Description

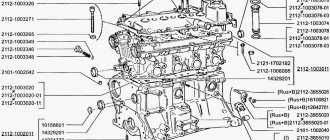

The VAZ-11183 engine was designed and put into production in 2004. Many design elements are taken from the VAZ-21114 engine. VAZ-11183 was produced until 2021. In 2011 it underwent a slight modernization, as a result of which it received an electronic drive for controlling the throttle valve (gas pedal).

The VAZ-11183 is a 1.6-liter gasoline inline four-cylinder engine with a power of 80 hp. s and torque 120 Nm.

Installed on Lada cars:

- 2112 (2004-2008);

- 2113 Samara (2004-2014);

- Grant (2011-2018);

- Kalina (2004-2013).

In addition to Lada, it can be seen under the hood of On-Do 1 (Datsun).

The opinion of auto experts about the engine is clear - the engine is simple in design and design compared to many other 8-valve AvtoVAZ engines.

The cylinder block is made of high-strength cast iron. The height is increased by 2.3 mm (compared to the VAZ-2110). Not sleeved.

The cylinder head is aluminum, with one camshaft and 8 valves (SOHC). To increase the compression ratio, the volume of the combustion chambers has been increased. There are no hydraulic compensators, so the thermal clearance of the valves has to be adjusted manually.

The crankshaft is steel, forged. It has a crank radius increased by 2.3 mm, which provides a piston stroke of 75.6 mm.

Timing belt drive. The main advantage is that the valves do not bend when they meet the pistons when the belt breaks. The engine simply stalls at this moment.

The attachments have their own drive belts.

Alternator belt drive

Power supply system – injector, distributed fuel injection. Practice has shown the possibility of using AI-92 gasoline. Justification - the compression ratio does not exceed 10 units (above 10 - only AI-95 or AI-98).

The advantage of the engine is the reserved safety margin, i.e. there is the possibility of tuning without reducing the mileage resource.

Tuning

Engine tuning is most often carried out in order to increase the power above that indicated in the passport. On a VAZ 11183 engine, it can be increased without special costs through a number of sequential operations:

- Increase engine power to 90 hp. With. It is possible if you replace the existing camshaft with “OKB Dinamika 108” or “Nuzhdin 10.93” and install a split gear. With the correct phase settings, the power unit can develop power up to 90 hp. With.

- By installing a receiver, an enlarged 54 mm throttle body and a Spider 4-2-1 exhaust, you can increase the engine power to 100 hp. With.

- After modification of the cylinder head and intake manifold, the engine power will increase to 115 hp. With. True, for this it is necessary to replace the standard valves with lighter ones (T-shaped).

- By replacing the piston group with a lighter one (for example, from a LADA Priora car), we get a power of more than 120 hp. With.

The same result can be obtained if you install on the engine:

- compressor PK-23-1;

- camshaft “Nuzhdin 10.42” or “Nuzhdin 10.63”.

The power of the 8-valve power unit can be further increased, but this will lead to a significant reduction in its service life.

Specifications

| Manufacturer | Concern "AvtoVAZ" | |

| Engine code | VAZ-11183 | VAZ-11183-50 |

| Start year of release | 2004 | 2011 |

| Volume, cm³ | 1596 | 1596 |

| Power, l. With | 80 | 82 |

| Torque, Nm | 120 | 132 |

| Compression ratio | 9.6 | 9.8 |

| Cylinder block | cast iron | cast iron |

| Number of cylinders | 4 | 4 |

| Fuel injection order | 1-3-4-2 | 1-3-4-2 |

| cylinder head | aluminum | aluminum |

| Cylinder diameter, mm | 82 | 82 |

| Piston stroke, mm | 75.6 | 75.6 |

| Number of valves per cylinder | 2 | 2 |

| Timing drive | belt | belt |

| Turbocharging | No | No |

| Hydraulic compensators | No | No |

| Valve timing regulator | No | No |

| Lubrication system capacity, l | 3.5 | 3.5 |

| Oil used | 5W-30 (40), 10W-40, 15W-40 | 5W-30 (40), 10W-40, 15W-40 |

| Fuel supply system | injector | injector |

| Fuel | gasoline AI-92 | gasoline AI-95 |

| Environmental standards | Euro 2-3 | Euro 4 |

| Resource, thousand km | 150 | 150 |

| Location | transverse | transverse |

| Weight, kg | 112 | 112 |

| Tuning (potential), l. With | 180* | 180* |

*tuning up to 120 hp is possible without loss of service life. With.

Recommendations for servicing the Lada Kalina engine

The service life of any engine depends on proper maintenance from the very first days of operation; the VAZ 11183 1.6 engine is no exception to the rule.

The manufacturer recommends servicing this engine in the following order:

- During the first kilometers of driving, the entire car undergoes grinding in of parts, including the engine. The grinding-in period is called the running-in period. It lasts about 1.5 thousand kilometers. After it expires, you need to replace the engine lubricant and the oil filter element.

- The next stage of maintenance must be performed after a mileage of 10 thousand kilometers. The engine oil and oil filter must be replaced. Also, at this stage it is necessary to change the air filter, measure the compression in the cylinders and adjust the valves.

- After 20,000 kilometers, it is necessary to diagnose all mechanisms and systems of the internal combustion engine. Naturally, you need to change the engine oil, since it must be replaced every next 10,000 kilometers.

- After 30 thousand, you only need to change the engine lubricant and filter element

- After a mileage of 40 thousand km, many engine elements and parts must be replaced:

- replacing the air flow filter element;

- replacing the fuel filter element;

- replacing the timing belt and roller;

- replacing the alternator belt if necessary;

- replacing the pump at the slightest play in the fuel pump pulley;

- replacing the valve cover gasket;

- other parts requiring replacement;

- In addition to replacing parts, during this period of operation the valves should be adjusted and diagnostics of the internal combustion engine systems should be carried out.

Subsequent maintenance must be carried out in accordance with points 2 and 5. The exception is motor oil and filter. They need to be replaced every 10 thousand kilometers.

Oil change video

Engine VAZ-11183-50

This engine is a modification of the VAZ-11183. There are no fundamental design differences, but as a result of modifications:

- Power increased to 82 hp. With.

- Torque increased by 12 Nm.

- The environmental standard has increased to Euro

The main difference is that the unit is equipped with an electronic throttle control mechanism (type of action - “E-Gas”). The innovation improved engine controllability, but at the same time created a problem with the TPS sensor.

Engine builders managed to eliminate a number of shortcomings that were observed on its predecessor. For example, constant contamination of the throttle valve is a thing of the past.

Throttle Position Sensor (TPS)

As a result of modernization, the level of torque of the internal combustion engine and its elasticity have increased.

Car enthusiasts note that in general the engine has become more reliable and less capricious. At the same time, engine efficiency has decreased.

16 valve engine

This is a more technically advanced brother of the 8-valve. In fact, it represents a deep modernization of the VAZ-21126 engine. The model received an intake receiver of variable length, due to which its power increased from 98 hp. up to 106 hp

Advantages of a 16-valve engine

If you tune the version with 16 valves, you can reduce the acceleration time of the car to 9 seconds. This is ideal for highways where speeds exceed 100 km/h. At these speeds, the 16-valve model feels more confident in handling.

The design of the internal combustion engine includes hydraulic compensators, which save the machine from zero maintenance with valve adjustment. There is a groove in the engine, so there is no need to be afraid that the valves will be bent.

Disadvantages of the 16-valve engine:

- cost - in some versions of the Lada Granta, the price difference between models with 8 and 16 valves is 100,000 rubles.

In terms of torque, the 16-valve version is inferior to the 8-valve version. To spin the engine to 148 N*m, you will need more than 4000 rpm.

Among the design flaws, it is worth mentioning the problem of spark plug wells sweating with a mileage of 10,000 km or more. Oil begins to drip inside. This is due to the use of sealant rather than gasket as a seal.

Reliability, weaknesses, maintainability

Reliability

According to the conclusion of servicemen and car owners, the VAZ-11183 is more reliable in comparison with the concern’s previously produced engines. The increased quality of components and mechanisms used in the engine is especially noticeable.

The manufacturer has determined the average mileage resource. In reality, it is more than twice as much as stated. This fact is clearly confirmed by the increased reliability of the unit.

In addition, the engine is unpretentious during operation. The lubrication system especially benefits in this regard. The oil quality requirements are somewhat underestimated due to the lack of hydraulic compensators. The stable operation of the engine on low-octane gasoline also pleases most car owners. In other words, the efficiency of the internal combustion engine has been increased without sacrificing reliability.

The reliability of the timing system is beyond praise. A broken drive belt does not cause the valves to bend, which saves the car owner from expensive repairs.

On various forums you can find the following reviews: “... the engine is class, the traction is what you need, at low speeds 3 uphill, and even with a load of 4 people. 80 kg each. I only fill with 92, because... the engine is structurally very simple, it doesn’t need much to work well.” Another one - “... the 1.6 eight-valve engine is, by today’s standards, a stone age. But let's take a closer look at how it behaves on the road. When fully loaded, the power is quite enough, I drove the swallow 150 and there is still some reserve left.”

Thus, we can conclude that the VAZ-11183 is a completely reliable and economical engine.

Weak spots

Every engine has weak points. The unit in question did not escape them either.

Most often, car owners are alarmed by knocking noises in the engine. Moreover, both warm and cold. It is appropriate to note here that the engine itself is quite loud in operation (a design feature of the engine). But knocking can also be caused by unregulated valves. In any case, to find out the reasons for the loud operation, you need to contact a car service.

Engine overheating. The problem is typical for all VAZ engines. Usually solved by replacing the thermostat.

Electrics. It is also a weak link. Especially the different sensors. For example, DMRV. The result of its failure is engine failure (stalls while driving). Computer diagnostics of the internal combustion engine will help identify the resulting malfunction. Sometimes the ECU starts to malfunction. Also, you can’t do without computer diagnostics here.

Troubling of the internal combustion engine at idle speed can be caused by unadjusted valve clearances or burnt-out valves. The cause may be spark plugs. The true cause of the tripping can be easily identified at a specialized service station.

Oil leakage is a fairly common occurrence. The problem lies in poor-quality seals of mating parts and engine components. A simple tightening or replacement of the oil seal (gasket) allows you to forget about oil leaks for a long time.

In any case, the engine must be constantly monitored and any detected faults must be corrected in a timely manner.

Design Features

After modernizing the 21114 engine taken as a standard, the 11183 engine has the following design nuances:

Cylinder head 11183

To reduce manufacturing costs, a connecting rod-piston group, a pulley and a crankshaft flywheel from the 2110 engine are installed in the engine. The volumes of the combustion chambers are increased for the engine with the sole purpose of ensuring a compression ratio of 9.6 - 10.0.

The manufacturer does not provide hydraulic compensators in this internal combustion engine, therefore, on the one hand, the use of lower quality oil is allowed. On the other hand, the savings in the operating budget when using cheap lubricants are “eaten up” by the costs of periodically adjusting the valves in a service station, since the manufacturer recommends doing it more often.

The main attachments are driven by their own belts. The design of tensioners (for example, a generator) leaves much to be desired. But the internal combustion engine allows you to increase power in the following ways. Moreover, a reasonable boost does not require major repairs to be carried out more often than the established deadline.

Belt drive of the generator

Even without improving the characteristics, the motor is high-torque and torquey, and produces 200% of the resource declared by the manufacturer. The available repair dimensions of the piston group make it possible to increase the service life, taking into account several overhauls, up to a million kilometers.