Purpose of VAZ-2110 generator bearings

First, let's look at the purpose of the devices; there is nothing complicated about it. Bearings of the VAZ 2110 generator are used to ensure smooth and uniform rotation of the rotor of the unit. The "ten" generator sets use two bearing devices - front and rear, they are located under protective covers. To get to the devices, you will need to remove the assembly and remove the covers.

Front and rear bearings of the VAZ 2110 generator

Expert opinion

Nikolay Gray

More than 5 years of experience Specialization: body repair, customization, preparation for painting, detailing

The purpose of generator bearings is very simple: to ensure smooth and uniform rotation of the generator rotor. Both bearings: front and rear are under protective covers. And you can get to them only after dismantling the generator and removing the protective elements.

When is it necessary to change?

If a car generator begins to creak and howl during operation, this is the main sign that the bearings need to be urgently replaced. Howling, as a rule, occurs due to the lack of lubrication in the separators of these parts. Alternatively, the bearing cage may simply fail due to wear or fatigue stress.

There is one nuance here that should definitely be mentioned. Sometimes on a VAZ 2110, what is heard from the generator area is not a howl, but a thin, barely audible creak, which the car owner can mistake for the creak of a failed bearing. But most often it’s the pump creaking or the sound coming from the pulley on the timing belt. To understand that it is the generator bearing that is creaking, you should remove the belt. If the sound does not disappear, then the problem is in the bearings.

Replacing a VAZ 2110 generator bearing with your own hands is an operation that should be performed by every average motorist independently, since a car service center will charge from 2,000 rubles for such a service.

A generator is a device for renewing energy in a car, converting mechanical energy into electrical energy. On VAZs, generators require increased attention during operation. Problematic elements of the mechanism: terminals, stator winding, brushes, pulley, armature, as well as bearings.

The design of the VAZ 2110 (2114, 2112, 2111, 2115) generator has two bearings - rear and front, wear of which occurs in case of long-term use of the car, as well as when exposed to internal and external factors.

Some novice motorists are sure that the source of energy in a car is exclusively the battery. But this is not so. The battery's job is to supply the necessary current to start the engine and provide power to the starter so that it turns the crankshaft.

The engine starts, and at this moment the electrical equipment begins to be powered by the generator. The quality of operation of electrically dependent equipment and timely recharging of the battery depend on the generator. If the generator breaks down, the entire load goes to the battery. Once it runs out of power, the entire car will be left without power.

In almost 90% of cases, generator failure is associated with its bearings. That’s why we’ll talk about them in more detail today.

Element appearance

What are VAZ-2110 generator bearings

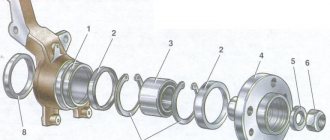

The parts consist of two – front and rear, respectively – metal rings with a relief surface and a small hole diameter (see photo below). Their purpose is to ensure uniform and smooth rotation of the generator rotor. Each bearing is located under a special sealed cover - thus, it is not possible to get to them without removing the generator itself and the covers.

Generators on the “tens” are always equipped with closed-type single-row ball bearings with a double-sided seal:

- front marking – 6202 2RS (in domestic catalogs under number 180202);

- rear bearing - 6103 2RS (aka - 24940220).

The first sign that the bearings are clearly not functioning as they should is a sharp, unpleasant sound, similar to a howl, that comes from the generator when you turn on the car's ignition. This will mean that there is no longer any lubrication in the bearing cages, which means that wear is tens of times greater due to the interaction of several hard, non-lubricated surfaces.

Important! It is necessary to distinguish between problems associated with the generator and failures of other spare parts. So, for example, if instead of a howl in a VAZ-2110 you hear a sound similar to a grinding sound, this is either a pump or a pulley on the timing belt. Of course, it’s always worth checking once again what exactly the problem is, because the likelihood that a failed bearing is to blame, although small in this case, does exist. To do this, you need to remove the belt and start the car again to see if the annoying sound goes away.

- the appearance of an uncharacteristic hum and whistle after starting the engine;

- the battery has become unstable in charging, this is due to problems in the operation of the shaft;

- turning the pulley;

- overheating of devices as a result of friction of worn elements.

Worn and new bearings for the “ten”

If these symptoms appear, it is quite possible that the cause lies precisely in the bearing device.

If you have suspicions regarding the performance of this part, we recommend that you perform a simple check of the devices by performing the following steps:

- First of all, the belt must be removed from the assembly pulley.

- Then the car engine starts.

- If, after startup, the hum and whistle, as well as other symptoms of a malfunction, disappear, this indicates the need to replace the device.

For what reasons could this part fail:

- Some components of the structure have worn out as a result of long-term use. In particular, we can talk about the surfaces of the raceways, the rolling elements themselves, the separator, and the sealing component.

- The bearing device has run out of lubricant; this may be due to leakage.

- Wear of devices, as well as low accuracy of the manufactured product, can lead to rotation of the outer race on the housing or the inner race on the shaft of the rotor itself.

- Also, malfunctions in the operation of parts can be caused by abrasive elements getting inside the device. This problem leads to increased squeaking.

- Perhaps the failure of the bearing is due to the fact that it has simply exhausted its service life.

- Another possible reason is an imbalance of the pulley itself or wear of the strap (the author of the video is Anton Volokhovich).

Signs that indicate that the VAZ 2110 generator bearings are faulty:

- Whistle, hum when the rotor rotates in the generator;

- Instability of battery charging due to problems with shaft rotation;

- The pulley turns;

- Intense heating due to friction of worn parts;

- See the generator noise in the video.

Noise from the front bearing of the VAZ 2110 generator

If the listed symptoms appear and you suspect that the bearing is faulty, then carry out a simple diagnosis:

- Remove the belt from the pulley;

- Start the car;

- If the whistle, hum, and other signs disappear, this means that a new generator bearing needs to be installed.

- Next, we move on to repairing the VAZ generator.

- Watch how to check the node yourself in the video.

How to check the bearings of a VAZ generator

Reasons why a bearing fails:

- Wear of rolling parts (raceways, rolling bodies, cage, seals).

- Insufficient quantity or leakage of lubricant.

- Rotation of the outer race in the housing or the inner race on the rotor shaft (due to low accuracy of the product or when parts are worn).

- If abrasive particles get inside the element, a squeak appears.

- Expiration of service life before failure.

- Pulley imbalance, belt fault.

- Rotating the pulley.

Before you start replacing the bearing, watch a detailed video of removing the generator and disassembling it.

How to remove and disassemble VAZ 2010 generators

The replacement process is divided into operations:

- Preparatory activities;

- Removal and further analysis of the mechanism;

- Dismantling of old parts;

- Repair and installation of new parts, replacement, assembly, installation, testing the functionality of the unit.

The detail of the unit is presented in two diagrams, assembled and disassembled.

To install the bearings, prepare a set of tools:

- Heads with ratchet, keys (27, 13, 10, 8, and for 17 - preferably two);

- Minus, Phillips screwdrivers;

- Vise;

- Hammer;

- Pliers;

- Two-pin puller with claws;

- WD-40 liquid and marker.

Next, place the car in a place with good lighting above the hood to remove the mechanism without difficulty, open the hood, find the belt on the pulleys, as well as the terminals. Now we move on to removing the generator and dismantling the bearing.

- First, disconnect the negative terminal of the battery, then the terminals of the device itself. To do this, you need to unscrew the fastenings of these terminals.

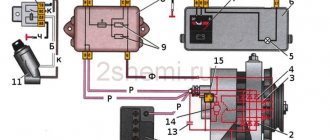

- Study the fastener diagram to begin dismantling the mechanism.

- Next, remove the crankcase protection, then climb under the car. Next, unscrew the fasteners that secure the generator to the frame (positions 5, 2 in the diagram). The process is shown in detail in the photo.

- We hold the mechanism with our hands when unscrewing the last fastener.

- We take out the unit, remove the dirt, and wipe it with a rag. Lubricate the threaded connections with WD-40.

- Now we move on to removing the protective plastic back cover on the generator; we do this carefully with a screwdriver.

- We unscrew the fastenings of the brush holders and the voltage regulator with a Phillips screwdriver. The sequence is shown in the photo.

- After this, remove the pulley from the axle and clamp the product in a vice.

- Using an adjustable or other wrench, unscrew the nut on the pulley so that the shaft does not rotate; insert the hexagon into a special groove at the end.

- Now we remove the washer and disassemble the unit body by unscrewing the corresponding bolts; before doing this, be sure to mark the positions of the body halves with a marker. The entire disassembly process is shown in the photographs.

- We remove the plastic casing and the front ball bearing, gaining access to the armature.

- Now we press the rear bearing of the generator from the armature in two ways:

- Using a two-jaw puller;

- Without a removable device, using two 19mm open-end wrenches (watch the video on how to remove a generator bearing without a puller).

How to remove a bearing from a generator armature without a puller

- Next, we press the rolling element out of the cover of the generating unit.

- We knock it out with a hammer with a mandrel to fit the outer size of the ball bearing (see dimensions below), a 27 socket head is also suitable.

- Before installing a new bearing in the VAZ 2110 generator, you should wipe the seating surfaces (rotor, housing cover hole) with a rag.

- Next, carefully remove the seal and add thick lubricant to the ball bearing, for example Litol.

- Let's start pressing the rear bearing onto the shaft. To do this, secure the assembly in a vice, place the new part on the shaft, and use a pipe and a hammer to press the part onto the rotor. The force is applied strictly to the inner race.

- We press the front bearing into the front cover of the generator using the old rolling element or a 27-inch head. We insert the new product into the hole evenly, without distortions, place the old element on top, then hammer the part into the hole. We apply force only to the outer ring.

- After replacing the bearings, reassemble the mechanism in the reverse order and install it back on the car. Watch the video for assembly procedure.

- This completes the replacement. Don't forget to read the tips and tricks at the end of the article.

Replacing a VAZ generator bearing

To the question: “What bearings are on the VAZ 2110 generator?” you can answer knowing the following characteristics of the car:

- What year is the car?

- 16 valves?

- Injector?

- Front or rear bearing?

In the “Ten” generator of a late production year, components of a different standard size and marking are installed, since the diameter of the rotor axis is different.

Bearing by number in GOST (front and rear):

- 6-180302 and 6-202 (according to ISO: 6302-2RS, 6202-2RS) - late models;

- 6-180303 and 6-203 (according to ISO: 6303-2RS, 6203-2RS) are new models.

To accurately determine the markings of parts, before buying bearings you should take measurements of the overall dimensions of the products, measure the rotor, and compare the data obtained in the table.

A generator for a car, of course, is not the “heart”, it is considered the engine, but without a generator you can’t go far - you can only get there. Driving without music is nothing, but without lighting, side lights and battery recharging, it’s bad. Once you start the engine, the generator is responsible for powering all electrical appliances.

The weakest point of a generator is often the bearings. They have quite a heavy load on them. If you hear an unusual noise when the engine is running, which increases as you increase speed, you can safely assume that the generator bearing has failed. Make sure that the source of the problem is the bearing, perhaps even in an open field.

If you hear creaking and howling while the generator is running, then you have discovered the main sign of bearing failure. The only correct solution is replacement.

Creaking and howling occur due to the fact that the bearing separators lose lubrication, they wear out, and are destroyed as a result of prolonged use under heavy loads.

Sometimes a thin creaking sound can be heard from the generator, which is often confused with bearing failure. In fact, it could be the timing belt pulley or the water pump. Because to make sure, just remove the belt. If the sound remains, then the culprit is the bearing.

What to use

Generator bearing replacement process

General view of the front and rear bearing of the generator

Existing play indicates that the bearing has indeed failed.

So, let's consider the step-by-step process of replacing a product with a VAZ-2112.

- We place the car on a pit or overpass. The main thing is that there is access from below.

- We dismantle the “minus terminal”.

- Remove the generator belt.

Pull the alternator belt through the slot

- To further carry out the work, you will need to dismantle the generator itself.

- Disconnect the appropriate wires to the generator.

Disconnect all wires that go to the generator

- Loosen the nut that holds the tension bolt.

- Remove the adjusting bolt.

Unscrew and remove the generator adjusting bolt

- Remove the lower engine protection.

We dismantle the engine protection

- Unscrew the 2 lower mounting bolts.

- We are dismantling the generator. It comes out through the bottom.

We unscrew the fastenings and dismantle the generator

- When the generator is in your hands, you can put it on the table. Now, you can proceed directly to the repair.

- Having blocked the rotor from turning, remove the pulley.

- We dismantle the casing. To do this, you need to pull back the latches.

Block the rotor and unscrew the pulley

- Remove the front and back covers.

Generator disassembly diagram

- Now feel free to move on directly to replacing the bearing.

Using a hammer, knock out the rotor from the cover along with the bearing

- The product can be dismantled using a special puller, or simply by knocking it out of its seat.

- Installation is carried out in reverse order.

Replacing bearings

- We clean the load-bearing elements well.

Disassembled generator

- Apply sealant to the seat.

Applying sealant

- We press in new bearings.

One bearing is pressed in

- The most difficult part is to press in the inner bearing. First we remove it. There is a puller, but if it is not available, then we use a regular key.

Removing a bearing without using a puller

- We put on a new one.

New bearing ready for use

Next, we assemble the generator and install it back!

What bearings are on the VAZ-2112 generator?

The choice of bearing should be taken seriously, since the stable voltage in the on-board network, as well as the wear of the generator itself, depends on this part.

Since there are 2 bearings in the unit - front and rear, each of them has its own markings and dimensions.

So, the front ones are marked - 6302 or 6303, but the rear ones - 6202 or 6203.

Generator front and rear bearings

Since there are many fakes on the automotive spare parts market , especially with regard to bearings, when choosing, you should pay special attention to the production of this product. The wear of many other parts of the generator will depend on the quality. Therefore, it is recommended to check the availability of a quality certificate, as well as the presence of markings and holograms.

Original

6303-10B is the original catalog number of the generator bearing for the 10 series of Lada cars produced by AvtoVAZ. The average cost of a product is up to 150 rubles .

Analogs

Not original bearings, strip, and plug. Vologda bearings VBF

In addition to the original, you can buy a substitute product. Of course, now bearings can be selected depending on the size or number, but manufacturers of analogues still decided to produce high-quality products for cars.

| Manufacturer's name | Catalog number | Price |

| F.A.G. | 6303 | 450 |

| Nachi | 6203ZZ | 150 |

| NTN | 6203ZZ | 180 |

| Koyo | 6303C3 | 200 |

| SNR | 6203.ZZ | 400 |

Reasons for failure

There are several reasons for generator bearing failure:

- Wear . Like any part, the generator bearing fails during operation.

- Violation of the rules of operation and maintenance will lead to the product failure.

- External factors such as dirt, salt and road chemicals lead to the part being subject to increased wear.

- Poor quality can cause premature failure.

- Lack of lubrication. The grease may have dried out over time.

The lubricant is almost invisible

We recommend: Independent replacement of the VAZ 2114/15 heater radiator: how to carry out the procedure in different ways

Replacing the rear and front bearings of the VAZ 2110 generator (2114, 2112, 2111, 2115)

Bearings in generators of VAZ 2110 cars are closed type, ball, single row, have a double-sided seal.

- The front marking is 6202 2RS (in domestic catalogs under number 180202).

- Rear bearing - 6103 2RS (aka - 24940220).

You can also find hubs on the market from 23 GPP (this is Vologda) and 3 GPP (this is Saratov). It is strictly not recommended to buy bearings on which the hubs are not marked. You also cannot buy Chinese generator bearings, which are now found everywhere, since the quality of these bearings does not stand up to criticism.

Initially, in the design of the 2110 generator, as mentioned above, two bearing devices are usually installed. In older versions of the car, parts marked 6302 or 6303 (these are front units), or 6202 (rear units) are used; in more modern versions, 6203 bearings are installed at the rear.

As for the sizes, they are as follows:

- for 6303 (or the domestic analogue under number 180302) the dimensions are 17*47*14;

- for marking 6302 (or domestic analogue 180303) - 15*42*13;

- for marking 6202 (Russian parts are marked as 180202) the dimensions are 15*35*11;

- for 6203 (domestic equivalent - 180203) dimensions - 17*40*12.

What types of bearings are in the top ten: part numbers and sizes

Bearings in generators of VAZ 2110 cars are closed type, ball, single row, have a double-sided seal.

- The front marking is 6202 2RS (in domestic catalogs under number 180202).

- Rear bearing - 6103 2RS (aka - 24940220).

An important point: when choosing bearings, you should pay special attention to the manufacturers of their hubs. Typically, VAZ 2110 bearing hubs are produced in Samara, their marking is SP3-4.

You can also find hubs on the market from 23 GPP (this is Vologda) and 3 GPP (this is Saratov). It is strictly not recommended to buy bearings on which the hubs are not marked. You also cannot buy Chinese generator bearings, which are now found everywhere, since the quality of these bearings does not stand up to criticism.

Necessary tools and sequence of actions for replacement

To independently dismantle old bearings and replace them with new similar parts, you will need to stock up on the following tools:

- open-end wrenches (set);

- flat blade screwdriver (size – medium);

- device for safely removing the generator pulley;

- vice;

- hammer.

Having taken everything you need and driven the car into the garage, you can begin. The sequence of actions when replacing bearings will be as follows:

- The positive terminal of the battery is removed.

- The timing belt is removed by alternately unscrewing the fastening nut and fixing bolt using open-end wrenches.

- All wires connected to it are unscrewed from the generator, the generator itself is removed from the fasteners and taken out.

- Using a vice, a wrench and a puller, the pulley is unscrewed and removed.

- Remove the generator cover where the front bearing is located. It is removed using a mandrel, the diameter of which will be approximately equal to the outer ring of the bearing itself and the hammer. A new one is immediately installed in place of the old bearing.

- Next, the rear bearing is removed by first dismantling the stator. Removal from the pulley is carried out in the same way, using a special device. Installation of a new rear bearing is carried out either under a hydraulic press or any alternative method that will avoid damaging the thread surface from possible damage.

- Generator bearing set (front and rear).

- Set of open-end wrenches.

- Flat blade screwdriver (medium size).

- Hammer.

- Vise.

- Puller for generator pulley.

Video “More visual replacement instructions”

You can replace the generator bearing either at a car service station or in a garage. The only condition for replacing it yourself is that you must have a vice, as well as a special puller for dismantling. From the tool kit, you will need a standard mechanic's tool, including screwdrivers, wrenches and a hammer (the author of the video about replacement in garage conditions is the Expert R channel).

- First you need to disconnect the battery and remove the timing belt. To do this, use a 13 wrench to unscrew the fastening nut, and then, using a 10 wrench, loosen the tensioner; the fastening screw itself must be unscrewed.

- You need to disconnect all the wires from the generator device, after which you need to unscrew the lower clamp using a 13mm wrench, remove the screws, and dismantle the assembly itself.

- After removal, we proceed to disassemble the mechanism. First, unscrew the pulley, for this you use a 24mm wrench, at this stage you may need a vice. To remove the pulley from the axle, you must use a puller.

- After removing this element, the brush assembly, control device, capacitor, and diode rectifier are dismantled. All these components are located under a plastic cover. To disassemble, you will need to unscrew the four mounting bolts; they are used to secure the second part of the case. These bolts are typically welded and can be difficult to remove, so spray them with WD-40 and wait a few minutes before removing them.

- When the bolts are unscrewed, the front cover of the device can be removed - the front bearing is installed in this cover. To remove this device, you will have to use a special mandrel, and its diameter should be slightly smaller than the diameter of the outer ring. Alternatively, you can use a piece of pipe. The mandrel is mounted directly onto the ring, after which a hammer will be used to knock out the bearing part.

- When the device is removed, a new part is mounted in its place, then it is pressed into the cover, for this a mandrel with a hammer is also used.

- After completing these steps, the rear bearing is replaced; to do this, it is necessary to dismantle the stator. After removal, the plastic support of the part is pushed out and removed from the rotor. Only by doing this will you gain access to the bearing.

- The procedure for dismantling the device is carried out with a puller; when the part is dismantled, a new bearing is installed. Only in this case, the diameter of the mandrel must correspond to the size of the inner ring. When installing, try not to damage the ring itself; also during installation, keep in mind that under no circumstances should you clamp the rotor in a vice. This is because the rear part of the rotor is quite soft; therefore, when it is installed in a vice, scuffing may occur. And they, in turn, will not allow you to assemble the unit correctly.

- It is best to use a hydraulic pump to mount the part, but if it is not available, then the rotor should be placed on a wooden surface during installation. It is necessary to screw any nut directly onto the thread itself on which the pulley is installed; this will make it possible to further protect the thread from possible damage.

- When the bearing element is pressed into the structure, you can begin assembling the unit. The assembly procedure is carried out in reverse order.

Price issue

The cost of devices varies depending on the manufacturer. On average, prices for bearings vary around 70-150 rubles.

The video below provides more detailed and visual instructions for repairing a generator set and replacing bearings (the author of the video is Ivan Kirillov).

Instructions for removing the unit and replacing bearings

The generator bearing is replaced if symptoms of a malfunction are detected, if diagnostics have shown that this device has failed. Before we tell you how to remove the bearing, it should be noted that this will require completely dismantling the generator assembly and disassembling it to get to the worn parts. For dismantling, you will need a special tool - a generator bearing puller; it can be purchased at any auto store.

How to perform a replacement in a garage:

- First you need to turn off the engine, turn off the ignition, open the hood and disconnect the terminals of the car battery.

- Next, using a wrench of the appropriate size, you need to loosen the nuts that secure the strap tensioner, after which the belt itself can be removed.

- The next step will be to dismantle the strap and tension the strap. Disconnect the wiring, remove the fastening, after which the assembly can be completely removed.

- Having completed these steps, you can begin to disassemble the generator unit housing. First of all, to do this, you need to remove the back plastic cover; it is fixed with three special clips.

- After removing the cover, you need to dismantle the brush assembly; it is removed together with the voltage regulator relay. Along the way, evaluate the condition of all components and parts of the generator unit, and if necessary, replace failed or worn parts.

- Next, dismantle the diode bridge; it is secured with three bolts, as well as the power terminal stud. Unscrew the bolts themselves, as well as the nut, usually a 10mm wrench is used for this.

- Now inspect the rear aluminum cover, there are three bolts on it. Unscrew them, then remove the cover, as well as the winding of the stator mechanism.

- The next step will be to disassemble the front of the generator assembly. The rotor mechanism should be carefully clamped in a vice or fixed with improvised means if there is no vice. When the rotor is fixed, the nut that secures the pulley is unscrewed, after which the pulley itself can be removed.

- Now, using a hammer and tapping it, you need to remove the front cover with the bearing device from the seat. All you have to do is, using a puller, dismantle the part and replace it with a new one.

Photo gallery “Do it yourself replacement”

1. Analysis of the device fixed in a vice

2. Analysis of the rotor mechanism

3. Dismantling the bearing part with a puller

Loading...

Choosing a generator bearing for a VAZ-2110 car

Structurally, a conventional generator has two bearings - front and rear. The front one, as usual, is more powerful, since it remains under a relatively large load, which arises due to the influence of the tension of the generator belt. The integrity of the bearings should be checked by external inspection. Cracks in the clips, the presence of rust or metal chipping, etc. are unacceptable.

The next step is to check the ease of rotation, the presence of play or extraneous noise. It is recommended to replace the front bearing together with the cover, since it is rolled into the generator cover, but it is cheaper, if the cost of repairs matters, to press it out and replace it separately from the cover. If you decide to carry out the repairs yourself, without resorting to the services of a specialist, this will allow you to save some money. You will only need to spend money on purchasing bearings.

KATEK generators are routinely installed on dozens of them. With the digital designation 5102.3771 or 94.3701, the power of both is 80 amperes, voltage is 14 volts. Answer the question “What bearings are on the VAZ-2110 generator?” you can do this: if it is a standard KATEK generator, then this generator most often has two bearings. These are the front 6302 in older versions, or 6303, and the rear 6202, or, accordingly, in a more modern version 6203.

The dimensions of the front bearing (6303) are 17×47×14, the dimensions of the bearing (6302) are 15×42×13. Their domestic “twins” are designated as 180302 and, accordingly, 180303 and are called 303 closed, or 302 closed.

The dimensions of the rear bearing (6202) are 15×35×11, those of the bearing (6203) are 17×40×12. Domestic analogues are designated as 180202 and 180203.

Selection and search of bearings for a car generator

Many motorists operating older cars with mileage of more than 100,000 km have probably encountered the need for repair or scheduled maintenance of the generator. And, as is known, bearings are subject to the greatest wear in the entire generator structure. Diagnosing generator bearing failure is often not at all difficult. If an extraneous hum appears during engine operation, increasing as the number of revolutions increases, then one of the sources of its origin may be the generator bearing. For a more accurate diagnosis, it is necessary to loosen the generator belt tensioner, then remove the belt and release the generator pulley. Next, we start the engine and, if the hum disappears, then the reason is clear. The generator bearing needs to be replaced. Replacing generator bearings is a labor-intensive, but moderately complex technical operation. Therefore, many motorists carry out repairs and maintenance of the generator themselves, without resorting to the services of auto repair shops. This solution has both pros and cons. The main advantage is that replacing the generator bearings yourself allows you to save a certain amount of money. Of all the costs, only the cost of purchasing bearings will fall on the shoulders of the car enthusiast. The disadvantages include the fact that when carrying out the work you will certainly need a special tool, for example a hydraulic press and various pullers, without which you will have to work hard and be smart. Another important point is the correct choice of bearing for the generator. And DAS LAGER specialists will help you understand this difficult issue.

The most convenient option would be to perform the work in the following sequence:

- Remove the generator from the car;

- Unscrew all fasteners, disconnecting the stator, rotor, diode bridge, etc.

- Remove the front and rear generator bearings;

- Identify bearings by the markings on them. If the markings have not been preserved, then perform identification by taking the installation dimensions;

- Purchase the necessary bearings from a trusted supplier;

- Install new bearings into the seats and assemble the generator in the recommended order.

And if the process of disassembling and assembling the generator does not raise any special questions, then choosing the right bearing is not so easy. Below we present the most common bearing options used in generators of various automobile brands. So, the design of a standard generator includes two bearings - front and rear. The front bearing of the generator is usually more powerful. This is due to the fact that the front bearing bears the entire main load. This load appears due to the action of a tense drive belt on the generator pulley. The pulley transfers the load to the shaft, and the shaft, in turn, acts on the bearing. Different manufacturers use different bearings when producing generators. We have identified the most popular ones from the total number. The following bearings are often installed in Russian generator models:

6302-2RS

has dimensions

15x42x13.

Its domestic analogue is designated as 180302 or simply called 302nd closed.

This bearing is used as a front bearing on older generators. One of the places where it is installed is the generators of VAZ2110 and VAZ2112 cars. 6303-2RS

has dimensions

17x47x14

.

Its domestic analogue is designated as 180303 or simply called 303rd closed. This bearing is used as a front bearing on newer generators. One of the places where it is installed is the generators of VAZ2110 and VAZ2112 cars. 6202-2RS

has dimensions

15x35x11

.

Its domestic analogue is designated as 180202 or simply called 202nd closed. This bearing is used as a rear bearing on newer generators. One of the places where it is installed is the generators of VAZ2110 and VAZ2112 cars. 6203-2RS

has dimensions

17x40x12

.

Its domestic analogue is designated as 180203 or simply called 203rd closed. This bearing is used as a rear bearing on newer generators. One of the places where it is installed is the generators of VAZ2110 and VAZ2112 cars. 6003-2RS

has dimensions

17x35x10

.

Its domestic analogue is designated as 180103 or simply called the 103rd closed. This bearing is used as the rear bearing of the generator. One of the places where it is installed is the generators of VAZ2110 and VAZ2112 cars. 62202-2RS

has dimensions

15x35x14

. Its domestic analogue is designated as 180502 or simply called 502nd closed. This bearing is used as the rear bearing of the generator. One of the places where it is installed is the generators of VAZ2110 VAZ2112 VAZ2115 cars.

BOSCH generators are common on imported cars. The bearings in them vary depending on the characteristics of the generator itself. For example, in the widespread Bosch 14V 53-98A 0124 415 038 generator (installed on many economy class foreign cars) bearings 6003-2RS (rear) and 6303-2RS (front) are used. This pair of bearings is found in many imported generators. There are also variations where the rear bearing is designated 6000-2RS, and the front bearing 6203-2RS. Experts are unanimous in their opinion that when replacing generator bearings, it is necessary to choose high-quality imported bearings. The best option would be a bearing from DAS LAGER Germany

. These bearings will work for a long time and are reasonably priced. If there is any difficulty in selecting the right bearing, then feel free to call our managers - they will definitely help.

Imported or domestic

Belarusian 90-amp BATE and Japanese Denso generators have bearings of the same size.

Most 80-amp generators have bearings of similar sizes, at least this applies to domestic ones. If the generator has already been replaced before you, then you may be faced with the fact that a generator from a different manufacturer is installed and the bearings are of different sizes. Depending on the generator manufacturer, bearings of other sizes are sometimes found, for example, in the fairly common Bosch 14V 53-98A 0124 415 038 generator, bearings 6003-2RS (rear) are installed, the dimensions of which are 17 × 35 × 10 and 6303-2RS (front) , respectively, 15×35×14.

In order to accurately determine the dimensions of the bearing, it will have to be removed. If the markings on the bearing are not visible, then it is best to turn to professionals (you should not trust a caliper).

If you have decided on the size of the bearing, then to the repeated question “What bearings are on the VAZ-2110?” The answer suggests itself - original!

The quality of bearings varies from manufacturer to manufacturer; some prefer to install bearings from domestic manufacturers on their generators, while others prefer imported ones. When repairing a generator, everyone decides this issue for themselves, but after listening to numerous tips, some car enthusiasts are inclined to choose imported ones.

If you focus on price-quality ratio, many experts recommend DAS LAGER Germany. But there are other suppliers of quality bearings: the French company SNR; FAG is one of the leading companies in Germany; NSK is another major bearing manufacturer from Japan; NTN – Japan; Kouo - part of the Toyota concern of Japan; Kraft or BOSCH.

We also supply bearings from Chinese manufacturers, but the attitude of motorists towards generators and bearings from the Middle Kingdom is far from flattering. A bearing is considered original if it is approved by the vehicle manufacturer for sale on the market. It usually corresponds to what is (or was previously) supplied to the assembly line. The car manufacturer guarantees that these bearings will not let you down.

If you are considering various options, then all the bearings with the corresponding markings at first glance look the same, but after opening the package, you need to pay attention to the marking, which, in addition to the designation of the bearing itself, consisting of digital and letter designations, must contain an indication of the manufacturer and necessarily the country of origin.