We cut off part of the pipe.

Mark all the necessary elements on a metal sheet, outline the pipe and the bearing.

Marking out future details

We cut out the parts with a grinder and grind them to meet the exact parameters.

Cut parts

We drill holes for the bolt in the obtained washers.

Drilling holes for bolts

How to make a two-jaw wheel bearing puller: video

Making a bearing puller with your own hands is not at all difficult - you don’t need either expensive materials or specific skills. Using the instructions, you will easily cope with the task and get a useful tool for car repair.

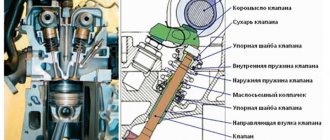

Changing valve stem seals with your own hands

Hi all! As the owner of products from the domestic automotive industry, there was a need to replace valve seals, since, judging by all the signs, they began to leak - increased oil consumption, spark plug threads in carbon deposits, smoke from the chimney during startup.

The car already has a decent mileage and requires constant investments, so I decided to save money and replace the caps with my own hands without resorting to service, at the same time combining this with replacing the worn camshaft and cams, so as not to have to climb ten times.

The necessary tools and materials were purchased in advance: a set of caps, a camshaft with rockers, a pair of springs and crackers, just in case. Among the tools, we will need a set of wrenches and sockets, a torque wrench, a hammer, a magnetized screwdriver or tweezers, narrow-nose pliers for removing caps, a valve sealer, a tin rod, a piece of heat-shrinkable tubing, if the seal kit does not include an installation sleeve.

The package arrived promptly with a mandrel for hammering in the caps.

It is a piece of metal rod, bored to fit the shape of the oil seal - simple and reliable.

So let's get started. We turn off the engine and let it cool. We remove the valve cover and set the timing marks at the Top Dead Center of the 4th cylinder (TDC).

In this position we can replace the caps on the 1st and 4th cylinder. We remove the camshaft sprocket and connect it to the chain so that the chain does not jump and the marks do not get lost, since we will still need to turn the crankshaft.

Now, using a flashlight, we make sure that the pistons of cylinders 1 and 4 are in the upper position. Let's start the replacement from the first cylinder, remove the springs and rocker. We put them aside according to the numbering of the cylinders, so that later during assembly we can put each one in its place.

We insert a tin rod into the spark plug hole under the valve on which we will replace the cap, put on the desiccant and push through the plate with the spring, removing the released crackers, remove the valve springs, as well as the lower plate of the small spring, since it will interfere with us.

That's it, access to the oil seal is open. Now, using narrow-nose pliers, carefully, so as not to damage the valve guide, remove the old oil seal upwards.

We wipe the seat from oil, put an installation sleeve on the tip of the valve so as not to damage the new oil seal on sharp edges, and carefully put on the cap, lubricating the working edge with oil. We remove the bushing, put on the mandrel and, with gentle blows of a hammer, press the oil seal into place until it stops.

Since it seemed that the recess for the valve stem in the mandrel was not long enough, I first drilled the hole a little with a drill, since the metal is quite soft. I also sanded the sharp edges with sandpaper.

Now we put the springs and desiccant back and dry the valve, after that we take out the rod and apply several gentle blows with a hammer to the valve stem to make sure that the desiccant are securely in place.

Similarly, we change the oil seals on the second valve and on the valves of the 4th cylinder, then rotate the crankshaft 180 degrees and replace the oil seals of the 2nd and 3rd cylinders. Before installing the rockers and camshaft, we once again carefully check the “dryness” of the valves and put everything back together.

After installing the camshaft, we adjust the valve clearances.

Since I was changing the caps for the first time, the work took all day. Unfortunately, the replacement didn’t help much, since when checked, the valve guides also turned out to be worn out. But valuable experience has been gained and, I think, in the future, if you have to change these guides, it will still be useful.

Also, before work, I recommend that you prepare thoroughly and find instructions for replacing the caps for your specific car, since there are many nuances that could not be included in this review. And it is still advisable to have a similar collet cap puller instead of pliers https://www.avtoall.ru/s_emnik_kolpachkov_maslootrajayushih_5_6mm_avtom-959842/ - it will save a lot of time. Well, a short video below, maybe it will help someone, replacing the caps with your own hands is not that difficult.

Replacing valves on a Priora 16 valves. Inevitable repairs

Quite often it is necessary to replace valves on a Priora 16 valves. The reason is some technical features of the engine of this model. Most often, the valve bends as a result of the timing belt breaking or stretching. In such a case, the camshafts either stop or start working at a different time than the crankshaft. As a result, the pistons hit the valves, which leads to deformation. Sometimes damaged pistons can also be added to bent valves. To avoid problems, engine maintenance work should be carried out in a timely manner. But, if the valves are still bent, you will have to change them, this work is not difficult, it is enough to have basic skills in car repair. Reasons and symptoms Replacing valves on a Priora 16 valves is not only done if they are bent. Sometimes they can burn out. The reason for this wear is the poor quality of the parts, as well as the poor quality of the mixture. If the engine overheats, then gradually the working surfaces of the valves wear out (burn out). The valve mechanism contains a return spring. When it wears out, the valve may hit the piston, the result will be similar to a damaged timing belt. It is important to correctly diagnose the problem with the valves. The very first sign of a problem is a decrease in engine response, that is, the driver receives a noticeable decrease in power. Sometimes you can hear tapping. A common symptom is the appearance of black smoke from the exhaust pipe, combined with increased oil consumption. Unstable idle operation may occur. The difficulty in diagnosing valves lies in the impossibility of accurately determining the cause without disassembling the engine. Masters who work with engines know many examples when a car came to them with obvious signs of failed valves, but in reality it turned out that everything was fine with them. Therefore, for a complete diagnosis you will have to remove the cylinder head. This is the only way you can check the valves for sure. What will be required? The repair work will require a certain set of tools, which will greatly simplify the process. So, you will need the following devices:

- Set of keys;

- Valve spring puller;

- Several screwdrivers;

- Oil seal remover;

- Tweezers;

- Cylinder head gasket;

- New valves.

Please note that valves are only sold as a complete set. It doesn't make sense to change just one of them. When replacing one of the valves, you will soon need to disassemble the engine again due to the malfunction of other valves. Remove the block head. From this work, begin the procedure for replacing the valves. The cylinder head is removed in the following order:

- Pressure is released from the fuel system;

- The battery is disconnected; to do this, remove the terminal from the negative terminal;

- Disconnect the wires from all sensors;

- The liquid is drained;

- The rear engine mount is dismantled;

- Remove the valve cover;

- We unscrew the screw securing the ground harness, and also remove the wire going to the negative battery;

- Using a 13mm head, unscrew the 2 screws securing the thermostat and remove it;

- Remove the timing belt; at the same time, the camshaft pulleys are dismantled;

- The guide of the oil check tube is removed;

- Using a 17 key, disconnect the fuel supply tube to the ramp;

- Disconnect all the harnesses coming from the engine control unit;

- Using a 10mm hex, unscrew all 8 screws securing the cylinder head, after which it is removed.

It makes sense to check the condition of the lower head mirror. To do this, take a ruler and make sure that there are no distortions. Replacing valves Before starting work, place the head on a wooden base, this will avoid damage to the valves. We do this as follows:

- The block with camshaft bearings is dismantled. It is secured with 20 screws. To do this, use an “8” socket wrench;

- Remove the camshafts and also remove the oil seals from their front ends;

- Remove all plugs from the ends of the cylinder head;

- Remove the valve lifters.

Now we move on to the process of replacing the valves themselves..

- Remove the oil seal from it. To simplify it, it is better to use a special puller. As a last resort, this can be done using pliers.

Inspect the valve. It is worth replacing if there is visible damage to the rod, this is not only bent, but also cracks and chips. Also, there should be no damage on the valve planes, such as scratches or chips. It shouldn't be burnt. Inspect the valve seat. If there is even the slightest damage, then it makes sense to carry out grinding. Otherwise, the new valves may leak gases from the combustion chamber. Reassembly is carried out in the reverse order. At the same time, pay attention to the little things, this will avoid problems in the future:

- Always install only a new gasket under the cylinder head. It is better to take it immediately with a sealant, otherwise you will also have to purchase a heat-resistant sealant;

- When installing valves and screws, lubricate them with engine oil. This will improve the build quality;

- For final tightening of the screws securing the bearing block, as well as the cylinder head screws, it is necessary to use a torque wrench.

Useful tips.

The job of replacing the valves is not too difficult, but it is best to avoid it. To do this, monitor the condition of the timing belt; it is important to replace it in a timely manner, otherwise the consequences of a break will be tragic. Also, use only high-quality fuel. Bad gasoline causes carbon deposits to form on the valves, which in turn leads to improper heat transfer and, accordingly, to rapid burnout of the valve. Conclusion. During the operation of a car, its parts wear out at different rates. In this regard, such work as replacing valves on a Priora 16 valves is not uncommon. Often, the reason for its need is the inattention of the car owner. This work in itself is not difficult, but it requires accuracy and attention. AutoFlit.ru

How to properly replace, trim and process valve seats

Valve seat - a small ring with a bevel on the inner surface.

It is installed in the holes of the cylinder head intended for installing valves and distilling the air-fuel mixture and exhaust gases through them. The part is pressed into the cylinder head at the factory.

Performs the following functions:

- hole tightness;

- provides the necessary air flow when the mechanism is open.

transfers excess heat to the cylinder head;

Replacing the valve seat is required when it is not possible to restore its tightness using mechanical processing (numerous treatments in the past, burnout, severe wear). You can do this yourself.

Part repairs are performed when:

- plate burnout;

- after replacing the guide bushings;

- with a moderate degree of natural wear;

- if the tightness of the connection between the ring and the plate is broken.

Correcting worn and damaged saddles at home is done using cutters. In addition, you may need a welding machine or a powerful gas torch, a standard set of wrenches necessary for dismantling and disassembling the cylinder head, lapping paste, and a drill.

Which valve stem seals are best? Quality above all

The time has come to replace them and the owners are faced with the question of which valve stem seals are better.

Whether the owners want it or not, one day they will have to think about it, especially if the car already has a “solid” mileage. On some models, this need may arise after a long period of operation, while on others it happens more often. The replacement procedure should not be delayed, since an increase in engine oil consumption incurs additional financial costs and environmental problems. Owners need to know which valve stem seals are better for the very reason that they can navigate the offers of service centers or retail outlets and make the right choice. Today there is no total shortage of not only valve seals, but also spare parts in general. All that remains is to learn correctly, choose good quality products and distinguish fakes from originals. Why are they installed in engines? All rubbing couples in engines receive a certain portion of lubricant to reduce friction, and the task of oil seals is to reduce its entry into the combustion chamber to a minimum. Such a pair in the cylinder head is the guide sleeve and the valve stem. It is impossible to make this connection without a gap, so valve seals are used for sealing. They are made from special oil-resistant reinforced rubber. The top of these seals is pressed against the valve stem by a spring. PTFE was once widely used for these, but is now rarely used in the manufacture of these replacement parts. Instructions for car repair and operation recommend that when replacing, install only those parts that were installed by the manufacturer. Today, this recommendation is often violated, since the use of high-quality materials and modern technologies makes it possible to create products that are in no way inferior to, and sometimes even superior to, the original caps in their characteristics. Why do they need to be replaced? The only reason for removing them and installing new parts can be wear of the edge valve seals, which compresses the valve stem. During engine operation, they perform a huge amount of work, experience high temperature loads and exposure to an aggressive environment. This cannot but affect their resistance and durability. Most of these spare parts are based on rubber, which, under the influence of all these negative factors, begins to harden, the working edges begin to crack, wear out and abrade. This leads to the appearance of a gap for the penetration of engine oil into the working chamber, “dirty” exhaust appears and increased lubricant consumption . You should not be afraid that replacement will be very frequent; manufacturers have learned to produce good products whose service life is 100,000 km, or even more. But unfortunately, there are still many such cars for which replacement happens more often than usual. How to choose the best? Almost until the mid-90s, domestic cars were equipped with products from the Kursk Rubber Products Plant. The average temperature in the working area is approximately 1800°C, and the rubber used to make them was only rated up to 1500°C. Therefore, the mileage of such parts was no more than 30 thousand kilometers. Today they are not produced, but occasionally they still appear on sale. With the advent of technologies from Porsche in the domestic auto industry, the production of caps based on a new composition has developed. It was based on fluorine rubber, the use of which gave positive results. After comparative tests with the products of these and Elring, good results were obtained. For an unworn pair of valve stem and guide sleeve, the caps perform well. Their production is based on high-quality rubber; they successfully replace fluoroplastic products in Mercedes M110 and M123 engines. In addition to the names listed, products from such companies as Glazer and other companies have proven themselves well. About the reasons for replacement There are many reasons for such a replacement, let's consider some of them. An example is the cost of “native” products; the price of individual copies can range from $5 per piece or more. There are also situations when one of the oil seals may be damaged during assembly, and you need to look for a replacement. In this case, knowledge of the characteristics of manufactured spare parts can come to the rescue in order to select replacements. We can talk for a long time about the advantages and disadvantages of such products of domestic and imported production. We tried to tell you which valve stem seals are better in accessible words. In conclusion, I would like to note that, unfortunately, the quality of domestic products is still inferior to foreign caps. AutoFlit.ru

Replacing seats

The replacement procedure consists of two important procedures: removing old parts and installing new ones.

Removing old planting elements

Replacement of valve seats is carried out on a dismantled cylinder head with a disassembled gas distribution mechanism. You can remove the old ring using a welding machine, if the material from which it is made allows this.

To perform the procedure, a valve seat remover is made - an old unnecessary valve is taken, the plate of which must be machined to the size of the inner diameter of the seat.

After this, the resulting tool is recessed into the seat, 2-3 mm short of the edge, and “grabbed” by welding in 2-3 places. Afterwards, the valve along with the metal ring is knocked out from the back side with a hammer.

Important! The welding procedure may cause some deformation of the seat. In this case, standard saddles will have weak fastening, which can lead to their spontaneous dismantling during engine operation. Rings of increased diameter are required, which are not sold in stores, but are made to order.

Valve seats made from non-weldable metals can be removed by screwing a piece of pipe into the seat as a valve seat remover. To do this, a thread is cut on the inner surface of the ring. A similar thread is applied to the outer surface of a metal pipe of suitable diameter.

An old valve is taken and first welded to the end of the pipe in the reverse position. In this case, the valve stem is inserted into the hole intended for it, the pipe is screwed into the thread, after which the element is removed by tapping the stem.

Installation of new saddles

Before starting the installation procedure of new saddles, the seats under them are cleaned of dirt. After the cylinder head should be heated evenly to a temperature exceeding 100˚C. At the same time, the metal expands, allowing the ring to be pressed in.

The mounted part is cooled using liquid nitrogen. In its absence, you can use a combination of ice and acetone, which allows you to reduce the temperature of the metal to -70˚C. The dimensions of the parts are selected in such a way that the difference between the diameter of the seat and the ring is no more than 0.05-0.09 mm on cold parts.

The valve seat is pressed into place using a special mandrel or a piece of pipe of suitable diameter. The part should fit into the seat with little effort. It is important that the ring fits without distortion.

After pressing in and cooling the cylinder head, you should check whether the element is loose in the seat. If there is no gap and the replaced element is held tightly in place, the replacement procedure can be considered complete. Next, you need to trim the valve seats using cutters.

Important! During the standard replacement procedure, the valve plates of all valves are set quite high. However, some experts recommend processing the chamfers so that the exhaust valves sit slightly deeper than the normal position. The intake valve seat is left in its normal position.