Despite the variety of power plants of the VAZ 2110 (from carburetor ones, inherited from the V8, to limited versions with an Opel 150 l/s engine), we will focus on the more modern 8 and 16 valves with a volume of 1.6 liters. Questions about diagnosing and replacing the mass air flow sensor on a VAZ 2110 most often concern these particular internal combustion engines.

The German concern BOSCH produces several variants of flow meters for engines of this VAZ family: 0280218004, 0280218037 and 0280218116. The first option is practically not used, it can be easily replaced with a product with index 037. The only difference is in the design of the air measuring channel: on the new one (037) version, it is devoid of a childhood disease: uneven air intake for measurement.

The third option (116) is used on 16 valve VAZ 2110 equipped with a modern BOSCH-M7.9.7 or January 7 series controller.

Externally, these mass air flow sensors for the VAZ 2110 are practically the same, but installing 0280218116 instead of 0280218037 is not allowed, since the flow meters have different calibrations of the sensor readings relative to the air flow.

Therefore, owners of a VAZ 2110 with an 8-valve engine should install BOSCH 0280218037, and for 16-valve engines - BOSCH 0280218116. It is not necessary to look for products from a German manufacturer; for those who want to save money, there are analogues, including from Russian companies. Many of them actually produce only a housing with a measuring channel into which a set of sensors and a control board of the original Bosch are installed.

Information about the operation and design of the mass air flow sensor

Again, we will not consider the historically outdated mechanical options with a weather vane and the General Motors frequency flow meter, which was used in conjunction with the January 4-series ECU. Modern flow meters for the VAZ 10 series operate on the principle of a hot-wire anemometer.

It is based on the properties of some metals to significantly change resistance depending on heat (the MAF sensor uses an alloy of iridium with platinum, which causes the high cost of the device). There are two resistors in the air flow: one is precision, the second can change the resistance using heat. Voltage is applied to it, the thread is heated until it matches the standard. Depending on the strength of the air flow, the thread cools and the resistance changes. By increasing the voltage across the resistor, the temperature and, accordingly, the resistance are restored. This happens in real time, that is, the control of the air mass is constant. At the output, the mass air flow sensor displays the signal voltage with an accuracy of hundredths of a volt. The received information is processed by the ECU to accurately dose gasoline into the fuel-air mixture.

What happens if the flow meter breaks down? The engine will continue to operate, but in emergency mode. At idle speed without load, the speed will be set to 1500, power will be lost, and fuel consumption will increase. In some modes the motor may stall.

All elements are arranged into a single electronic model, which is placed in the measuring channel (air duct).

Symptoms of malfunction

There are several signs by which you can determine a malfunction of the mass air flow sensor:

- The check engine light comes on on the instrument panel;

- Fuel consumption increases noticeably;

- The car loses dynamics and power, failures occur when trying to increase engine speed;

- Difficulties arise when starting on a hot engine.

But what exactly causes these symptoms? The causes of sensor malfunction are as follows.

- The connector has lost contact.

- The air filter, grilles or sensor temperature detectors are dirty.

- Mechanical damage to sensor elements has occurred.

When the first signs of a malfunction occur, you should definitely check the mass air flow sensor, and then, depending on the situation, clean or replace the device.

Examination

Now let's talk about how to check our sensor. Today, two main methods of checking the mass air flow sensor are used.

- The engine is tested in operation with the mass air flow sensor disconnected. Simply turn off the power from the regulator and start the motor. When the mass air flow sensor is not present during startup, the electronic control unit turns on the power unit in emergency mode. The speed is adjusted to 1500 rpm. After disconnecting the sensor, drive a few kilometers and evaluate the dynamics and power. If the engine is running normally, then the sensor is the cause of the symptoms.

- The second method will require the use of a car tester or voltmeter. After starting the ignition, do not start the engine. The voltage threshold is set on the tester to 2V. The positive probe connects to the yellow wire on the sensor connector, and the black probe connects to the green wire. Next, refer to the table.

| Index | Air flow sensor condition |

| 0,99-1,02 | The sensor is functioning normally |

| 1,02-1,03 | Not ideal, but still acceptable voltage readings |

| 1,04-1,05 | Maximum permissible values that indicate imminent sensor failure |

| 1.05 or more | The air flow sensor has failed and needs to be replaced |

Prevention and testing of mass air flow sensor on VAZ 2110

As a preventive measure, we can recommend timely replacement of the air filter. The use of sports zeros shortens the life of the flow meter. In any case, regular cleaning of the air flow sensor will not hurt.

- We disconnect the sensor connector, having first removed the ground from the battery.

- Carefully unscrew the flow meter housing from the intake manifold flange.

- If dust deposits are detected, blow out the cavities with compressed air.

- Of course, you also need to clean the air duct and air filter box at the same time.

Tip: It is recommended to repeat this operation every time you replace the air filter.

If the contamination is severe (with oil and moisture), you can use a special cleaner for flow meters or carburetors; the manufacturer does not matter. To do this, it is necessary to direct the jet not only to visible sensors, but also to hidden cavities where the platinum resistor (thread) is located.

After this, the flow meter is installed in its regular place and the functionality of the electronic part is checked.

Replacing the air flow sensor

To replace the VAZ 2110 mass air flow sensor, you need a part suitable for this model (the new sensor must have the same markings as the old one). In terms of selection, there are three price categories:

- Chinese-made sensors (relatively inexpensive);

- mid-price sensors from the manufacturer AvtoVAZ and some foreign manufacturers;

- high-quality and reliable, but quite expensive imported sensors;

When choosing a new sensor, you should focus on both the price and the manufacturer (Siemens, Bosch, etc.). In any case, you can buy a VAZ mass air flow sensor at any auto supply store, taking into account financial capabilities and personal preferences.

We also recommend reading the article about what kind of oil to pour into a VAZ 2110 gearbox. From this article you will learn about the features of selecting a VAZ 2110 gearbox, how much oil is in a 2110 gearbox, and what you need to consider when choosing a lubricant.

Replacing the mass air flow sensor itself involves dismantling the old device and installing a new one. The procedure is quite simple, accessible to every car owner and can be done with your own hands. Before replacing the sensor, it is necessary to carry out a number of preparatory work:

- buy a mass air flow sensor with the same markings as on the body of the old sensor;

- prepare the necessary set of tools, screwdrivers of different sizes, wrenches or socket wrenches or wrenches with socket heads;

- multimeter (if necessary).

General procedure:

- Place the car on a level surface, lift the hood, remove the negative terminal from the battery;

- disconnect the mass air flow sensor connector;

- loosen the fastening screw of the corrugated hose with the mass air flow sensor housing;

- using a “10” wrench, disconnecting the hose, unscrew the two mounting bolts of the sensor with the air filter housing;

- Remove the old sensor housing and replace it with a new one, installing it in the reverse order of removal.

Please note that after the repair it is necessary to make a test drive to check the dynamics and power. You may also need to replace the air filter if the existing filter element is too dirty. It is also recommended to blow out the air filter housing with a compressor before assembly.

How to check the mass air flow sensor on a VAZ 2110 with a multimeter

Important! All disconnections and connections of connectors are made with the battery disconnected.

A. _ Checking the wiring harness and contacts. At this stage, the interaction between the ECU and the mass air flow sensor is tested. Performed with the connector removed and the ignition key in the “ON” position. You need to know the pinout of the sensor connector on the ECU side:

- Contact No. 1 is not involved in the test.

- Contact No. 2 - 12 volt power supply. A deviation of even 0.5 volts is not acceptable.

- Contact No. 3 - “ground”, mass.

- Contact No. 4 - 5 volt sensor power supply. Likewise: deviations are not allowed.

B. _ After making sure that the cable harness is intact and the ECU is working, we check the signal voltage on the connected flow meter. Turn the ignition key to the “ON” position and do not start the engine! We connect a digital multimeter to ground and contact No. 5 of the air flow sensor.

The multimeter is set to 2 volt measurement mode with an error of 1/100 volt. These readings accurately indicate the condition of the flow meter, so the accuracy class of the tester must be high.

If the device shows a voltage within 0.99-1.02 V, your flow meter is new or in excellent condition.

Readings from 1.03 to 1.05 volts are acceptable, but the air flow sensor will soon fail. You can still drive with such a sensor, but the quality of the fuel-air mixture will be far from ideal.

If there is no voltage or its level is above 1.05 V, the flow meter is faulty and requires replacement.

Advice: you should not skimp on replacing the mass air flow sensor. Excessive fuel consumption and increased engine wear will cover all the imaginary benefits.

Methods for checking sensor functionality

How to check the flow meter yourself? There are several diagnostic options, we suggest you familiarize yourself with each of them (the author of the video is the Bezdelnik TV channel).

Shutdown

First you need to try disconnecting the flow meter from the power supply. To do this, you need to start the engine and let it run for a while. Next, you will need to disconnect the plug from the flow meter - after this, the emergency mode of operation of the motor should be activated. In this case, the volume of required air flow will be calculated in accordance with the throttle position. If, after switching off, you notice that the engine began to work more correctly and at the same time it became more dynamic, then the mass air flow sensor definitely needs to be replaced.

Diagnostics using a multimeter

Diagnostics can be performed using a multimeter; for this we recommend that you read the operating instructions for the tester. The device must be configured in the DC voltage measurement mode; it is usually marked with the symbols DCV or V.

To ensure that connecting the device does not cause difficulties, you need to know exactly the pinout of the device:

- black-red or pink contact is a connection to the control module;

- green is ground (grounding, ground), connected to the body or battery;

- gray-white contact - output voltage;

- yellow - used to supply current to the input.

Diagnostics with a multimeter is performed as follows:

- To begin with, the tester should be turned on and the voltage value set on it to 20 volts, and then the probes from the device are connected to the corresponding contacts on the plug.

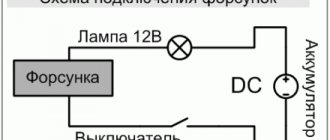

- To make the connection more convenient, you can use pins; you will need two of them. Each of them is installed in a hole with green and yellow contacts. Then you will need to connect the probes of the device to these pins.

- The next step is to activate the ignition and measure the voltage. Read more about the test results below (the author of the video is the IZO channel)))LENTA).

On a working device, the voltage level will be around 1.01-1.04. If the readings are between 1.02 and 1.05 volts, this indicates that the device will need to be changed in the near future. If the readings obtained are higher, then the flow meter must be replaced because it is faulty.

It should be noted that during operation, the voltage parameter will only increase, since the resistor components of the device wear out, and the resistance value, accordingly, decreases. You can also accurately determine the voltage using the on-board computer, if it has the appropriate function. To search, go to the flowmeter voltage section and find the U value.

Visual inspection

As for visual diagnostics, first of all it is necessary to check the condition of the corrugation in which the flow meter is installed, as well as the device itself. If, as a result of the check, you see traces of motor fluid or condensation, then it is possible that the device does not work for this reason. In some cases, cleaning the device from contaminants allows the flowmeter to resume operation and prevent possible replacement. It should be taken into account that contaminants usually accumulate as a result of infrequent replacement of the air filter element (the author of the video about the regulator malfunction is the channel In Sandro’s Garage).

If you notice traces of engine fluid, then there is a possibility that the reason lies in a clogged oil seal, or the problem may lie in exceeding the permissible level of lubricant in the crankcase. When cleaning is complete, you will need to make a visual inspection of the regulator - on the front of it you can see the rubber seal that is used for sealing. The seal is necessary to prevent uncleaned air flow and it may be that the rubber band moves a little - this will lead to the accumulation of dust on the flowmeter grid.

External signs of a malfunction of the VAZ 2110 mass air flow sensor

This is the third way to diagnose the sensor. To determine its serviceability, carefully inspect the internal cavities of the air pipe where the mass air flow sensor is mounted. In order to do this, you will need a shaped screwdriver. Loosen the clamp and disconnect the corrugated pipe. The surface of the corrugation should be as dry as possible, without an oil film.

It should be noted that the main signs of a malfunction of the mass air flow sensor are dirt on the working surface. It is formed due to the fact that the air filter was not replaced in time. Oil deposits will tell the driver that the oil level in the lubrication system is high or that the oil cutter is not working properly. With these signs, the sensor may still work, but will soon fail.

Next you need to completely remove the mass air flow sensor. You will find signs of a malfunction after a visual inspection of the device. To carry out this operation, you will need a 10mm wrench. Unscrew the two screws and remove the device from the air filter housing. A rubber seal will come out with the sensor. If the seal remains in the housing, this is the main sign of imminent failure.