Stabilizer bushings. Signs of malfunction. Consequences.

For the best damping of vibration and force impacts on the car body, the vast majority of suspension elements are connected by means of elastic elements.

The same applies to the stabilizer. To secure it, special bushings (rubber bands, cushions) made of durable rubber or polyurethane are used. Over time, as the vehicle is used, these bushings may begin to deteriorate and noticeably lose their elasticity. The result of this is unsatisfactory operation of the stabilizer =. More serious defects may begin to appear, which will only grow faster over time. The first symptom indicating replacement of the bushings will be a slight knocking sound from the suspension. A similar knock can be observed with “tired” shock absorbers. Only in the case of bushings it will be heard not only on potholes and potholes, but also when entering relatively sharp turns. At the same time, the car often feels excessively rolly and sluggish. The knocking sound that appears will be a consequence of play that has arisen in the connecting nodes of the stabilizer arms due to worn bushings.

If measures are not taken in time, the knocking will only intensify in the future and will begin to accompany the operation of the suspension everywhere due to increasing deformation and destruction of the bushings. Body roll and excessive play in the steering wheel may occur. The car may “yaw” not only when turning, but also when braking or changing lanes. Most car manufacturers recommend changing stabilizer bushings every 30–40 thousand mileage. However, in our conditions it is better to focus on bushing wear. Therefore, a sudden knocking sound and slight rattling in corners will be clear signs of an impending component replacement.

As a popular method of checking the bushings for serviceability, it is proposed to drive the speed bump diagonally in 2nd gear. A dull knock appeared in the area of the pedals - most likely due to the hub bushings. You can also just crawl under the car and inspect everything yourself. A worn bushing will be pleased with the presence of cracks and abrasions characteristic of worn and cracked rubber. Auto mechanics sometimes also call these cracks “daisies.”

Also, the rubber of the bushings can simply harden and lose the necessary elasticity. If you can’t get a good look at the stabilizer bushings, just swing your hand strongly up and down and to the sides on the stabilizer itself. If you feel play, creaks and knocks in the lower part of the suspension, it means that the bushings have become unusable.

But for the best results, it is, of course, better to drive onto an overpass, an inspection hole, or use a lift. The only tools you will need are a crowbar or a mounting spade, which you simply need to rest against the bottom of the car and slightly “shake” the stabilizer where it connects to the body. If you feel noticeable play or loss of elasticity, then it’s time to think about replacing the bushings.

What tools may be needed when replacing stabilizers yourself?

Performing this work will not require the driver to use high-tech devices. To do this you need to have the following tools:

- jack;

- extension for key;

- socket wrench for 10 and 13;

- ruler;

- socket heads for 13 and 14. Preferably elongated;

- ratchet wrench.

This is the minimum required set of tools, without which you definitely cannot carry out repairs. However, you may need an additional set. This need may arise when removing the fastening nuts. The fact is that during operation they can stick to the part. In this case, you may need a grinder or a hacksaw. You need to use these tools very carefully, because you can damage the stabilizer links. If this happens, then you will need to change them too.

Benefits of timely replacement

Every driver can cope with replacing bushings on his car, because this process is not a very complicated repair. You can do everything yourself, but if you don’t have the time or desire, then it is advisable to seek help from specialists. This will protect the stabilizer bar links from premature wear.

Driving on poor-quality road surfaces will fade into the background if you have previously installed new bushings. And in general, installed new bushings mean the absence of difficulties and problems when moving, as well as comfort and safety.

Smooth road to everyone: how and why to change stabilizer bushings

No need to heel!

If cars always drove in a straight line, and did not accelerate or brake, a stabilizer would not be needed at all.

Its work begins every time the car tries to tilt. Whether it's lateral roll when turning or longitudinal roll when braking, the stabilizer tries to keep the body parallel to the road surface. And despite the elementary design, he does it well. The stabilizer is just a rod connecting the subframe to the wheel mount (today we will talk about the MacPherson front suspension, so let’s put it more simply - with the suspension arm). It should be noted that MacPherson really, really needs the use of a stabilizer, mainly due to some compromise in the design. The camber angle there is static, but during roll it changes due to the peculiarities of the suspension design. Why is this bad? Because changing camber angles inevitably reduces the area of contact between the tire and the road. And the only way to avoid this phenomenon is to reduce the roll. This is where the stabilizer, which works like a torsion bar, helps: with a lateral roll, the opposite ends, fixed in the levers, begin to move in different directions, twisting the middle part. The resulting moment prevents further relative movement of the wheels, reducing roll. As you can see, it works very simply.

Articles / Practice Let's burn like a child: how and why to change rear suspension silent blocks Often the word “silent block” written on the Internet makes you want to pick up a drill and drill out your eyes. No matter how they write it, the “salenblock” option is the most common. We see... 51584 1 2 12/19/2016

But in order not to become a fan of the cult of the stabilizer, it is necessary to say a few words about its shortcomings. Firstly, the stabilizer willy-nilly reduces the suspension travel. Of course, this is not critical for a passenger car, but for an SUV it can be harmful. Well, secondly, you shouldn’t get carried away with replacing the stabilizer with something more rigid, which some car owners sometimes like to do. In their opinion, a more durable stabilizer will help to almost completely avoid rolls and turn the Zhiguli into a Formula 1 car. This is a very dangerous misconception.

The first thing Kulibin will encounter with an arm-thick piece of iron in the front suspension is an unexpectedly easy drift due to an unhealthy imbalance of the grip of the front and rear wheels with the road (it will be insufficient for the rear wheels). It must be understood that the engineers who developed the suspensions carefully calculated not only each of the suspensions, but also their joint work. And if you incorrectly interfere with the operation of one of them, the overall controllability will decrease, although the roll, quite possibly, will become a little less.

So, what does the bushings have to do with it, and why change them? As I already said, the stabilizer must be able to twist from multidirectional forces on the right and left wheels. If it is welded or rigidly attached to the subframe in any other way, it will be deprived of this opportunity, which is why it is attached to it using bushings. Over time, they wear out, and the stabilizer begins to “walk” in them.

This play, like any other, increases the degrees of freedom of the part, which nullify all its ability to prevent roll. And then, when cornering, the car begins to lean on its side more than it should.

Not every car enthusiast will immediately notice this, so they change the bushings in other cases: if wear is detected during suspension diagnostics, or if it is already starting to knock. However, the second situation is usually more typical not due to physical wear, but due to a good impact or other mechanical impact.

So, we have come to understand that bushings must be replaced periodically, and this is completely normal. Let's see how to do this.

What will you need?

What's great about this renovation is that it's inexpensive. And I would even say that there is no point in doing it with your own hands, no matter how skillful they may be. Therefore, let's go to the service center and just watch how a specialist does it.

You will need a minimum of tools: an 18 mm socket and a 10 mm wrench (or socket). But look at the wrench: why has life crippled it so much? In fact, what we have in front of us is not just a key, but the Modernized Special Tool of Alexey Teleshov, we will call it that.

Since we will be changing the bushings on Logan, we will have to take into account some of its features, so such a tricky key may come in handy. In addition, you will have to look for a lift, and quite possibly a hydraulic strut (we used it, in any case) along with an angle grinder. So, despite the apparent simplicity, everything is not so simple.

Now about the cost of spare parts. There is no point in chasing the original, there are very worthy manufacturers, especially since the bushing is a piece of elastic, and it is not so difficult to do something there. Therefore, we pay attention to two popular models: the French Sasic for 160 rubles and the Belgian Sidem for 180. We will choose Sasic.

We go into the box and get on the lift.

As usually happens with threaded connections at the bottom of the machine, they have all long since become covered with a layer of dirt and have become sour. Therefore, before starting work, it makes sense to pour WD40 on the bolts. We wait a little and pull out into the light that same key with a broken fate and try to unscrew the ten bolt from above (seen in the photo).

Naturally, this is as useless as asking a cat to quickly walk through an open door (if you have a cat, you will understand the futility of the plan). But in this case, the design of the Logan suspension itself helps us: this bolt is usually simply cut off, because its purpose is unclear to anyone, even in the heavier and off-road Duster this unit is made simpler and a little more gentle (and the bolt has a smaller diameter). Therefore, the specialist draws a mark with a white marker at which it will be necessary to cut off the ear of the clamp. Now it’s up to the “grinder”: cut off this ear and move to the other side.

1 / 3

2 / 3

3 / 3

Here the matter is complicated by the dangerous proximity of the clamp to the fuel pipes. They will have to be removed. This is easy to do: unscrew the nearest bolt protecting the oil pan, after which the tubes can be pulled out of the clamps and moved to the side. To keep them out of the way, they can be secured with a hook made of any fairly stiff wire. But all this will have to be done only if the eye has to be cut off on this side as well - for some reason the bolt here came off easily.

1 / 3

2 / 3

3 / 3

Now remove the clamp. We unscrew the only fixing bolt with a head. Removing the clamp is not so easy, so we take the mounting bracket and hook it to the hole of this bolt. That's it, the clamp is in our hands. Now, using the same installation, we remove the stabilizer from the subframe and take out the bushing. Just for fun, let's compare the new and old bushings. The part we just removed shows wear, but it is not critical yet. A completely dead bushing has a well-defined ovality. But once we start making changes, we do the work until the end.

1 / 4

2 / 4

3 / 4

4 / 4

We take the assembly again and again move the stabilizer away from the subframe. We insert the sleeve, after which the mounting can be removed. To make it easier to install the clamp, we use grease (we used copper). We apply it to both the clamp and the bolt.

1 / 4

2 / 4

3 / 4

4 / 4

This is necessary so that, firstly, it is easier to put on the clamp, and secondly, it is easier to unscrew the bolt next time. It is not always possible to press the clamp into place by hand. I would even say that it always doesn’t work out. Hitting the rubber with a hammer is usually useless, so we drag a hydraulic strut under the car. We rest it against the clamp and lift it slightly. If everything is assembled correctly (although what could be assembled incorrectly?), then the holes on the clamp and the subframe will coincide, and all we have to do is tighten the bolt and then tighten it to the end.

1 / 3

2 / 3

3 / 3

Articles / Practice Quietly and quickly: how and why to change gears in a manual transmission There was a time when three forward gears in a manual transmission were enough for car enthusiasts to move comfortably. But then four of them appeared, and now there have never been fewer than five... 22903 0 7 12/05/2016

It happens that the clamp does not want to go into place. In this case, you should not try to pull it onto the bushing with excessive force: it can be damaged or deformed and simply tighten it crookedly. It will turn out even worse than it was, because the stabilizer is equally contraindicated by excessive play and too tight a position, when it cannot work as a torsion bar. Most likely, the problem is insufficient lubrication - without it, friction between the iron of the clamp and the rubber of the bushing will not allow the part to be installed correctly and without unnecessary effort. Add a little of it and everything will go much easier.

And now we repeat exactly the same operation on the other side, not forgetting to return the fuel pipes to their place and tighten the protection bolt if they still had to be removed. That's all.

What's the result?

In principle, there are no fundamental differences on other cars with MacPherson front suspension. And there is hardly anything difficult in this work, if not for the use of a lift and some other tools to deal with soured bolts.

Work in the service would cost 440 rubles per side. Inexpensive, but you can try to make it yourself. There is a beauty here: if something goes wrong, you can carefully drive to the service station without a stabilizer at all, and then everything will be put back together as expected. Well, maybe they will laugh, but this will happen in your absence.

It will be much worse to continue driving with broken or worn bushings. Even if there is no knocking at the bottom (and at first there will definitely be nothing knocking), the controllability will decrease, sometimes even to the point of disgrace. There is no point in bringing it to this point; every turn will be much more dangerous than it actually is.

For assistance in preparing the material, we thank the network of specialized stores and car services “Logan-Shop” (St. Petersburg, Shkolnaya St., 73/2, tel: 928-32-20)

Survey

Have you ever had a stabilizer bar?

Your voice

Total votes:

Replacing the Kia stabilizer bushing

Replacing the Kia stabilizer bushings involves the following algorithm: • Raise the front of the car and remove the wheels. Find the steering shaft and make a mark (for easy further installation in the original place), remove the mounting bolt. • Using a jack, lift the gearbox, unscrew the rear cushion and subframe. • To simplify access to the rear cushions, four bolts are removed to secure the subframe. • Raise the front part of the subframe using a jack. • Remove the fastening and treat it with an oil solution to prevent the development of corrosion processes on the metal. • Screw them into place only four to five turns.

This is done crosswise to provide additional security and uniform tightening of the plane. • Loosen the jack to a level where you can reach the bushing bolts. • The bushing on the right side can be easily unscrewed through the engine compartment, and on the left side - from below. • Insert staples. This procedure is carried out in a careful manner so as not to damage the clamp on the steering boot. • The process is repeated in reverse order. The peculiarity of the Kia Sid car is that the steering shaft has a telescopic appearance, and therefore its installation occurs at the last moment.

Replacement and repair of SPU - when is it required and how is it done?

The anti-roll bar should be repaired immediately if its elements are noticeably deformed. If you notice that the bar is slightly bent, it is recommended that you carefully align it. However, if there is significant deformation, the solution is to replace immediately.

In addition, repair or replacement of the SPU is carried out when the mechanism cushions lose elasticity (severe wear) and are poorly close to the stand. To repair or install new blocks, do the following: Unscrew the mounting bolts from the clamp holding the blocks; Insert a screwdriver under the hook, gently push it down and remove it.

After completing these steps, you can remove the airbag (the right airbag must be taken outside to disassemble the car, the left one - towards the center) and repaired or installed a new one. Removing and replacing SPU spacers also takes very little time. We carry out this process with a 14 mm wrench according to the following scheme:

- Remove the nut on the boom holding the mounting bolt;

- Remove the bushing (top);

- Pull out the rocker arm suspension bolt (direction down), then remove two bushings - rubber and special gasket.

In the same way, disassemble the second shelf, replace or repair them, and then reassemble in reverse order. If we want to disassemble the bar, after removing the struts we remove the pillow supports (we described this operation earlier), then the bar moves out of place without any problems.

The suspension of any car is always the first to absorb the impact of road irregularities. Depending on the design and settings, the suspension components do their job: absorb shock loads arising from surface unevenness, and provide controllability and stability at high speeds when cornering, as well as sudden changes in trajectory (“snake”, avoiding obstacles). Not only comfort, but also the safety of the driver and passengers depends on the performance of the suspension. Each suspension element plays its role. Handles and levers support the wheel in a given plane, providing free rotation in two planes (when turning).

The following types of bushings exist:

1. Spherical (or “iron”) bushing. The design resembles a ball joint;

2. Rubber bushing.

Today, polyurethane type stabilizer bushings are becoming increasingly popular. They are quite easy to replace, which is an important advantage, and they also have good operating characteristics. Experienced drivers can safely say that these are the parts that are most convenient.

If a malfunction occurs in the area of the stabilizer bushing , it must be replaced without fail. Otherwise, this can have a very bad effect on the performance and handling of the vehicle. When the bushing is deformed or cracks appear on it, some noise may appear in the area of the car suspension (mainly when the car hits an obstacle or increases speed). In principle, problems in the suspension area are identified precisely by such noise.

In order to make sure that it is necessary to replace the bushings, periodically it is necessary to carry out diagnostics of the suspension, after which the malfunction will be identified or prevented.

In the event that it is determined that it is necessary to replace the stabilizer bushing, this can be done independently. Moreover, there is nothing complicated about it and the procedure is very simple. First, the bolts with which the clamp is attached are unscrewed. Then the stabilizer is moved to the side and the old parts are removed. Well, for the final action, the new part is installed very carefully.

It is according to this scheme that both the front stabilizer and the rear stabilizer are replaced . After replacing spare parts, driving a car will be much more pleasant and comfortable, and various kinds of road obstacles will be overcome without any difficulties. Among other things, the new elements will maximize the performance of the racks.

Throttle sensor: purpose, types, types, malfunctions, photos

Idle speed sensor: principle of operation, device, types, photo, purpose

Air flow sensor: principle of operation, types, malfunctions, photos

Advantages and disadvantages of SPU

Despite the apparent simplicity of the design of the mechanism we are interested in (for its fastening you only need a strong support, a high-quality rubber bushing, rods, bones), it easily copes with the tasks assigned to it. It is worth mentioning here, however, that LSS reduces the travel of the independent suspension and “takes away” several other important properties from it. For this reason, a stabilizer bar is not installed on SUVs.

When driving such all-terrain vehicles equipped with all-terrain tires on bad roads, there is a noticeable loss of contact between the wheel and the road and its suspension. This negative phenomenon is caused precisely by the use of SPU. It is obvious that car designers do not intend to abandon the use of a stabilizer in these cases either. Currently, several options for modernizing SPU designed for SUVs have been developed.

For example, TRW has developed a modern system consisting of hydraulic cylinders that act as struts, a lateral acceleration sensor, a hydraulic pump and a special control unit. This system, which does not require rubber bushings, has proven to be an effective replacement for traditional LSS.

Western automakers have begun installing adaptive suspensions on their cars. These mechanisms eliminate the need for SPU, guaranteeing ideal vehicle behavior (no roll) in all driving conditions (acceleration, cornering, hard braking, etc.).

The principle of operation of stabilizers

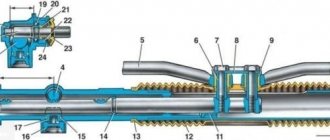

Springs provide elasticity and return the suspension elements to their original state, and shock absorbers provide smooth ride and damping of elastic vibrations of the body. At the same time, even the perfect operation of the listed elements is not enough to ensure safe movement. If you hang the car on a lift or drive it into an inspection hole, in addition to the levers, springs and shock absorbers on any modern passenger car, you can see another element - the anti-roll bar. In the front axle suspension, the stabilizer is a curved lever, attached with one shoulder to the wheel hub assembly, and the other to the subframe. The fastenings are not rigid, with the ability to move along the axis in one plane.

The principle of operation of the stabilizer is to redistribute the weight of the car body over the wheels when it rolls. For example, when taking turns with a small radius or when suddenly changing the trajectory of movement. In the widely used front suspension of the McPherson type, the anti-roll bar is a torsion bar that works to twist. This lever has a rigid connection to the body or subframe. The forces from the suspension are transmitted to it using additional levers pivotally connected to the suspension. Such a simple device can prevent a strong roll of the car (and, accordingly, its capsizing), while maintaining a straight trajectory.

In the rear axle suspension, an anti-roll bar is usually installed on vehicles with all-wheel drive. On many rear-wheel drive car models with a solid rear axle beam, the role of a stabilizer is performed by a reaction rod (Panhard rod). Some all-wheel drive Japanese-made models of previous years (Toyota Sprinter Carib, Land Cruiser 80, etc.), along with a Panhard rod, are equipped with a stabilizer - a curved rod passing through the entire rear axle beam and connected through short levers to the power elements of the body or frame. The principle of operation of the rear stabilizer is similar to the principle of operation of the front one: reducing the overturning moment of the body when it rolls.

How to replace front and rear stabilizer bushings?

Anti-roll bar bushings are an integral element of the system that ensures lateral stability of the vehicle in corners. During a turn, centrifugal force tends to tilt the body in the opposite direction, and the stabilizer torsion bar, attached to the body and suspension using bushings, resists this influence. Over time, bushings wear out, break down and become unusable, after which they must be replaced. We will talk about how to determine whether bushings require replacement and how to change them.