Why doesn't the scooter pull?

Some motorcyclists are faced with a problem when the engine of the equipment works properly, but the scooter does not pull. The device simply does not move or moves slowly. Oddly enough, this is a fairly simple problem that even a novice rider can fix. Therefore, let's figure out why the scooter does not pull, and how to “reanimate” the equipment.

Why the VAZ-2114 engine pulls poorly: the main reasons and repairs

At the same time, in many cases the engine runs smoothly, does not tremble, there are no increased vibrations, extraneous sounds, knocking or noise during operation of the internal combustion engine. Let us note right away that there is a fairly wide list of possible reasons why a warm engine does not run, and there is a loss of engine power when cold and/or when hot.

In this article we will talk about why the engine does not pull, and also consider the most common malfunctions that manifest themselves in the form of loss of traction of the power unit.

If the carburetor engine does not pull

First of all, carburetor engines do not gain speed due to the power system. Lack or excess of fuel are the main reasons for this. Mixing of air and fuel occurs directly in the carburetor, and the latter needs periodic cleaning and proper adjustment. Obviously, the lack of one of the components of the fuel mixture leads to a decrease in traction.

The correct fuel assembly ratio, for example, on a VAZ 2106 or 2107 is 15/1. If the amount of gasoline exceeds the norm, it does not burn completely, which reduces the engine response. In addition, fuel consumption increases significantly, which leads to other problems with the power unit. A small percentage of gasoline completely causes the engine to starve. And if the mixture is insufficiently ignited, the piston moves slowly.

Proper adjustment of the carburetor is a complex process that only specialists can do. First of all, the correct jets are selected - the air jet should be slightly larger in volume than the fuel jet. Then the float chamber is adjusted. The carburetor adjustment can be considered successful if the engine idle speed remains stable.

Signs of loss of engine power

Operating the engine under difficult conditions and poor fuel quality can lead to a decrease in engine power.

This article provides a list of the main faults that affect the power of a car engine. If the time required to accelerate a car increases by more than 25 percent, and the optimal speed decreases by 15 percent or more, this is a clear sign. The drop in engine power is clearly felt when the car moves uphill.

Here is a list of the main signs of a drop in engine power:

- the car does not respond properly to pressing the gas pedal, there are delays of several seconds;

- the engine speed suddenly decreases for no apparent reason;

- After pressing the gas accelerator, jerks occur in the movement of the car.

Reasons for loss of power in a carburetor engine

Here it is worth immediately checking the fuel level and the operation of the fuel pump: “underfilling” of fuel immediately reveals itself under load as a loss in dynamics, shooting into the carburetor. Overfilling due to a faulty carburetor shut-off needle will also lead to a loss of engine power, here black smoke and firing from the muffler will become a characteristic sign.

The car's dynamics are perceived better when accelerating, so a defect in the accelerator pump may also be a possible reason for the car's “dullness.” The fact is that all carburetor systems are designed to operate in static modes; as the speed increases, the mixture becomes leaner. The accelerator pump is used to combat this over-depletion: when you press the gas pedal, the diaphragm pushes a dose of gasoline through the shut-off valve into the nozzles that exit into the diffusers. If the diaphragm of the accelerator pump ruptures or the nozzles become clogged, the acceleration of the car will immediately deteriorate so much that it is difficult not to notice. It’s not difficult to check the accelerator pump - after removing the air filter or “turtle” from the carburetor, you need to sharply press the throttle valve drive: your fingers will feel resistance (the diaphragm will create pressure in the accelerator pump), and streams of gasoline should hit the inlet from the nozzles.

The engine has stopped pulling, there is no acceleration of the internal combustion engine: the most common malfunctions

Let's start with the fact that an experienced car enthusiast knows his car well and its “character” (acceleration dynamics, torque speed and maximum power speed, etc.). It is quite obvious that a drop in power usually becomes immediately noticeable and is a reason for diagnosis.

As for the reasons, there are quite a few of them, but in each case there is a loss of engine power and a deterioration in its throttle response. Also, among additional indirect signs, it is worth noting that the engine may operate unstably, stall and smoke.

So, a decrease in traction is often caused by the following reasons:

- Outside air temperature. It is especially strongly felt on simple small-displacement 3 or 4 cylinder naturally aspirated engines (usually 8-valve) with a displacement of up to 1.5 liters in budget cars.

For example, in extreme heat, many owners of such cars note that the car “does not drive”, the dynamics drop, you need to press the gas pedal harder and spin the internal combustion engine to higher speeds to maintain the usual driving pace.

Simply put, the volume of hot air from the atmosphere in the engine decreases, as a result of which the thrust also deteriorates. Please note that this cannot be considered a breakdown. Once the outside temperature drops, everything will return to normal.

- Fuel is of low quality, the octane number of gasoline does not match, etc. To put it simply, engine response may noticeably deteriorate immediately after refueling at a gas station. In this case, power is reduced, engine detonation may occur, problems with starting the internal combustion engine are likely, etc.

In some situations you just need to dilute the fuel with a better quality one, in others you need to completely drain the fuel from the tank. The most problematic situation can be considered the need not only to drain the fuel, but also to flush the engine power system.

- Air filter dirty. If said filter is clogged, then the engine is not getting enough air. As a result, there is not enough oxygen for complete combustion of the entire volume of supplied fuel. In other words, the fuel charge does not transfer maximum of its energy to the piston.

In such a situation, the engine not only does not pull, but also smokes. The solution to the problem is simple - you need to replace the engine air filter, and you can do this replacement yourself.

- Contaminated or damaged spark plugs. It is important to consider that these elements on gasoline engines are consumables. If you also take into account the poor quality of domestic gasoline, then you shouldn’t count heavily on expensive iridium or platinum spark plugs with a long declared resource.

As practice shows, it is advisable to change conventional single-electrode spark plugs every 15 thousand km. As for more expensive multi-electrode analogues or products with platinum or iridium electrodes, the service life often does not exceed 50-60% of that declared by the manufacturer of certain spark plugs.

Also, disturbances in the operation of spark plugs can be caused by contamination of the electrodes, the appearance of soot and deposits, changes in the gap between the electrodes, etc. In this case, the gap must be adjusted and the spark plugs cleaned.

If the spark plugs are old or dirty, or are selected incorrectly for a specific internal combustion engine, then the ignition process of the fuel and air mixture in the cylinders is disrupted, engine detonation may occur, etc. In such conditions, the engine loses throttle response and may have trouble starting.

First of all, if the spark plugs are new, you need to find out what leads to their rapid contamination. If the spark plugs simply have not been changed for a long time, then it is necessary to select the necessary elements of the ignition system for a specific engine and install a new set on the engine. Also worthy of attention is the setting of the ignition system, armored wire, coil, correctly set ignition timing (ignition timing), etc.

- Fuel system. As with the air supply system, a dirty supply system will result in insufficient fuel being supplied to the engine. In such a situation, the working fuel-air mixture becomes very lean, that is, there is a lot of air in the mixture, but not enough fuel.

Usually, a common cause is a clogged fuel filter, which, according to the recommendation of specialists, is also advisable to change every 15-20 thousand km. It should also be added that it is periodically necessary to clean the injector or carburetor, since dirty jets or injectors may well cause a clear lack of fuel in the engine.

It should also be separately noted that a decrease in the performance of the fuel pump can be attributed to frequent causes of loss of engine traction. On carburetor internal combustion engines it is easier to diagnose the problem, since the device is located in plain sight.

However, on engines with an injector, you need to separately check the electric fuel pump, which is located in the fuel tank. Also, in some cases, the additional mesh filter of the fuel pump should be changed or cleaned after removing the device.

- Problems in the exhaust system. Not everyone knows that severe contamination of the exhaust system also leads to a decrease in engine response. This is especially true for injection cars with a catalyst.

This element is a filter through which exhaust gases pass for purification. If the throughput of the catalyst is reduced, then the engine “suffocates”, power naturally drops, and traction deteriorates.

The most correct way to solve this problem is to replace the catalyst with a new one, but it must be taken into account that this element is very expensive. For this reason, the practice of removing the catalyst is widespread in the CIS.

Note that it is not possible to successfully cut out the catalyst on all cars, but if all the work is done correctly, then the engine runs normally. At the same time, the main disadvantages are that additional noise appears in the exhaust system, the car begins to pollute the environment heavily, the smell of exhaust gases is constantly present during engine operation, etc.

- Engine wear or damage to internal combustion engine parts and components. This situation is the most problematic, since the reason for the decrease in traction and throttle response is engine failure. As a rule, we are talking about a decrease in compression, the appearance of scuffing on the cylinder bore, severe wear and sticking of piston rings, problems with timing valves, etc.

However, not in all cases you should immediately set yourself up for a major engine overhaul. Everything will depend on the state of the power unit. Sometimes it is enough to replace the piston rings, clean the engine of coke and carbon deposits, replace the oil seals, adjust the valves, etc.

After a series of manipulations, such a motor can still be “revitalized” and further operated. In any case, you should not make any hasty conclusions until a comprehensive diagnosis and troubleshooting of the engine is carried out in the event of its disassembly.

- We also note that in both the case of carburetor and injection engines, it is necessary to eliminate the possibility of excess air leaking into the intake, as well as fuel leaks or airing of the power system.

Such malfunctions lead to disruption of mixture formation; the composition of the working mixture (ratio of fuel and air) changes, as a result of which such a mixture may not correspond to the operating mode of the engine.

Violation of valve timing

The main parts of the gas distribution mechanism (GRM) are the intake and exhaust valves. They are “obliged” to open and close only at the right moment so that the fuel mixture enters the cylinders on time and exhaust gases are removed. This process is called phase distribution. If it is violated, you will see that the power of the engine has disappeared, which will begin to “triple” and sometimes have difficulty starting.

Causes of valve timing violations:

- wear, as well as incorrect installation, displacement of the chain or timing belt (most often this is a jump by one tooth (link));

- play or deformation of the pulley on the crankshaft;

- wear of hydraulic compensators, camshaft and (or) its bed;

- burnout or rupture of the head gasket;

- Malfunction of the camshaft position sensor (DPRV).

To restore normal operation of the timing belt, it is necessary to set the position of the timing and crankshaft shafts according to the marks. If the chain is worn, replace it. The same applies to the camshaft with a bed, hydraulic compensators, gasket and DPRV.

Fuel injection and oxygen supply

An engine that does not receive the required amount of fuel at a sufficiently high pressure cannot, of course, develop the full power provided by the automaker. If the car has a problem with the supply of fuel to the combustion chamber, then there is a malfunction in the injector. This is why it is so important to clean the injector regularly.

In diesel engines, the high pressure fuel pump most often fails. In gasoline engines, a problem with fuel supply may also be associated with a failure of the lambda probe, which measures the oxygen level in the exhaust system, reporting data to the engine control unit. In this case, the fuel injection and air-fuel mixture will be incorrect, which will lead not only to loss of power, but also to problems with engine operation. To the point of failure to start.

How to assess the problem?

Troubleshooting based on the diagnosis of “poor diesel engine traction” is a rather difficult procedure. The fact is that there can be a lot of reasons for breakdowns, as we have already written, and therefore it is extremely important to have a complete history of the origin of the “car disease”. If such information is not available, the verification algorithm will become too extensive, because many parts can simultaneously cause a drop in power. Perhaps some electronic mechanism is not turning on the machine's systems. Perhaps one error leads to another. At times, diagnosing this issue looks very confusing.

In order to conduct a full diagnostic of your car, you need to have special tools to check each system. It is quite expensive to buy all this for self-diagnosis; it is much more profitable to contact Turbo Diesel Service. We are faced with these types of problems every day and over 7 years of work we have learned how to solve them effectively.

Poor dynamics of the internal combustion engine due to the catalyst: how to check

The topic of a drop in dynamics due to a clogged catalyst deserves a separate paragraph. This malfunction has become very common among motorists lately; questions about this are often found on forums.

We will not delve into the thematic jungle regarding what a catalyst is and why it is needed. Let's consider only the main signs indicating its malfunction. And a drop in engine power is not the only symptom.

The main sign is, of course, the “Check” light that comes on. However, a malfunction of the catalyst is not always detected so easily; in most cases, it passes gradually, and the “Check” signal is not displayed immediately. But the throttle response of the internal combustion engine decreases, the overall dynamics of acceleration decreases and starting becomes more difficult.

Whether to remove the catalyst or not is the choice of the car owner, but it should be remembered that there is nothing “totally superfluous” in the car

The reason for the drop in power characteristics can also be a clogged reel honeycomb. Because of this, the throughput of the catalyst decreases, since gases that did not have time to pass through the catalyst “crush” the power of the power plant.

Note. The bobbin honeycombs can not only become clogged, but also collapse or melt over time.

Problems with the catalyst can also be associated with abrasion of the platinum layers. The lambda sensor instantly notices this and sends a signal to the driver.

You can check whether the catalyst is working normally or not by looking at the strength of the gas flow. If it is difficult to block the flow by hand, then everything is fine with the catalyst, but when it is clogged, the flow will be weak.

The car accelerates poorly - Section 3. Malfunctions on the road

There are many reasons for the deterioration of dynamics, the main ones can be defined as follows.

1. Engine malfunction: decreased compression in one or more cylinders, leakage of additional air into the engine intake tract. Coking of the exhaust system or damage to the exhaust gas converter (if the vehicle is equipped with a catalytic converter).

2. Malfunction of the power supply system: clogged injectors and fuel filter, hoses of the fuel supply system. Insufficient fuel pump supply. Use of low quality fuel.

Ignition system in gasoline engines

One of the most common reasons for a loss of power in a gasoline engine is a failure of the ignition system. Most often, a failure in the ignition system is associated with faulty spark plugs, problems with the ignition coils, or worn-out high-voltage wires. Usually, if these components are defective, not only the car’s power may decrease, but problems with starting the engine may also occur. Plus, the following may be observed: car jerking, sharp fluctuations in engine speed, detonation.

This is why it is so important to change your spark plugs regularly (at a minimum, following the car manufacturer's recommendations). In practice, in Russia, spark plugs need to be changed earlier than recommended by the scheduled maintenance regulations. The reason is bad fuel at the gas station. In addition, it is recommended to check the operation of the ignition coils and periodically change the high-voltage wires.

Main reasons

There are many reasons for this phenomenon and in most cases they are associated with a malfunction of the systems and mechanisms of the power plant.

Some of them are trivial and very easy to fix, others require quite serious repairs.

The main problem with the fact that the engine does not pull is not related to eliminating the malfunction, but to finding it.

In some cases, it is very difficult to determine what caused the reduction in traction effort and you have to go through almost the entire engine.

Therefore, we will try to indicate the main reasons why the car accelerates very “sluggishly”.

Since engines on different cars have their own design features, we will consider specific models.

How to determine the power indicators of a power plant

In the process of diagnosing 4-cylinder internal combustion engines, it is recommended to turn off three cylinders and use the resulting mechanical losses as a load. If diagnosing 6-cylinder or more power plants is carried out, additional load devices are used simultaneously with turning off a certain number of cylinders, which makes it possible to carry out the study much more efficiently.

Today, there are various techniques that help the owner independently check the power characteristics of the power unit of his car. For example, install special equipment that can monitor the slightest changes in the functioning of the internal combustion engine, a drop in dynamics, etc. But the price of such devices is quite high, and not every Russian motorist can afford to buy them.

Note. It is more advisable to install these devices on sports cars, the functioning of the internal combustion engines of which requires regular checks.

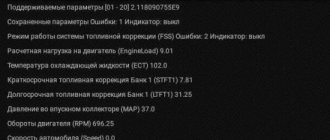

Fortunately for car enthusiasts, there is also a budget diagnostic option. It implies the presence of a computer, special programs and a cable for integration with the on-board computer (BC) of the car. As soon as the driver drives the car a certain distance at different speeds, the computer will automatically calculate the power of the car's power plant.

Attention. Despite the fact that this method of verification has a considerable share of errors in the readings, it is widely used by motorists in many countries around the world. The method gives at least a general idea of the power characteristics.

But still. Only a dynamometer can provide the most accurate indicators. Representing highly professional equipment, it is an indispensable component of any well-known car service.

We recommend watching a video review of measuring the power characteristics of the Nissan GT-R power plant.

How to increase throttle response in simple ways

Every experienced motorist knows and uses his own, favorite way to improve the car's former dynamics. Let's look at the most popular ones, but let's not forget that only eliminating the reasons that contributed to the decline in the power characteristics of internal combustion engines will guarantee a return to their former positions.

- Use fuel with a higher octane number (OC). Indeed, the higher the OC, the better the fuel will resist self-ignition during compression. This will directly affect the greater power from the gas explosion.

- Application of "Suprotek". This is a lubricant that is a composition of several components. This is not an additive or additive, but a special composition that interacts with the metal surfaces of internal combustion engine elements. Excellent for removing wear on metal surfaces.

- Replacing a classic air filter with a modernized one. This way you can ensure that a richer mixture is supplied to the engine.

- Changing the exhaust system. Forward flow helps increase power.

- Turbocharged.

- Replacement of worn parts and much more.

In a word, it is necessary and possible to normalize the engine of your car. It is recommended to do this in professional car services, but if the driver has specific knowledge and the required equipment - in his own garage.

Adjusting the OZ on an injection engine

Everything here is controlled by electronics. First you need to make sure that it is functioning properly and that the throttle sensor is working properly. At idle, it should be slightly open by about 1% (if this is not the case, set up a mechanical drive), the normal voltage at its contacts is 0.45-0.55 V (the car’s bot network should produce 13-14.3 V). When you sharply press the gas pedal, the damper should open 90", and the voltage on the sensor should increase to 4.5 V. If this is not the case, you need to adjust the damper drive and check the serviceability of the sensor (TPS).

To do this:

- take the tester and place it in the voltage measurement position;

- disconnect the connector from the sensor - you will see three contacts - one goes to ground, the other to the ECU (which one is connected where, determine from the diagram);

- start the engine and check the supply voltage - it should be approximately 5 V;

- turn off the engine and switch the tester to resistance measurement mode;

- with the damper closed, between ground and the contact going to the computer, the device should show 0.8-1.2 kOhm;

- with the damper open, resistance is 2.3-2.7 kOhm.

If the received data does not correspond to the above parameters, the sensor must be replaced. If this does not work, you should check the ECU.