in idle mode, tripping, jerking while driving and a drop in power during acceleration.

It is possible to identify a breakdown of the recirculation system by visually inspecting the condition of the pipelines and sensor connectors. Accurate diagnostics include electronic scanning and other procedures that check the functioning of the actuators and the EGR valve.

Diesel Engine Recirculation Systems

To ensure that diesel engines comply with Euro 4 standards, they are equipped with high-pressure EGR valves. According to international standards, the permissible amount of nitrogen oxides in exhaust gases should be no higher than 0.25 g/km.

The principle of operation of the recirculation system is to select exhaust gases before entering the turbine, redirecting them into a special channel leading to the intake manifold.

The recirculation system consists of the following elements:

- EGR valve.

- Electric or pneumatic drive.

- Pipes used for transporting gases.

From the exhaust system, the EGR valve takes part of the exhaust gases and directs them to the intake manifold.

To operate a pneumatic valve, a vacuum is created in the area of the intake manifold of the gasoline power unit. In diesel engines, air rarefaction occurs due to the operation of a vacuum pump. Due to the resulting vacuum, the recirculation valve is activated.

The intensity of recirculation depends on the engine operating mode and on the pressure difference across the intake and exhaust manifolds. The intake system controls pressure by changing the position of the throttle valve. When intake pressure is low, the throttle valve is in the closed position. The higher the recirculation intensity, the lower the flow of exhaust gases directed to the turbocharger.

Active recirculation leads to a drop in turbocharging pressure in a diesel engine equipped with an EGR system. When the diesel engine is running at idle speed, with the throttle valve fully open, until the engine is completely warmed up and operating temperature values are reached, the EGR system is in low activity mode.

The operation of the USR system in a diesel engine is controlled by the electronic control unit of the power unit. The valve begins to operate when a control signal is received from the computer, which regulates the opening of the throttle valve in accordance with the readings of the potentiometric sensor.

USR repair on diesel

Repair of the EGR system consists of mechanically cleaning it from carbon deposits and deposits using a small metal brush and rinsing with a “WD” cleaner, which is designed to remove deposits and rust from metal. At the end of the procedure, wipe the inside of the valve with a rag soaked in solvent. Repairing the USR on a diesel engine also includes cleaning the solenoid (if there is one), which serves as a filter element that prevents debris from entering the vacuum system.

Flushing the USR valve from burning is carried out after removing it, treating it through the holes with a special aerosol used to clean carburetors, then the part is placed in a container filled with lighting kerosene. Then they disassemble it by unscrewing 4 bolts and clean it from the inside. This service will eliminate signs of EGR valve failure and restore it to proper operation. The procedure should be carried out regularly after 60-100 thousand kilometers.

avtoexperts.ru

In the previous article we looked at the design of the USR valve, how it works, and gave examples of malfunctions and the reasons that cause them. And today we will pay close attention to directly turning off the valve, why owners do this, and most importantly, how to turn off the EGR valve with your own hands.

EGR valve l6735 Chevrolet Lacetti

Why turn off the EGR valve?

We already know that, in principle, the USR system is designed to recirculate exhaust gases back into the intake system for mixing with gasoline or diesel. Due to recirculation, the amount of clean air is reduced, and the formation of various nitrogen oxides is also reduced compared to if only pure oxygen was used.

The main element in this system is the USR valve, which is responsible for opening the “path” for exhaust gases at a certain moment, directing them to the intake manifold. Thus, the proportion of oxygen is reduced, and, accordingly, the combustion temperature. We must understand the root causes of the system’s appearance, this is the reduction of emissions, and they have the greatest impact at high combustion temperatures. Therefore, the circulation of exhaust gases allows reducing emissions by lowering the combustion temperature.

Operating principle of the EGR valve

Thus, through the valve, part of the total share of exhaust gases is transferred back to the engine (usually the system is set to rpm, after 2,000 the valve opens and releases exhaust gases), reducing emissions into the atmosphere. But, you yourself understand that exhaust gases are “dirty”, and when passing through the valve, they clog it, which makes it necessary to periodically clean it. A clogged valve disrupts the mixture formation process, that is, it prevents the supply of clean air and at the same time does not even allow exhaust gases to pass through in the required quantities. When the mixture is too rich, more fuel is supplied than usual. The engine becomes clogged with carbon deposits, the USR valve itself becomes covered with carbon deposits, and a film of unburnt mixture appears on the cylinders, causing rapid wear of the piston group.

And most importantly, after disabling the USR, fuel consumption decreases. When the USR is turned off, the fuel mixture is formed better, without waste impurities, the amount of oxygen increases, which is why the fuel mixture burns more efficiently in the cylinders, without leaving soot.

And besides, recently they have begun to openly say that, as such, the benefit of the valve is almost zero. If during operation of the valve the emission of nitrogen into the atmosphere is reduced, then when it is turned off, the emission of soot, carbon dioxide and carbon monoxide is reduced.

Plus, if the valve is contaminated, malfunctions in the operation of the internal combustion engine are observed, the power and service life of the engine are reduced. As you can see, there are many more real reasons to disable this system.

Dirty EGR valve Mercedes W203 C220

That is, we can distinguish the following group of reasons in which cases they decide to turn off the USR valve:

• The valve is dirty, there is no desire to clean it or buy a new one.

• Disturbance in mixture formation.

• Problems with sensors on which the mixture formation process depends.

• Rapid wear of the cylinder-piston group.

• Increased fuel consumption.

• Reduction of internal combustion engine power.

• Unstable operation of the internal combustion engine.

It is worth noting that all these reasons in most cases appear after the valve fails or becomes dirty. And its diagnosis, replacement, repair, and cleaning is quite an expensive undertaking, so the most attractive for domestic drivers seems to be a banal blocking of the operation of this system, completely or partially.

How to turn off the EGR valve?

First, you need to understand that in addition to the mechanical part of the USR system, there is also an electronic one, which sends indicators to the ECU, influencing the formation of the fuel mixture. Accordingly, to properly turn off the valve, you need to use:

• Electronic jamming.

• Mechanical intervention.

But owners do not always use both options. Rather, on the contrary, in the process of jamming, they resort to the least expensive and complex method, namely mechanical blocking. So, options for disabling the EGR valve:

1. The most common thing that every driver can do is simply “throw off” the chip from the valve. But there is a drawback: on almost all machines, after such manipulations, the “check” is constantly on. It cannot be reset so easily, so if there really is any malfunction, the driver is unlikely to know about it in advance. Not the best option to switch off.

Removed the EGR valve connector chip Renault Laguna 1.5 Dci

2. Replacing the valve gasket. At the place where the valve is mounted in the intake manifold, there is a gasket with holes for intake, etc. What do you need to do? Using the template, cut out a similar gasket, completely “blind” without any holes. Naturally, don't forget about the fastening.

EGR valve plug

You can use any material, even aluminum, brass, stainless steel. But, keep in mind that the exposure temperature will always be high, so it is better to immediately select the appropriate thickness so that the gasket lasts longer.

Installed EGR valve plug

In some cars, the plug also causes errors in the ECU, and accordingly the “check” will light up. Remember this.

3. Many car owners act in a generally “barbaric” manner: in the channel where the EGR valve is located, they tighten an ordinary bolt with the required thread, and if necessary, the thread is even cut.

4. Installing a plug not only after the valve, but also before it. Since, by installing metal plates or removing a chip, exhaust gases will still fall on the valve, contaminate it and disrupt the operation of the internal combustion engine. To get rid of this, you need to block the channel of exhaust gases from the exhaust manifold to the intake manifold. There are usually simple hoses that screw onto a nut, like water hoses. On many machines, instead of attaching the hose to the valve, they insert either a coin or a metal circle of the same shape and size. Thus, blocking the flow of gases from the exhaust manifold.

Valve plug for Lacetti

5. The most effective and efficient method, it involves software disabling the USR valve through the ECU. In this case, the “check” will not light up due to circulation problems. In all of the above cases, “check” would definitely “pop up”. But, with amendments to the “brains”, this problem can be solved. But you need to have experience, knowledge, equipment, which you won’t be able to find in every service.

Software shutdown of the EGR valve

Software silencing involves removing the USR valve firmware from the ECU. That is, using a computer and a special program for this. As a rule, large service stations have craftsmen who specialize in this topic. By turning off the valve programmatically, there is even no need for mechanical damping. Many people don’t even disconnect the chips after this and drive with the valve. After all, by and large, the “brains” no longer give the command to open/close the valve and there is no need to dismantle it. But others advise doing physical jamming as a couple, using one of the methods listed above.

Conclusion

As a result, I would like to emphasize that in our country it is still possible to turn off this valve without consequences. Large-scale production causes much more harm, so you can calm your own conscience. Moreover, disabling this system allows you not only to reduce consumption, increase engine power, but also to increase the service life of not only the internal combustion engine itself, but also the various sensors that depend on it.

There are a lot of options for turning off, the main thing is to understand that with mechanical intervention, you won’t be able to turn off the electronics, which is why a constantly lit “check” will cause inconvenience. A really effective way to disable this system completely is to make changes to the “brains”, the main thing is to find a good master.

How to properly shut off the EGR valve on a diesel engine

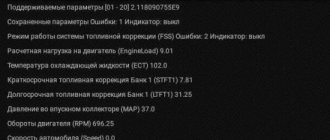

Correctly disabling EGR on a diesel engine involves:

- Mechanical method of damping the valve.

- Switching off using the control unit.

At the first stage, a mechanical valve plug is installed, after which the system is turned off electronically. You should know that physically turning off the valve is only sufficient on some cars. After the valve is mechanically blocked, it must be switched off by software in the ECU, otherwise the “check” lamp will light up on the instrument panel due to an error in the recirculation system, and the engine will engage in emergency mode, which limits the power output.

The simplest version of the valve plug is as follows:

- The valve, which is most often located near the intake manifold, is removed by unscrewing several bolts.

- If necessary, dismantle the intake manifold and clean its channels from contamination.

- Remove the gasket located at the valve mounting location.

- The removed gasket is used as a template, according to which a blank gasket is cut out of a steel sheet and holes are made in it for the bolts. You can often find a plug for some car models on sale.

- Reinstalling the valve using a gasket and plug. Bolts must be tightened with extreme care due to their fragility.

- The vacuum hoses are disconnected, since they are no longer used in the valve opening system.

- Making a change to the ECU firmware to get rid of the EGR error.

Valve cleaning

If a relatively new valve is not working correctly, it is recommended to clean it. To do this, prepare a set of wrenches, a couple of carburetor cleaners (foam and spray), a Phillips screwdriver and a special lapping compound for valves. After dismantling the valve using wrenches, of course, the following steps must be performed:

- soak the insides of the part with carburetor cleaner;

- flush the channel in the manifold using a tube and foam cleaner;

- repeat the procedure several times (depending on the degree of contamination);

- unscrew the bolts and disassemble the valve;

- use paste to grind in;

- wash away all plaque and cleaners;

- dry thoroughly and install the part in place.

Reasons for valve shutdown

Do I need to turn off the EGR valve? Experts answer that if the engine mileage exceeds 100 thousand km, it should be turned off.

Many inexperienced motorists do not know why they should turn off the EGR valve. In its operation, the engine converts gases into nitrogen oxide. This is what modern ecologists consider the enemy of nature. Disabling the USR valve, in their opinion, is not always effective for engine operation. A dirty system can cause even more damage to the engine. The malfunction leads to a decrease in engine power and an increase in fuel consumption.