Details on how to independently measure fuel pressure on a VAZ 2110

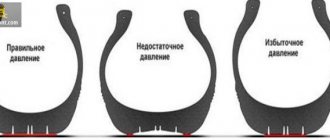

Fuel pressure in the power supply system of a VAZ vehicle plays an important role in the operation of the power unit under various loads. What should be the pressure in the fuel rail and the reasons for its violation in the fuel system of a VAZ 2110 car, as well as how to solve this problem, you will learn from this publication.

If the VAZ 2110 engine starts to stall at idle, and when driving uphill there is a loss of power, most likely the fuel pressure in the system is not normal. In such cases, it is necessary to carry out diagnostics and identify the causes of the malfunction. To check the fuel pressure, you will need a special device with a pressure gauge, which is connected to the fuel line and the corresponding measurements are taken at different engine operating modes. An alternative to such a device can be the most common pressure gauge for checking the pressure in car tires with a rubber hose with an internal diameter of 9 mm connected to it.

How to check the pressure in the fuel rail of a VAZ 2110

- There is a fitting on the fuel rail of the VAZ 2110 engine, which is closed with a plastic cap. It is to this fitting that we will connect the pressure gauge to measure the fuel pressure. After removing the cap, unscrew the nipple and put on the hose, securing it with a metal clamp. Details on how to independently measure the fuel pressure on a VAZ 2110. Be careful if there is excess pressure; when unscrewing the nipple, a certain amount of gasoline may spill out. To prevent this from happening, you can relieve the pressure in the VAZ 2110 fuel system in advance by removing the fuel pump fuse, start the engine and let it stall on its own, then return the fuse to its place.

- After the pressure gauge has been connected, you can start the engine and check the readings at idle and with the vacuum hose removed.

Allowable fuel pressure values for VAZ 2110

- Idle speed - 2.8–3.2 bar (2.8–3.2 atm)

- With the vacuum hose removed, the VAZ 2110 fuel pressure may rise by 0.2–0.7 bar (0.2–0.7 atm), which indicates that the pressure regulator is working properly.

Find out more about self-repair of VAZ cars

Air intake and throttle valve

The first thing we will consider from the design of the VAZ-2110 fuel system (injector, 8 valves) is the air supply. An air purification filter is installed at the inlet - on the “tens” it is made of paper, flat, and has a large surface area. Due to this, filtration occurs as efficiently as possible. The design of the throttle assembly looks like this:

- The pipe through which liquid from the cooling system is supplied to the housing.

- The pipe through which the crankcase is ventilated during idle operation.

- A pipe through which liquid is drained.

- A sensor that allows you to determine the position of the damper when the engine is running.

- Idle air control (you can’t call it a sensor, since the device doesn’t measure anything). This is a simple stepper electric motor that allows you to change the amount of air supplied to the ramp when idling.

- Fitting – necessary for purging the adsorber.

How to check fuel pressure in the rail - step-by-step instructions

The main indicator of a malfunction of the engine power system in VAZ 2110, 2111 and 2112 vehicles is the fuel pressure in the fuel rail.

So, if the fuel pressure is insufficient, the following symptoms occur:

- the engine stops at idle;

- unstable engine operation;

- reduced or increased crankshaft speed at idle;

- poor car response;

- dips or jerks in engine operation while it is moving.

The first thing to do in this case is the reliability of the electrical contacts of the injection system, which are responsible for supplying fuel to the system (injectors, fuel pump).

The fuel pressure in the rail can be checked using a pressure gauge with a hose and an adapter for connecting to the rail. So, let's move directly to the process of checking the pressure:

- The first thing to do is turn on the ignition and wait a few seconds for the fuel pump to start working. If you do not hear the sound of the fuel pump, then you should check the electrical power circuit of the pump.

Note: if you turned on the ignition 3 times in a row and did not turn on the starter, then once again the fuel pump may not work - this is quite normal and is not a malfunction; it will start working simultaneously with the engine starting.

- Next, reduce the pressure in the power system. In order to check the fuel pressure in the rail, you must connect a pressure gauge with a measurement limit of at least 5 kgf/cm2.

- We start the engine and check the pressure.

Normal idle pressure should be about 300 kPa (3.0 kgf/cm2) for engines 2111 and 2112 and about 380 kPa (3.8 kgf/cm2) for engines 21114 and 21124.

Low fuel pressure can be due to several reasons:

- fuel pump malfunction;

- Fuel pressure regulator malfunction.

- We turn off the engine and reduce the pressure in the power system.

- Disconnect the pressure gauge from the ramp control valve and screw on the valve cap.

Differences in power systems

It is worth noting that the power supply systems for the VAZ-2111 and VAZ-2112 engines are slightly different from the VAZ-21114 and VAZ-21124. The last two do not have a return line through which gasoline returns to the tank. The reason is that the fuel pressure regulator is located in the same module as the fuel pump, in the tank. Therefore, it is possible to control the pressure in the system at an early stage, so to speak. And in this case, there is no need to lay a return line.

In addition, in order to connect various components of the line, the VAZ-21114 and VAZ-21124 engines use clamp-type tips, rather than threaded fittings. There are also differences in the shape and design of the ramp; newer injectors are installed on it. And most importantly, the pressure in the system is slightly higher than on earlier engine models.

No pressure in the fuel rail VAZ 2110 8 valves

pressure in the VAZ ramp is free. check, pressure, ramp, VAZ, check.

2.1.10 VAZ 2115 timing belt.

Fuel rail - checking operating pressure.

How to remove the fuel rail on a VAZ-2111 car engine yourself.

2. Remove the decorative trim of the engine (see 8.1.4).

Comment on Removing and replacing the fuel rail of the VAZ-2111 engine.

Removing the fuel rail of the VAZ-2112-8 engine.

If the regulator is working properly, the fuel pressure should increase by 0.2–0.7 bar (20.

We move the pressure plate of the fuel supply pipe along the ramp and remove the pipes.

There is no pressure in the fuel rail of the VAZ 2110.

The tuning pressure is 6 atm in the VAZ fuel rail, not in order.

Removal and installation of the fuel rail and regulator VAZ fuel 2110, VAZ 2111.

Removing the fuel rail and fuel pressure regulator of the VAZ-2112 engine.

2.17.1.7. Checking and replacing the fuel pressure regulator.

Removing the fuel rail of the VAZ-2111-1 engine.

a special membrane-type valve, on which it turns on one side.

Pressure in the fuel rail of a VAZ 2110 - pictures and photos.

Checking the pressure in the fuel rail of a VAZ 2109 Do it yourself.

It is installed in the injector rail and represents.

8. Screw in the bleeder fitting until it stops.

DIY car repair. fuel rail. DIY car repair.

diagram for disassembling the fuel rail of a VAZ 2110.

There is no pressure in the fuel rail of the VAZ 2110.

If the regulator is working properly, the fuel pressure should increase by 0.2–0.7 bar (0.

There is no pressure in the fuel rail of the VAZ 2110.

Checking the pressure in the fuel rail on VAZ and Lada cars with an injection engine

The article will describe a testing technique that does not require special devices.

From the tool you will need:

1. We took a regular gas pressure gauge with a scale of up to 1.0 MPa. It has a threaded connection and screws perfectly onto a 9 mm oxygen hose. You can use a mechanical one to check tire pressure. They are usually inserted into the fuel hoses by 8 mm.

2. Screw it into the hose and tighten it with a clamp:

3. Unscrew the plastic cap from the fuel rail. It should unscrew by hand, but if it hasn’t been touched for a long time, you may need pliers:

4. If the car has just been turned off, then the gas in the ramp is under pressure. First, it is recommended to release the pressure by pressing on the spool and placing a rag or a plastic “bottle” with the neck cut off. It is more convenient to bleed using a wheel cap.

5. Unscrew the nipple with the cap. It is similar to a wheel nipple:

6. We put a hose with a pressure gauge on the threaded part and tighten the connection with a clamp:

7. Start the car and first of all make sure that there are no gasoline leaks from the connections. Then we look at the pressure gauge readings.

8. For fuel systems with “return” (a pressure regulator is installed on the fuel rail, from which a tube goes back to the tank), a pressure of 2.7 atm is considered normal (when re-gasping it should jump up to 3 atmospheres). However, a pressure of 2.5 atm is also acceptable. If the pressure is less, then the fuel system is faulty. Pressure pulsation (0.2 atm) indicates a clogged coarse mesh (located in the tank with the fuel pump).

Lada Priora Hatchback ✤ℨℰȴеℋÅЯ МОШℵИЯ!!! › Logbook › The main thing about the pressure in the fuel system.

Fuel pressure in the car system is one of the important parameters that is used in engine diagnostics. The behavior of the car in various operating modes depends on the pressure. How to measure the pressure in the fuel system with your own hands

For example, buy a device to check fuel pressure. A kit with a fuel pressure gauge, adapter and drain will cost you 1400-1500 rubles. Pay 300-400 rubles to the service station and take measurements there. You can also measure the pressure in the fuel system with an air pressure gauge, which is used to measure tire pressure. Here at this point in more detail. Let's take the example of the tenth VAZ 2110 family. Otherwise, the procedure is similar to any other car. The peculiarity of pressure gauges is that their initial scale values have relative inaccuracy. What does it mean. If the air pressure gauge has a scale of up to 16-20 atm (when the measurement limit for fuel is 5-7 atm), then pressure measurements will not be accurate due to this error, which will fall within the initial values of the instrument scale. Therefore, it is correct to check the fuel pressure with a fuel pressure gauge with a limit of 6-7 atm.

We take a pressure gauge and wrap a piece of foam (plumbing flax) under the pipe and put on an oxygen hose with an internal diameter of 9 mm. Secure with clamps. Place a rag on the generator (so as not to start a fire under the hood). Unscrew the plastic cap on the fuel rail.

put the hose on the pressure gauge

Under the cap there is a hole with a nipple. Unscrew it from the wheel cap. Due to the residual pressure in the rail after removing the nipple, gasoline will splash out.

If desired, you can relieve the pressure in the vehicle's fuel system. To do this, you need to remove the fuel pump fuse and wait until the running car stalls.

We put the second end of the hose on the ramp hole and secure it with a clamp. We remove the rag from the generator and start the engine. Don’t forget to cover the generator with a rag again before removing the hose from the ramp. That's it, now you know how to check the pressure in the fuel system in the field.

attach the hose with pressure gauge to the fitting

check the fuel pressure in the system

By the way, instead of clamps, you can use the classic adjusting bolt bushing. It screws perfectly onto the ramp fitting. To seal, we put a suitable rubber ring on the fitting. On the other side of the bushing we solder a fitting onto which we put a hose with a pressure gauge.

What pressure should be in the VAZ 2110 fuel system? 2.8–3.2 bar (2.8–3.2 atm)

How to measure fuel pressure in a system where there is no return? On VAZ 2110 with 1.6 liter engines, the pressure in the ramp is constant and amounts to 3.6-4.0 atm. Otherwise, the measurement technique is similar. Alternative ways:

It is measured at the outlet fitting of the fuel pump module - this is the one with one tube. You will need a flexible gas-resistant hose with an internal diameter of about 8 mm and a pressure gauge (you need to remove the tube and put on a hose with a pressure gauge instead). The pressure should be 5-7 atm. Close the return line, as is done on an internal combustion engine with a drain ramp, but you must turn it off again at the fuel pump itself. We pull off the second hose (double) and insert a plug into the removed hose, made, for example, from an old fuel filter (saw off the nipple from it and plug it). A single hose must be put on the pump fitting, and now the measurement must be made at the fuel rail. According to the power system diagram, everything will be clear.

Pressure regulators VAZ 2110 - design and operation

A fuel pressure regulator (FPR) is needed to maintain gasoline pressure in the fuel system at a constant certain level, regardless of engine operation. It is installed in the injector rail and is a diaphragm valve connected to the fuel supply channel to the injectors, the drain line and the air tube supplied from the intake manifold.

The RTD valve is affected by fuel pressure, on the one hand, and, on the other, by air pressure in the tube and spring force, adjusted to certain operating parameters in the system. When the engine is running, a serviceable RTD maintains the following indicators in the system: 2.9–3.3 kgf/cm 2 (284–325 kPa).

Fuel pressure adjustment

How is pressure maintained in the fuel system of the VAZ-2110? On cars with VAZ-2111 and VAZ-2112 engines, a pressure regulator is installed directly on the fuel rail. With its help, a certain pressure value is maintained inside. Moreover, it allows you to maintain both air pressure in the intake pipe and fuel inside the ramp.

The design of the regulator is not very complicated. Inside it are a valve, a diaphragm and a return spring. When the engine is running, the regulator allows you to maintain pressure in the range of 284-325 kPa. On the one hand, the diaphragm of the device is affected by fuel, and on the other, by low pressure in the intake pipe. As soon as the pressure in the intake manifold decreases, the valve begins to open. In this case, excess fuel is passed into the drain line to the tank. The pressure in the ramp is significantly reduced.

As soon as the pressure in the intake manifold increases (this happens when the damper opens), the valve on the regulator begins to open at a significantly higher pressure of the fuel mixture. At the same time, the fuel pressure inside the ramp increases significantly.

But on VAZ-2114 and VAZ-21124 engines, the pressure regulator is placed inside the module, next to the fuel pump. This is a kind of check valve in the fuel system of the VAZ-2110, which operates at a certain pressure (about 400 kPa). If the pressure exceeds the norm, the drain line opens and excess fuel is returned back to the tank.

Types and symptoms of regulator malfunction

The types of RTD malfunctions are as follows. The valve does not hold - fuel begins to circulate freely throughout the fuel system, the pressure in which decreases because of this. As a result, the engine does not have enough fuel when the speed increases, and its power decreases; The pressure in the system should not change after stopping the engine, but since the valve is not able to hold it, when starting the engine, you have to work with the starter for a long time to create the required pressure.

A completely inoperative valve means fuel is not discharged into the tank, and because of this, the pressure in the system increases. As a result, the amount of fuel supplied to the combustion chambers through the injectors increases - there is overconsumption and incomplete combustion of gasoline.

Signs of a faulty RTD are the following engine operation:

- unstable;

- stalls at idle;

- insufficient pickup;

- cannot develop full power;

- the crankshaft rotates at idle speed with a reduced or increased frequency;

- dips and jerks while the machine is moving;

- difficult starting - not always;

- the content of CO and CH in the exhaust gases significantly exceeds the permissible standards;

- excessive consumption of gasoline.

Old style fuel pressure regulator with engine capacity 1.5 liters

- Manufacturer: RES

- 0 reviews

- Description

- Characteristics

- Video

- Reviews 0 ? '(' + product.reviewsCount +')' : »>>

Dear customers, in order to avoid errors when sending a fuel pressure regulator for VAZ, Lada with an engine capacity of 1.5 liters, old model, in the “Comment” line indicate the engine size, model of your car, year of manufacture.

Any breakdown is not the end of the world, but a completely solvable problem. For an injection engine to operate, a certain pressure must be maintained in the fuel system. This task is performed by the RDT 300 pressure regulator. A faulty device will not allow the engine to operate normally and must be replaced.

On VAZ and LADA vehicles, the RDT 300 fuel pressure regulator ensures the functioning of the fuel injection system in normal mode. With its help, the optimal pressure value is maintained in the fuel rail, which is necessary for the gasoline to be in a state of fog. Due to the pressure, which is higher than atmospheric, the air-fuel mixture is injected into the combustion chambers. If the regulator fails, the entire injection system does not work correctly and serious problems in the functioning of the engine are possible.

The fuel pressure regulator (RDT 300) maintains gasoline pressure in the fuel system at a constant certain level, regardless of engine operation. It is installed in the injector rail and is a diaphragm valve connected to the fuel supply channel to the injectors, the drain line and the air tube supplied from the intake manifold.

The RDT 300 valve is affected by fuel pressure, on the one hand, and, on the other, by air pressure in the tube and spring force, adjusted to certain operating parameters in the system. When the engine is running, a serviceable RTD maintains the following indicators in the system: 2.9–3.3 kgf/cm2 (284–325 kPa).

Among the most common device breakdowns are the following:

- The valve does not hold - fuel begins to circulate freely throughout the fuel system, the pressure in which decreases because of this. As a result, the engine does not have enough fuel when the speed increases, and its power decreases; The pressure in the system should not change after stopping the engine, but since the valve is not able to hold it, when starting the engine, you have to work with the starter for a long time to create the required pressure.

— A completely inoperative valve - fuel is not discharged into the tank, and because of this, the pressure in the system increases. As a result, the amount of fuel supplied to the combustion chambers through the injectors increases - there is overconsumption and incomplete combustion of gasoline.

Signs of a faulty RTD are the following engine operation:

- stalls at idle;

- cannot develop full power;

— the crankshaft rotates at idle speed with a reduced or increased frequency;

— dips and jerks while the machine is moving;

- difficult starting - not always;

— the content of CO and CH in the exhaust gases significantly exceeds the permissible standards;

To check the operation of the RTD 300, you will need a 24mm wrench, a 5mm hexagon and a pressure gauge (for example, a tire gauge):

— Unscrew the plug of the pressure control fitting on the end surface of the injector ramp;

— Using the metal tire valve cap, unscrew the spool valve from the fitting.

— Connect the pressure gauge to the fitting through a hose, the ends of which are secured with clamps, and start the engine.

Check the pressure - disconnect the vacuum hose from the RDT 300.

The pressure gauge readings should increase by 0.2–0.7 kgf/cm2 (20–70 kPa). Otherwise, the RTD must be replaced.

Replacing the RDT 300 regulator:

- release pressure in the fuel line;

— unscrew the nut securing the fuel return pipe to the RDT 300;

— unscrew the 2 bolts securing the RTD to the injector ramp;

— carefully remove the RTD fitting from the ramp hole;

— disconnect the fuel pipe from the RTD and remove it;

— install the new RTD 300 in the reverse order, first moistening the rubber sealing cuffs with gasoline (replace inelastic and torn rings).

Other article numbers of the product and its analogues in the catalogues: 21120116001000, 211201160010-01, RDT 300.

VAZ 2104-05-07, VAZ 2108-09-099, VAZ 2110-11-12, VAZ 2113-14-15 injection.

Any breakdown is not the end of the world, but a completely solvable problem!

How to independently replace the fuel pressure regulator with an engine capacity of 1.5 liters, an old model in a VAZ, LADA car of their modifications?

How to identify a problem with the idle air regulator (IAC) on a VAZ or Lada car of their modifications?

How to independently replace the idle air regulator (IAC) in a VAZ, LADA car of their modifications?

AvtoAzbuka online store, repair costs will be minimal.

Just COMPARE and BE SURE.

Don't forget to share the information you find with your friends and acquaintances, because they may also need it - just click one of the social networking buttons located above.

How to check the pressure in a system with no return?

The VAZ-2110 with a volume of 1.6 liters has constant pressure indicators in the ramp, which, as a rule, vary around 3.6-4 bars.

In addition to the most commonly used measurement methods described above, there are several more unusual solutions:

a) Here we return again to the hose with a pressure gauge, the diameter of which should be 7.5-8 millimeters. Measurements should be taken at the outlet of the fuel pump module. Five to seven atmospheres are normal test results.

b) Remember how the return line is closed on motors with a drain frame. It is recommended to turn off the engine directly at the gasoline pump. Next, you will need to remove the double hose and insert a plug (“The nipple” from an old fuel filter may also be suitable for this task). Now you need to pull a single tube onto the pump fitting. The measurements themselves must be made at the fuel rail.

How to clear a blockage if the fuel supply line is clogged.

One of the reasons for low pressure may be a malfunction of the sensor that regulates the fuel pressure before injection. Low pressure may also be a consequence of a clogged fuel line. By taking proper measurements, you can accurately determine the cause of the malfunction. First, you should check the pressure of the pump and line, then measure the pressure in the ramp. All of the above will help determine the exact cause.

How to clear clogged fuel injectors.

There are several signs to tell you that your fuel injectors are dirty. Let's start in order.

- Difficulty starting the engine.

- Unstable engine operation.

- Dips in the timing of sharp pressure on the gas pedal.

- Loss of power and deterioration in acceleration dynamics.

- Increased toxicity of treated gases.

- Increased fuel consumption.

- The occurrence of detonation.

- Popping sounds in the exhaust system.

- Misfires.

To solve this problem you need to clean the fuel injectors.

Clogged valve. How to identify and fix the problem.

When the valve is clogged, fuel is difficult to pass through, and because of this, it begins to leak everywhere. A significantly increased fuel consumption indicates that it is time to change the regulator, since it is the leading component. Fuel stops being supplied to the supply system if the valve becomes completely clogged.

What to do if the valve is stuck.

Uneven pressure in the system is usually the result of a stuck valve. Because of this, the vehicle's movement may be uneven. The car may also jerk or stall.