Thank you for your answer to a previously asked question. I want to find the break myself. I bought a multimeter. How to check the wires correctly? I am attaching a photo. I can’t find a decent electrician on this issue.

4 wires. I don’t know the pinout yet, but you can identify the wires this way. Remove the chip from the sensor. 4 wires, one 12V, second ground, third 5V, 4th wire DMRV signal. Turn on the ignition, find 12v? Is there 5v? Is there mass? And the last one is a signal. Now, if you put the chip on and the plus probes of the multimeter on the signal and the minus probe on the ground wire and start the engine, then the sensor readings will be in volts. What they should be like needs to be looked at online. I'll write up the thread later.

The check is not difficult. Here's the extract:

Let me add a little: when you take readings from the white wire, this information is the most IMPORTANT. The readings of a new and working sensor should be from 0.99 to 1.02 volts. If it is higher by at least 0.01V, it is already a dying sensor. And if it’s even more, then the sensor has worked out and needs to be changed. When the engine is running, the values there may be higher than those indicated in this description, depending on the engine speed. The most important measurements are the initial ones, when the motor is not running.

And one more important note, you need to know that the multimeter works without error, because very accurate readings from the MAF sensor are needed. I have one Chinese multimeter, and I once compared its readings with a good expensive voltmeter, it turned out that the “Chinese” was lying by 0.4 volts, for example, when taking readings of the battery capacity.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

What to do with errors p0172 and p0175 on a Nissan Maxima?

The mass air flow sensor, abbreviated as MAF, is an important organ in the injection system. It is also called a consumable. The main task of the unit is to calculate the required amount of fresh air that enters the cylinders during engine operation. A sensor is installed in the air duct and measures the temperature and amount of incoming air. Under the hood it can be found inside the intake tract.

Principle of operation

The piston stroke occurs when fuel is burned with air in a ratio of 1:14, maintaining which ensures optimal operation of the power plant. When the proportion decreases or increases, the engine does not stop working, but there is excessive fuel consumption or a decrease in engine operating power. We need a mass air flow sensor so that air flows in portions. The operation of the unit proceeds as follows: the VAZ 2110 air flow sensor calculates the portion of fresh air, and then sends the data to the main computer, which, based on this information, calculates the portion of fuel.

The harder you push the gas, the more filtered air the powerplant requires. The mass flow sensor detects the increase and commands the electronics to increase the amount of fuel. When moving at the same speed, each portion should be equal to the previous one. The mass air flow sensor receives data on the load of the power unit, and then calculates the required portion of air. When the driver presses the pedal, the throttle valve opens, thereby increasing the volume of intake air - the load increases. When the pedal is released, the load drops.

Basic faults

The mass air flow sensor rarely fails, but if this happens, it will not be difficult to determine the malfunction. To do this, know the main signs with which you can check the condition:

- Excessive consumption of fuel. We learn about this from the on-board computer indicators. If a malfunction occurs, consumption may increase by 1 liter or more.

- Decrease in dynamics. The engine does not produce the power that yesterday was not a difficult task for the VAZ 2110.

- Interruptions in the operation of the power plant. Slow acceleration or too fast.

- The engine does not start or does not start the first time.

- Floating speed. This concept means that a spontaneous increase or decrease in speed occurs.

Testing and diagnostic methods

Shutdown

This method involves starting the motor with the sensor removed - we need to disconnect its connector. When turned off, the controller starts emergency mode, and new portions of the mixture are calculated based on the position of the damper. We need to drive a little, the speed should be above 1500 rpm. If the car behaves more dynamically without a mass air flow sensor, then the diagnosis is complete - it’s time to change the consumable.

Checking with a multimeter

This test requires that you have skills in using a multimeter (tester). The method is suitable for almost all VAZ models, including 2110. We need to take a multimeter and set it to a mode that measures constant voltage, which is usually designated DCV or only V. To work with the mass air flow sensor, you need to understand its pinout, it is as follows:

- Yellow, closest to the windshield, supplies current to the signal input;

- Green indicates ground;

- The pink or red-black wire comes from the main relay;

- The white-gray wire is responsible for the voltage output.

Depending on the model, the colors may be different, but the location does not change. Here you will have to deal with a specific model. But once you find the input signal wiring (closer to the windshield) and grounding, you can do it without instructions. The wiring is clear, now you need to turn on the ignition without starting the engine. The tester sets a limit of 2 Volts. The black probe of the tester is connected to the green ground wire of the air flow sensor, and the red one is connected to the yellow one. The measurement takes place between two terminals. The probes must be inserted carefully; an additional needle is not required, since the probes can be freely inserted along the wires without damaging the insulation.

We look at the tester display. If the consumable is new, then there we will see a voltage indicator of 1.01. Over time, the indicator increases as the resistors wear out (the resistance drops). The larger the number, the greater the wear of the sensitive element:

- In good condition, the indicator will be 1.01… 1.02;

- With “normal” - 1.02... 1.03;

- The sensor will soon stop working – 1.03… 1.04;

- The dying state of the flow meter is accompanied by an indicator of 1.04… 1.05;

- Replacement of the unit is required when the reading is 1.05 or higher.

Diagnostics can also be carried out without a multimeter. Instead, you can use the on-board computer. To do this, you need to go to the “voltage from the mass flow sensor” section; we are interested in the “U MAF” indicator.

see also

Visual inspection

Here we need to carefully examine the surface of the corrugation and consumables. To check the condition, we need to loosen the air intake clamp at the outlet of the mass air flow sensor, and then pull it off. If you see traces of grease or condensation on the surface, then most likely they have damaged the unit. Sometimes the sensor can be “reanimated” by removing all the dirt. It ends up in the consumables due to rare changes of the air filter. If liquid appears on the sensitive element, this is a 90% failure. Lubricating oil enters due to a clogged oil separator or due to an increased level in the crankcase.

How do they check the sensor in Kalina?

How to check the DMRV? It is possible to perform diagnostics manually in a regular garage.

The following methods will come to the rescue here.

- Turn off the air sensor and start the engine. In this case, the ECU switches to operating according to the emergency program. The air-fuel mixture is prepared only in accordance with the position of the valve in the throttle assembly. We start moving and feel a change in dynamics in a positive direction. Verdict - replace the sensor!

- Alternative firmware version of the on-board engine control module. It is possible that the firmware was previously replaced and the owner of the Lada Kalina does not know what exactly is “hardwired” in it in case of activation of the emergency engine operation program (with the mass air flow sensor disabled). In this option, we place a plate 1 mm thick under the damper stop. The revs will naturally rise. At this moment we remove the “chip” from the connector on the sensor. If the motor stops, then the firmware itself is to blame, or rather, the steps of the XX regulator for emergency mode.

- We measure the voltage at the terminals of the connected mass air flow sensor. We set the multimeter to a range with a limit of 2 Volts. Turn on the ignition and take measurements. The absence of a malfunction will be confirmed by a voltage value of 1.01-1.02 V.

- We inspect visually. Using a screwdriver, remove the clamp and corrugated pipe of the air supply system to the manifold. We remove the sensor itself and look at its external condition. There are no traces of moisture or scratches. If the air sensor is covered with a film of oil, then we suspect the engine for wear of its elements or the crankcase ventilation system.

Replacement and installation instructions

After dismantling the old non-working sensor, before purchasing, you can ask a friend for a temporary air flow sensor from his car, and then check it in your 2110. If with another sensor the engine works without interruptions, the consumption does not increase, then it’s time to replace your flow meter. This is the simplest diagnosis that can be carried out when the first signs of a malfunction appear.

We have studied the malfunctions and symptoms, what a mass air flow sensor is is now clear. If we succeed in checking, and we know that the flow meter is faulty, all that remains is to replace it. To do this, you need to prepare a replacement unit (you can buy a non-standard model) and a screwdriver. Visual inspection implies analysis, but let’s repeat it again:

- You need to turn off the engine and remove the key from the ignition.

Installing a new element is done in exactly the same way.

The mass air flow sensor (MAF or flow meter) is an important part of the car, the proper operation of which determines the engine power and its fuel consumption. You can find it under the hood of the car, where it is located between the air filter and the air pipe directed to the throttle valve. The task of the mass air flow sensor is to measure the amount of air passing into the cylinders and transmit this information to the electronic control unit, that is, the “brains” of the machine. Based on the data from the mass air flow sensor, the control unit decides whether to increase or decrease the air supply to the combustible mixture.

If a mass air flow sensor fails, it is almost never repaired, but simply replaced with a new one. Its design is quite simple, and it consists of a housing in which a device for measuring air flow is placed - a hot-wire anemometer. It is enough to damage the diagnostic device during the process of dismantling the mass air flow sensor or cleaning it, and the entire sensor will need to be replaced. It can also fail after a long service life, but you can verify its malfunction only after checking.

Signs of malfunction of the air flow sensor Kalina

In order to identify loss of sensor functionality, pay attention to the following characteristic signs:

- interruptions in engine operation at idle;

- fluctuation in speed or delayed response when pressing the gas pedal;

- loss of dynamic (poor acceleration) properties of the engine;

- increase in fuel consumption on average from 25 to 40% (depending on the outside air temperature);

- the appearance of a corresponding engine error on the dashboard.

"Important! In some cases, the above signs of incorrect engine operation are a consequence of wear and damage to the air corrugation. Therefore, it is recommended to check the integrity and tightness of the joints.”

The main causes of breakdowns of the Lada Kalina mass air flow sensor

There are 4 main reasons that contribute to the failure of the measuring sensor:

- Natural wear and tear. As you know, nothing lasts forever, especially the fragile elements of the sensor, which are subject to constant changes in operating temperatures (heating and cooling).

- Physical damage to the bond as a result of road accidents.

- Use of non-original auto parts.

- Damage to the device during repair work on the vehicle.

Symptoms of a malfunctioning mass air flow sensor

Before you start checking the mass air flow sensor, you need to understand from the primary symptoms that it is faulty. The following symptoms may indicate problems with the sensor:

- The “Check Engine” icon is lit on the car’s dashboard;

- The car began to consume more fuel, while its acceleration dynamics decreased;

- Idle speed has changed up or down. The engine idles jerkily;

- The motor does not start.

The above symptoms indicate that air is not supplied to the combustible mixture in the volume required. Moreover, this problem can occur not only when the mass air flow sensor fails. In particular cases, the malfunction may be due to a lack of power supply to the sensor through the electrical wiring or when cracks appear in the connecting hoses.

Symptoms of the error

Undoubtedly, with error P0102, the car can continue to drive, but the operation of its engine will be unstable.

First, the Check Engine sign lights up on the instrument panel, indicating a problem. In this case, the car may have difficulty starting. Instead of stable speed, a cold engine will work intermittently, you will have to rev up the gas so that the engine does not stall.

The error signal may disappear for some time, but later the situation only gets worse: failures can occur not only at idle, but also while the engine is running under load. For example, during overtaking, when you need to squeeze out maximum power, the car may begin to jerk without gaining speed. The car may stall while driving as soon as your foot is removed from the gas pedal. All this can lead to an emergency on the road.

How to check the mass air flow sensor for serviceability

There are several basic methods for checking the mass air flow sensor, which allow you to verify its malfunction.

Checking the mass air flow sensor in motion

The easiest way to diagnose a flow meter is to analyze the operation of the engine when the sensor is forcibly turned off. The check proceeds as follows:

- It is necessary to open the hood and disconnect the connector from the mass air flow sensor. After this, close the hood;

- Next, get behind the wheel of the car and start the engine. The car should begin to operate in emergency mode, in which the Check Engine light will light up. In such a situation, the amount of air in the fuel mixture will be determined depending on the throttle position;

- Try driving the car and pay attention to its dynamics in comparison with how the car worked before the mass air flow sensor was turned off. With the sensor turned off, the car should become “more lively”, that is, accelerate faster. If this is the case, then we can confidently talk about problems with the mass air flow sensor.

It is highly not recommended to operate a car for a long time with the mass air flow sensor turned off.

Checking the mass air flow sensor with a multimeter

You can diagnose a problem with the sensor using a multimeter. To do this, you must first understand the design of the device and its “pinout,” that is, the wiring of the wires on the board. There are 4 wires coming out of the mass air flow sensor. Depending on the MAF model and manufacturer, their colors may vary, but in most cases they are as follows:

- Pink (or pink-black): wire to main relay;

- Green: wire to ground;

- Gray: wire to power;

- Yellow: signal input.

To check the mass air flow sensor, the multimeter must be set to constant voltage measurement mode and set the limit to 2 Volts. Next, you need to turn on the ignition, but do not start the engine. Once this is done, connect the multimeter's red lead to the sensor's signal input (yellow wire) and the black lead to ground (green wire). This can be done without “exposing” the wires by inserting the probes of the diagnostic device through the rubber seal of the connector.

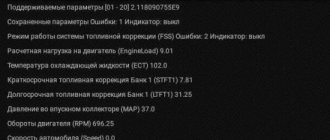

Based on the measurement results, conclusions can be drawn about the state of the sensor:

- Fully serviceable device (new): 0.996 - 1.01 Volts;

- The sensor is in good condition, but has already worked: 1.01 - 1.02 Volts;

- The sensor has been working for a long time, but is still working: 1.02 - 1.03 Volts;

- The mass air flow sensor will soon need to be replaced: 1-03 - 1.04 Volts;

- The flow meter is close to failure, but continues to cope with the tasks: 1.04 - 1.05 Volts;

- The sensor needs to be changed: 1.05 Volts and above.

Some modern on-board computers allow you to view the voltage on the mass air flow sensor. In such situations, you can do without a multimeter.

Visual inspection of the mass air flow sensor

Experienced motorists can determine a malfunction of the mass air flow sensor by its appearance. The first step is to remove the mass air flow sensor, and then inspect it carefully. Signs of a malfunction are liquid getting into the air pipe and the mass air flow sensor (or the presence of mechanical damage).

Most often, liquid may end up in the sensor for the following reasons:

- Increased oil level in the crankcase. In such a situation, oil enters the sensor;

- Clogged oil sump of the crankcase ventilation system;

- Untimely replacement of the air filter, due to which dirt gets onto the MAF hot air anemometer.

The easiest and most reliable way to diagnose problems with the mass air flow sensor is to replace it with a working device. For example, you can remove a suitable working sensor from another car, install it and make sure that engine operation has stabilized. In such a situation, you can immediately go buy a new sensor without diagnosing it with a multimeter or other methods.

Checking the mass air flow sensor with a multimeter

1. Check the voltage on the mass air flow sensor block:

- Set the multimeter to voltmeter mode.

- Remove the connector with the wires from the mass air flow sensor (snap off the lock).

- Turn on the ignition.

- We connect the negative probe of the device to the engine ground, and the other to terminal No. 2 of the block (there is a number on the block).

- We measure the voltage at terminal No. 4 of the block.

The voltage at pin No. 2 should be at least 12 V, and at pin No. 4 about 5 V. If the device readings are different, it means the battery is discharged, the power circuit or the computer is faulty.

2. We check the Bosch mass air flow sensor on Lada Priora and Kalina 1 (with article numbers: 0 280 218 004, 0 280 218 037, 0 280 218 116):

- Set the multimeter to voltmeter mode. (measurement limit 2 V).

- Turn on the ignition.

- We connect the “negative” probe of the device to terminal No. 3, and the other to terminal No. 1.

Compare the device readings with the table:

| Voltage, V | Air flow sensor condition |

| 0.996…1.01 V | Voltage of the new mass air flow sensor |

| 1.01…1.02 | Good condition of the sensor |

| 1.02…1.03 | Normal sensor condition |

| 1.03…1.04 | Sensor life is coming to an end |

| 1.04…1.05 | “Near-death” state, if there are no negative symptoms, then we continue to exploit |

| 1.05...and higher | It's time to replace the sensor |

Checking the mass air flow sensor is also shown in the video:

Another way to check the mass air flow sensor is to replace it with a known good one.

Have you encountered a malfunction of the mass air flow sensor? If the mass air flow sensor turns out to be in good condition, and there are problems with the engine, read “Why the engine shakes, jerks, or pulls poorly” and “Why the speed fluctuates.”

Keywords: lada xray sensors | Lada Vesta sensors | Lada Largus sensors | Lada Granta sensors | Lada Kalina sensors | Lada Priora sensors | Niva sensors | ECM Lada Vesta | ECM Lada XRAY | ECM Lada Largus | ECM Lada Granta | ECM Lada Kalina | ECM Lada Priora | ECM Niva | universal article