The VAZ 2108 device, like any other vehicle, involves powering electrical circuits from a battery. To ensure that the battery is always in good condition and does not let you down at the most inopportune moment, a generator is always connected to it.

The battery is especially important when the engine is ignited; while driving, when the car develops sufficient speed, the entire electrical circuit is powered by the generator.

When the question arises about connecting additional powerful electrical appliances to the car, it is very important to match their load with the permissible power of the generator. To do this, it is important to know its technical characteristics. And if the battery lack of charge indicator suddenly lights up, it’s better not to even look under the hood without understanding how the electrical charging circuit, voltage regulator and ignition work.

After reading today's article to the end, you will learn about the connection diagram and dimensions of the VAZ 2108 generator, the main reasons for failure and how to check the voltage in the circuit. If trouble happens to the generator, then don’t worry, we will clearly show you the process of removing and installing it.

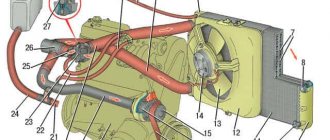

VAZ 2108 generator circuit

The VAZ-2108 generator has a rather massive stator winding, since it uses a large cross-section wire. It is with its help that electricity is generated. The wire is wound evenly over the entire inner surface of the stator into recesses specially provided for this purpose in the magnetic core.

It’s worth talking about the latter separately. The middle part, the generator stator, consists of a series of thin metal plates pressed tightly together. They are often boiled on the outside to prevent separation.

- Alternator. The 37.3701 or 94.3701 series can be installed.

- Negative diode.

- Additional diode.

- Positive diode.

- Alternator warning lamp, also known as battery discharge lamp.

- Instrument cluster.

- Voltmeter.

- Relay and fuse box located in the engine compartment in the compartment between the engine and the vehicle interior.

- Additional resistors built into the fuse mounting block.

- Ignition relay.

- Egnition lock.

- Accumulator battery.

- Capacitor.

- Rotor winding.

- The voltage relay is located in the engine compartment.

Assembling the unit

We are starting to assemble a generator for the VAZ 2108, the repair has reached its final stage:

- Assembly begins by pressing the rear bearing back onto the shaft. We perform this action using a small board and a hammer.

- Place the bearing on the shaft with two or three strong blows

- If you removed the rectifier unit, return it to the same four studs for securing the rectifier unit, located in the back cover

- Now we install the back cover itself back on the rotor so that the bearing completely “sits” into the intended seat located in the back cover

- To simplify the procedure, you can use a hammer and hit the cover with gentle blows through a wooden block to “plant” it completely on the shaft

- In our front cover we replace the small (front) bearing and secure it with plates

- We take the unit out of the vice and before putting on the front cover, put a spacer ring on the shaft, which should be located between the front ball bearing and the thrust recess located on the shaft

- We put the front cover on, tighten the nuts on the studs “crosswise” so that they are tightened evenly

- We install the key into the recess of the rotor shaft, then insert the impeller and tighten it with a nut

Now the generator is assembled, now it’s convenient to install the relay with brushes in place.

Returning the unit to its place

The installation procedure is the reverse process of removal:

- We insert it into the mounting bracket

- With one hand we press on the motor from above, and with the other hand, from the side of the front right wheel, we insert the bracket mounting bolt into place

- Screw on the bolt nut, but do not tighten it

- Then we secure the dust protection using self-tapping screws.

- Now we put the drive belt on the unit pulley and install the belt tensioner bar

- We tighten the drive belt to the desired deflection value (1 - 1.5 centimeters) and at the same time tighten the nut located on the tensioner plate

- Now we tighten the nut located on the mounting bracket of our generator.

That's it, the unit has been installed successfully. Completed for vases. Make sure once again that the minus terminal is removed from the battery and connect all the wires back to the generator. Remember that: paired wires are attached with a nut to a stud located on the back cover of the generator, and a single wire is connected using female-male connectors. Now you can connect the negative terminal to the battery and start the engine. If the work was done correctly, then the repair of electrical equipment (generator in particular) on the VAZ 2108 is completed and is no longer a problem for you. The power source began to produce the required voltage for the vehicle to operate. To be completely sure of proper operation, you can check the voltage it produces with a voltmeter. If not everything is clear about the design of the generator, then look for repairs of the VAZ 2108 in the electrical equipment section or use the training video.

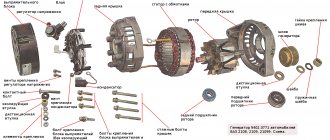

The generator of VAZ 2108, 2109, 21099 cars is a synchronous, three-phase electric machine, alternating current with electromagnetic excitation. It has a built-in rectifier (diode bridge) based on silicon diodes and an electronic voltage regulator. In addition, there is a rotor - the rotating part of the generator and a stator - the stationary part. The rotor is driven by a belt from a pulley on the engine crankshaft. On VAZ engines 2108, 21081, 21083 there is a V-belt, on 2111 there is a poly-V belt. A number of cars were equipped with generators made in Bulgaria, Slovenia, and Germany. Their characteristics are similar to domestic generators, but they may differ slightly in design.

On VAZ carburetor engines a generator 37.3701

, for engine 2111

generator 9402.3701

.

Both generators are similar in design and characteristics, the only differences are in the amount of current supplied (9402.3701 is more powerful). Technical characteristics of the generator 37.3701

- The value of the delivered current (at 6000 rpm -1 and a voltage of 13 V) - 55 A

- The voltage value - 13.6 - 14.6 V

- The direction of rotation of the rotor is right

- The maximum rotor speed is 13000 rpm -1

— Gear ratio engine/generator 1/2.04

Technical characteristics of the generator 9402.3701

— The value of the delivered current (at 6000 rpm -1 and a voltage of 13 V) – 80 A

— The voltage value – 13.2 – 14.7 V

— The direction of rotation of the rotor is right

A normally working, serviceable generator of VAZ 2108, 2109, 21099 cars and their modifications produces a voltage in the range of 13.6 V - 14.6 V

. This can be visually tracked using a voltmeter on the instrument panel, or it is better to measure the voltage with a voltmeter (multimeter, autotester...). Based on this, generator malfunctions come down to just two problems:

— the generator does not provide charging current at all

, or gives it in a small volume (the voltage is small - the voltmeter needle is in the red zone or close to it);

— the generator produces too much charging current

(the voltage is higher than normal, the voltmeter needle points too far to the right).

In the first case, the battery is undercharged and, after some time, starting the engine will be problematic. In the second case, the battery is overcharged and, as a result, its electrolyte boils away (the battery “boils”), the plates fall off, and then the final failure occurs.

It is advisable to have at least the simplest tester in order to diagnose generator malfunctions with a high degree of probability. In addition, based on the instrument readings, you can also draw certain conclusions about the performance of the generator set.

Several articles on our website provide the most suitable generators for VAZ 2108, 2109, 21099 cars with recommendations for diagnosing and eliminating them.

The generator in cars is designed to generate electricity and charge the battery. If the normal operation of a car electric generator is disrupted, the battery begins to discharge and soon the car will stop starting completely - there is not enough battery charge. This device consists of a three-phase diode bridge, which, in turn, has 6 silicon diodes. Electrical voltage is created by the excitation of the rectifier at the moment when the rotor poles change under the stator windings. When the rotor rotates inside the machine stator, the poles of the rotor change. To increase the value of magnetic fluxes, the stator contains an electromagnetic exciting winding in the area of the magnetic cores. Marking and designation of wires:

- P - pink.

- F - purple.

- O - orange.

- B&W - black and white.

- KB - brown and white.

- CHG - black and blue.

- K - brown.

- H - black.

- B - white.

Technical characteristics of the VAZ 2108 generator

The following generator models are installed on VAZ 2108 cars:

- 3701

- 3701

Technical characteristics of the first:

- The value of the delivered current (at 6000 rpm-1 and a voltage of 13 V) – 55 A — The voltage value – 13.6 – 14.6 V

- Rotor rotation direction – right – Maximum rotor speed – 13000 rpm-1

- Engine/generator gear ratio 1/2.04

Technical characteristics of the second:

- The value of the delivered current (at 6000 rpm-1 and a voltage of 13 V) – 80 A — The voltage value – 13.2 – 14.7 V

- Rotor rotation direction: right

A normally working, serviceable generator of VAZ 2108, 2109, 21099 cars and their modifications produces a voltage in the range of 13.6 V - 14.6 V. This can be visually tracked using a voltmeter on the instrument panel, but it is better to measure the voltage with a voltmeter (multimeter, autotester

repair of generator 37.3701 - cars VAZ 2108, VAZ 2109, VAZ 21099

1. Remove the generator from the VAZ 2108, VAZ 2109, VAZ 21099 (see “Removing and installing generator 37.3701”).

2. Unscrew the nut and remove the generator adjustment bar. Mark in any way (most conveniently with a felt-tip pen) the relative positions of the covers and the generator stator.

3. Unscrew the fastening nut and remove the clamping sleeve.

4. Remove the bolt and bracket from the generator.

5. Unscrew the fastening nut, holding the generator pulley from turning (see “Replacing the generator pulley 37.3701”), and remove the pulley along with the fan impeller. Remove the segment key from the armature shaft.

6. Unscrew the nut and disconnect the capacitor wire from terminal “30” of the generator.

7. Unscrew the screw and remove the capacitor from the generator.

8. Disconnect the connector with the wire from the brush holder on the generator.

9. Unscrew the two screws securing the brush holder.

10. Remove the brush holder with the voltage regulator.

11. Unscrew the four fastening nuts...

12... and remove the four coupling bolts.

13. Using a puller, remove the drive-side generator cover from the armature shaft.

14. Remove the spacer from the armature shaft.

15. Remove the generator armature from the generator cover on the commutator side.

16. Unscrew the three fastening nuts and disconnect the stator leads from the rectifier unit.

17. Remove the three bolts securing the rectifier unit and stator leads with insulating pads.

18. Remove the generator stator from the generator cover.

19. Unscrew the nut securing terminal “30” on the generator.

20. Using a screwdriver, press out the protrusion on the plug inside the connector and push the plug with the wire inside the generator cover. In this case, the plastic connector remains on the generator cover.

21. Remove the rectifier unit from the generator cover.

22. To replace the bearing in the generator cover on the drive side, unscrew the four fastening nuts, remove the bolts...

23... and remove the inner and outer bearing mounting washers. Then, using a suitable mandrel, press the bearing out of the generator cover. Press the new bearing flush with the surface of the generator cover. Force must be applied only to the outer ring of the generator cover bearing.

24. To replace the generator armature shaft bearing on the commutator side, press the bearing with a puller from the armature shaft. Press the new bearing onto the armature shaft until it stops, applying force only to the inner race of the bearing.

25. Inspect the slip rings. If they have burrs, marks, scratches, signs of wear from brushes, etc., the rings must be sanded. If damage to the rings cannot be removed with sandpaper, turn the rings on a lathe, removing a minimum layer of metal, and then sand them.

26. Check the resistance of the generator rotor winding with an ohmmeter (tester) by connecting the ohmmeter to the slip rings. If the ohmmeter shows infinity, it means there is a break in the windings and the rotor needs to be replaced.

27. Using a test lamp, check whether the winding is shorted to the rotor body. Connect the test lamp to a 220 V AC power supply (you can use a battery and a 12 V lamp). Connect one of the wires to the rotor body, and the second to each ring in turn. In both cases, the lamp should not light. If the lamp lights up, then the winding is short-circuited: the rotor must be replaced.

28. Inspect the generator stator. There should be no traces of the armature touching the stator on the inner surface of the stator. If there is wear, you need to replace the bearings or generator covers.

29. Check if there is a break in the stator winding. To do this, turn on the test lamp to a 220 V AC power supply (you can use a battery and a 12 V lamp). Connect a test lamp one by one between all terminals of the stator winding. In all three cases the lamp should be on. If the lamp does not light up, there is a break in the stator winding. Replace stator or winding.

30. Check if the stator windings are shorted to the housing. To do this, turn on the test lamp to a 220 V AC power supply (you can use a battery and a 12 V lamp). Connect the lamp to the terminal of the stator winding, and the wire from the current source to the stator housing. If the lamp lights up, it means there is a short circuit - the stator or stator winding must be replaced. 31. Inspect the generator cover on the drive side. If there are cracks, especially in the alternator mounting areas, replace the alternator cover. Measure the diameter of the bearing seat in the generator cover on the drive side. If the bearing hole is deformed or its diameter exceeds 42 mm, replace the generator cover. 32. Check the ease of rotation of the generator bearings. If, when the bearings rotate, there is play between the rings, rolling or jamming of the rolling elements, the generator bearings must be replaced. Also replace bearings with damaged protective rings or signs of lubricant leakage. 33. Inspect the generator cover from the slip ring side. If there is damage or the bearing seat ring is worn, replace the generator cover.

34. Check the serviceability of the voltage regulator. Connect a 12V test lamp to the voltage regulator brushes. Apply 12 V voltage: “+” to the terminal, “-” to the “ground” of the brush holder. The indicator lamp should light up.

35. Increase the voltage to 15-16 V - the lamp should go out. If the lamp does not go out or light up at 12 V, replace the voltage regulator with brush holder.

36. Check the ease of movement of the brushes in the brush holder and their protrusion. If the brushes protrude less than 5 mm from the brush holder, replace the voltage regulator with brush holder. If chips or cracks are found on the brushes, replace the voltage regulator.

37. The serviceability of the generator capacitor can be checked with a megger or tester (on a scale of 1-10 MOhm). Connect the tester probes to the capacitor contacts. Before connecting, the device shows infinity. At the moment of connection, the resistance decreases and then returns to infinity again. In this case, the capacitor is OK. The faulty generator capacitor must be replaced. You can check the diodes of the generator rectifier block either with the generator removed or without removing the generator from the VAZ 2108, VAZ 2109, VAZ 21099. The procedure for checking the generator rectifier block is the same. For clarity, the rectifier unit test circuits are shown on a removed generator. To check the rectifier unit on a VAZ 2108, VAZ 2109, VAZ 21099, disconnect the wires from the battery and generator, and also remove the block with the wire from the terminal of the voltage regulator.

1 - positive diodes; 2 - negative diodes;. 3 - additional diodes.

38. Check the rectifier unit diodes using a 12 V test lamp and battery. To check the short circuit in the positive and negative diodes, connect the “+” of the battery through a test lamp to terminal “30” of the generator, and the “-” of the battery to the generator housing. If the lamp lights up, then there is a short circuit in the diodes and the rectifier unit must be replaced.

39. To check the positive diodes, connect the “+” battery through a test lamp to terminal “30” of the generator, and the wire coming from the “-” battery to one of the rectifier unit mounting bolts. If the lamp is on, it means there is a short circuit in the positive diodes: the rectifier unit must be replaced.

40. To check the negative diodes, connect the “+” battery through a test lamp to one of the rectifier unit mounting bolts, and the wire coming from the “-” battery to the generator housing. If the lamp lights up, then there is a short circuit in the negative diodes - the rectifier unit must be replaced.

WARNING A burning lamp when checking negative diodes may also indicate a short circuit of the stator winding to the generator housing, however, such a malfunction is much less common than a short circuit of diodes.

41. To check additional diodes, connect the “+” wire from the battery through a test lamp to terminal “61” of the generator, and the wire coming from the “-” battery to one of the rectifier unit mounting bolts. If the lamp lights up, it means there is a short circuit in the additional diodes. The rectifier unit needs to be replaced. 42. Reassemble the generator in the reverse order of disassembly. At the same time, orient the generator covers in accordance with the previously made marks. Install the spring washer of the generator pulley with its convex side facing the nut. Tighten the nut to a torque of 39-90 N•m (3.9-9.0 kgf•m).

- Author: admin

Rate this article: Share with friends!

replacing generator pulley 37.3701 on a VAZ 2108, VAZ 2109, VAZ 21099

repair of generator 94.3701 - cars VAZ 2108, VAZ 2109, VAZ 21099

Reasons for failure of the VAZ 2108 generator

Experts believe that the main reasons for the failure of the VAZ 2108 generator are:

- voltage regulator failure;

- damage to the diode bridge (aka rectifier);

- wear of current collecting brushes;

- defects in the charging circuit wires;

- damage or operational wear of the pulley;

- wear of slip rings or commutator;

- short circuit of individual turns on the stator winding;

- bearing failure.

Every self-respecting car enthusiast should understand what causes generator malfunctions most often and how they can be dealt with. It is also necessary not to forget that timely prevention helps to avoid serious problems. Towards the end of the article, we will look at some tips that will help you learn how to test the generator yourself. But let's first learn about the internal structure of the node.

Connection diagram for the VAZ-2101 generator

Structurally, generator 2101 consists of the following main elements:

- The rotor

is a moving part that rotates from the engine crankshaft. Has an excitation winding. - The stator

is the stationary part of the generator and also has a winding. - Front and rear covers

, inside of which bearings are installed. They have eyelets for attaching to the internal combustion engine. The back cover contains a capacitor necessary to cut off the alternating current component. - Semiconductor bridge

- called a “horseshoe” for its similarity. Three pairs of semiconductor power diodes are mounted on a horseshoe-shaped base. - A pulley

on which the VAZ-2101 generator belt is placed. The belt is V-shaped (on modern cars a multi-ribbed belt is used). - The voltage regulator

is installed in the engine compartment, away from the generator. But still it must be considered part of the structure. - The brushes

are mounted inside the generator and transmit the supply voltage to the field winding (on the rotor).

How to check the voltage of the VAZ 2108 generator

In order to check the performance of the VAZ 2108 generator, you need to perform the following steps:

- Using a voltmeter, diagnose the voltage at the battery terminals. When the engine is running and the generator unit is operating normally, this parameter should be around 13.8-14.5 volts.

- Try placing your palm on the unit body with the engine running, you need to feel the vibration. If there is vibration, you will notice it immediately. Moreover, it may be due to wear of bearing parts.

- It is also necessary to diagnose the tension of the device strap, while the motor must be turned off. Press the strap with your finger - the deflection should be no more than 1.5 cm

Connection diagram for the VAZ-2110 generator

On VAZ-2110, 2111 and 2112 cars, a 94.3701 generator was installed with a maximum output current of 80 Amperes and a voltage = 13.2–14.7 Volts.

Here is a breakdown of the connection diagram for the generator on the ten

:

- Battery 12V;

- generator 94.3701;

- mounting block;

- egnition lock;

- battery charge indicator lamp in the instrument cluster

Interchangeability of the VAZ 2108 and VAZ 2106 generator

The idea of replacing a generator on a classic is as old as the history of the car itself, because everyone who installs more bells and whistles on their own car than a weak Chinese radio, the native 42A G-221 is no longer enough for everyone.

True, even those who neglect the hassle of installing a more powerful generator are annoyed by the weak low beam at idle and poor battery charge. Once, an acquaintance fitted me with a 55A generator on a ball and the idea arose about telling you how to install it in our classic.

Having scoured the Internet to find at least something about installing and connecting it to a car, I didn’t find anything useful, a lot of comments like “Plug it in and forget it” or long discussions of professional electricians, but they spoke in a language that would suit a simple Russian to a person, it’s like a Chinese song, nothing is clear.

In this regard, it was decided to write an understandable article for ordinary people in order to help them do this simple procedure of replacing the generator themselves, without any problems and special skills in working with electricity, but with their hands. It is important to know: There are many alternatives to a standard generator, since with the appropriate skills, means and desire it is possible to install any generator. In the provided article I examine only “economical” VAZ generators from other models, because:

- They are cheaper.

- They are more common.

- They are easier to change - you don’t need to find or make any special fasteners and completely change the electrical system.

How to check the generator yourself

How to check a VAZ generator using the example of model 2109. Generator type 94.3701 alternating current, three-phase, with a built-in rectifier unit and an electronic voltage regulator, right-hand rotation.

Generator connection diagram

. The voltage to excite the generator when the ignition is turned on is supplied to terminal “D+” of the regulator (terminal “D” of the generator) through indicator lamp 4 located in the instrument cluster. After starting the engine, the excitation winding is powered by three additional diodes installed on the generator rectifier block. The operation of the generator is controlled by a warning lamp in the instrument cluster. When the ignition is turned on, the lamp should be on, and after starting the engine, it should go out if the generator is working. If the lamp is brightly lit or glows half-lit, it indicates a malfunction.

The “minus” of the battery should always be connected to ground, and the “plus” should always be connected to the “B+” terminal of the generator. Failure to turn the battery back on will immediately cause increased current through the generator valves and damage them.

It is not allowed to operate the generator with the battery disconnected. This will cause short-term overvoltages to occur at the “B+” terminal of the generator, which can damage the generator voltage regulator and electronic devices in the vehicle’s on-board network.

It is prohibited to check the functionality of the generator “for spark” even by briefly connecting the “B+” terminal of the generator to ground. In this case, significant current flows through the valves and they are damaged.

How to remove the generator on a VAZ 2108 yourself step by step instructions

In order to remove the VAZ 2108 generator with your own hands, you must perform the following procedure:

- In order to easily remove the VAZ 2108 generator, it is necessary to remove the engine protection.

- During the dismantling process, the VAZ generator must be removed together with the bracket, since its fastening bolt will be impossible to pull out due to the position of the body side member.

- Now disconnect all electrical terminals from the generator

- Then you need to loosen the adjusting nut and the generator mounting nut from below.

- Move the generator forward and remove the loose belt

- Unscrew the bolt and remove the adjusting bar

- We find it at the bottom of the engine compartment (shown in the photo) and unscrew the two bolts securing the bracket.

- Then, carefully pushing down, remove the VAZ 2108 generator

- After repairing or purchasing a new generator, we install it in the reverse order, taking into account the fact that the long bolt securing the bracket should be closer to the generator drive.

- After completing the installation of the VAZ 2108 generator, tension the drive belt

How to install and connect a VAZ 2108 generator - step-by-step instructions

Installation of a new generator is carried out in the reverse order. Take a close look at the condition of the bottom bolt. If there is damage to the threads, it is better to replace it.

It will be easier for you to repair the generator later. When installing, pay special attention to belt tension. If it is not tensioned enough, your battery will not charge well. But if you tighten the belt too much, the bearing in the front cover will be destroyed. As a result, you will get an unpleasant whistle when the engine is running. And the reason for this is the appearance of play in the bearing.

The installation of the generator on the VAZ 2108 must be carried out in such a way that even the slightest distortion does not occur.