Types of flame arresters

- Active, single layer. This type of fire arrestor uses fiberglass or mineral wool core. They are less durable than reactive ones due to the fact that the filler used quickly burns out due to high temperatures. But while it is functioning, it does its job well, for up to 2 years.

- Reactive. The work of such a product is famous for its durability. The basic principle of reducing the energy of gases is based on the damping of sound waves. They can last up to 10 years, depending on the quality of materials, manufacturing and operation.

If we take into account the design features of the exhaust system, flame arresters can also be manifold (which during installation must be removed and installed together with the exhaust manifold) and free-standing.

We will discuss in more detail the characteristics of certain types of flame arresters, the difference in price and the features of their installation in subsequent subtopics.

What is the service life and operation of the flame arrester?

The average lifespan of a free-standing stainless steel flame arrester ranges from 5 to 10 years. Collective flame arresters last a little less (3-5 years), since they are located directly in the “hottest” place. I would like to note that the flame arrester itself is practically not destroyed; the welds and exhaust pipes suffer. For example, if you take an MG-Race flame arrester installed in a stainless steel line and welded in an argon environment, then the service life of such a structure will be tens of years. If you install a conventional flame arrester made of aluminized steel and weld it with an iron exhaust pipe in a CO2 environment, then naturally the service life will be shorter. It is also worth taking into account the operating climate, the health of the engine and, of course, mechanical impacts (shocks, scuffing, etc.).

Characteristics of flame arresters

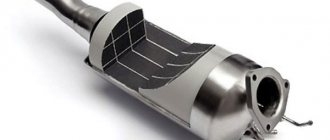

The resonator, also known as a flame arrester, must be temperature stable and withstand heavy mechanical loads, because the speed and temperature of the exhaust generated from the fuel burned in the cylinder are very high, and accordingly they impart their energy to all components involved in the process. The name of the flame arrester speaks for itself. It directly “puts out the flames”, reduces the temperature and converts the exhaust gas streams into one smoother and cooler stream. A good, high-quality flame arrester is designed in two layers, for better absorption of vibrations during the exhaust and to dampen excess noise, and the second layer must be made of anti-corrosion, stainless material, due to the fact that the flame arrester is constantly under the aggressive influence of the atmosphere. Splashes, dirt, salt deposits, a poorly fixed muffler, loads and vibrations from a running engine and when the car is moving, all have a destructive effect on this element and therefore the design and materials must withstand all of the above.

To improve sound insulation, fillers are used: mineral or basalt. In high-quality flame arresters, this factor is also controlled by the introduction of an additional diffuser chamber. The exhaust is pre-processed in this chamber, and then further muffled by hitting the padding layer. The diffuser chamber reduces wear on the flame arrester.

The device of a classic flame arrester

The “straight” (that is, the first) type from our rating is considered classic. I will try to tell you more about its device:

- A straight pipe is taken and holes (or perforations) are drilled into it.

- Then the body is made, as I indicated above, from two sheets of iron, and a “spacer” between them. Welded in the form of a cylinder or ellipse.

- Insert the pipe into this “barrel”. And they lay a special, non-flammable material on the sides, usually basalt wool.

- Then the top and the barrel are welded, leaving only one pipe.

That's all, gases enter the pipe and settle in the material through the perforation. Giving away temperature and part of the sound wave.

Flame arrestor and catalyst. Advantages and disadvantages

A flame arrester is a kind of catalyst substitute. Both units have their pros and cons, but if we take into account the efficiency of the engine and the car, the flame arrester outperforms the catalyst on all fronts. The catalyst, due to its design, is a more complex device than a flame arrester; the materials used are rarer, which is very noticeable when you compare the prices of these parts.

The flame arrester costs significantly less and does not delay the exit of exhaust gases as much as the catalyst does. This in turn affects the power supplied by the engine to the drive. Due to certain factors, namely due to poor fuel quality or mixture formation in the combustion chamber of the cylinders, the catalyst tends to quickly fail (clog).

If the catalyst is not replaced in a timely manner, this will adversely affect the engine itself, because the exhaust process will not be carried out fully, and it can also harm people in the cabin, because the exhaust from the inability to find a way out through the muffler will smoke inside the car.

Also, when they want to achieve greater efficiency from the engine, they tune the exhaust system by replacing the catalyst with a flame arrester. This long-lasting exhaust “filter” will equalize the flow and pressure of gases leaving the engine manifold, thereby improving its technical characteristics.

The main disadvantage, which of course can cover up all the advantages of this unit, is that its filtration properties are not as good as those of the catalyst, simply put, they are not there. This means that significant harm is caused to the environment. In the Russian Federation, laws still allow the use of flame arresters as an alternative to catalysts, this is facilitated by established emission standards, but if you want to pull off such a scam in EU countries, you will not pass the scheduled technical inspection of the vehicle and will not be able to use the car.

Faulty catalyst: causes and consequences

This is a real problem for a car driver. The machine cannot clean the exhausts in other ways; as a result, they are not discharged or are partially discharged, and the pressure between the engine and the plug increases. Special sensors detect this as a malfunction and artificially reduce the vehicle's power.

Catalysts fail for various reasons. For example, due to low quality fuel or a faulty ignition system. But more often this is natural wear and tear resulting from contamination of internal cavities.

Regardless of the cause of the breakdown, cutting out the catalyst will be the optimal solution to the problem. But not all car owners plan to install a new part after this. Moreover, it is possible to adapt the operation of sensors to new operating conditions.

Installing a flame arrester instead of a catalyst

A catalyst is an element of a car's exhaust system that is responsible for cleaning exhaust gases. Simply put, the catalyst burns the car’s exhaust gases to environmental standards. Unfortunately, like most car parts, catalysts also fail. This process is often accelerated by mechanical damage and low-quality fuel. Those car enthusiasts who have not yet encountered a similar problem may be very surprised: “Why “reinvent the wheel”, isn’t it easier to replace the unusable catalyst with a new one?” they will say. Of course it’s simpler, but... There are some pitfalls here, and the main one is the huge price of a new spare part. And in some cars several catalysts are installed simultaneously. All this pushes car owners to look for alternative options, one of which is installing a flame arrester instead of a catalyst.

Causes of flame arrester failure

Of course, removal of a flame arrester can also occur for other reasons:

- The flame arrester housing is rusty. The flame arrester becomes a “victim” of corrosion, first of all, not because of water, but because of the chemical reagents that road services sprinkle on roads in Russian cities in winter. But you can also protect your car from them by carrying out anti-corrosion treatment on the underside of the car and, accordingly, all elements of its exhaust system, including the flame arrester, on the eve of winter.

- The flame arrester housing has lost its tightness due to mechanical damage. Considering the “famous” quality of Russian roads, which Karamzin wrote about, not a single car is insured against a stone bouncing from under a car wheel or a pothole in the asphalt. Moreover, its flame arrester, which is located under the bottom.

- And finally, the flame arrester may break simply because it was of poor quality to begin with. Thus, the life of almost all home-made units is short: they are for the most part made from materials of poor quality, and their welds leave much to be desired.

- The flame arrester filter may burn out, thereby turning the device into a simple hollow pipe. This is the problem with flame arresters with filters made of fire-resistant mineral wool. Although this material is called fireproof, mineral wool is not able to withstand the effects of gases heated to two hundred degrees for a long time.

Read more: Are you allowed to stop at the specified location?

What happens if you just remove the catalytic converter?

Often, car owners whose cars are equipped with several catalysts resort to installing flame arresters.

The question is quite relevant, given, as already mentioned, the high cost of a new part. If you don’t go deeper, it may seem that the catalyst can simply be thrown away and a regular straight pipe put in its place. We hasten to disappoint those who were counting on it. Firstly, the noise level will increase significantly, and secondly, the temperature of the exhaust gases will increase (remember that one of the functions of the catalytic converter is cooling the exhaust gases). It is the second point that is most dangerous when operating a car - prolonged operation of the exhaust system at high temperatures can damage it.

In addition, cars that meet Euro-4 standards and higher are equipped with special oxygen sensors - lambda probes. Simply dismantling them will not work, because in this case the car’s engine may begin to work unstably, and the instrument panel will constantly irritate you with error messages. The problem is eliminated by flashing the electronic control unit or using special “cheats”.

Hence we conclude: throwing away the catalyst “with all its giblets” is not the best idea. So what remains? There aren't many options:

- Install the original catalytic converter.

- Find and try to “fit” a universal catalyst to your car.

- Install a flame arrester.

Each option has a number of advantages and disadvantages, respectively. Below we will look at them in more detail. However, if your choice has already fallen on the option of installing a flame arrester instead of an unusable catalyst, you can skip the part that talks about the first two points and go straight to the last one.

Assembly of the flame arrester

A large pipe should be 30-40 mm larger in diameter. After holes are made around the circumference of the small pipe, it must be cleaned with a metal brush and inserted into the large pipe (strictly in the middle). The larger pipe must be placed with the same indentation on each side relative to the smaller one, and then the pre-cut parts should be folded and welded (the seams are also welded hermetically).

Next, turn the pipes with the unwelded side facing you: you will need to put dish brushes on the smaller pipe, after which they need to be compacted tightly inside the resulting “glass”. After this procedure, you need to bend the petals to the smaller pipe and weld it to it in the same way (do not forget about the seams). Welding must be done carefully to avoid leaking joints. The finished flame arrester must be thoroughly cleaned with a brush to remove dirt and rust, and then coated with silver paint (spray cans can be used).

Now it's time to reassemble the old exhaust system. A newly manufactured flame arrester must be welded to the place where the catalyst was previously installed. Then the exhaust system is installed in its original place. It would be a good idea to treat its surface and coat it with a heat-resistant anti-corrosion compound.

How to fool an electronic oxygen sensor

It is known that a faulty catalyst will signal to the driver that the exhaust system is malfunctioning. This will be facilitated by a lambda probe (oxygen sensor), which sends a corresponding signal to the machine ECU. One of the popular ways to solve this issue is to deceive the lambda probe (not to the detriment of the ECU). For this purpose, so-called mechanical blendes are used, the essence of which is to limit the incoming volume of gases to the sensitive element of the sensor. Of course, the volume of oxygen (its concentration) becomes significantly higher.

To make such a trick, a special spacer is installed at the place where the catalyst itself and the oxygen sensor (lambda probe) are installed. In this case, the second sensor is placed at a certain distance from the catalyst. The essence of how the blende works is as follows: gas flows pass through its hole, losing their concentration and dissipating. The displaced lambda probe records the oxygen saturation in the exhaust stream, and, without noticing the “deception,” sends a signal to the controller that everything is within normal limits.

Application of universal catalytic converter

It is a completely rational option, especially if we consider such a procedure in terms of its cost. The catalyst, including installation on the car, will cost you approximately 7,000 - 8,000 rubles. Agree - the difference is amazing. The main difference between a universal catalyst is that cheaper materials are used for its manufacture.

- affordable price;

- acceptable level of emissions;

- there is no need to reflash the control unit or install a fake oxygen sensor.

- fragility;

- complete lack of guarantees;

- low reliability indicators.

Installing a universal catalyst is a compromise between price and environmental concerns

Flame arrestor instead of catalyst

This is the decision that owners of cars with a failed catalyst make most often. This procedure is very inexpensive (about 5,000 rubles). But we have already mentioned that cars that meet Euro-4 standards and higher require additional modifications. Such work, depending on the specific car, can cost the owner another couple of thousand rubles.

The advantages of a flame arrester include:

- low cost;

- long service life;

- high reliability;

- warranty on flame arrester;

- increase in engine power.

- loss of car warranty (for new cars);

- increased levels of harmful substances in the exhaust;

- the need for additional procedures (firmware of the control unit, installation of “falseware”).

Why change the catalyst to a flame arrester?

As mentioned above, a catalyst is a much more complex and fragile device than a flame arrester. This is especially true for ceramic catalytic converters: they can easily fail even from a relatively small impact. The ingress of fuel vapors into the catalysts, as well as significant temperature fluctuations (they occur, for example, when a well-warmed-up car drives into cool water), are also very dangerous for catalysts.

It should also be noted that all catalytic converters, without exception, fail prematurely with prolonged use of low-quality fuel or the independent addition of various additives to it. Since even with a fairly careful attitude towards the car, the risk of failure of the catalyst in Russian operating conditions is quite high, and it is very expensive, this is the main reason that it is often replaced with a much simpler, cheaper and unpretentious flame arrester .

How to make a flame arrester yourself

In some situations, it is quite difficult to find a ready-made flame arrester, so many car owners have to take up the tool and make this element on their own. There is nothing complicated about making a flame arrester instead of a catalyst with your own hands; we will prove this with the following example:

- To make a flame arrester we will need two pieces of iron pipe. One of the pipes should match the diameter of the exhaust pipe of the car, and the second should have a larger diameter (this will be the flame arrester body). In addition, we will stock up on regular kitchen steel wool.

- We drill holes with a diameter of about 3 mm in the inner pipe over its entire area. Next, we insert it inside the housing (pipes with a large diameter). We brew one side.

- Place a washer approximately in the middle of the inner pipe. The washer should have a hole equal to ⅔ the diameter of the inner pipe.

- In the next step, we push metal wool between the two pipes (as if putting them on the inner one). Pack tightly. You need to fill the entire space from top to bottom; in the example given, 26 washcloths were needed. We are almost finished - all that remains is to cut the free edge of the pipe (body), bend it and scald it.

That's probably all. The replacement of the catalyst with a flame arrester is completed by removing the catalytic converter itself from the exhaust system and installing in its place the result of your efforts - a self-made flame arrester.

Types of flame arresters

There are two types depending on the type and functional features:

- Active. Here, mineral wool and synthetic fibers are used as the main working element. These products are single-layer, and their durability is weaker. The operation of these units is associated with high temperatures and the filler simply burns out. But at the same time, those who installed such a flame arrester instead of a catalyst leave mostly positive reviews. This is silence, comfort and quality.

- Reactive systems. They are based on reflective surfaces made of heat-resistant steel. This resonator is very durable.

Many owners who decide to replace do not have definite opinions. Both of these designs work equally well. Both types have both advantages and disadvantages.

Making a flame arrester with your own hands

Due to the tightening of International environmental requirements, a mandatory condition for the operation of vehicles is the installation of catalytic exhaust gas converters. But, this element belongs to the category of expensive, since the design of its filter unit contains alloys of precious metals, so if it fails, it is best to install a flame arrester instead of a catalyst with your own hands. The exhaust gas converter is very demanding on the quality of the fuel; during the operation of the vehicle, its cells become covered with an abundant layer of soot deposits, which reduce the throughput of the device and cause a decrease in engine power.

Important! Any catalyst is very sensitive to mechanical stress; even minor damage to its honeycombs can completely damage the part. It is quite problematic to restore the original functionality of the element, so most experienced auto mechanics suggest making a flame arrester from a used catalyst.

When the neutralizer honeycombs are contaminated, there is a significant increase in pressure inside the exhaust system, which causes a decrease in the acceleration dynamics of the vehicle and a significant increase in fuel consumption. The complexity of the problem lies in the fact that the exhaust system of most vehicle models contains several of these elements.

A flame arrester and its difference from a resonator. Tuning flame arresters. Domestic flame arresters.

What is a flame arrester?

And why is this name given to a part located, as a rule, immediately after the exhaust pipe of the muffler? Because this is the part that extinguishes the flame? Or is it something else? Let’s be honest, we don’t know where this part of the exhaust system got its name. In addition, foreign manufacturers of exhaust system parts do not offer a similar name in English. The terms they use are usually translated as “pre-silencer”; "front muffler"; "resonator". Therefore, we will not touch further on the theoretical side of this issue, especially since our readers are primarily interested in the practical application of the information received. Let's dwell on this definition of a flame arrester, which is accepted in Ukraine: a part of the exhaust gas exhaust system installed in the front part of the exhaust tract directly after the exhaust pipe and, in most cases, in the same place where the exhaust gas catalytic converter is installed.

What are the requirements for a flame arrester and how does it differ from a resonator?

A flame arrester is a resonator, or rather, one of the types of resonator. Unlike other types of resonators, the flame arrester must be as reliable as possible, since it experiences the greatest loads compared to other parts of the exhaust system. The temperature of the gases escaping from the combustion chamber is very high, the speed is also not low, and our poor flame arrester must accept all these gases, then process them and release them on their further journey already colder, not so fast and, which is also important, mix the pulsating flows from each individual cylinder into one smoother flow. Plus, the body of the flame arrester should not emit any extraneous sounds, which is forced by the gases beating into it - for example, everyone knows the sound of the Volga or the sound of an empty catalyst, which occurs precisely for this reason. In addition, in addition to the considerable internal load, the flame arrester is also affected by external vibrations transmitted from a running engine, jerks from a dangling muffler and a terrible salt solution splashing on a heated part in winter. Such is the difficult life of a flame arrester.

Which resonator can be called a flame arrester?

The requirements for the flame arrester listed above entail the need for some design features of its design. Let's consider them too.

According to a simplified scheme, noise silencers are divided into active, where the principle of absorption of sound waves is used, and passive, where sound is damped due to the reflection of sound waves. The filler used in the first case (basalt or synthetic fiber) does not withstand the high temperature of the exhaust gases in the front part of the muffler and burns out in a few months if it is protected by a stainless mesh, and in a few days if it is not protected by anything. Therefore, the reflection method is still more acceptable for parts exposed to high temperatures.

The body of the flame arrester must necessarily be two-layer, so that the vibrations of the inner layer are damped by the outer layer, otherwise the body itself will rattle like a tin can when a sharp sound wave hits it. Well, the material from which the outer layer is made must be sufficiently resistant to corrosion - sudden temperature changes, combined with salt baths, kill even aluminized steel in a couple of winters, so it is desirable that the body be made of stainless, heat-resistant steel. The requirements for the material from which the internal parts of the flame arrester are made are no longer so strict, since at the beginning of the exhaust system, corrosion practically does not develop inside, unlike the rear parts, in which condensation and moisture accumulates, entering through the exhaust pipe of the muffler. Also, do not forget about the volume of the flame arrester itself, which determines how the parts following it (resonator and muffler) will work. If its volume is insufficient, usually in the resonator or muffler, when you sharply press the gas pedal, an unpleasant rattling sound occurs. and at the exit from the muffler the overall sound level becomes slightly higher. In the case where the muffler and resonator are of the direct-flow type, the chatter is usually not so significant.

Now that the main criteria by which a flame arrester is characterized are outlined in general terms, we will go down to earth, or rather to car services and auto parts stores in the city of Kyiv. Unlike Europe, America or Japan, the standards for the content of CO, CH and nitrogen compounds in exhaust gases in Ukraine are much softer, cars and spare parts are more expensive, and the average income of car owners is lower. Therefore, there are very few people who want to replace a “dead” neutralizer with a new one - it’s a very expensive thing. And a flame arrester under such circumstances becomes a more acceptable option. What kind of parts we don’t call flame arresters! They are installed in the thousands on the favorite cars of unsuspecting customers instead of catalysts. The most common of them are: “universal flame arresters” - “Platinic”; “Asmet” “Ferroz” (all Poland); “Asso” (Italy) “Simons” (Finland), resonators from VW Golf, Passat manufactured by “Bozal”; "Walker" (Belgium; Sweden; Turkey; Poland); "Universal" (Estonia); "Marmittesara" (Italy). All these are, in principle, the same type of parts, which are the simplest resonators and do not meet all the above requirements. They cannot fully perform their intended function with sufficient quality, even if in some cases clients remain more or less satisfied with the result of their installation. How are these parts arranged? All of them are direct-flow type and have a single-layer body made of aluminized steel, some of better quality (for example, Walker) and others of worse quality (Asso, Universal). An internal perforated pipe made of aluminized or black steel and padding made of basalt or synthetic fiber, or even ordinary mineral wool. A single-layer, and therefore potentially rattling, body, and quickly burning out packing are the main drawbacks of such parts. The so-called “turbines” are even simpler. Stamped holes instead of through round ones on the inner pipe are a cheaper way to produce perforations, but the need for invention is cunning and the explanation for such a device was given simply mind-blowing: supposedly this type of holes, arranged in a spiral, adds power to the motor. Comments are unnecessary here.

In addition to universal parts that differ in external dimensions and inner pipe diameter, there are also standard flame arresters, that is, designed for a specific car model. The most common of them are Walker, Bozal, Ernst, Tesh. They are of better quality than the previously listed universal ones, since they often have a two-layer body, and sometimes have a correct internal structure, almost the same as the original parts.

The original parts, intended for cars without a catalytic converter, always have a two-layer body, most often they are made of stainless steel, and noise suppression is carried out by combining reflection and absorption methods, while the main function is performed by an additional chamber with a diffuser installed in it (European cars ): a washer or a perforated cone (Japanese cars). Stream processing in additional The chamber is carried out according to the principle of reflection, and the packing made of stainless mesh and basalt fiber plays a secondary role in this case, and usually after it burns out the sound does not change much. Of course, original parts are the best option for your car, if you do not take into account their considerable cost and the frequent absence of original flame arresters for cars that were produced only with catalysts.

Up to this point, we considered the flame arrester as a part that can be installed by welding or screwing onto the exhaust tract, but in Kyiv, some companies also offer to install the flame arrester in the catalyst housing. What is it? Another invention of the Russian Kulibins? But in fact, there is nothing unusual or requiring patenting here. It's just that the part we're talking about here is made by hand in this case. And this method probably also has a right to life, especially since it has its advantages: the part is obtained with the largest possible volume and with a stainless, albeit used, body. The main thing is that the direct performer of this operation understands what exactly he is doing and is truly capable of performing this rather responsible and complex work, after all, it is Hand made.

Flame arrestor and tuning

Now let's turn to tuning. When installing a tuning exhaust system of the direct-flow type, the sound requirements are usually somewhat different - you need a thoroughbred, not at all quiet sound with a predominance of low frequencies - bass. Therefore, a direct-flow flame arrester used for tuning can be simpler in design - after all, the parts installed after it are also direct-flow and therefore do not require serious flow processing. The main thing is that it is reliable, has a two-layer body and a flow section corresponding to the engine power, and of course the appearance is also important. But unfortunately, even famous tuning brands (Supersprint, Remus, Sebring, APEXi, etc.) practically do not have direct-flow resonators with a two-layer casing in their assortment, because in the West there is much stricter control over exhaust cleanliness, and catalysts for metal base with low resistance. It is also considered normal for them to leave a standard catalyst after the configured collector - “spider”. The lack of demand for parts that can be installed instead of a catalyst is the main reason why Western manufacturers do not offer anything that would fall under our definition of a flame arrester.

Domestic flame arresters

Since Ukraine is a special country and the situation with catalysts is somewhat different, and the demand for flame arresters is therefore quite large, it is not surprising that a fairly large selection of domestically produced flame arresters has appeared in Kyiv stores and car services. True, many of them do not deserve a single kind word, but there are also details worthy of attention, which in some respects even surpass similar products from serious European brands, and are not as expensive as their Western counterparts.

How can you tell the right flame arresters from the wrong ones? If you have carefully read this article, then probably now it will not be so difficult, and will allow you not to throw away your money.

What happens if the catalyst is completely removed from the car?

This issue is almost a priority for most vehicle owners. Many people believe that the solution to all problems will be to install a direct flow instead of a used converter. But, in addition to the fact that this will lead to a significant increase in noise, the exhaust gases will constantly be at a high temperature, and this negatively affects the operation of other components of the car.

On many modern cars, a special sensor is installed along with the catalytic converter, the removal of which will certainly cause an error signal to appear. Before dismantling the neutralizer and sensor, it is best to consult with a specialist who will help in solving this problem, since this will require an integrated approach.

How to solve a problem?

The issue with a failed catalyst can be resolved in one of the following ways:

- Purchase and install an expensive original neutralizer.

- Use a universal part.

- Make a flame arrester with your own hands from a catalyst and install it on a car.

Note that each of the listed options has both its pros and cons. Let's describe in more detail the last item on the list - making your own flame arrester from a used exhaust gas neutralizer.

How does the replacement take place?

The first question that arises among car enthusiasts is why install a flame arrester at all, if you can simply cut a piece of iron pipe in place of the catalyst. Many owners of domestic cars do this. Why this approach is unacceptable:

- Due to its design features, the neutralizer partially absorbs sound. If you replace it with a pipe, the volume of the car's exhaust will increase noticeably.

- On various brands of cars there are main and collector type catalysts. If instead of the first one you can install a straight section with flanges, then the second one needs to be redone - cut the tank, weld the pipe, and so on. It’s easier to immediately install a ready-made flame arrester “puck”, which is commercially available.

If you want to save money on buying a stronger, make it yourself from an old catalyst or entrust this task to a craftsman. You need to dismantle the neutralizer, carefully cut the body along the seam and shake out the contents, then cut in a perforated pipe and fill the free space with kaolin wool. At the end, the barrel body is hermetically welded.

Installing a flame arrester instead of a catalyst is carried out in several stages:

- Drive the car onto an inspection hole or overpass, let the exhaust pipe cool and remove the worn converter.

- Remake the stronger to fit the flanges of the removed element. To do this, you will have to cut them off and weld them to the pipes of the new part.

- Install a flame arrester between the exhaust flanges using new graphite gaskets.

If your car is equipped with one lambda probe, then at this stage the replacement procedure ends. Since the device records the composition of combustion products before the catalyst, the installation of a stronger will not affect its further readings.

When a second sensor is installed in the tract (behind the changing element), the Check Engine sign will light up on the dashboard and other problems may arise: unstable engine operation, increased fuel consumption and decreased power.

If you can remove the catalyst and insert the flame arrester yourself, then the modification of the oxygen sensor should be entrusted to experienced specialists. The best option is to install an electronic emulator in the lambda probe circuit, simulating the correct signals of the device. Mechanical tricks are unreliable in operation.

Distinctive features of the flame arrester

In the exhaust system of vehicles, this element has the following design: a durable double cylindrical body made of stainless steel, divided inside into special chambers. Thanks to this device, the flame arrester effectively suppresses vibration, and the presence of direct flow does not trap exhaust gases in the system, as with a neutralizer installed. In addition, the resonator on a car with an installed flame arrester begins to operate more steadily and steadily due to the redistribution of the primary flow of exhaust gases. Most motorists replace the resonator with a stronger, which prevents the formation of back pressure, which negatively affects the operation of the power unit, causing a sharp decrease in its power.

Despite the fact that a vehicle can function perfectly without a stronger, if it has been decided to make a flame arrester and install it in the exhaust system, it is still advisable to use this element.

What is a flame arrester?

Flame extinguisher is a device for extinguishing the temperature of exhaust gases and reducing their resonance. Literally, the flame arrester very effectively reduces the temperature of the exhaust gases, and also acts as a primary resonator. Flame arrestors are divided into manifold (installed in the exhaust manifold block) and free-standing (installed on a straight line or exhaust pipe). They come in several shapes: round, oval and turbine. In life it is called briefly and clearly - “flamegas”

Why is it better to make a flame arrester yourself rather than buy a ready-made one?

The market for automobile spare parts and components is replete with flame arresters of various models. But despite this, selecting an element for a specific car is almost impossible. The whole point is that the dimensions of the flame arrester must completely correspond to the dimensions of the neutralizer removed from the system, otherwise the entire exhaust tract will have to be completely rebuilt. Exclusively for this reason, it is advisable to independently manufacture a flame arrester, since only in this case will it be possible to correctly select the dimensions and characteristics of the part.

Let's sum it up

Taking into account the above information, it becomes clear that installing a flame arrester allows you to get rid of the catalyst. In some cases, this is the only possible solution, since the owner of an old or budget car may simply not have the money to buy a new replacement catalyst. The fact is that the high cost of this spare part is the main reason for manipulations and changes to the standard design.

When it comes to installing a flame arrester, both the advantages discussed above and the disadvantages are obvious. In any case, by installing a flame arrester and performing other work on tuning the engine, turning off the lambda probe or installing decoys, you can continue to operate the car in normal mode.

The only exception is modern models of premium brands, where it is often very difficult and expensive to “deceive” the ECU and remove the catalyst. In this case, the only solution is to replace the catalyst with a new element, which will allow the engine to operate normally in normal mode.

How to make your own flame arrester from a catalyst?

To make a flame arrester you will need:

- welding machine;

- two metal pipes, one of them should be of a smaller diameter;

- metal brushes-scrapers for washing dishes;

- old exhaust gas converter.

Our homemade flame arrester will be located in the catalytic converter housing, so it will need to be cut in half and the non-working honeycomb removed. The diameter of one of the pipes must completely correspond to the diameter of the exhaust tract. The second pipe should be slightly larger in diameter so that it completely covers the first, and metal scraper brushes can be pressed into the gap between them. In this case, a larger diameter pipe must be placed in the body of the non-working catalyst.

In a pipe of smaller diameter (which will connect to the exhaust tract of the car), it is necessary to drill small holes. Next, we insert the smaller pipe into the larger one, having previously centered them and welded one of the edges. Now you need to fill all the space between the pipes with metal scrapers for washing dishes. They need to be compacted tightly, then bend the edges of the pipe around the circumference and completely scald them. We place the resulting structure in the catalyst body, assemble it and weld it at the cut points.

The resulting flame arrester can be welded into the exhaust system. But that is not all. To ensure correct operation of the exhaust system and power unit, and to remove the Check Engine error, it is necessary to install a special blende.

Removing the catalyst

Muffler resonator: purpose, design and features

To properly remove the catalyst from the car, you need to jack it up or put the car on a viewing hole. The process of removing the catalytic converter will not take more than thirty minutes and no special tools are needed for the work. The catalyst housing is located on the Samara behind the engine exhaust manifold. So:

- we find the mounts for the resonator, which is located behind the exhaust manifold or pants, as experts call it;

- unscrew the fastenings;

- remove the spring type washers;

Removing the catalyst

- unscrew the fastenings of the exhaust pipe (in this case, you need to remove the bolts along with the springs, holding the catalyst with the other hand from below):

- remove the catalyst.

Now the owner himself decides what to do. He can put a new catalyst on the car, or he can make a homemade flame arrester and install it.

Making a flame arrester

Homemade flame arrester VAZ

A flame arrester and a catalyst have a lot in common. But the flame arrester, compared to the catalyst, does not delay the flow of hot exhaust, thereby increasing the jerk and power of the engine. In addition, it has a direct-flow design, and it will cost less to install than a new catalytic converter. It is not possible to buy a ready-made flame arrester. Therefore, you will have to do it yourself. On a VAZ 2114, replacing the catalyst with a flame arrester will require a little skill and knowledge of certain secrets. Let's start with the pipes. We take two metal tubes of different sizes. The diameter of the first pipe should be the same as that of the exhaust system. The second one has much more. Replacing the VAZ 2114 catalyst begins with the following:

- drill 3-6 mm holes in the first pipe around the circumference and the entire length;

- we insert the pipe in the center into the second one, which has a much larger diameter;

- connect the welding machine;

- We weld one edge of the pipe connection;

- leave the other edge and cut it lightly with a grinder (this is done to leave room for bending);

- take metal sponges and stretch them;

Metal wool on the flame arrester

- they should be inserted alternately onto the edge of the pipe;

- taking a metal rod, push the washcloths as deep as possible (basically, it takes about 30 washcloths used by housewives in the kitchen);

- we bend the cut edge of the large pipe (this must be done so as not to remove the metal wool from the pipe);

- bends should be welded (scouring pads and tight welding will help to avoid the noise that the flame arrester will make while the car is operating);

- take good anti-corrosion paint (high-quality paint is sold in cans);

- we treat the flame arrester with it;

- cut out the old catalyst;

- insert the flame arrester there.

It is worth noting that even a homemade flame arrester meets all Euro 2 standards. In this article you can see how to replace the VAZ 2114 video catalyst and understand the main nuances of the work.

What is a lambda probe

Catalyst circuit and oxygen sensor

The replacement of the VAZ 2114 catalyst, as mentioned above, meets all the parameters. But if, nevertheless, the standard should be higher than Euro 2, you can use a lambda probe. This is a special sensor that, after removal, transmits an error to the control unit. But this is not a solution either, since this installation will affect engine performance or fuel consumption.

- A sensor is a special device that measures the oxygen content in exhaust gases.

- It then transmits this information to the electronic power system.

- The power system, in turn, begins to control the composition of the combustible mixture, that is, fuel, and maintains the optimal ratio of air and gasoline.

- If the sensor is faulty, it gives a signal to the control to maximize the enrichment of the working mixture.

The same thing happens not only when the sensor is faulty, but also when it is turned off. Measuring CO at the moment, the device shows up to 9%. Well, the deterioration in engine performance and an increase in fuel consumption by as much as 50% is unlikely to go unnoticed by the driver. It turns out that on cars such as the VAZ 2114, where a catalyst is installed or to replace the catalyst with a VAZ 2114, a special device operates in the exhaust system , which measures CO.

What and how to replace the oxygen sensor?

If the catalytic converter malfunctions in vehicles, a corresponding signal appears on the instrument panel, which is transmitted to the control unit by a special oxygen sensor, or lambda probe. In order for all systems to work correctly and the error signal no longer occurs, it is necessary to use the so-called “decoy”. The most common mechanical type of such devices.

Note that the operation of the “falsehoods” is based on the principle of limiting the volume of exhaust gases, which is constantly monitored using an appropriate sensor. Thanks to this, there is significantly more oxygen in the car’s exhaust, and the system can function correctly.

The manufacturing process of such a part will not be difficult. It is enough to install a so-called spacer at the location of the lambda probe and catalytic converter, and move the second lambda slightly away from the catalyst. The exhaust gases that will pass through the spacer lose the concentration of harmful impurities and substances in them, and the oxygen sensor moved from the converter will begin to record the normal oxygen concentration and issue a corresponding signal.

It turns out that making a reliable and functional flame arrester yourself and installing it instead of an expensive catalyst is not so difficult. Moreover, such a homemade element will not cause any harm not only to the exhaust tract and power unit of vehicles, but also to the environment.