Symptoms

To understand that the valves on the VAZ 2110 engine need adjustment, it is enough to know the behavior of the engine.

After prolonged use, the car owner may notice that the engine has begun to work somehow differently. This fact should alert you, because the consequences can be serious. The main symptoms of a faulty valve mechanism adjustment on a VAZ 2110 look like this:

- the engine is noisy when starting up after a long period of parking (clacks);

- compression in the cylinders disappears (the engine loses its former power);

- Valve cover gasket leaks oil;

- “shots” appeared in the carburetor or muffler;

- fuel consumption has increased.

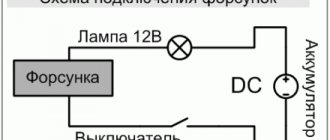

The listed signs can be diagnosed independently, without resorting to the services of a car service. Before you put the VAZ 2110 in for repairs and begin adjusting the valves, you should prepare a mechanic’s tool: a micrometer, a rack for pressing the pushers and a multi-part feeler gauge. The last thing to measure is the thermal gap between the camshaft cam and the adjusting washer. Instead of a rack, it is possible to use two powerful slotted screwdrivers. An installation kit (clamp and probe) is sold in most Auto Parts stores. Its cost varies from 200 to 500 rubles. Correct installation of valves on a VAZ 2110 8 valve injector or carburetor is the key to success.

Self-adjustment of thermal valve clearances on a VAZ 2110

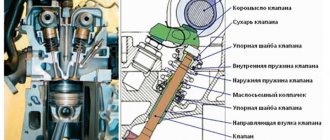

Despite its age, the good old eight-valve engine in all its variations not only does not leave the roads, but also continues to be produced in new incarnations by the Togliatti plant. But despite its unpretentiousness and sufficient resource, in some ways it has long been outdated - and to a large extent the gas distribution mechanism is outdated. No matter how simple and “indestructible” the “camshaft-pushrod-valve” system is, wear in it is inevitable, and hence the need for regular adjustment of thermal clearances.

Reasons for replacement

As mentioned above, the reason for replacing the valves may be a broken timing belt, but this is not always the only reason. Often the valves need to be replaced due to the motor chain jumping. When this happens, the valves simply turn out and it is clear that their further operation becomes impossible. After this, the valves look like this:

Replacing valve guides for VAZ 2110

In addition, the valves themselves may wear out. More precisely, it is the valve stem, which has a certain size, that is subject to wear. The leg is specially measured with a micrometer to check compliance with the standards. So, if the valve stem has a size that is less than 7.97 mm, then this is wear and tear and such a valve should be sent to the trash bin. Finally, a burnout or crack in the plate itself may cause the valves to be replaced.

Replacing valve guides on a VAZ 2110

Setting rules

Every car owner can refer to the manual regulations. It is worth saying that the nominal installation of valves on the VAZ 2110 8-valve injector occurs at the factory. According to the operating instructions, it is recommended to carry out the first adjustment at 10,000 km. This mode is called running-in. And then, adjustments should be made every 45,000 km. In some cases, engines operate properly up to 80,000 km.

For reference! The installation of valve pusher washers on VAZ 2110-12 vehicles (8 valves), with injection and carburetor engines, is completely identical.

Valve adjustment frequency

After using the car for a long time, its owner may notice that the engine is no longer performing as well as it was before. In principle, all changes in engine operation should always alert the driver, since this is often fraught with quite serious consequences. In most cases, adjustment of the VAZ-2110 valves (8 valves) is required if the following symptoms are present:

- excessive noise when starting the engine after the car has been idle for a long time;

- lack of compression in the cylinders (a noticeable decrease in engine power);

- oil leaks through the cover gasket;

- regular “shots” in the muffler or carburetor;

- increased fuel consumption.

It is not necessary to go to a specialized car service in order to diagnose the above problems.

Adjustment process

Replacing the thermostat on a VAZ-2112 16 valves with your own hands (+ video)

You should not buy adjusting washers in advance, since the cost of these parts is quite high. First of all, you should decide on the size of the gaps, and only then go to the store in order to select the right size of washers and buy them in the right quantity. All work should be carried out in a garage with good lighting, since a closed room will protect the car from the extremely undesirable effects of rain and wind, which inevitably carry dirt into the uncovered camshaft.

At the same time, do not forget to cool the engine before adjusting the valves of the VAZ-2110 eight-valve engine

Disassembling VAZ 2110 valves

Adjusting the VAZ-2110 valves (8 valves) always begins with dismantling the necessary components, which is performed as follows:

- The battery terminal is disconnected.

- The air filter housing is dismantled (if the car uses a carburetor engine).

- The gas cable bracket, as well as the crankcase gas hoses, are disconnected from the valve cover.

- All the bolts that secure the timing case are completely removed. Once the cover is removed, you can freely work with the pulley.

- Get the spark plugs. Due to this, the rotation of the crankshaft will be simplified, which will help to find BDC and TDC.

- The valve cover is removed.

Before proceeding with the actual adjustment, you should understand the features of the timing mechanism.

Read the instructions for your car and read the operating order of the valves. In particular, there will be a table indicating the order in which the valves are adjusted. It is worth noting that the adjustment of the VAZ-2112 valves (16 valves) provides for a completely different scheme.

How to adjust gaps yourself

After dismantling the valve cover, any remaining engine oil near the tappets should be completely eliminated. To do this, you should use an ordinary rubber bulb or a special medical syringe. If you have a retaining rod, you will need to place it on the two outer studs, with which the cylinder head cover is secured.

After this, you can proceed directly to the repair:

- The top dead center is set. To do this, you will need to align the marks located on the inner timing case and the camshaft pulley. To do this, you can hang and spin one front wheel, then use a spanner to turn the camshaft, securing it to the bolt securing the pulley. However, you should immediately warn that this operation may result in the bolt breaking, so it should be performed extremely carefully, and it is even better to first stock up on an additional bolt.

- Once top dead center is located, the camshaft should be rotated to move the pulley approximately 40-50 degrees from TDC. Now you will need to put your mark, from which several more rotations of the camshaft will be carried out with additional marks.

- The thermal clearance of the exhaust valve is measured. To do this, one of the screws should be placed between the pusher and the camshaft cam. The standard gap is 0.35 mm.

- If the probe passes without any obstacles, you should take a larger one and repeat the procedure in increments of 0.05 mm.

- If a probe with a diameter of 0.4 or 0.45 mm can no longer pass, this indicates the need to replace the adjusting washer.

- The pusher turns so that the groove is facing you, after which you will need to push the locking rack lever on it and remove the used washer from there using simple tweezers. There will be numbers on it indicating the original size.

- To obtain the required size, you need to subtract the difference between the measured and nominal gap from the thickness of the used washer, and then write it down in a notebook so that you can later buy the required washer in the store.

- The nominal clearance in the intake valve is 0.2 mm. The gap is measured in the same increments as in the previous case.

- The washer is replaced in the same way as in the previous case.

- In accordance with the table, the crankshaft is rotated to the desired angle, after which the procedure is performed with each valve separately.

- All the necessary washers are purchased at the store.

- The washers are mounted in the pushers.

- All gaps must correspond to the standard ones, that is, 0.2 or 0.35.

- New thermal clearances are being checked.

- When the new washers are installed, all dismantled components are returned to the workplace.

- The engine is started and its operation is monitored.

Preparatory stage

It starts with turning off the on-board power supply to the car, for which the terminals are removed from the battery and it is necessary to drain the old engine oil into a prepared container through a service plug and coolant from the engine crankcase, this is done by disconnecting the lowest radiator pipe from the cylinder block, the only precaution is Carrying out the procedure on a cooled engine, otherwise you can get your hands burned!

Spare parts and tools for work

Before starting work on replacing valves on a VAZ 2110, high-quality new parts are purchased, the names and original articles of which are as follows:

- Set of gaskets: valve cover (art. 2108-1003270/77) and cylinder head (art. 21083-1003020), intake and exhaust manifolds (set art. 21083-1008081), exhaust gas intake pipe (art. 2103-1203020-04) , as well as an oil seal (art. 2108-1005034) and oil flinger rings (art. 2108-1007026-86) (the so-called cylinder head repair kit)

- New valves for the fuel mixture intake system 4 pcs. (art. 21083-1007010)

- New exhaust system valves 4 pcs. (art. 2108-1007012)

- Valve guides 8 pcs. (art. 2108-1007032-87)

- Engine coolant

- New bolts securing the cylinder head to the cylinder block (art. 2108-1003271Н/О)

- Timing belt (art. 2108-1006040-86) and generator drive belt (art. 1000012562)

- Engine oil and oil filter

Repairs to replace worn-out parts are carried out using a standard set of tools, which are usually sold as a set, namely:

- a set of open-end wrenches marked from 8 to 21 mm;

- set of internal hex keys;

- a set of sockets with a diameter from 8 to 24 mm;

- valve desiccant;

- screw valve guide puller;

- torque wrench (needed for proper tightening of the camshaft, cylinder head and camshaft gear bolts);

- Screwdriver Set;

- electric drill;

- specialized lapping paste of two types (for rough lapping of valves to their working surface of the combustion chamber and for finishing grinding);

- gloves to protect hands from possible damage.

This is interesting: Removing and replacing the trapezoid and wiper motor on a VAZ-2107 - detailed instructions

The availability of tools, parts and a covered room will allow you to carry out troubleshooting work yourself, since the price of replacing 8 valves on a VAZ 2110 in non-certified services in the fall of 2021 varies from 30 to 45 thousand rubles. At a certified service station of official dealers, such work will cost more than 50 thousand, which will greatly affect the financial situation of the car owner.

Adjusting the clearances in the valve drive:

1. First, loosen the clamp and remove the ventilation hose from the cylinder head cover pipe.

2. Remove the hose of the main ventilation branch from the fitting of the cylinder head cover, first loosen the clamp.

3. Next, you will need to unscrew both bolts that secure the accelerator cable bracket and, without disconnecting the cable from the bracket, move it to the side.

4. Remove the hose of the small ventilation branch from the fitting of the cylinder head cover, also first loosening the clamp.

5. Unscrew the cap nuts that secure the block head cover. Remove and, if necessary, replace rubber bushings and washers. Remove the cylinder head cover.

6. After all the manipulations described above, use feeler gauges to measure the gaps on the valve actuator numbers four, six, seven and eight (those with the cams pointing upward). Important: write down the measured gaps.

7. The next step is to get the adjusting washer. To do this, you should turn the pusher by the groove to such an extent that you can pry the washer off. To make removal convenient, there are two grooves in the pusher. For more convenient operation, we recommend cleaning the oil around the pushers.

8. Install the head cover mount, a special device for compressing valve springs onto the studs.

9. Place the studs on the washers. To avoid jamming the flanges, turn them over and tighten the cap nuts.

10. Press the pusher downwards. Replace the adjusting washer on the pusher and insert it under the camshaft. Insert the retainer.

11. The latch should be inserted so that it leaves the pusher in the recessed position.

12. Next, you should pry the adjusting washer with a screwdriver and pull out (you can use tweezers) the washer from the pusher.

13. We recommend that you remember (or better yet, write down) the thickness of the adjusting washer. This data should be on one side. If the mark is not visible, measure the thickness with a micrometer.

14. Calculate the thickness of the new washer using the formula H=B+A–C.

- A is the value of the measured gap;

- B is the thickness of the old washer;

- C—nominal clearance;

- H is the thickness of the new washer.