The design of any modern car, the VAZ 2114 is no exception, is such that the successful production of a car depends on a number of positions. Previously, this was enough for the mechanical pump to supply fuel to the carburetor, and for the spark plugs to produce a spark. Today there are a lot of problems that prevent the engine from starting. An electronic injector requires the participation of several sensors, and the matter is not limited to them. In this article we will tell you why not and how to deal with it.

In general, all causes of malfunction can be divided into two large categories:

- Fuel system problems. This group includes any breakdowns as a result of which fuel is not supplied to the engine at all, is supplied incorrectly, or mixture quality errors occur.

- Electrical problems. Ignition of the fuel mixture is ensured by sending an electrical signal to the spark plugs. If problems arise here (and there are a huge number of electrical elements), the car will not start.

The most terrible malfunctions can be included in a separate category - for example, a “knocking” VAZ 2114 engine, a broken timing belt and, as a result, bending of the valves. In these situations, expensive repairs cannot be avoided.

Fuel system problems

Among the elements of the fuel system, the following factors influence engine starting:

- presence of gasoline in the tank;

- the integrity of the fuel lines under the “belly” of the car;

- cleanliness of the filters: coarse cleaning (located in the tank) and fine cleaning (located under the car, to the right of the spare wheel compartment).

Also included in this category are electrical components that are directly related to the fuel supply. This is an electric fuel pump and a fuel pump relay.

Before checking other methods, you must be completely sure that the VAZ 2114 with an injector is filled. “Yes, there are still five liters there” according to the indicator on the tidy or “I filled it up yesterday, I couldn’t spend that much” are not suitable. The gauge may be lying, and there may be leaks in the tank or fuel lines. Carefully check the car for fuel leaks; just in case, fill in 5-7 liters of gasoline from a canister.

The mesh in the tank rarely gets clogged, leave this option for last, but it’s worth trying to change the fine filter if electrical problems are ruled out.

The operation of the fuel pump is checked by ear (after turning the key, its operation should be heard; if not, the pump has “died”, or the pump relay, or a wiring break). According to the manual, you need to connect a pressure gauge to the fuel system. If the pressure does not stay within 2-2.5 atm, the VAZ 2114 will not catch due to insufficient fuel pressure.

Electrical faults

Most of the problems lie here, so we’ll look at each option in detail here:

Nothing happens when I turn the key

On a VAZ 2114, this usually indicates a violation in the ignition switch - starter line, but one of the reasons for the breakdown “for blondes” is a dead battery, do not forget about it (checked with a voltmeter: it should be at least 11.8 V - and with a hydrometer, if the battery is serviceable : at least 1.22 in each jar).

Let's move on. The cause of such a malfunction may be a breakdown of the ignition switch cylinder, and the injector has nothing to do with it. If, when turning the key, new sensations arise (something catches, turning has become easier or, conversely, more difficult), that’s the problem.

Under the panel, approximately above the clutch, there are two relays: ignition switch and starter release. The reason may be a malfunction of one of them. They are checked according to the manual by a good electrician or replaced with a known working one.

Starter. Often the cause may be a jammed “retractor”. If you are standing in a field, you should try hitting it with something heavy like a large key (without fanaticism) - it may help. If the car is parked in a garage, you should remove the starter and try to start it directly from the battery.

To do this, press the housing to the zero terminal of the battery, install the wire with the alligator clip on the positive terminal of the battery and bring it to the positive of the retractor. If the starter tries to jump out of your hands, everything is fine (be careful, it is not recommended to carry out this procedure without basic knowledge of safety precautions and an assistant!).

If there is no reaction, the problem is in the retractor. If the relay buzzes, but the starter does not turn, the problem is in the brushes. If the starter makes a terrible sound, but does not turn, the problem is in the bendix.

If the starter turns, replace the battery and check the power supply to the chips that are connected to the starter (with an assistant, one turns the key, the other measures it with a multimeter).

Also pay attention to the ground wire that goes to the battery. If there are breaks in the wiring at the point of contact with the body or at the terminal, it must be replaced. It is also worth disconnecting the wire from the body and thoroughly cleaning it with a metal brush. The reason for the failure to start may be simple oxidation.

The starter turns, but the car does not start

This is the most common situation in the case of the VAZ 2114. The procedure for solving it must begin with answering the question of whether there is a spark. To do this, take an assistant, unscrew one spark plug, put an armor wire on it and very carefully (avoid touching live parts, hold the insulated part of the wire) apply the spark plug to the cylinder head cover. While the assistant turns the engine, watch the behavior of the spark plug. If there is no spark, you need to look for it.

If there's no spark

The ignition module is one of the key problems of the VAZ 2114 on the injector. It breaks often and sometimes a new one comes with a defect. You can read more about checking the ignition module in other material on our website. Please note that the problem may also lie in the chip that is connected to the module. The presence of power on it must also be checked.

DPCV is another reason why there may be no spark. Since this sensor monitors the firing phases of the cylinders, it is one of the key elements of the ignition system. Note that the probability of its failure is lower than that of the ignition module. It is checked by an electrician using an oscilloscope; garage methods do not provide an accurate assessment of the condition of the sensor (only replacement with a guaranteed working one).

ECU. “January” is a relatively reliable injector, but the “brains” can also malfunction from time to time. Often the problem with them is identified by a violation of the injection phases: for example, a spark is supplied only to cylinders 2 and 4, or only to cylinders 1 and 3. Sometimes the issue can be resolved by simply cleaning the contacts on the ECU chip; it is also subject to oxidation, which causes signal loss.

If there's a spark

Not often, but this problem does happen. By all indications, the car should start (gasoline splashes into the ramp, the starter turns, there is a spark), but the engine does not catch. There are also pitfalls here.

Injectors. In most cases, the problem is in them; it is worth taking the car for diagnostics and cleaning it with ultrasound. If trouble strikes you on the road, pay attention to the candles. If the injector supplies the mixture, they must be filled with gasoline; if the spark plugs are dry, the probability of an injector malfunction is high. However, keep in mind that injectors rarely fail suddenly and all at once. As a rule, the engine should start running before the car stops starting.

Poor quality gasoline. It is assumed that a serviceable engine should start almost on water, unless it runs poorly. In reality this is nonsense. There are enough examples of “dead” engines after refueling (both at “Uncle Ashot” and at completely official gas stations of well-known brands). Keep this in mind. If the car stops gripping immediately or a short time after refueling, you should not discount this option. The solution is to drain the gasoline and add another.

Lack of required pressure in the ramp. Here we return to problems with the fuel system. Perhaps the problem is the pump or problems with the TPS (unlikely). If you have January 7.2, the cause may be a malfunction of the mass air flow sensor. Unlike January 5.1, here this sensor is polled at startup and, if there is an error, the ECU may prevent the engine from starting.

Finally, we note that the reasons for non-starting in the presence of gasoline and spark may include the following:

- the phases are incorrectly set when replacing the timing belt, as well as its breakage or rotation - it’s worth checking;

- due to overheating, the cylinder head “started”;

- uneven compression in the cylinders, “stacking” of the rings.

Unplanted VAZ 2114 is a common situation, and there are many reasons that cause it. Therefore, it is worth approaching this issue fully armed.

No spark VAZ (injector, 8 valves)

The other day, out of the blue, the car (Kalina 1.6, 8 valves) began to shake terribly. Diagnostics showed misfires in cylinders 1 and 4. After a little checking (see how to check correctly here), I came to the conclusion that there was no spark . And only in cylinders 1-4.

Next, in order to find out the reason for the loss of spark, I will go in order.

The first thing to check is the spark plugs. The spark plug looked normal, so I didn’t have much hope that replacing it would fix the situation. And so it happened - the new spark plug still refused to produce a spark.

This is interesting: The starter turns poorly when the battery is charged

The second is checking high-voltage wires. They are checked with a conventional multimeter in resistance measurement mode. The resistance should be within 15 kOhm. The wires also turned out to be fine.

Third, and probably most important, is the ignition coil. She, like no one else, is responsible for the spark. Its operability is also checked with a multimeter in continuity and resistance measurement mode. First you need to check the resistance between pins 1-4 and 2-3. It should be about 4 kOhm. If the tester shows infinity, then the coil is broken and must be completely replaced. Next, check the resistance between pins 1a and 1b. There shouldn't be a break here. And the last thing is to check the central contact for breakdown to the housing. The tester should show infinity.

My reel passed the test perfectly. It seems that all the main parts are working properly, so why is there no spark? After digging a little on the Internet, I realized that I still need to check the circuit from the ECU to the coil itself.

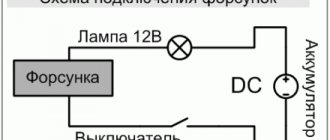

A 3-pin chip is placed on the ignition coil, therefore you need to check these 3 wires. The central contact is +12V, which is constantly supplied when the ignition is on. The extreme contacts - 1a and 1b - provide a control signal (negative) at the moment when a spark is needed. How can all this be checked? Very simple - using a regular light bulb.

We connect the lamp to the central terminal and contact 1a and ask a partner to crank the engine a little (first remove the fuel pump fuse and relieve the pressure in the rail). When cranking the starter, the lamp should flash. The same procedure must be done with pin 1b - the lamp should also blink.

When I turned on the ignition, the lamp started to light up, just constantly on (pin 1b and central). This means that the control wire has a short to ground somewhere or that the transistor (VT1) in the ECU is broken. To find out, we need to find the ECU, disconnect the wiring harness from it, find the wires we need (1b) and test them for integrity.

Having found the contact diagram, I found out that contact 1b goes to pin 5 of the ECU, 1a goes to pin 2, 3 goes to ground of the ignition circuit. I rang them for integrity - they were all intact. I called ground and everything is fine too. Therefore, you need to check the transistor in the controller itself.

My car has a January 7.2 controller. Inside there are 2 transistors that pass control signals to pins 1a and 1b of the ignition coil. So one of these transistors was broken, i.e. was constantly in the open position.

How to check the transistor for serviceability? It has 3 pins - 2 of which are soldered. It is necessary to ring each outer terminal with the central one. In both cases, the tester should not beep. The contacts must not be closed.

Now all that’s left to do is to unsolder the broken transistor (its marking is gb10nb37lz), solder a new one in its place and rejoice at the spark that appears.

Checking the control unit

If the VAZ 2114 does not have a spark in cylinders 1 and 4, and the spark plugs, armored wires and ignition module are working properly, then the last reason remains - a breakdown in the electronic control unit. This is easy to check - just connect to the unit using a light bulb with two wires. If the light blinks periodically, then the unit is working; if not, then the problem lies with it.

In this case, you should disconnect the unit, open its case and remove the board, then carefully inspect it. Very often the breakdown of this device is the burnout of the transistors (they look like the largest electronic components with three legs). If one of them looks burnt, it should be replaced.

For this you will need:

- tester;

- soldering station or hair dryer;

- tweezers (preferably with ceramic tips);

- low-melting solder.

First you need to check the transistor using a multimeter. If it shows no signal, then the element will need to be unsoldered, and in its place soldered a new one - similar or similar in its properties (transistors can be purchased in stores for radio amateurs or ordered from China, for example, from Ali. In the latter case, they will cost less than 15 rubles).

Transistors should be desoldered and soldered using a soldering station or a single hair dryer, since they are made in a chip design. If soldering is carried out with a soldering iron, then it should be done extremely carefully and using low-melting solders.

After the transistor is replaced, the electronic unit will need to be assembled and installed in place, and then try to start the car. If all 4 cylinders work properly, then the problem has been resolved; if not, then you should continue your search and check all other electronic components of the device with a tester. If additional parts are found to be faulty, they should also be re-soldered.

If such a check does not show results or the task of finding burnt elements turns out to be too difficult, you will need to replace the unit with a new one - similar or similar in characteristics.

True, if an immobilizer is installed on the car, then the burnt-out unit should be replaced exclusively with exactly the same one (installing even a close analogue will lead to the fact that the car simply will not start).

There is no spark in the VAZ 2114 car

Probably, many car enthusiasts have encountered a problem when there is no spark on the high voltage wires, so if the vehicle engine does not start, but the driver hears the functioning of the fuel pump in the tank, then you need to pay attention to the ignition system. One of the most common problems with a car's ignition system is that there is simply no spark at high voltage wiring. That is why the main topic of today’s article will be the following questions:

Why are there no sparks on high voltage wiring? What to do if there are no sparks on the high-voltage wiring of the VAZ 2114?

Naturally, in addition to these questions, we will consider several more and here are a few of them:

- What is the ignition system of the VAZ 2114 car injector?

- Diagnostics of the electronic part of the VAZ 2114 system;

- The main breakdowns encountered by the ignition system of a VAZ 2114 car;

- The main signs of failure of the ignition module of the VAZ 2114 injector;

- Diagnostics of the ignition module VAZ 2114 injector;

- Algorithm for removing and installing the ignition module VAZ 2114 injector;

- How to check whether sparks occur or not?

- What to do if there is no spark on a VAZ 2114 car?

Why there is no spark on the VAZ-2110 injector 8 valves: reasons

All possible malfunctions can be divided into three large groups: fuel system breakdowns, electrical malfunctions and global malfunctions. An inexperienced car enthusiast with any problem with ignition makes a verdict: “No spark.” On the VAZ-2110 car, different engines are installed, for example, an 8-valve injector. Let's talk about the problems that are inherent in such a system.

Possible breakdowns by group

Modern cars are equipped with a large number of auxiliary components and sensors that make the driver’s life easier and at the same time make repair work more complex. The electronic injector uses several sensors at once, which can cause a lack of spark in the ignition. But the matter is not limited to them; there are several groups of breakdowns:

- Problems with the fuel system. This group includes malfunctions in which fuel does not enter the engine, its supply occurs with malfunctions, or other errors occur.

- Malfunctions in the electrical part are among the most common on the VAZ-2110 injector. In the event of such breakdowns, an electrical signal is not supplied to the spark plugs and, accordingly, the fuel mixture does not ignite.

- Global breakdowns include engine failure, bent valves, and broken timing belts. We will not dwell on such cases in detail, since they require more complex repairs.

Basic information about the ignition system of a VAZ 2114 car

An injector is a method of guiding a car's engine system. In addition, it is a method of supplying the fuel mixture.

On cars with an injection engine, the fuel mixture is supplied using a computer through special nozzles. Most likely, every car owner has ever encountered a problem when there is no spark on the high voltage wires, but the driver can hear how the fuel pump functions, then pay attention to the ignition system of your vehicle. One of the most common problems with a car's ignition system is that there is simply no spark at high voltage wiring.

During operation of the machine, some malfunctions of electrical components may occur and this may affect the functioning of:

- Instruments, and this does not make it possible to control the ignition system and other components;

- power unit, thereby making it impossible to develop standard power;

- Light fixtures and convenience mechanisms, which include lighting, heating and power windows.

The main breakdowns encountered by the ignition system of a VAZ 2114 car:

- Reduced vehicle power;

- Failure during the development of vehicle engine power;

- Idle speed instability;

- Violation of the normal functioning of the cylinder.

You need to start looking for the cause of malfunctions in the ignition system with the formation of sparks on high voltage wiring.

Sparking process

If you hear the fuel pump operating, but there are no sparks on the high-voltage wiring, then check the functioning of the ignition system. The system is checked for the presence of sparks on high voltage wiring, and for this a special device called a spark gap is used. The use of this device is considered more comfortable, because most injector-type engines use static ignition distribution with simultaneous transmission of high voltage to two spark plugs.

To carry out such a test, you need to connect the spark gap and crank the engine using the starter. If sparks appear only on one of the wires, then the reason is a breakdown at the wire ground or at the coil terminal. Sometimes the reason may be a broken wiring or winding that relates to the car's ignition system module.

If there are no sparks on several wires at the same time in any sequence, then the cause of the malfunction lies in the coil, module or vehicle controller.

Please note that damage may occur due to the fact that the high voltage wiring line is broken. In this case, it is necessary to check the high voltage wiring for integrity, and this can be done by taking measurements of the resistance level of the wiring itself. The standard resistance value on the wiring should be no more than 200 kilo-ohms. It is also worth paying your attention to the fact that there should not be a large difference between the resistance levels of the wiring.

Ignition module on a VAZ 2114 car

If the discharge of sparks from high-voltage wiring has always been stable, this indicates that the cause of malfunctions in the injection engine lies in the spark plugs.

If there are no sparks, then the cause of the malfunction may lie in the primary circuit that runs from the generator to the ignition coil. Most often, the cause is a malfunction of the ignition module, and the easiest way to determine whether this is the cause or not is to establish a properly functioning device. That is, if sparks appeared after replacement, then the problem was in the ignition module, and the instructions for use do not provide for its repair.

Algorithm for removing and installing the VAZ 2114 injector ignition module:

- Disconnect the negative terminal on the battery or using the ground disconnect button;

- Remove the tip from all candles;

- We bend the clamp, disconnecting the low voltage wiring block of the module;

- Disconnect the high voltage wiring from the module connectors;

- We unscrew the 2 bolts securing the crankcase to the engine using a 13mm wrench;

- We loosen the 3rd bolt together with the head using a 17 wrench;

- Remove the module together with the bracket;

- Unscrew the bolts securing the module to the bracket. They are located under the hexagon;

- Installation occurs in reverse order.

If sparks still do not begin to form, then it is very likely that the reason lies in the controller or the wiring connecting the module and the ignition coil. In this case, you need to check for the presence of sparks on all cylinders one by one, and if there is no spark on one coil, then replace it with the one next to it. If after replacing one coil with another a spark appears, then the reason is a broken coil, otherwise the controller or wiring is broken.

VAZ 2114: no spark injector

A very good opportunity has arisen to show in practice how to look for a fault on VAZ fuel-injected cars. Here we have a clear, understated nine. Now I’ll show you something else interesting. Problem: won't start. Primary diagnostics showed that there is no spark, and now we will look for the reason. In order to determine the reason, we need to look at the signals on the connector...*. Now let's turn on the ignition and take a look.

This is interesting: Checking the starter from the battery

We must have a ground indicator on the connector....* On the connector we have plus 12 V and ground, and also two control signals. We can now see the control signals, or should, in any case, see them when the starter rotates. We should hear a squeak. But there are no squeaks, because the control signals also do not arrive, so there is no spark. You can also check the signals on the injectors, but there are none either, so you can’t do without diagnostics and a computer (computer).

As I said earlier, when you turn on the ignition, look at the “Check” light. The light is on, which means the brains are turned on. We also listen to the fuel pump - the fuel pump turns on. And when the starter rotates, the fuel pump turns on again, this indicates that the crankshaft position sensor, if faulty, is at least receiving some impulses. The injectors do not open. Just in case, I turned off the immobilizer, it is located here, I just pulled out the connector. Accordingly, the diagnostics, of course, will not work now, but you never know... And, since it is not clear what is the reason for the lack of a spark and injectors*, suspicion fell on a glitchy immobilizer. And now we are flashing the block. I downloaded the firmware, removed the immobilizer from the firmware and uploaded it back.

Reasons for no spark VAZ 2114 injector 8 valves

Using the 2111 injection engine of VAZ 21083, 21093, 21099 cars as an example, we will understand the causes of the “no spark, injector” malfunction.

Symptoms of a “no spark, injector” malfunction

There are only three signs of a “no spark, injector” malfunction in relation to the ignition system of the 2111 engine.

— The car engine does not start

— The car engine starts and stalls

— The engine “troits” or “doubles” at idle

Causes of the “no spark, injector” malfunction

Spark plugs are faulty

Black deposits on the electrodes of the spark plug allow the spark to travel along it to ground.

In rare cases, all spark plugs may fail at once. But most often one or two of them fail. The engine begins to run unsteadily at idle. The cause of spark plug malfunction is a breakdown of the insulator to ground (the spark goes not to the spark plug electrodes, but to the engine), carbon deposits on the electrodes due to the engine running on a rich fuel mixture, a malfunction of the spark plug itself (does not pass current), etc. See "Spark plug malfunctions" and "Checking the spark plugs of an injection engine."

In addition, the reasons for the disappearance of the spark on the spark plugs may be faulty high-voltage wires and the ignition module.

The ignition module (“coil”) is faulty

The ignition system of the 2111 engine uses an ignition module consisting of four coils. Most often, two of them fail, and the engine, at best, begins to “doubly” - only two cylinders work, but most likely it will not start at all. Under certain conditions, difficult starting and ghosting of a cold engine may occur; when the engine is warm, the problems disappear.

Checking the module (ignition coil) VAZ 21083, 21093, 21099

You can check the ignition module yourself “Checking the ignition module of VAZ 21083, 21093, 21099, injector”.

And in case of malfunction, replace it.

High voltage wires are faulty

Checking high-voltage wires using a multimeter (in ohmmeter mode)

High-voltage wires are designed to conduct high-voltage current from the ignition module to the spark plugs (the so-called high-voltage circuit). If a “break” occurs in this circuit, then there can be no talk of any spark. The cause of the “break” may be burnout of the central core of the armored wire, oxidation, or burnout of the contacts (tips). Or a violation of the integrity of the wire insulator (“breakdown”) due to which the spark goes to the “ground” and not to the spark plug.

The signs of malfunction of high-voltage wires are the same as those of spark plugs (“triples”, “doubles”, does not start, stalls).

You can check the high-voltage wires yourself. “Checking high-voltage wires of VAZ 2108, 2109, 21099.”

The ECM crankshaft position sensor is faulty

In the event of a complete failure of the DPKV sensor or a “break” in its circuit, the ECU does not receive an impulse when the pistons pass the top dead center. Accordingly, there will be no command to ignite the fuel mixture in the combustion chambers, and there will also be no spark on the spark plugs. When the DPKV fails, the “Check Engine” warning lamp (CHEK ENGINE) lights up in the instrument panel.

"DPKV malfunctions"

You can check the crankshaft position sensor yourself using the "Checking the Crankshaft Position Sensor" section.

Checking the DPKV engine crankshaft position sensor

Ignition module low voltage circuit is faulty

The diagram at the beginning of the article shows the electrical circuit of the 2111 engine ignition system. If there is a break in any of the system wires, the ignition system will not work.

Using the diagram, check the reliability of fastening of the wire blocks (chips) and the oxidation of the contacts in them.

The control unit (ECU) is faulty

If the test establishes that all elements of the ignition system are in working order, then the controller (ECU) of the electronic engine control system (ECM) is most likely faulty, since the ignition system of an injection engine operates on its command.

Or the main relay (position 1 in the picture) and the ignition system fuse (6) in the relay and fuse box under the instrument panel have failed.

Relays and fuses of the ECM for injection VAZ 21083, 21093, 21099

A faulty controller will have to be replaced or sent for repair. You can check the relay and fuse yourself.

Notes and additions

Similar symptoms (the engine does not start, the engine stalls) can occur not only due to a malfunction of the ignition system, but also the power system, control system, or the engine itself.

How to save 20% fuel?

This thing really saves 10-30% on gasoline. You simply install this device on the fuel supply hose and...

My homemade adapter is used. Let's connect to the brains...* The loader used is this one - CombiLoader, this version is like this. I downloaded the firmware for myself, I’ll read why this firmware is cool. Maybe people saw it that way according to the version, I don’t know. Usually, when I repair a car, I use standard water and there are no more problems. And then all sorts of Sports, Economy and others - you won’t understand later that it* works so poorly. I'll show you the results.

I deceived you, unfortunately, I won’t show you how the problem was solved. And the problem was quite interesting. It seems that, based on the first signs, the crankshaft sensor was alive, one might say “conditionally alive”, because when the crankshaft rotated, the fuel pump turned on again and I, as it were, temporarily got rid of this problem. But, as it turned out later, the car had recently been repaired, the head was removed, and inexperienced mechanics laid a wire leading to the crankshaft position sensor near the exhaust manifold.

The wire melted and one of the wires shorted to the braid. For those who don’t know, there is a shielded cable in which two wires are laid. Surprisingly, the brain recognized the pulse in this position and turned on the actuator, that is, the fuel pump relay was turned on, but, accordingly, the engine control unit* was unable to calculate the position of the top dead center, or calculate the position of the pulses. I noticed it purely by chance (I was already freezing, I had no time for filming), just moving the wire near the crankshaft position sensor.

I took it off, checked the sensor - the sensor seemed to start* correctly. Pulling the wire, rotating the starter, the engine began to seize. At this point it became clear that the problem was with the wiring, and after looking carefully at the wire, I saw that it was burnt out. I cut out the damaged area, connected it - and the car started up perfectly and drove away*. It was already dark, I wanted to go home, so there was no time for filming. Nevertheless, I am reporting on the results and a little bit (about) my technique, which I talked about a little earlier in the video, about how to find a spark - the sensor can turn on the pump and at the same time not give a spark - a very interesting case came across. I think you'll take note.

VAZ 2114 does not start, spark plugs are dry

If the VAZ 2114 does not start, first of all we unscrew the spark plugs. The fact that they are dry indicates that fuel is not supplied to the cylinders. If there is a spark, then we immediately discard the crankshaft position sensor, because the control unit definitely understands the position of the cylinders at the moment of time, since it supplies a spark to the spark plugs.

To begin with, turn on the ignition and listen to whether the fuel pump is working. If the fuel pump does not work, then first of all we check its fuse. In addition, it is worth paying attention to whether the fuel pump relay clicks after turning on the ignition. If this is not the case, then the problem is most likely in the ignition switch, or the relay itself is faulty. If the relay clicks, this indicates that the fuel pump activation circuit is closed. Then you need to check the voltage at the relay, after which we remove the back seat, remove the chip from the fuel pump, turn on the ignition and measure the voltage at the chip. In general, the fuel pump chain runs through the cabin, so rarely anything happens to it. From this we conclude that the fuel pump most likely simply burned out. After the replacement everything will return to normal.