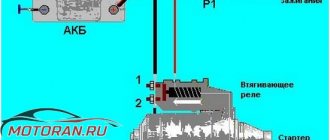

The wiring diagram for hatchbacks 2112 is a unique thing in itself. In order for voltage to appear on the solenoid relay, the following parts must be in good working order: the ignition switch, the ECU unit and two more relays - the main and additional ones. Some cars do not have an additional relay, which can be considered good luck. But, if when you turn the key on a VAZ-2112 the starter does not turn, then the fault must be looked for in the wiring. A broken immobilizer code can also cause problems. The last malfunction can be cured by replacing the ECU or disabling the immobilizer. Well, let's look at something simpler.

Example in the video: the immobilizer was damaged and the starter stopped working.

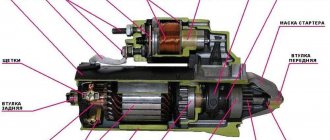

All features of the standard scheme

The reader will be surprised, but there will be more than one scheme here. The most difficult option is shown below.

Scheme with an additional starter relay Please note: relay K2 is not at all “unloading”. A significant current flows through the lock contacts, and relay K2 can be called “blocking”: when it does not work, the starter does not turn. Why is this necessary, think for yourself.

If an attacker closes the contacts in the lock, he will not only be unable to start the engine, but also not use the starter. That is, the hijacker will not drain our battery. The circuit shown above is used with 1.6 liter injection engines. There may be another option - a simpler one.

Circuit without additional relay There is no blocking relay here. The current flows to the solenoid relay from pin 50. A simple version of the circuit is typical for cars from early years of production. Which applies to the entire “Ten” family, including hatchbacks. That is, an interesting combination occurs: the model is VAZ-2112, and the starter will turn even in the absence of all relays and ECUs!

Starter malfunctions and reasons for their occurrence

The unit does not spin the flywheel due to many factors. Below we will discuss defects in the immobilizer, pull-out relay, injector, as well as in the car wiring. Sometimes repairs are not enough, in which case the device needs to be replaced.

Good to know! All elements of the VAZ 2110 that come into contact with electricity are highly reliable. But if the device fails, a complete or partial replacement will be required. Signs of malfunction are also an important factor. For example, when the unit clicks, but does not start or turn over, the problem can be solved by repair.

Faulty injector

The standard version of the VAZ 2110 is not equipped with injectors, but they can be supplied separately. Drivers choose these devices for many reasons: reduced fuel consumption, no need to warm up the engine in cold weather, increased power characteristics.

The starter doesn't turn, what happens?

We know that there are two variants of the scheme. If “option 2” is implemented, voltage to the starter is supplied directly from the lock. But the ignition switch in the “Tens” is short-lived, since 30-40 Amperes are transmitted through it (the current of the solenoid relay).

This is true for both the sedan and the 2112 hatchback, and the starter may not turn only because the lock is broken. Draw your conclusions!

All of the above also applies to “diagram 1” - look at it carefully. The main relay is located in the extension block. It is located under the stove on the right.

An additional relay is located in the main unit (see photo). However, it may be missing.

If “option 2” is implemented, check only the lock. And if there is an additional relay, it is not recommended to install a jumper instead. Marked in the photo:

- Additional relay (white arrow);

- Main relay (element “6”).

VAZ 2110 won't start, the injector turns the starter

Probably every motorist has encountered a situation in which your car does not start, and there is little pleasure in it, especially if it happens on the road.

To begin with, it is recommended to conduct a general diagnostic of the engine and try to identify the malfunction. In this situation, in order to determine the malfunction of the VAZ 2110 power plant, it is recommended to check all operating systems of the engine, proceeding from general to specific.

The starter turns but the engine does not catch.

The fact that when you turn the key, the engine begins to rotate under the influence of the starter torque is not a bad sign. This indicates, first of all, that the malfunction lies in a malfunction of one of the systems, namely the fuel supply system, air supply system, or ignition system. (Cases of breakdown of the crank and gas distribution mechanisms assemblies are not taken into account, since these breakdowns are extremely rare).

Possible malfunctions of the fuel supply system of the VAZ 2110

One of the major malfunctions of the fuel supply system is: - failure of the fuel pump.

- clogged fuel line

- clogged distributed injection nozzles

To diagnose the performance of the fuel supply pump, it is necessary to remove the hose from the fuel rail and check the pressure in the system. If necessary, the pressure is measured with a special pressure gauge. If there is no pressure in the fuel line, it is necessary to check the serviceability of the fuel pump, as well as the correct operation of the electrical circuit.

Clogged fuel injector nozzles can be checked by removing the fuel rail. A working fuel injector should spray fuel into a vapor state. A faulty or clogged nozzle does not spray, gasoline may not flow at all, or may flow in a stream. Failure of all injection nozzles to pass through may also indicate improper operation of the vehicle's Electronic Control Unit.

Typical malfunctions of the VAZ 2110 ignition system

If the fuel supply and distributed injection systems are fully operational, you should check the serviceability of the vehicle’s ignition system.

In this system, malfunctions in the operation of the following components are possible:

1. Faulty spark plug. As a rule, when 1-2 spark plugs come out, the car will start, but it will be difficult or the engine will start to seize.

2. Breakdown of high-voltage wires; if armored wires are not replaced in a timely manner, they may fail. Accordingly, voltage will not be supplied to the spark plugs.

3. Failure of the ignition module. The electric current converter may fail at the moment the spark is applied; in such a situation, it is necessary to check the voltage at the output.

Possible malfunctions in the timing belt

- the timing belt slips through the pulley teeth by 1-2 positions. Because of this, the position of the valve timing changes and the engine may not start at all. -Slipping of the camshaft pulley, or damage to the shaft. - malfunction or incorrect operation of the crankshaft position sensor. In a situation where it is not possible, from a technical point of view, to identify a malfunction using general diagnostics, it is necessary to carry out general computer diagnostics of the engine with connection to the ECU

Final check before replacing the starter

We turn the key to position II, and nothing happens... In this case, open the hood and remove the air filter by unscrewing the screw on the body and loosening the clamp on the pipe. The starter is located under the filter housing. In the photo we see the following: someone disconnected the solenoid relay cord.

What we found under the filter, we check with a needle probe that when you turn the key, “+12” appears. Then, after checking, we wrap the cord with electrical tape.

Sometimes voltage seems to be supplied to the starter, but the solenoid relay is activated “every time”. Well, try cleaning the terminal - both in the connector and on the starter itself. Consider the situation:

- The copper is polished to a shine;

- The wire (see photo) is supplied with “plus”;

- The starter doesn't even click.

The first thing you need to check is the battery contacts. We remove the terminals (key “10”) and look at what is under them. There is no point in measuring the voltage with a probe - it will show “12 Volts”.

Solenoid relay current – 40 Amperes. The presence of a resistance of 0.1 Ohm results in a voltage drop of 4 Volts. So consider... And the starter motor consumes 200 Amperes during operation.

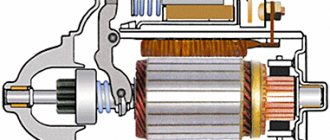

Checking the functionality of the solenoid and contact relay

When the VR is not working well, when you try to start the engine, clear dry clicks are heard; if the cause of the defect is a contact relay, the clicking in this case is quiet and quite soft. First, we check the functionality of the starter itself, this is done something like this:

- remove the starting device from the car;

- We connect the terminal wires to the removed battery, connecting their other ends to the main positive and ground of the starter;

- we connect another wire to the starter winding, with its other end we touch the positive terminal of the battery, while holding the starting device;

- if the starter is working, the bendix will engage, the rotor will rotate, if not, there will be no rotation, and when voltage is applied, slight sparking will occur;

- To completely make sure that the starter does not respond or, on the contrary, responds to the power supply, we apply plus directly to the winding.

Now, without disassembling the starter assembly, you can check the operation of the solenoid relay:

- apply minus to the winding output;

- briefly touch the BP contact pin, where power is supplied from the ignition switch (on many cars this contact is equipped with a “chip”);

- when power is applied and the relay is working properly, a clear click will be heard, and the bendix will move backward;

- if the bendix does not come out, you need to disassemble and diagnose the solenoid relay.

We recommend: Replacing the cylinder head gasket on a VAZ 2107

You can also check the VR when it is removed from the starter; here we also supply power with wires from the battery (plus and minus). When “+” is applied to the control contact, the core on a working relay will be retracted; if the VR is faulty, the full stroke of the core is not observed.

The starter contact relay (SCR), which is usually located inside the car or in the engine compartment on the panel next to the windshield wipers, may also be faulty. In this case, when you turn the ignition key, faint clicks may be heard, or more often no sounds can be heard at all. Before you start checking the RPC itself, you need to make sure that power is supplied to the relay. It is convenient to check the presence of voltage using a test light by connecting the ends of the probes to the corresponding terminals; the minus here should be constant, and the plus should appear at the appropriate position of the ignition switch (Z.Z.).

It should be taken into account that each car model has its own circuit, some cars have a starter blocking relay installed (has a different purpose), some cars do not have a starter lock relay at all. You need to check the chain according to the electrical diagram, but the principle of operation, we assume, is generally clear. If the plus does not come to the corresponding contact in the block, the 3Z contact group is probably faulty, there may also be a break in the wires, a poor connection in the blocks, in some cases, upon careful inspection, you can see traces of melted insulation.

The ECR itself is also checked using a test light or a multimeter, but when searching for a defect on your own, it is more convenient to have a working relay in stock, given that the part is inexpensive and is almost always available in car dealerships.

Why doesn't the starter turn over?

Depending on what caused the starter to fail, it is necessary to take the next steps - repair or replace the unit. In addition, in some cases, you do not need to repair the starting device itself, but manipulate other components. In most cases, you can get by with repairs, but experienced car enthusiasts recommend immediately replacing the unit so that there are no more problems with it.

- Most VAZ-2110s do not have a standard injector, but many car enthusiasts install this unit themselves. It helps reduce fuel consumption, helps start the engine in cold weather without warming up and increases power. The injector fails, and along with it the starter, due to low-quality fuel. Another reason may be failure to follow the connection diagram, but then you will discover a malfunction immediately after installing the injector. Otherwise, you need to flush the injector to remove any suspended matter that is carried into it by the fuel.

- If the car starts, but after a short stop the engine cannot be restarted, then the problem lies in the overrunning clutch. At the moment of failure, you may hear clicking sounds from under the hood and notice that the car radio begins to turn on by itself. In this case, you need to cool the power unit before restarting or not make short stops. You will also need to replace the overrunning clutch with its geared counterpart. Be sure to check the conductors that come from this node. Sometimes, to restore the functionality of the coupling, it is enough to replace the wires that visually look damaged.

- The retractor part of the starter especially often fails. When such a breakdown occurs, the dashboard lights first light up and then go out. Before replacing the solenoid relay, you must close the starter and turn off the alarm. If the listed components are in working order, then you will simply have to replace the relay.

- Clicking sounds in the starter and failure to start the engine are often caused by damaged contacts. In this case, first inspect the battery, clean the terminals if oxide appears on them. Sometimes on a VAZ-2110 it is enough to tap the starter relay to get rid of the problem. Be sure to take an assistant with you who will start the engine while you tap the relay. If with such a rough approach it was possible to start the engine, then it is worth replacing the relay completely. Repair will be impractical.

- An unexpected engine stop is caused by problems with the immobilizer. You will not be able to start the engine because the protection is triggered. This only happens on injection VAZ-2110s. It is impossible to fix the problem on your own; call a tow truck and go to the nearest service station, where they will be able to restore your car’s functionality.

The starter relay clicks, but it doesn't turn over.

If, when you turn the ignition key, clicks are heard from the starter relay, but the unit itself does not spin, then the problem may be associated with a malfunction of the control cable that powers the relay, or with a problem in the performance of the relay itself.

In such a situation, the car can be started if you short-circuit the “plus” from the battery to the positive control terminal from the ignition switch (the smallest wire of the three is connected to it). If, with such a connection, the starter starts to spin, then the malfunction is definitely not related to the battery, and the problem should be looked for in the relay, ignition switch or wiring.

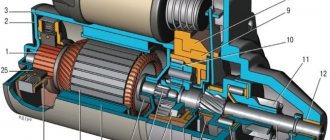

Solenoid relay diagnostics

If the starter does not turn when the engine starts, but clicks are heard, the first step is to diagnose the relay itself. It connects to the battery and ignition switch via 2 cables. One of them (thick section) comes from the positive terminal of the battery, and the second (thin section) goes from the positive control terminal of the ignition switch. The relay also has a third terminal (thick section), which connects it to the starter motor.

To diagnose a possible malfunction in the solenoid relay, you need to use a jumper to connect two terminals to which thick wires are suitable. To connect them to each other, you can use a regular screwdriver, wrench or other available tools. Grasp the insulated surface of such a tool and use it to connect the two large terminals (it is important that the “jumper” does not touch any other metal parts under the hood).

If the result of shorting the terminals is the rotation of the starter, then the problem is related to the contact pads in the relay, which could be burned due to the high current supply. In such a situation, it is necessary to replace the relay, since the procedure for cleaning the contacts will take a lot of time, but due to the lack of an alloy of non-ferrous metals on them, which is applied at the factory, they will not work for long.

Diagnostics of wiring and contacts

If the starter clicks but does not turn, poor contacts or wiring problems may be to blame. Most often, a malfunction occurs along the path of current transmission from the positive terminal of the battery to the solenoid relay. The starter requires about 200 Amps to start, but if there are problems in the wiring and contacts, much less current can reach it. This leads to the fact that it is possible to power the solenoid relay (which requires 10 Amps), but there is not enough current to spin up the starter itself.

With such a malfunction, clicks may be heard in series or stop from time to time. If there is such a problem, you need to check the wiring, make sure there is no oxidation on the pads and that they are tightened enough to fully transfer current.

How to accurately determine that the starter needs to be replaced

It is not always worth wasting your time to fix a faulty starting device with minor or partial repairs. Large-scale troubleshooting is often impractical at this site. Before removing, let alone disassembling, the starter, you need to remember three signs when you should rush to purchase new spare parts:

- When you turn the key in the ignition, you hear a grinding noise in the engine compartment area. This directly indicates a malfunction of the bendix (overrunning clutch) or flywheel. It is these parts that need to be replaced.

- Clicking noises when the starter fails to operate means the relay is faulty.

- A strained engine start is evidence of failure of the starter brushes.

The most common cause of clicking sounds in the starter is considered to be a failure of the retractor. The relay is not that expensive, and you can also try to fix it yourself. This will require a lot of effort, but will save you from replacing the unit. Just remember that this is a temporary measure, the restored relay will not be enough for a long time, and in some cases the bulkhead will not help.

Under the relay body you can find the armature, coil, rod and contacts. Most often, oxide appears on parts of this device, which is time to try to clean. However, it is worth remembering that this measure is sometimes ineffective. Therefore, it is best to immediately buy a new spare part.

We are trying to make a friend without his atrium

TIP - before closing the starter, it is advisable to inspect it and make a diagnosis.

Initially, it would be good to try to find out the reasons for the failure of the starter - what if you are lucky and the problems associated with its failure can be eliminated yourself.

The most common breakdowns are the following:

- Starter relay failure.

- The solenoid relay does not operate fully.

- Severe wear on the teeth of the Bendix gear, namely, the gear rotates, but does not engage with the teeth of the engine flywheel ring.

- The stator winding in the starter burned out.

So, let’s start the “heart” of the car.

Method 1, or how to start a car from a push, or “from a pusher”?

Everything is quite simple, but at the same time very reliable. Its essence is that the driver needs to find at least a couple of people, let them be, for example, neighbors in a garage cooperative who sympathize with him. And they don’t need to be of strong build, the main thing here is the number of participants: the more, the better. The entire team (company) rests their hands on the trunk, rear pillars, etc., and begins to push the car, accelerating it. The driver, in turn, sitting behind the wheel, already with the ignition on and, better yet, with third gear engaged, as well as with the clutch depressed, after waiting for the car to accelerate, the clutch is already released. After this, the engine “sneezes” and starts. The higher the acceleration speed, the faster the engine will start.

With this method, it is important to remember that after starting the engine, the car will begin to accelerate and you must immediately depress the clutch and turn off the gear, but, of course, do not turn off the engine!

In addition, do not forget to press the brake so as not to hit the car pulling you in the rear and put your car on the handbrake, and after that you can go and unhook the cable.

Method three, or we start the engine by simply closing the starter.

In addition to the above options, the engine can be started without “violent” methods. Just need to have at least a little idea of how to close the starter directly?

Often, drivers close the starter using everything that is at hand in the car. This could be a screwdriver, a spatula, a wrench, etc.

TIP - a screwdriver will be effective if the starter relay is faulty.

This is easily recognized by the characteristic clicks coming from the engine compartment when starting the engine. This sound tells the driver: “Hey, friend, the relay is on, but the Bendix gear is not able to turn the engine crankshaft.” There is only one way out - you bridge the starter, and with this action you apply voltage to the winding.

In this case, you will need a large screwdriver, but you can use any open-end wrench. Any of these items must close the terminals of the solenoid relay and that’s it. But, do not forget, before closing the starter directly, you must:

- The ignition key must be placed in the appropriate position.

- The gear lever must be in neutral.

- The car must be put on the handbrake.

With this method, a screwdriver (wrench) plays the role of a solenoid relay and the engine of your car must start.

Engine starting methods

If such a nuisance takes a car enthusiast by surprise on the road, there are a number of practice-tested methods and techniques that will allow you to start the engine in extreme conditions. This will require a minimum of tools and a maximum of dedication and dexterity of the driver.

Among them are:

- direct impact on the starter contacts and solenoid relay;

- mechanical manipulation using a hammer handle;

- changing the position of the starter power contacts;

- impact on the drive axle of the car.

The first option is considered if the ignition switch has failed or power is not supplied to the “retractor” winding.

Its essence is as follows: the car is put in neutral, the handbrake is “cocked”, the ignition is turned on, and with the help of any metal object, be it a screwdriver or a pry bar, two power contacts are closed. Their role is played by the power contact from the battery and the underwater contact going to the auxiliary relay terminal.

What to do if something happened to the Bendix drive elements? A proven patented tool that has no analogues in the whole world will come to the rescue - the “hammer”.