Checking and adjusting thermal clearances in the valve drive (8V) Lada Largus

Tools:

- Open-end wrench 10 mm

- Set of flat probes

- adjustable wrench

Notes:

We carry out the work when characteristic clicking knocks appear in the area of the cylinder head with a frequency half the speed of the crankshaft. Basically, knocking occurs as a result of wear of valve mechanism parts and the associated increase in thermal clearances in the valve drive.

Knocks can be heard clearly when the engine is idling.

It is also recommended to check the gaps when the car has driven more than 100 thousand km.

We carry out the work on a cold engine.

Valve arrangement in the cylinder head

1 – row of intake valves; 2 – row of exhaust valves.

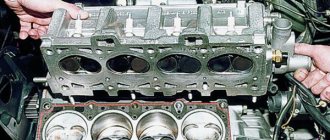

1. Remove the cylinder head cover.

2. We remove the upper timing cover and, following the mark on the camshaft gear pulley, set the piston of the first cylinder to TDC at the end of the compression stroke.

Note:

The cylinders are counted from the flywheel.

3. Then we check one by one and, if necessary, adjust the clearances in the drive of the intake and exhaust valves of the 1st cylinder. When checking (in this position of the crankshaft and camshaft), the heels of the rocker arms of the indicated valves should face the backs of the heads - the cylindrical parts of the camshaft cams. In this case, the rocker arms can swing on the axis within the clearance in the drive.

4. Using the flat feeler gauges from the kit, we check the thermal gap between the ends of the valve stem and the adjusting screw.

The gap should be within 0.2 (+0.05 -0.075) mm for intake valves and 0.4 (+0.05 -0.075) mm for exhaust valves. The feeler gauge should move in the gap with little effort.

5. If the gap size (thickness of the feeler gauge) differs from the required value, use a 10 wrench to loosen the tightening of the lock nut of the adjusting screw, holding the screw by the flats (width - 3 mm) with an adjustable wrench.

6. Then, by rotating the adjusting screw, we set the desired gap.

7. Tighten the locknut while holding the adjusting screw with a wrench. We check the gap again and repeat the adjustment if necessary.

8. Consistently turning the crankshaft clockwise each time by the bolt securing the auxiliary drive pulley 180°, we check and, if necessary, adjust the thermal clearances in the valve drive of the 3rd, then the 4th and then the 2nd cylinders.

9. After adjusting the thermal clearances in the valve drive, install the removed parts in the reverse order.

The article is missing:

- High-quality photos of repairs

- Photo of the instrument

Timing diagram Lada Largus 8 valves

- 1 - crankshaft toothed pulley

- 2 - coolant pump toothed pulley

- 3 - tension roller

- 4 - rear protective cover

- 5 - camshaft gear pulley

- 6 - timing belt

- A - boss on the rear protective cover

- B - mark on the camshaft pulley

- C - mark on the oil pump cover

- D - mark on the crankshaft pulley.

Another feature of the engine is the location of the water pump (pump), which is rotated by the same timing belt. That is, in case of coolant leaks or characteristic noise/whistle/hum in the timing drive area, checking the belt is mandatory. If the pump bearing crumbles and the belt comes off, then in addition to replacing the water pump housing and belt, you will also have to go through the cylinder head, removing bent valves from there.

AvtoVAZ uses a very reliable Gates belt as the original belt. Often the service life of the Gates belt is much higher than the service life of the pump and tension pulley of the Lada Largus 8-valve engine.

Adjusting thermal clearances in valves

First, select a level area on which to place the car. Next, use a jack to release one of the front wheels and engage fourth speed. In the engine compartment, remove the air filter, first disconnecting the pipes from it. Next, remove the spark plug high-voltage wires, remove the connector connected to the ignition module and carefully move all the wire harnesses towards the passenger compartment. Be sure to wipe the valve cover: this must be done so that any dirt on it is not transferred inside the mechanism. If you think that the ignition module is bothering you, remove it too. Further steps:

- Transferring the pistons to top dead center (TDC). To achieve this, spin the freed front wheel so that the Latin letter “F2” appears on the edge of the camshaft drive gear. In this case, the piston of the 1st cylinder (you need to count from the flywheel) will be in the TDC position, then both the intake and exhaust valves will be closed.

- Arm yourself with 0.2 and 0.4 mm probes. Using the first of them, check the valve operating on the inlet, the second - on the outlet. The feeler gauge should fit into the gap between the valve and the adjusting screw with little force. If this is not the case, the mechanism should be adjusted.

- Take pliers and tighten the adjusting nut with them. Unscrew the locknut with an open-end wrench to “10”. Achieve the required gap and secure it with a nut.

- The order of adjustment for cylinders is: 1,3,4,2. That is, the rocker should touch the camshaft cam within the smallest radius when viewed from the center of rotation.

- After completing the procedure, carry out a control check of the gaps and, if necessary, adjust those that do not meet the standard.

Adjusting valve clearances

| Author: pakhan74 Published: 2187 days ago (October 6, 2015) Logbook: My Log Category: Uncategorized Edited: 5 times - last October 25, 2016 | +10↑ Votes: 10 |

Today the weather was good, there was nothing to do, I decided to check the gaps. I opened the hood, removed the air vent, and blew off the dust.

I unscrewed eight 8mm bolts and saw the “insides”

I jacked up this drive wheel, I’m right-handed and it’s more convenient to turn with my right foot

I spun the wheel until the letter “Fe” appeared. Then I had to lie, because the shaft was already in the right position. But that doesn't always happen

TDC of the first cylinder corresponds to the letter F on the pulley, or the green mark on the shaft.

I turn the wheel towards myself, adjusting the next edge on the shaft, which corresponds to TDC 3 cylinders

In the same way I adjust the edge without marks - this is the 4th cylinder

And the fourth side with the mark - cylinder 2

A couple of pictures of the timing belt

The image has been reduced. Click to see original.

← How to quickly repair a tubeless tire

Create your own logbook, and you will be able to share with forum members your opinion about Largus, useful developments, installed additional information. equipment and tuning, trips and travel! To create a logbook, you must register on the site.

Tags: valve clearance adjustment, engine

Popular in in-flight magazines

DRL Traveling on Largus Fuel consumption Armrest Mileage Discs Radio To1 First impressions Buying Largus Electrics Covers for Largus Bumper net Modifications HBO Speakers Rear view camera Wipers Interior lighting Brake light Tuning Tires and wheels Check valve Tuning lights Noise insulation Winter tires Rugs Largus DVR Rki-19 Winter operation Roof box PTF Tail lights Izhevsk Car audio Injectors Mudguards Washer reservoir Hood stops Low beam lamp Installing a cabin filter Parking sensors Thresholds Lada Largus LED Carpet covers Floating idle speed Trunk lighting Tinting Trunk shelf Trip to the sea Hood seal Accident Owner's review Fender liners Walkie Talkie Additional Socket Eyeglass case Replacement 5th gear

Comments (20)

| Andrey-174 October 6, 2015 at 08:18 pm +1 | |

|

| Den 73 rus October 6, 2015 at 09:28 pm 0 | |

|

| burnt October 6, 2015 at 09:33 pm 0 | |

|

| Den 73 rus October 6, 2015 at 09:37 pm 0 | |

|

| burnt October 6, 2015 at 09:50 pm 0 | |

|

| burnt October 6, 2015 at 08:31 pm 0 | |

|

| Dima October 6, 2015 at 08:41 pm 0 | |

|

| Andrey-174 October 6, 2015 at 08:48 pm 0 | |

|

| LarqusMen585 October 7, 2015 at 07:21 0 | |

|

| pakhan74 October 6, 2015 at 09:01 pm 0 | |

|

| pakhan74 October 6, 2015 at 08:59 pm 0 | |

|

| burnt October 6, 2015 at 09:18 pm 0 | |

|

| pakhan74 October 6, 2015 at 09:25 pm 0 | |

|

| Andrey-174 October 7, 2015 at 06:59 0 | |

|

| pakhan74 October 7, 2015 at 09:01 0 | |

|

| Kuryan October 7, 2015 at 11:46 am 0 | |

|

| pakhan74 October 7, 2015 at 5:31 pm 0 | |

|

| Kuryan October 8, 2015 at 11:24 am 0 | |

|

| Dima October 8, 2015 at 03:35 pm 0 | |

|

| starryway October 29, 2015 at 10:33 pm 0 | |

|

| Add a comment | RSS comments feed |

Additional comments:

Adjusting valves on Lada Largus

What is valve adjustment? This is an increase or decrease in thermal clearances between the camshaft cam and the part of the mechanism that opens the valve.

If the gap is larger or smaller than necessary, the engine will not be able to operate at full capacity. Because of this, parts will wear out faster, fuel consumption will increase and traction will deteriorate.

TIP: On the Lada Largus you need to adjust the valves every 100 thousand km. mileage If the car runs on gas, then the valves need to be checked more often - every 50-70 thousand km.

INTERESTING: The correct thermal gap is extremely important because metal expands when heated. The valves lengthen slightly as they warm up. If changes in size are not compensated, the combustion chamber loses its tightness.

Disadvantages of the Lada Largus 1.6 16 valve engine

1. The first and most unpleasant drawback that the 1.6 engine from Lada Largus has is increased oil consumption. Although, according to the manufacturer’s stated data, the maximum oil consumption should not exceed 100 ml per 1000 km, in fact this figure can be 2.5 times higher. Of course, this problem will not affect many at all, but for many it will be an unpleasant surprise. However, you should not immediately run to a car service center and ask to have the engine rebuilt due to increased consumption. You may simply have chosen the wrong engine oil.

2. The second significant drawback is the bending of the valves when the timing belt breaks . Yes, engine 21129 bends the valve when the timing belt breaks. Unfortunately, nothing can be done about this problem. There is only one way out - timely change the timing belt and rollers and monitor their condition.

3. The third drawback is the knocking of the hydraulic compensators. Since valve clearance is regulated by hydraulic compensators, they tend to knock. This can occur both on a cold engine and on a hot one. Most often, this problem is caused by low-quality engine oil or its untimely replacement. But this drawback exists and does exist.

What happens if you don't adjust the valves?

The main noticeable consequences of incorrect clearances are increased fuel consumption, poor traction and noisy engine operation.

Due to incorrect clearances, the load on the valves and catalyst increases. The valves cool less well and the engine does not operate at full capacity.

Increased and decreased thermal gap

The thermal gap may increase or decrease over time.

With an increased thermal gap, the camshaft hits the valve mechanism. The valves do not close completely and at the wrong time. Because of this, not all of the fuel-air mixture burns, and the engine produces noticeably less power.

With a reduced clearance, the valves do not close tightly, and the combustion chamber ceases to be sealed. Because of this, compression drops. The valves cool less well and may burn out over time. The load on the catalyst also increases.

In both cases the motor does not work properly. Fuel consumption increases, engine power decreases and the load on parts increases.

Consequences of incorrect adjustment

The optimal value of thermal clearances was determined by analyzing the operation of the valve mechanism, gas distribution system and carrying out accurate calculations. With an increased distance, noise appears when the engine is running, especially when it is not warmed up, due to shock loads that negatively affect the entire timing system. This can lead to desiccation of the valve, its jamming, and when it meets the piston at TDC, the gap bends the valve on Largus.

Large thermal gaps do not allow the combustion chamber to be effectively filled with the working mixture, which reduces engine power and impairs the efficiency of its operation.

Too small thermal clearances reduce compression, lead to strong heating of the valve and seat and lead to their burnout. In such a situation, not only does camshaft wear increase, but more serious damage to the timing system may also occur. In both the first and second cases, the result of incorrect adjustment will be the replacement of valves on the Lada Largus, and the entire set will have to be changed

How do you know when the valves need to be adjusted?

Adjusting the valves is a standard procedure. We recommend that Lada Largus owners contact the service every 100 thousand kilometers if the car runs on gasoline. If gas equipment is installed, then you need to check the gaps more often.

INTERESTING: The main sign of a changed thermal gap: the “clattering” of an unheated engine.

TIP: In critical cases, the “clicking” does not stop even after warming up. This means that the gaps have already changed too much and you need to urgently contact service.

If the engine begins to run louder than usual, then first of all you need to listen to the valves. Quite often, it is the changed thermal clearances that explain the increased noise.

How are valves adjusted?

The procedure takes approximately one and a half hours. During this time, the technician will measure the gaps and adjust them if necessary.

- Remove the valve cover.

- We measure the gaps with a feeler gauge in 0.05 mm increments.

- We adjust thermal gaps.

- Clean the cover and space for the gasket.

- We install a new gasket and put on the cover.

- We tighten the cover in 2 stages with a torque wrench.

- We check the operation of the engine.

In addition to adjusting the gaps, it is important to clean the surfaces and seal the valve cover tightly. Otherwise oil will leak.

After adjusting and installing the cover, it is tightened in 2 stages with a torque wrench. First with a load of 2 Newton meters, then with a load of 10. Thanks to this, the lid stands evenly, without distortions or deformation of the gasket.

Adjusting valves in Logan-Shop St. Petersburg takes only an hour and a half. We recommend periodically listening to a running, cold engine and contacting service as soon as you hear a “clunking” sound. This way you will significantly extend the life of the valves, catalyst and engine as a whole.