A rather successful development of the domestic automobile industry was the VAZ 2107 engine, which provided 1690 cubic centimeters of displacement. These characteristics allow the power unit to develop a maximum power of 79 horsepower. In this case, the peak torque of the engine is 127 Nm at 3200 rpm.

The VAZ 2107 injection engine was slightly redesigned by the manufacturers, as they added single fuel injection. Thanks to this solution, the inline four-cylinder engine began to work much better, and problems with it arose much less frequently.

Specifications

| Engine capacity, cc | 1690 |

| Maximum power, hp | 79 |

| Maximum torque, N*m (kg*m) at rpm. | 127 (13) / 3200 |

| Fuel used | Gasoline AI-92 |

| Fuel consumption, l/100 km | 6.9 |

| engine's type | In-line, 4-cylinder |

| Add. engine information | single injection |

| Maximum power, hp (kW) at rpm | 79 (58) / 5200 |

| Number of valves per cylinder | 2 |

Principle of operation

The internal combustion engine is designed to convert thermal energy into mechanical energy. The conversion process occurs in the cylinder block during combustion of the combustible composition. The preparation and delivery of a mixture of gasoline and air into the combustion chamber of the cylinder is carried out in different ways.

In an engine with external mixture formation, the mixture is prepared in the carburetor. The fuel is mixed with air and enters the combustion chamber through the suction manifold through the inlet valve. It is ignited by a spark plug and burns, expanding the gas, driving the piston.

In an engine with an injection system, the process occurs differently. The fuel-air mixture is prepared in the suction manifold just before entering the combustion chamber.

When the intake valve opens, the injector opens and sprays gasoline. It mixes with air, enters the combustion chamber and at a certain moment is ignited by a candle. From the generated heat, the gas expands and presses on the piston. A working process is taking place.

The VAZ 2107i was equipped with an engine with a distributed injection system, i.e. Each cylinder is supplied with fuel individually through its own injector. There are four injectors according to the number of cylinders.

The injectors, or rather the entire system, are controlled by an electronic control unit (ECU). Judging by its functionality and the amount of work performed, it can be called an on-board computer. All data from electronic and mechanical sensors enters the unit, is processed and commands the actuators to perform certain actions.

The operating principle is as follows. From the gas tank through the filter, the fuel pump supplies gasoline to the fuel rail, then to the injectors. Inside the ramp, a constant pressure of 300 mPa is maintained using a regulator. If the pressure rises, the excess fuel is dumped into the gas tank through a cutoff automatically.

The ECU sends a signal to open and close the injectors in the order in which the cylinders operate, while being guided by readings from the crankshaft position sensor.

The amount of fuel passing through the injector depends on the length of time it is open. The time is calculated by the control unit using information received from the mass fuel flow sensor and the throttle position sensor.

These are the fundamental parameters under which the engine can operate, but for the correct and smooth operation of the unit, the electronic control unit takes additional readings:

The ECU also controls the fuel pump, idle air control and ignition system.

Peculiarities

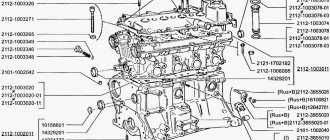

The VAZ 2107 engine with an injector had a cylinder block made of high-quality cast iron. In it, all 4 cylinders are located in one row. The mass of the block is quite large, since it is the heaviest part of the structure, as it is made of cast iron.

The VAZ 2107 engine with a carburetor was also produced, and it was no different from its counterpart with an injector. The crankshaft was also made of cast iron, and it is placed on five supports, which are known among people as journals. The journals are hardened with high frequency current, and the crankshaft is machined with great precision.

Connecting rods are the parts that experience maximum loads in the structure, so forged steel was used for their production. The engine has 4 connecting rods - one for each cylinder. Inside there are piston pins that are installed from the factory. The markings on these parts correspond to the cylinders, since they cannot be swapped with each other.

The displacement of the VAZ 2107 engine is also achieved due to the fact that its pistons are cast from lightweight aluminum, as is the cylinder head. In order for the pistons to have better contact with the cylinder walls, a layer of tin is applied to the outer surfaces.

The gas distribution mechanism is driven by a chain. Together with it, there is a damper and tensioner, which manufacturers used for quieter operation of the power unit. But in practice this is practically not noticed.

The VAZ 2107 engine number, like most classic models from domestic manufacturers, is located near the oil filter. This is a kind of marking plate that is very difficult to confuse with other data, and is relatively easy to find.

Tuning on carburetor modifications of the VAZ 2107

All old textbooks on servicing classic Zhiguli models describe a method for setting the moment of spark formation using a light bulb, although experienced motorists can easily do without it. You will understand why this happens as you read this material, but for beginners it will be useful to familiarize yourself with the old proven technique.

In order to check the performance of the carburetor or adjust its operation, it is recommended to read the following material: https://vazweb.ru/desyatka/dvigatel/remont-karbyuratora-vaz-2107.html

To correctly set the ignition of the “seven”, you need to ensure that the following conditions are met simultaneously:

- the notch on the crankshaft pulley is opposite the long mark on the timing cover;

- in this case, the round mark marked on the camshaft chain drive gear coincides with the boss on its body;

- the piston of the 4th cylinder has completed the compression stroke and is at top dead center;

- the contacts inside the distributor are open;

- The movable contact of the slider faces the fixed contact on the distributor cover, where the wire from the spark plug of the 4th cylinder is connected.

Note. On non-contact systems, at this moment the Hall sensor sends a signal to the switch to break the low voltage electrical circuit, which leads to the appearance of a high voltage pulse on the wire leading to the spark plug of the 4th cylinder.

The diagram shows what happens in the cylinders when the marks are aligned

The light bulb is used to control the ignition timing, for which it must be connected with one wire to the “K” contact of the high-voltage coil, and with the second to the vehicle ground. You should know that at the same moment the piston of the first cylinder is also in the TDC position, only there the air-fuel mixture is not compressed, but exhaust gases are released after its combustion. This is why ignorant car enthusiasts often confuse the first cylinder with the fourth when installing the ignition.

Layout of marks on the timing cover

When the above actions occur simultaneously, a spark discharge occurs on the electrodes of the spark plug of the 4th cylinder, as evidenced by the flash of the connected light bulb. To achieve these conditions and set the ignition correctly, follow the instructions:

- Turn the crankshaft with a 36 mm wrench, aligning the notch on the pulley with the long notch on the timing cover.

- If at this moment the engine valve cover is removed, then it is better to navigate by the mark on the camshaft gear, placing it opposite the housing boss.

- Take the ignition distributor, remove the cover and turn its shaft to place the slider opposite the wire leading to cylinder No. 4 (there are cylinder number markings on the cover). Insert the distributor into the engine hole, holding the slider and housing in this position, and then secure it with a 13 mm wrench nut.

- Connect the light bulb wires and turn on the ignition by turning the key. Loosen the nut securing the distributor and slowly turn it by the housing until the lamp flashes, indicating the moment of sparking. Reattach the distributor.

- Turn off the ignition and make sure that the contacts inside the distributor are currently open. Take a 0.35 mm feeler gauge and check the gap between them, if necessary, adjust it by loosening the fastening screws with a screwdriver.

The marks must be aligned by turning the crankshaft with a wrench

Note. The instructions imply that before starting work the distributor was removed from the engine without aligning the marks.

The ignition is considered to be set correctly if, after installing the distributor cap and connecting the wires, you manage to start the engine, and then you need to adjust the timing. The non-contact system is installed in the same way, with the exception of checking the gap in the contact group due to its absence.

Instructions for replacing the timing chain in a VAZ 2107 car are presented here: https://vazweb.ru/desyatka/dvigatel/zamena-tsepi-grm-na-vaz-2107.html

The mark on the camshaft gear is aligned with the boss on the body

Important point. In most cases, the ignition is set without removing the valve cover, which is why the position of the mark on the gear is not visible. You have done everything according to the instructions, but the engine does not start. This means that a spark is supplied to the 4th cylinder during the exhaust stroke, and compression at this moment occurs in the first cylinder. The problem can be solved simply:

- remove the distributor cover;

- unscrew the nut securing it;

- pull the distributor out of the socket, turn the slider exactly 180° and insert the element back;

- Press the distributor skirt with the nut and install the cover.

Advice. If the engine does not start after these steps, but begins to show signs of life, then the problem lies not in the ignition setting, but in a malfunction of one of the system elements.

Photo instructions for setting up

Video about correct ignition installation

Advantages

That's what, and with positive qualities, domestic engines constantly have problems. But despite this, the advantages of such engines still exist, which is why they are used in cars even today. The main positive qualities are the following:

- Repairing a VAZ 2107 engine is very simple. Its design features mean that even capitalizing the engine will not be difficult. The cylinder walls are thick enough to allow the engine to be bored more than once.

- Easy to maintain. The simplest design of the motor means that it can be repaired from almost any breakdown without much difficulty. Owners of such cars carry with them only a minimum set of tools.

- The engine speed of the VAZ 2107 is distributed in such a way that the car with it under the hood is quite high-torque.

- Engine life is its main advantage. In practice, such engines can travel more than 200 thousand kilometers without the need for major repairs. Only in order to achieve such indicators is it necessary to properly maintain the power unit.

Brake system

| Service brake system: | ||||

| front wheel brake | disc, with two-piston caliper | |||

| rear wheel brake | drum, with one working cylinder and two pistons | |||

| Service brake system drive | foot, hydraulic, dual-circuit, with a vacuum booster, rear wheel brake pressure regulator and low brake fluid level sensor | |||

| Parking brake | with manual cable drive on the brake pads of the rear wheels | |||

Problems

Cars with such engines under the hood have enough problems with frequent breakdowns. We must not forget that the engine was designed by Soviet engineers, so its vulnerabilities outnumber its positive qualities. The most common engine breakdowns are as follows:

- It often happens that the VAZ 2107 engine fails. This is a common breakdown that is associated with the fact that the batteries fail. Here it is worth paying attention not only to the ignition and its components, but also to look at the fuel pump.

- The power of the VAZ 2107 engine may drop significantly, and this is very noticeable, since the car stops accelerating normally. This is the first sign that the valves need to be adjusted, since there are no hydraulic compensators in the system.

- Often you have to add oil to the VAZ 2107 engine. Here everything looks much sadder, since this is a signal that the engine is gradually coming to an end. It is worth preparing mentally and financially for the fact that you will have to do major repairs.

- The temperature of the VAZ 2107 engine may not reach operating parameters or the car begins to quickly overheat. Everything is simple here - as a rule, the reason for this phenomenon is that the thermostat gets stuck in a large or small circle, respectively.

Switch

The last element in the circuit, the presence of which is required by a contactless electronic ignition system, is a switch. The ideal place in which it can be installed in a VAZ 2107 is between the washer reservoir and the left headlight. There is a flat area on which we will install the switch, with the radiator facing the body. Having leaned the switch, we mark the places for drilling holes in the body, through which we fasten it with self-tapping screws; in this case, you need to screw the black (neutral) wire from the connection block under one of the screws.

Maintenance

In order to get trouble-free operation, as well as to guarantee that the engine will work for as long as possible, you need to properly maintain it. Fortunately, this is quite simple to do, since maintenance can be carried out even in the garage. Many people wonder how much oil is in the VAZ 2107 engine, and the answer is quite simple - the block is designed for 3.75 liters, but during replacement you need to fill in 3.5.

The valves on such an engine need to be adjusted every 10 thousand kilometers. But as practice shows, owners of cars with such a power unit under the hood only do this when the car stops moving. The gasoline filter needs to be changed every 15 thousand kilometers. The chain is tensioned every 40 thousand kilometers and must be replaced after 100 thousand kilometers.