09.25.2021 8 411 Cylinder block

Author: Victor

Many owners of Lada Priora, in the process of car maintenance and repair, independently replace the head gasket or grind valves. When performing such work, it is important to observe the sequence and tightening torque of the cylinder head on the Priora.

[Hide]

In what cases is it necessary to tighten the block?

During the operation of any car, including the VAZ 2170 Priora, the engine head is exposed to long-term cyclic effects of gases located in the engine cylinders. On older power units, the tightening of the cylinder head screws could weaken under such loads and periodically needed to be brought to a normal level. Today, all VAZ Priora engines use bolts made of special steel, which are tightened once for their entire service life.

If a coolant and oil leak occurs, there is no point in further tightening and tightening these bolts, since this will not improve the tightness of the joint. The only correct way to combat a leak is to remove the head, check the evenness of the mating surfaces and replace the gasket. After performing any repair work related to removing the head from the engine, it must be tightened in compliance with all necessary conditions.

The video from the author Alex ZW shows the process of installing the cylinder head on an 8-valve engine.

Features of tightening fasteners

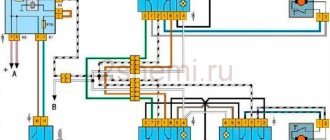

Even a non-professional can handle this work. It is important to follow two rules - the tightening torque and the sequence of working with fasteners. The tightening torque on engines with 8 and 16 valves is no different, while the sequence is different. Pay attention to the diagrams below; numbers indicate the order of tightening the bolts.

It is necessary to pay attention to the cylinder block:

- if during operation the bolts become loose due to vibration (the malfunction is detected by leakage of the gasket);

- after dismantling the cylinder head and installation;

- if the iron gasket is replaced;

- during tuning of the cylinder block.

Before work, take the instructions from your Priora to understand which engine is installed in the car.

Nuances of work

At different times, Lada Priora cars were equipped with engines with a displacement of 1.6 and 1.8 liters and a different number of valves in the heads - V8 (or 8V) and V16 (or 16V). The type of unit head determines the size of the bolts, the order of their installation and the tightening torque of the cylinder head on the Priora.

If the car has an 8-valve engine, then it can use head mounting bolts of different sizes:

- on old motors 21114, M12*1.25 hex head screws are used;

- on more modern 21116, which went into production approximately in mid-2011, M10*1.25 elements with an asterisk head are installed.

When installing a removed head, it is necessary to use new screws, since the old ones will be stretched and have internal damage.

Also, the engines use gaskets of different designs - combined on the old unit and all-iron on the new one. The procedure for tightening bolts for engines with metal and combined gaskets is absolutely identical.

The main nuances when performing work are checking the length of the fasteners, observing the sequence of tightening the screws and monitoring the tightening force. Violation of these conditions leads to damage to parts and the need for additional repair work. The procedure itself is not complicated and can be done independently in any convenient place - in a garage or in an open parking lot, with the exception of the case of installing the head on the engine, which is preferably installed indoors.

It is important to remember that tightening the bolts “by eye” without a torque wrench is unacceptable, since a uniform fit of the mating surfaces of the head and block will not be ensured.

Tools and materials

Before starting the tightening procedure, you should prepare everything necessary to perform:

- wrench with built-in dynamometer up to 100 H⋅m;

- a set of sockets and regular keys;

- Togh E14 key;

- calipers for measuring the remaining length of bolts;

- plate with a marked scale up to 180 degrees;

- new bolts.

A torque wrench is an important tool for DIY repairs.

Step-by-step instruction

Sequence of operation on an 8 valve engine:

- Wipe the cylinder head surfaces and dry the bolt holes in the engine block.

- Install the gasket on the block and align it along the guides.

- Mount the head on top and insert 10 M10 or M12 mounting bolts. If the owner decides to save money and keep the old screws, then they should have a length of no more than 135.5 mm.

- Tighten the elements according to the diagram. The tightening force should not exceed 20 N⋅m.

- Then you need to re-tighten the bolts. The second tightening force should be in the range from 70 to 85 N⋅m.

- Next, you need to tighten the screws by 90 degrees in the same sequence. The rotation angle can be controlled using a special device, which is a plate with an attached scale from 0 to 180 degrees.

- In accordance with the regulations, you need to tighten the bolts again by 90 degrees.

- The attachment of the 8 valve head to the block is complete.

- After assembling the motor, you need to check the quality of operation by starting and warming up the engine. A securely tightened joint between the head and the block should not allow working fluids to leak from the crankcase of the power unit.

Homemade device for controlling the rotation angle

If a more powerful and modern engine with sixteen valves is installed on a car, for example, the VAZ 21126 model or 126 for short, the procedure for pulling the bolts has its own characteristics.

In order to correctly tighten the cylinder head screws on such units, you need to:

- Remove oil from the mating surfaces and check that there is no liquid in the bolt holes.

- Install the gasket, center it and place the head on top.

- Insert 10 mounting screws M10*1.25 into the guide holes, having previously lubricated the threads with engine oil. If you decide to use old bolts, which is permissible for 16 valve heads, then their remaining length should not exceed 98 mm.

- Perform preliminary pulling according to the scheme with a torque of 12-20 N⋅m.

- Increase the tightening degree to 26-34 N⋅m and re-run all the bolts in the same sequence.

- Then you need to tighten the screws 90 degrees, with a force of about 50 N⋅m.

- Repeat tightening by 90 degrees again, the torque on the key will be approximately 80 N⋅m. Some instructions recommend waiting up to 20 minutes between turns, but in practice no advantages of such a scheme have been identified.

- After assembling the power unit, you should check the quality of the work performed.

The procedure for pulling the head on 1.8 liter engines, which are 1.6 liter engines with an enlarged cylinder, is completely identical to that described above.

If during the work process the correct moment of force is applied to the bolts, corresponding to design calculations, then the gasket will be evenly and tightly pressed along the joint, ensuring a reliable and tight connection. It is important to note that if it is necessary to remove the cylinder head from the engine, then the screws are also loosened according to the scheme established by the regulations. Chaotic unscrewing of the elements will lead to deformation of the head and the appearance of invisible microcracks.

Common Mistakes

Despite the fact that automakers clearly indicate the procedure and nuances of tightening the cylinder head, many car enthusiasts make mistakes when assembling the engine. The most common of them are:

- Pouring oil into the mounting holes to lubricate the threads (the liquid is incompressible, so poured oil will not allow the head to be properly tightened);

- Over-tightening (exceeding tightening forces leads to damage to the cylinder head and the fasteners themselves);

- The use of damaged or inappropriate keys (the edges of the bolt heads may be torn off, after which it will be problematic to tighten or unscrew them normally);

- Use of unsuitable bolts as replacements (fasteners from different engines may differ in length, thread spacing, head height and diameter);

To avoid problems in the future, you should use only fasteners designed for a specific engine and fully comply with the work conditions.

Photo gallery

The photo below shows the procedure for loosening the bolts and tightening them, which must be taken into account when repairing the cylinder head on a VAZ 2170 Priora.

Scheme for loosening bolts on an engine with 8 valves

Scheme for loosening bolts on an engine with 16 valves

16 valve head tightening diagram

8 valve head tightening diagram

Features of tightening fasteners

Even a non-professional can handle this work. It is important to follow two rules - the tightening torque and the sequence of working with fasteners. The tightening torque on engines with 8 and 16 valves is no different, while the sequence is different. Pay attention to the diagrams below; numbers indicate the order of tightening the bolts.

It is necessary to pay attention to the cylinder block:

- if during operation the bolts become loose due to vibration (the malfunction is detected by leakage of the gasket);

- after dismantling the cylinder head and installation;

- if the iron gasket is replaced;

- during tuning of the cylinder block.

Before work, take the instructions from your Priora to understand which engine is installed in the car.

Video “Installing and tightening the cylinder head on a Priora”

The assembly of the upper part of a 16 valve engine is presented in a video from the Expert R channel.

Do you have any questions? Specialists and readers of the AUTODVIG website will help you ask a question

Was this article helpful?

Thank you for your opinion!

The article was useful. Please share the information with your friends.

Yes (100.00%)

No

X

Please write what is wrong and leave recommendations on the article

Cancel reply

Rate this article: ( 3 votes, average: 5.00 out of 5)

Discuss the article:

Other cases in which dismantling of the cylinder head is required

Of course, it is not necessary to remove the cylinder head for every breakdown. This is only necessary if major repairs are needed. Such “major” cases include:

- Gasket wear.

- Formation of carbon deposits on parts.

- Valve deformation.

- Need to replace guide bushings.

- Failure of the camshaft, etc.

Of course, repairing it yourself or through a service in any case involves certain financial costs. To ensure smooth operation of the engine, regular diagnostics of the cylinder head are necessary. It is recommended to use high-quality fuel. In addition, try to prevent the car from overheating - because of this, the cylinder head may lead.

If some points remain unclear to you, then you can visually familiarize yourself with the process of replacing valves by watching the video:

Dear friends, today we will tell you in detail and with photographs how to independently replace valve stem seals on VAZ-2112, 2111 and 2112 equipped with a 16-valve engine. The beauty of our story is that in order to replace the oil caps we will not remove the head from the engine, and this is a significant saving of time and labor costs, there is no need to drain the antifreeze, unscrew the manifold, etc. At the same time, we will do this without using an expensive valve depressurizer, which allows us to do this, but will use a regular valve depressurizer for the VAZ-2110, which can be bought on the car market for 200 rubles. Even before starting work, I recommend purchasing this desiccant, if you have little experience in desiccaning and drying, then take a stock of heels of crackers, we will also need an anaerobic (do not use silicone) sealant, unlike conventional silicone, when in contact with oil, it does not clog the channels but dissolves in it, and also buy a key for tensioning the timing pulley for 50 rubles, since the belt will have to be removed and then set according to the marks. By the way, it wouldn’t hurt to replace the timing belt and rollers at the same time, ideally. If you are ready to do it yourself - no problem, if you lack determination - I can recommend contacting the guys in Minsk to replace the timing belt, they will definitely do it well and inexpensively. Well, if you’re ready to do everything yourself, then let’s get started. First, remove the plastic cover from the engine and gain access to the “intake manifold”

Consequences of incorrect cylinder head installation

Correct tightening of the cylinder head is very important, since the performance of the motor directly depends on it. The cylinder head acts as a cylinder cover, and any violations in its fit affect the processes occurring inside the power unit.

Insufficient tightening of the head leads to a drop in compression due to loss of tightness at the junction of the cylinder head with the cylinder block, burnout of the gasket, breakthrough of working gases from the cylinders and their entry into the channels of the lubrication or cooling systems, penetration of technical fluids into the combustion chambers, which in turn is negative affects the functioning of the power unit and can cause very serious damage.

Excessive tightening also does not bring anything good; in this case, damage to the head often occurs - cracks appear, or fasteners are destroyed - bolts break, threads break, etc.

General rules for performing work, methods used

There are a number of general rules that must be followed when installing the block head:

- It is important to strictly observe the tightening torque. For these purposes, a special tool is used - a torque wrench. It is not recommended to perform this operation with regular keys;

- The head bolts must be pulled smoothly, jerking is not allowed. Since the tightening force on the last approaches is significant, extending the wrench arm with a pipe can simplify the procedure and ensure smooth, uniform tightening;

- Before installing the bolts, you need to carefully inspect the condition of the threads on them. There should be no dirt or foreign particles on the coils.

- The threads of fasteners should be lubricated with engine oil before tightening. But you should not pour grease into the holes for the bolts (especially for “blind” holes), since in the future it will not allow the fasteners to be fully tightened.

Despite the fact that each engine has its own characteristics of tightening the cylinder head, the general technology of this operation is the same. In general, two methods are used to tighten fasteners:

- In several approaches, bringing the tightening force to the required value;

- Tightening the fasteners to a certain force (in one or more approaches), and then tightening the bolts twice to a certain angle.

The tightening method is selected based on the type of bolts.

The first method is used when using non-stretching bolts (these are not used now, but they can be found on old cars). But often this type of fasteners requires tightening after a certain period of engine operation in order to compensate for the shrinkage of the cylinder head gasket. But such fasteners are allowed for reuse, and more than once.

The second method of tightening the block is relevant for most modern cars. And all due to the use of tensile bolts (the so-called TTY type).

Such fasteners, due to elastic deformation, are able to compensate for thermal expansion of the head and shrinkage of the gasket, but for this they need to be put into deformation mode (in fact, just stretched a little).

To do this, it is necessary to tighten the bolts twice to a certain angle. On some cars this angle is 45 degrees, on others it is 90 degrees.

But after the elements are put into elastic deformation mode, they will no longer be able to return to their original state, and therefore their reuse is not allowed due to the high probability of destruction.