BOSCH injectors

Their use depends on the engine size and the number of valves. There is no particular variety in VAZ-2114 engines, so there are only the following options:

- Nozzle BOSCH 0280 158 022. The nozzle is marked black, has a productivity of 1.9644 mg/sec, operates under a standard pressure of 3.8 atmospheres. Installed on a 1600 cc engine with 16 valves. Works with January 7.2 controller.

BOSCH nozzle: productivity 1.9644 mg/sec

- Nozzle BOSCH 0280 158 017. The nozzle is also marked black, has a thin spray and a productivity of 1.922 mg/sec. The standard pressure is identical to the previous one - 3.8 atm, can be installed on a 1.6 liter 8-valve engine. Works with January 7.2 controller.

- Injector BOSCH 0280 158 996. Used until 2006, can be replaced with BOSCH 0280 150 110. Both injectors are designed for use in an 8-valve 1.5-liter engine. The only difference is in performance - the 996 has a performance of 1.653 mg/sec, the new 110 operates with a performance of 1.7 mg/sec, which has virtually no effect on engine performance.

The new injector may have a thicker O-ring and, accordingly, a longer nozzle. The injectors are completely interchangeable. These injectors can only work with the January 5.1 controller.

In addition, you need to know which engine control controller is installed on the car, since January 5.1 and January 7.2 may require injectors of different capacities.

How to replace old injectors with new ones

The fuel frame with all injectors is dismantled:

We compress the spring clamp and disconnect the power supply to the injector:

Slightly rocking from side to side, carefully remove the nozzle:

Using a screwdriver, slightly pry and remove the sealing ring:

Remove the ring from the sprayer:

Installation of new injectors is carried out strictly in the reverse order.

Siemens Deka injectors

There is no certainty with Siemens injectors, since the plant can install injectors of different markings on the same engine. However, there is a clear difference between the injectors for eight-valve and 16-valve engines.

In the first case, the nozzle is single-flame, in the second - double-flame, that is, it sprays fuel onto each of the intake valves separately.

They are marked as VAZ20734 (orange markings) and 20735 (blue markings). On eight-valve engines, a Siemens 6393 nozzle with a thick torch can be used. Its productivity is 1.662 mg/sec, and its operating pressure is 3 atm. Each of these injectors can be installed on a VAZ-2114 engine.

Advantages and disadvantages of the injector

To understand whether you are ready to invest effort into converting the carburetor into an injector on a VAZ-2019, you need to study the real capabilities of the car before and after modernization. Here are the advantages noted by the owners of domestic cars after the VAZ-2019 has already been converted:

- There are no problems starting the engine in any weather conditions.

- There is no need to adjust the ignition according to the quality of the air-fuel mass.

- Eliminates the risk of engine tripping.

- Requires less gasoline consumption.

- The VAZ-2109 moves better from the very beginning of the start until the end of the trip.

Now about the disadvantages of the alteration. Like any device, the injector is not immune to breakdown, then checking the condition of each part will require much more time. The good thing about an injector is that the engine starts easier than with a carburetor, it saves gas, it’s easier to drive the car, but servicing the mechanism really suffers and requires specific skills and knowledge, and the patience of the car enthusiast.

Some drivers express certain doubts whether it is worth spending so much money to convert the carburetor to an injector in the VAZ-2109. After all, fuel savings after modernization are no more than 3 liters, and the modification itself is estimated at 15,000 - 20,000 rubles. If one-time expenses are not so important to you, then do not neglect the conversion. Driving a modernized car will become more comfortable and, over a long period of use, more profitable.

When to change: self-diagnosis

The fuel system of an injection engine has a fairly extensive architecture and faults can only be identified after an accurate diagnosis of each of the system elements. For example, a drop in engine power may be the result of either a malfunction of the injectors, insufficient performance of the fuel pump or a clogged fuel filter.

In addition, jerks and dips, unstable idle and difficult starting, increased consumption, can occur when the injector is simply clogged.

You can check the injectors themselves directly on the engine without removing them. To do this, just start the engine and remove the wires from the connector one by one. If the stability of the engine changes at the same time, the engine starts to oscillate, then the injector is in order. If, when removing the wires from the connector, the stability of the motor does not change, the injector needs to be cleaned or replaced.

Methods for cleaning VAZ 2109 injectors

It should be noted that replacing nozzles is not always the only and justified way to restore the functionality of the atomizer. You can try cleaning the injector, especially since it is not difficult, and you can save quite a lot.

There are two most common methods for cleaning dirty injectors, each of which has its own advantages and disadvantages. Which one to choose is up to the car enthusiast.

method one

To work you will need:

• Injector cleaner. • Spray cleaner for carburetor. • New O-ring.

The operating algorithm is as follows:

We remove all the injectors (even if only one is clogged, it won’t hurt to clean everything).

Place the nozzle in a container with injector product and leave it there for a while.

At this time, use carburetor cleaner to wash the idle air control.

We clean the carbon deposits around the injector nozzles manually - its consistency resembles resin. You will have to tinker with carbon deposits. This is called external injector cleaning.

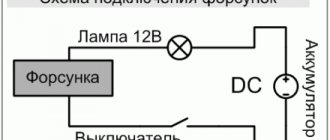

As for internal cleaning, you will need a power source with a voltage of 3 to 12 Volts (a car battery will do), as well as a foot pump with a built-in pressure gauge.

Remove the nozzle from the end of the pump hose, pour a little injection cleaner inside the hose, and place the hose on the nozzle. After this, pump up the pressure to 6 atmospheres, focusing on the pump pressure gauge. After this, a voltage of three volts must be applied to the injector. If the electromagnet does not work (the injector does not click), you need to increase the voltage.

Voltage should be applied to the injector in spurts for a short time, periodically pumping up the pressure. Blow all the injectors in the same way.

method two

To work you will need:

• Spey for carburetors. • Pump with pressure gauge. • Sealing ring.

• Instead of injector cleaner, we use a spray.

• We repeat in turn all the manipulations that were described in method No. 1, using carburetor cleaner.

• Be sure to clean the outside of the nozzle to remove carbon deposits.

• Apply the spray to a clean rag and thoroughly wipe all the nozzles on the outside.

• Gradually, under the influence of the spray, the carbon deposits will soften and it will be easy to clean off. You can carefully use a toothpick or flathead screwdriver.

• Before installing the nozzle in place, be sure to lubricate the sealing rings with a solution of laundry soap.

Both the first and second methods take no more than 3 hours in time, and in terms of money they cost tens of times less than the same service at a service station. After cleaning the injectors, check their operation - if there is no result, the injectors will have to be replaced.

Replacing injectors (full technology)

Before replacing injectors on a VAZ-2114 of any generation, it is necessary to relieve the pressure in the power system.

To do this, remove the rear seat cushion, open the hatch and remove the contact block from the fuel pump. Now it is de-energized and will not build up pressure.

We start the engine and wait a few minutes until all the fuel in the system is used up. The pressure has been relieved, now you can safely remove the old injectors and replace them with new ones. We proceed according to the following algorithm:

- We de-energize the car by removing the negative terminal from the battery.

Disconnect the negative terminal from the battery

- Remove the air filter and hose from the pressure regulator in the power system.

Remove the hose from the pressure regulator

- We press the plastic latch and remove the connector from the throttle position sensor.

Disconnect the electrical connector of the throttle position sensor

- In the same way, remove the connector from the idle air regulator.

Disconnect the connector from the idle air regulator

- Disconnect the connector block from the injector wiring harness.

Disconnect the connector block from the injector wires

- Unscrew the fuel rail mounting bolts.

Unscrew the fuel rail mounting bolts

- We move the fuel rail so that each of the injectors comes out of their seat.

We dismantle the fuel rail with injectors

- We release the spring clip and remove the wires from each injector.

Squeeze the spring clip and disconnect the electrical connector of the injector.

- We remove the injector from the ramp and replace it with a new one.

Rock the injector and remove it from the fuel rail.

Installation of injectors is carried out in the reverse order. Before installation, it is advisable to check the integrity of the O-rings; if they have lost their elasticity, it is better to replace them with new ones. The injectors are installed and ready for further use. Good luck to everyone!

Signs of malfunction of VAZ 2109 fuel injectors

If poor, low-quality fuel is used or the injector supply system is contaminated, they may fail. In this case, the fuel does not spray out of the injectors, but simply begins to drip or flow. The formation of the air-fuel mixture is disrupted, and as a result, the engine operates intermittently at different speeds. Power and throttle response drop significantly, the car moves jerkily, dips and jerking appear in the engine.

If the injector valve needle is stuck in the open position, ignition may occur after the engine is stopped, so-called detonation, as fuel continues to flow. The electrical part of the injector may also break. This may happen due to a broken wiring or short circuit. In this case, the injector cannot be repaired and must be replaced. A dirty nozzle can be washed. A special stand is used for this. After washing, the functionality of the nozzle is restored for some time.