How to adjust the 8 valve mechanism in the Lada Kalina model? Most owners of these practical Russian cars sooner or later ask themselves a similar question. Carrying out this procedure yourself will not only be interesting, but also useful in terms of gaining experience.

Now let's move on to a more detailed consideration of the issue outlined here: valve adjustment.

Why is adjustment necessary?

The correct procedure depends on:

- uninterrupted operation of the LADA Kalina engine (operation with a reduced noise level in the timing belt, no errors in the camshaft sensor);

- reduction of fuel consumption to a level close to that regulated by the manufacturer;

- less wear on the camshaft cams and the pushers interacting with them.

- cleanliness of combustion chambers and valve plates due to the absence of carbon deposits.

Valve adjustment in a Lada Kalina car should be carried out with a periodic mileage of 20 thousand km or a little more.

It is not recommended to neglect this procedure, since the regulatory value of the gaps at the valves of the intake and exhaust circuits changes. This circumstance provokes a loose fit of the valve discs to the seat seats, which inevitably leads to the formation of carbon deposits, incomplete combustion of fuel, damage to the discs with subsequent burnout and other troubles in the timing belt in the LADA Kalina model. As you can see, in the absence of the required clearances, there is a violation of the correct functioning of the engine as a whole, and the only harmless point here is the owner’s acoustic discomfort due to the increased noise of the timing belt.

Note that adjustment of the valve mechanism requires 8 valve engines of Lada Kalina cars.

Causes of pinched valves

The first factor is most often observed on those cars whose owners have equipped their cars with LPG equipment (gas equipment).

Gap too small

As you know, the valve has a plate - its widest part, which is located directly in the combustion chambers. On the reverse side it is attached to the cylinder head. As the car's mileage increases, the chamfer on the surface of the plate and the mounting location begin to wear out. As a result, when the rod is raised, the pusher is pressed too tightly against the camshaft cam. This is how compression occurs.

Such a phenomenon does not bring anything good to the motor.

| Processes | Consequences |

| The valve will begin to heat up. | Thermal expansion is not compensated by the gap, and the plate will begin to fly out of the mounting location. |

| There is a decrease in compression. | The answer is a reduction in power. |

| Heat removal is not carried out in normal mode. | There is a negative impact on the operation of the catalyst. |

| During combustion of the air-fuel mixture, part of the burning composition goes into the exhaust manifold. | Thus, the plate and chamfer are destroyed faster. |

The intake elements, unlike the exhaust elements, have the opportunity to be cooled by a new portion of the fuel mixture. There is virtually no exhaust heat removal.

Increased clearances

Another situation is when the gaps between the valve and the piston are too large. With use, natural metal wear occurs on the camshaft journals and on the surface of the cams. Accordingly, an increase in gap values appears. If adjustment is not carried out according to the regulations, for obvious reasons the gap will increase even more, including from shock wave loads. You can find out about this by the characteristic clatter of the engine even after reaching the optimal operating temperature.

Gradually, the valve timing begins to be disrupted, and the power of the power plant decreases. This happens due to the delayed opening of the intake and exhaust elements. The air-fuel mixture arrives late, and the exhaust gases cannot escape completely, as a result the engine begins to operate unstably, noise increases, etc.

It is important to carry out adjustments in a timely manner and not neglect this procedure. The last resort in the most advanced cases is a major overhaul of the cylinder head.

How to adjust the valves?

The main question is how to adjust the valves. To perform this procedure, the owner will need to acquire the following set of tools, accessories and consumables:

- screwdrivers and pliers with long jaws;

- heads for unscrewing bolts;

- ratchet;

- a set of probes;

- crank;

- a syringe to remove excess oil from the head baths;

- tweezers for removing washers;

- adjusting washers of different sizes (thickness) and a device for recessing the valves.

Before the valve adjustment begins, let the engine cool down (temperature no more than 20 degrees).

- Don't forget about safety and remove the terminals from the battery.

- Remove the valve cover with gasket.

- During the procedure, you will need to rotate the crankshaft of the Lada Kalina. To facilitate this action, it is recommended to unscrew the spark plugs, having first removed the tips of the high-voltage cables from them.

- Remove the timing cover.

- Use a syringe to remove the remaining oil from the baths.

- We install the device for recessing the valves on the mounting studs of the motor cover and secure it with standard nuts.

- By rotating the crankshaft (with a key on the pulley bolt or a wheel with 5th gear engaged in the box, after hanging the side of the car), we achieve the TDC position in the 1st cylinder (the rightmost one in the direction of the car).

- From this position, turn the camshaft to an angle of 40-50 degrees (three pulley teeth).

- Using a feeler gauge, we measure the size of the gap between the back surface of the cams and the washers of the 1st (exhaust) and 3rd (intake) valves (we count from the shaft drive gear). The feeler gauge should fit into the gap with a slight “tightness”.

- When the gap size differs from the required value, the pusher should be turned so that its groove is opposite the “adjuster”.

- Using the device, we recess the valve, securing the pusher from turning using a screwdriver (insert it into the groove). Using the latch, we lock the pusher in its lower position.

- We remove the washer using the previously indicated tweezers.

- Read the markings on the washer. It indicates thickness. If the inscription is erased, measure with a micrometer.

- We calculate the required thickness of the washer to be installed using the well-known formula, which, by the way, is different for intake and exhaust valves.

- We select a new washer from the set, with a thickness close to the value obtained in the calculation (deviation - plus 0.05 mm).

- We install the selected washer in the seat (in the pusher). In this case, the surface with the markings should be facing down.

- Having pressed the pusher with the device (drowning it deeper), we remove the latch.

- Now we move on to adjusting the next pair of valves. To do this, we rotate the crankshaft to an angle of 220-230 degrees and carry out the entire list of previously indicated adjustment actions with the valves: 5th (exhaust) and 2nd (intake).

Do-it-yourself valve adjustment on the Lada Kalina: photo, video

The issue with adjusting thermal clearances is a classic one: everyone should be able to change the washers on the pushrods of an 8-valve valve. But there is “bad advice” that applies to the VAZ-21116 engine: they say that for exhaust valves it is better to make the gap equal to 0.40, and let the tolerance be 0.05 mm.

In fact, the requirements have not changed since the 11183 engine: the average numbers should be 0.20 and 0.35. Following “bad advice”, you get one thing - the engine “knocks” when cold. And this is for a value of 0.40! You still need to be able to set it, but it may turn out to be 0.45... And then our adjustment will kill 4 of the 8 valves on the Lada Kalina.

We are talking about the Kalina 2 family, where the only 8-valve engine was the 21116 engine.

The following is a video where valve knocking is recorded.

All steps for adjusting valves inside and out

First, taking a Phillips screwdriver, loosen the clamps on the three supply hoses. These hoses are connected to the cylinder head cover. Each clamp is clamped with a Phillips screw (see photo).

After disconnecting all the hoses, you can remove the receiver mounting bracket. You will need a 10mm socket wrench to unscrew the three nuts.

The second extra part is the bracket

If even the studs are turned out, it doesn’t matter, they can be screwed back in. Use the same “10” wrench to unscrew the nuts on the cover.

There are washers under the nuts, which are important not to lose.

On any car, including the Lada Kalina, valve adjustment is carried out as follows: rotate the crankshaft pulley, moving the camshaft to the desired position. The camshaft pulley needs to be opened - to do this, the casing is removed.

Preparing for the test

Use a 6mm hex key to unscrew the fasteners of the top cover. The number of screws here is four.

Upper casing covering the timing belt

When the cover is removed, perform the main action:

- You need to rotate the crankshaft using the screw securing the generator pulley to align the marks (see photo).

You will need a key “17”. Camshaft pulley, marks - Do not touch the screw securing the camshaft pulley!

- The first pair of valves (3 and 1) does not correspond to angle “0”. To work with different pairs, the shaft is rotated at the following angles: 45, 225, etc.

Check the gaps, replace the washers

Now on the Lada Kalina we regulate not 8 valves, but two. The gap between the washer and the pusher is measured with feeler gauges (photo 1). For the intake valve the numbers should be 0.20 mm, for the exhaust valve - 0.35 mm. The tolerance is 0.05 mm.

Measuring and preparing for replacement

If the gap does not meet the required one, a special device is screwed to the studs (photo 2). Then do this:

- The valve pusher is turned with the slot towards itself;

- The valve is recessed down, for which the “fang” is inserted between the washer and the cam;

- A clamp is installed between the pusher and the camshaft.

The meaning of what has been said is clear from the photo.

Procedure for replacing one washer

The “old washer” is removed and replaced with a new one. Pre-measure the thickness of both washers. Use the formula R = B + ( A – S), where:

- R – thickness of the replacement washer;

- A – measured value of the gap;

- B – thickness of the “old washer”;

- S – 0.35 or 0.20 mm.

Please note that the inscriptions on the washer are on one side. Let this side look down!

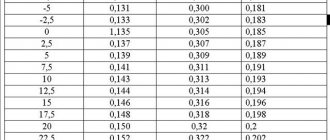

Rotation angles and access sequence

In practice, it is convenient to use the table:

Pulley rotation angle from position “0” Exhaust valve Inlet valve

| 40-50 | 1 | 3 |

| 220-230 | 5 | 2 |

| 400-410 | 8 | 6 |

| 580-590 | 4 | 7 |

Rotating the shaft clockwise, we go along the lines from top to bottom. Valve 1 is closest to the pulley.

Articles and regulations

When installing the cylinder head cover, it is recommended to replace the rubber gasket. Its article number is 21080-1003270-1 0. The last numbers may differ:

- 11 – BRT manufacturer (Balakovo);

- 12 – ELRING;

- 14 – CJSC VRT (Volzhsk).

All adjustment devices are universal. They don't have articles.

The pressure device can be replaced with a screwdriver. The latch is also a screwdriver, only a thin one. The interval between adjustments is 30 thousand km. Good luck!

All instructions in one video

Source: https://carfrance.ru/reguliruem-klapana-na-lada-kalina-8-klapanov-svoimi-rukami/

Let's sum it up

Now you know how to adjust the valves. When the mechanism in the LADA Kalina model is adjusted, we reinstall all previously dismantled parts, add oil to the engine and start it. We are pleased with the clear and quiet operation of the engine, as well as its improved throttle response.

How are Kalina valves adjusted? Many motorists will be interested in such information. Everyone who has their own car loves and cherishes it, trying to maintain their car as much as possible. Such procedures include adjusting valves.

Why adjustment is needed

A properly performed operation depends on:

- excellent operation of the gas distribution system;

- finding the gaps within normal limits;

- engine operation (it is much quieter and much easier to start, and the camshaft sensor, which controls the entire operation of the car, will show the good condition of the mechanisms);

- reduction of fuel consumption;

- better performance of the pusher and camshaft;

- no carbon deposits (the combustion chamber will remain virtually clean).

Lada Kalina valve adjustment is usually carried out after the car has traveled more than 20 thousand km. There is no point in delaying this, because when gaps appear in the valves, the settings made at the factory are violated, the cylinders are left without a sufficient amount of fuel, and if the gas is incompletely burned, it is released prematurely.

We can safely say that if the valve malfunctions, the entire operation of the car is disrupted. And if the valves burn out, the cylinder head will suffer.

Those who purchased a car like the Lada Kalina 2 know that valve adjustment after a certain mileage is necessary.

This type of machine comes with several types of engines. The first model is 8-valve, with a displacement of 1.6 liters. Valves need to be adjusted periodically. Time passed, and a car appeared with a smaller volume - 1.4 liters, but with 16 valves. Virtually no valve adjustment is required.

But the designers did not think to rest on this; as a result of their creativity, a new Kalina car engine appeared with 8 valves and a volume of 1.6 liters, but with a lightweight piston system. The most prestigious Lada Kalina 2 is a 16-valve model with a volume of 1.6 liters. Adjustment is very rarely needed, but the valves can become bent if the belt breaks.

Engine types

The first Lada Kalina cars received a 1.6-liter power unit and a timing belt with 8 valves. On these models, periodic adjustment of valve clearances is necessary. Later, the manufacturer offered a car with a 1.4-liter engine capacity and 16 valves, the clearances of which practically do not need to be adjusted. The next design option is a car with a 1.6 liter engine and a timing belt with 8 valves, which need to be adjusted periodically. And the “hit” model is the Lada Kalina with 16 valves and a 1.6 liter power plant. Here, adjustment is required very rarely: but if the timing belt breaks, the valves will bend.

How to adjust valves

To adjust the Kalina valves, you need a set of necessary tools:

- several screwdrivers and long-nose pliers;

- heads for unscrewing bolts;

- wrench, probes and ratchet;

- tweezers and a syringe, which will be needed to remove excess oil;

- adjusting washers and a device to accurately recess the valves.

You need to start by checking the engine: it must be cold. 20° is the right temperature for the gaps to be set perfectly.

The valves are replaced after the valve cover is removed, that is, the fastening bolts are removed, the spark plugs are unscrewed so that the engine turns better, and the camshaft and crankshaft are aligned to the marks. The camshaft must contain cams without wear. The head must be free of oil; it is better to use a syringe. You need to attach a tool to the studs to recess the valves.

Then the pistons of cylinders I and IV should lock at the top point. There are several methods, one of them is that the crankshaft does not need to be rotated 3 times and adjusting only 2 clearances, but in one revolution it is possible to adjust 4.

Extreme care is required: the four camshaft cams will definitely be in a position raised from the valve, and this is where the gaps need to be measured. Usually these are I, II, III, V valves. If the gaps are different from the nominal ones, adjustment is needed, and a washer and a formula will help, with which you can find out its thickness by summing the thickness of the removed washer, the nominal gap and the changed gap.

Valve adjustment value

If we talk about an internal combustion engine, we can briefly describe the cycles of its operation. This is intake, then compression, after which fuel combustion occurs, and stroke 4 is the release of exhaust gases. On the standard Kalina 2 engine and other VAZ cars, 4 valves are used for each cylinder. Two are responsible for exhaust and two for intake. The principle of their operation is simple: when the camshaft rotates, both intake ports open simultaneously, and after a certain time, two exhaust ports open.

Valve mechanism design

The intake stroke involves the downward movement of the piston. At the same time, the intake valves open, supplying a dose of a mixture of air and gasoline into the cylinder. At the next stage, the piston begins to rise up and the intake valves close. Thus, the compression stroke occurs. Having reached the top point of the cylinder, the piston is sharply thrown back by igniting the mixture with a spark plug. Once the piston reaches extreme bottom dead center, the exhaust valves open. When it begins to rise upward, exhaust gases are pushed out at the same time.

Accordingly, without valves, the operation of an internal combustion engine is virtually impossible. Their function directly depends on the correct rotation of the camshaft. And to be precise, the appendages on it, called pushers.

As for valves, the most important parameter of their operation is the thermal gap and the correctness of its adjustment. After all, every little detail is important for the stable functioning of the gas distribution mechanism.

Purpose of thermal gap

When this gap is properly adjusted, the tappet and camshaft lobe are pressed against each other as hard as possible to ensure perfect contact between the surfaces. It is necessary to take into account that all internal combustion engine parts are mainly made of different alloys and metals (aluminum, copper, cast iron compounds). The pushers, camshaft and valve group itself are also metal. As you know, any metal tends to increase in size when heated strongly. As a result, the gap that exists on a cold power unit differs significantly from that on a warm one. Simply put, the valves are either too tight or the surfaces are not in close contact.

Adjusting the gaps is the installation of special gaps between the valve and the piston, taking into account the expansion of metals when heated. These values are so small that microns are used to measure them. However, different values are used for exhaust and intake.

Each automaker, including AvtoVAZ, has regulations according to which the required indicators are set. This is what people call valve adjustment. The manufacturer clearly regulates the frequency of such a procedure: at least once every 50,000 km. Typically, special adjusting washers are used for these purposes, which are changed at the top of the pushers.

An increased or insufficient thermal gap has an extremely negative effect on the operation of the gas distribution mechanism. In general, the operation of the entire engine is disrupted.

Differences in load on exhaust and intake valves

Almost all elements of an internal combustion engine are subject to severe thermal loads, the valve group is no exception. The diameter of their rod does not exceed 5 mm. And when fuel burns, thermal energy is released, and the temperature in a short period of time can reach 2,000 degrees. A larger gap is established on the exhaust parts due to stronger heating from the release of hot exhaust gases. This means that the metal expands at such temperatures more than at the inlet.

Consequences of untimely adjustment

If thermal gaps are not adjusted, two main problems can arise. The first involves excessive clamping. The second, on the contrary, consists of too large gap values.

Engines "Lada Kalina"

Machines of this type are equipped with several types of engines. Each of them has its positive and negative sides. The first Lada Kalina produced by AvtoVAZ was equipped with an engine with eight valves. Its working volume was 1.6 liters. Then the car began to be produced with an engine with 16 valves, with a slightly smaller volume, only 1.4 liters. The most expensive model of the Kalina, which is a sports type, is equipped with an engine from the Priora, which has 16 valves and a volume of 1.6 liters. Three years ago, the brainchild of VAZ began to be equipped with a new engine. It, like the first engine, has 8 valves and a volume of 1.6 liters, but differs from its “brothers” in that it has a lighter piston system. As a result of this change, power increased and the engine began to behave more responsively. Today, this engine is mainly installed on the Grant, which replaced the Kalina Sedan. Perhaps in the future every Lada Kalina will be equipped with such an engine.

Adjusting valve clearances

Any engine installed on the Lada Kalina must be regulated. The difference in adjustment lies in the order in which the thermal gap is measured. All measurements are carried out only when the valves are completely closed. When adjusting, the engine crankshaft rotates in a clockwise direction. To adjust the Lada Kalina valves, special washers are used, located in the niches of the pushers. To obtain the required clearance, washers of the required thickness are selected.

Tools required for valve adjustment

To make the adjustment you need the following tool:

- Heads for unscrewing bolts;

- Collar;

- Ratchet;

- Syringe to remove oil;

- Screwdrivers;

- A special device used to recess the valves;

- Probes;

- Tweezers;

- Long nose pliers;

- Adjusting washers.

Valve adjustment "Lada Kalina", 8 valve

The entire technological adjustment diagram is shown in the pictures below. Work is performed on a cold unit. First, remove the valve cover. To do this, you need to unscrew and remove the mounting bolts.

Then the cover covering the timing belt is removed. The candles are turned out. In this case, the engine will turn over more easily. The head must be freed from oil. A syringe will make the job easier. The camshaft must have cams without wear. If damaged, it must be replaced. A device is screwed to the studs securing the valve cover, with which the valves are recessed. Use a wrench to turn the crankshaft until the pulley marks align with the belt cover. When the marks match, the shaft must be rotated by three additional teeth. The piston will find top dead center.

The gaps are checked, first on the first cam, then on the third. The size of the probe should vary in the range of 0.2 - 0.35 mm. If the probe passes freely, the washer needs to be replaced. You need to pick it up from the pushers and easily remove it through a special groove made in the upper edge. To find the groove you just need to turn the pusher. Using the device, you need to recess the valve. To prevent rotation of the pusher, hold it with a flat screwdriver, which must be inserted deep into the groove.

The lower position of the pusher is fixed. The washer is pulled out with tweezers. A new one of the required size is installed. It should be turned with its marking towards the pusher. Each washer is marked with its size. The retainer is then removed. Measuring the gaps is repeated again.

In the case of normal adjustment, the feeler gauge enters the gap with slight effort. Rotate the crankshaft again until the mark matches again. Rotation should be 90 degrees. After each rotation of the crankshaft, all remaining clearances are adjusted, adhering to a specific sequence. When the adjustment is complete, you need to fill in the oil, replace the gasket under the valve cover, and install the valve cover and belt.

In principle, the operation associated with adjusting the valves of the Lada Kalina is a fairly simple operation. If you follow the sequence described above, then even a novice car enthusiast can do this work with his own hands. If the work was done correctly and the exact regulation procedure was followed, then the gas distribution mechanism of the Lada Kalina will work perfectly. Correct adjustment allows you to travel more than 50,000 km without additional work.

Preparing for work

You will need a set of tools and accessories:

- a set of socket heads with a wrench and a ratchet;

- syringe for removing engine oil;

- figured and flat screwdrivers;

- special tool for recessing valves;

- a series of special probes;

- tweezers;

- long-nose pliers;

- adjusting washers.

The procedure is actually simple and can be done independently, without the participation of specialists. To save time or if the process seems too complicated, it is better to use the services of a car service. Such work does not cost that much: the standard figure does not exceed 800–1000 rubles, depending on the region.

Instructions for adjusting gaps

Before starting this operation, it is necessary to cool the engine. Afterwards, the bolts securing the cylinder head are unscrewed and the latter is dismantled. Further work looks like this.

- Remove the casing that covers the timing gear drive.

- Unscrew the spark plugs (this will make it easier to rotate the engine crankshaft).

- The surface under the head is cleared of oil using a syringe.

- If the camshaft has severe wear on the pusher cams, damaged and worn elements must be replaced.

- In place of the block head, a special device should be installed on the mounting studs, which will help to push the valves down.

- The pistons are set at dead center. To do this, the crankshaft is turned with a knob until the mark on the rear timing cover coincides with the mark on the pulley.

- After the marks match, the crankshaft rotates a few more teeth, and the first piston will be installed at top dead center.

- Using a feeler gauge, the gaps are measured first on the first cam, and then on the third. To do this, take a probe whose size is no more than 0.35 mm. If the dipstick passes without resistance, you should select another washer.

- Through a special groove in the upper edge, the washer is picked up and removed. In order to see the groove you need to move the pusher a little.

- Using a special device, the valve is recessed downwards; in this case, you should hold the pusher with a flat-end screwdriver, inserting it not into the groove, thus preventing its arbitrary rotation.

- After fixing the pusher with tweezers, the washer is removed and another one of suitable thickness is installed in its place. On one side of each washer there is a special marking indicating the size. The washer change is completed, the screwdriver is removed, the valve is returned to its place, and the gap is measured using a feeler gauge.

Ideal valve adjustment on Kalina involves inserting the dipstick into the gaps with little force (within reason). After this, you need to turn the engine again by one revolution of the crankshaft pulley and carry out a control measurement of the gap. Thus, all clearances are checked and adjusted, with the obligatory rotation of the crankshaft before each measurement. After the operation, you need to fill the engine oil to the required level, you will also need to replace the Kalina valve cover gasket, and then secure the valve cover and timing drive with fasteners.

The operation, if you look at it, is simple. You must strictly follow the step-by-step instructions, and even a beginner can handle this procedure.

Correct adjustment is immediately noticeable: the gas distribution mechanism works smoothly, the engine does not make noise, which means the car’s “heart health” is in order. At least for the next 50–60,000 kilometers, thermal gaps will not have a negative impact and no additional work will be required. And they will certainly be the result of incorrect or untimely adjustment.

We recommend reading:

- The adsorber purge valve for our Kalina

- Buying brake discs for Kalina

- Fuse box for Lada Kalina car

- Auto Lada Kalina hatchback: technical specifications

- Why do you need a spoiler for Kalina station wagon?

- Informative presentation of the Lada Kalina 2 car