The brake system of a car requires timely monitoring to identify possible faults and must be checked every six months.

| Standard brake pipe repair kit for VAZ 2110. |

It is best to time it to coincide with the end of the winter period, as it is the most difficult to operate. In winter, the road surface is treated with chemicals that have an aggressive effect on all elements of the body, including the brake system.

When checking the brake system, you need to check the condition of the brake fluid pipelines, brake hoses, their fastening, as well as the condition of the brake pads. At the same time, cracks, abrasions of the outer coating, swelling, leakage of brake fluid and other damage are not allowed on the brake pipes.

It is advisable to carry out the test using a powerful lamp and a mirror so that any malfunction can be identified. Timely replacement of worn-out brake system components will guarantee your safety.

If damage to the brake hoses or pipelines is revealed during the inspection, then a mandatory replacement of the VAZ 2110 brake pipes and hoses will be required.

Most often, you have to change brake hoses after a certain mileage, namely in the region of 70-100 thousand kilometers, or when a malfunction is detected. Brake pipes last quite a long time and replacement of VAZ 2110 brake pipes occurs when they are corroded or mechanically damaged.

To replace, you need to purchase a set of VAZ 2110 brake pipes. In this case, you can purchase either brake pipes already bent to the desired configuration, or simply straight ones, which will need to be given the profile of the removed brake pipes.

| Video of replacing brake pipes on front-wheel drive VAZ cars. After watching this video, we can say that replacing brake pipes on a VAZ 2110 at home is not particularly difficult. |

It is better to purchase ready-made (factory bent) tubes, which will significantly simplify the process of replacing them.

If you purchase straight brake pipes, you will need a tool to bend them (you can use a spring with a suitable internal diameter where the pipe should fit when bent). Steel double-layer brake pipes are more reliable.

It will be more economical to purchase an unmolded copper line, but you will need to bend it yourself, observing all the necessary dimensions, which will require more time to replace.

To work, you will need an inspection hole or overpass. Carrying out the replacement simply on a level surface with the help of a jack is also possible, but it is quite labor-intensive and dangerous in terms of work safety.

To replace faulty brake hoses or tubes, you will need a special wrench for working with the VAZ 2110 brake system, as an addition and a gas wrench (first number) for disconnecting the fittings on the master brake cylinder, working cylinders, as well as in the brake hose connections.

It is also necessary to have a set of wrenches for: 10, 13/14, 17 mm, composition VD 40 or similar and new brake fluid.

The procedure for replacing brake pipes on a VAZ 2110

- Before starting the replacement, you need to disconnect the terminal from the battery for safe work;

- Replacement of brake pipes must be done starting from the main brake cylinder in turn to each wheel cylinder;

- The wheel bolts are loosened and the car is jacked up to a convenient height for work;

- The brake pipe fittings are removed one by one from the brake master cylinder and the holes are closed with plugs;

- The pipeline is carefully released from plastic and metal fasteners towards a specific wheel. The protective plastic box must be removed;

- The brake hose fitting on the wheel is unscrewed, where the tube is replaced and the damaged line is removed;

- The new brake pipe is installed in the opposite direction, “going” from the wheel to the brake master cylinder;

- All tube holders are put back into place; those damaged during dismantling are replaced with new ones;

- The new pipeline is blown through with compressed air and connected.

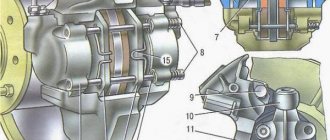

Replacement and installation

We put the car on a jack or lift, remove the wheel, for ease of access we unscrew the wheel in the opposite direction from the side of the hose being replaced. Use a 15mm wrench to hold the edge of the inner part of the hoses and use a 10mm wrench to unscrew the fitting. We put a rubber cap on the tip of the tube, removed from the bleeder fitting on the working brake cylinder on the wheel, no matter how much brake fluid flows. We take out the hose from the bracket on the shock absorber and use a 15 wrench to unscrew the fitting from the working brake cylinder. If the copper ring remains on the cylinder, remove it and thoroughly clean the area of dust and dirt before installation. If you don’t have a new copper ring, you can put in an old one, pre-treat it with sandpaper and level the surface. Installation is carried out in reverse order. It is important that after installation the new hose should not be twisted and when turning the wheel in any direction it should not touch the vehicle’s suspension elements.

When is it necessary to replace pipes and other elements of the brake system?

Brake pipes are changed quite rarely. The need for this arises only if the machine has been in use for a long time, in unfavorable conditions conducive to the development of corrosion, or in the event of any mechanical damage.

You can assess the condition of these components yourself by looking under the car body, or by bringing your “iron horse” for inspection by technicians from the service center. According to the regulations, diagnostics of all components of the brake system must be carried out at least once a year, preferably at the end of the winter period. You can combine the inspection with the next oil change.

Rubber hoses on all wheel cylinders must be replaced, regardless of their condition, every 70-100 thousand km. mileage Pipelines are replaced only as needed.

To carry out the work you will need the following tools:

- Jack;

- Phillips screwdrivers;

- Set of wrenches for: “10”, “14”, “17”;

- Clamping key to “10”;

- Clamping pliers;

- Balloon wrench;

- Anti-corrosion composition;

- Brake fluid (to replenish the system).

What to consider?

The design of the brake system and the principle of its operation are almost identical for all car models. Accordingly, the method of its restoration is also the same for all brands of vehicles.

All pipeline repair work can be carried out in a repair pit, overpass or on a flat area by lifting the machine with a jack.

A set of tubes can be purchased at any auto store. You can order a pipeline of a given length, already bent as required, specifically for a specific car model. Or you can buy a universal copper line, and then give it the required shape and length yourself. The latter option is more economical, however, and there is much more fuss.

The main stages of replacing brake pipes on a VAZ 2109, 2110

You can replace the pipeline lines in the direction from the main brake cylinder to each wheel according to the following diagram.

- Disconnect the battery terminals.

- Raise the car to the desired height using a jack.

- Remove the car wheels.

- Using a “10” wrench, unscrew the nut securing the tube to the master cylinder and install a plug for dust and dirt in the supply hole.

- Carefully release the pipeline towards the wheels. Remove the protective plastic box and remove the line from the metal and plastic holders. Try to do this carefully so as not to damage the clips.

- Unscrew the brake hose fitting and remove the damaged line.

- Start installing the new tube in the opposite direction: from the wheel to the master cylinder.

- Reinstall all holders, replacing worn or damaged parts as necessary.

- Blow out the pipeline with compressed air, connect it to the system and bleed the brake system according to the instructions, replenishing the missing fluid as necessary.

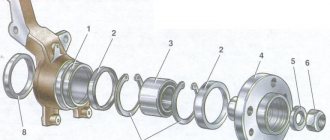

How to replace brake pipes on a VAZ 2110-VAZ 2112?

Note! There are 8 brake pipes in total on cars of the tenth family, as well as on cars of the Lada Samara and others, the most difficult thing to change is the main pipes, because they are not convenient to install and additional removal of other parts will be necessary, but the easiest way to change the pipes is in the front, nothing complicated This one doesn't and won't take a lot of time, unlike the back!

Removal: 1. Removal is not difficult, but you still have to prepare to replace the pipes, start from the very first, this is pumping out the brake fluid from the brake reservoir, you can pump it out from there using a rubber bulb or honey. syringe (This fluid cannot be reused, just fill in a new one), sometimes people manage to change the tubes without draining the brake fluid from the system at all, this is not difficult to do, then you just need to pump the brakes a little and that’s it, but that’s if one tube changes, if that’s all, then it’s better to drain the liquid, so there will be less hemorrhoids, and the whole point is the following: when you disconnect the tube (Depending on what you disconnected it from), the other ends of the elements are plugged with something (If you disconnected the tube from the GTZ, then the hole is closed with a plug of some kind be it from the brake hose, then the end of the hose is closed with a bolt of a suitable diameter or something else), so the tube is changed without draining the brake fluid from the system.

2. Both the front brake pipes and the rear ones are all changed identically, they have fittings at the ends, and the fittings have nuts, using special tools. key, they turn away and the tubes are disconnected, for more details on how to disconnect the tube from the hose, read the article entitled: “Replacing the brake hose on a VAZ”, in this article everything is described in detail, how the tubes from the Brake Master Cylinder are disconnected from the sorcerer, there is no point in telling we don’t see it at all, because everything is the same, the fitting nut is unscrewed (Indicated by the red arrow) and the tube is disconnected, everything is easy and simple.

3. And finally, let’s disassemble the brake main pipes, they are the longest and run under the bottom of the car (Go from the GTZ to the sorcerer), to remove them, you will need to disconnect them from all ends at the beginning, then unscrew the three nuts that secure the protection (see photo 1) and remove the plates, which are made of metal (one of them is indicated by a red arrow in photo 2), and remove the tubes from all the holders, replace those holders that will be deformed with new ones.

Installation: The tubes are installed in the reverse order, they are usually made of aluminum alloy, so they break easily, but they bend well, and the tubes will have to be adjusted 100%, when adjusting, do everything carefully, do not bend the tubes too much and do not break them, otherwise you will have to carry out the entire operation from the very beginning, to replace it.

Note! Upon completion of the operation, pour fluid into the brake reservoir and bleed the entire system (How to bleed the brakes, read the article: “Bleeding the brakes on a car”), otherwise there will be no brakes, after bleeding, press the brake pedal with great force, and another person (Assistant) let us look under the car to see if anything is leaking, if everything is tight, only after that you can operate the car!

Additional video clip: Brake pipes on most cars are replaced in a similar way; good tips for replacing pipes, using the example of a Volkswagen car, are given in the video below, be sure to study it.

Note! If you want to see with your own eyes how the tubes are changed, in this case, watch another video, which is also located below:

Features of replacing brake hoses

When replacing brake pipes on a VAZ 2110, it is a good idea to check the condition of the elastic hoses. If you notice even minor cracks and mechanical damage on them, replace them. Also install new hoses if the service life of the old ones has already exceeded the required limit.

The elastic hose replacement scheme consists of the following steps:

- Clean the cylinder well with a wire brush, treating it with rust remover if necessary;

- Using a “14” wrench, unscrew the wheel caliper fitting;

- Plug the caliper hole to prevent dirt from getting into it;

- Using wrenches “17” and “10”, unscrew the fitting and disconnect the hose from the tube;

- Remove the elastic hose holder;

- Install the new hose in sequence from tube to caliper.

Replacing the brake system elements described above is not a very pleasant matter. However, if you are going to replace the piping and hoses, be glad that you won't have to do it anytime soon.

The brake system appeared on the first cars. Its presence has become the key to the safety of the driver and passengers. The first brake system did not have a complex mechanism of action and consisted of several mechanical parts that created the necessary friction on the wheel drive for its subsequent stopping.

The second stage in the development of the braking system was the application of the laws of hydraulics. With this method of braking, the interaction between the brake pedal and the working parts of the brake system is carried out using a special fluid called “brake fluid” (or abbreviated as TF). Brake fluid allows you to stop your vehicle more efficiently. In addition, the use of brake fluid softened the pressure on the brake pedal and made driving more comfortable.

For successful circulation of brake fluid from the brake drive system to the working parts, it is carried out through special pipes. Initially, they were made in the form of hoses, but since they were unreliable, they were replaced by another material.

Replacing brake hoses, bleeding brakes on a VAZ 2110

What to do if you need to change some part on your car, but you don’t know how to approach it, where to start, and indeed where it is located? But what if, according to the regulations of your car, it’s time to change consumables, but you don’t know what it is? Well, in the end, what if your vehicle simply won’t start? You can learn about all this and much more without leaving your home, or even your car! You just need to go to the CAR.RU website, to the “car repair” section and find the instructions you need, similar to those outlined below.

If you made your next trip to a service station and found out there that when checking the brake hoses (TB) by auto mechanics, it was discovered that they were in very poor condition, then this problem needs to be dealt with somehow.

With a problem like this, you simply won’t be able to drive a car. Such things are no joke! That is, it is necessary to change the TS immediately and urgently. You can see with your own eyes exactly how the TC is changed on the domestically produced VAZ-2110 car.

Since this will air the system, it will be necessary to bleed the brakes. There is nothing criminal here, you will cope with this task.

A small educational program:

In any braking system, one of the main elements is the brake hoses. These are multilayer flexible tubes made of especially durable polymer materials. The strength of these tubes is determined by the fact that during operation they are subject to high pressures and hydraulic loads. Modern materials and manufacturing methods make it possible to produce reinforced tubes that are durable and have a long service life.

Brake pipes and hoses, almost always, at least in the technical regulations for servicing any car, you will not find any mention of their replacement. But, like all parts of the brake system, they must be inspected by a specialist at every maintenance. And on cars older than ten years, it’s worth paying extra attention to these components. We are talking about brake pipes and hoses, details that are inconspicuous, reliable, but nevertheless not at all eternal.

Purpose of the brake hose

The brake hose is designed to quickly transmit impulse to the wheel brake cylinders. At the moment when the driver presses the brake pedal, a pressure pulse through the brake fluid is transmitted through the brake hoses to the wheel cylinders, which already act directly on the pads. The pads, in contact with the brake drum (brake disc), create friction, which sharply reduces the speed of the car.

All car enthusiasts know very well that a serviceable and well-functioning braking system is a guarantee of safety on the road. When just one element is damaged, the operation of the entire system is disrupted. If the brake hoses are faulty, the brake system may fail with very dire consequences. This is why it is so important to check the serviceability of brake hoses in a timely manner. Indicators of serviceability are : elasticity of all brake hoses; absence of even small cracks on their surface; reliable holding of hoses on the tips; perfect condition of the threads on the tubes.

Changing the technical gear on a VAZ-2110 car

Purchase the necessary items in advance:

- two keys (a key for “fifteen” and a split key for “ten”);

- set of TS (front and rear);

- jack and wheel wrench (remove the wheel).

Instructions:

- Jack up the vehicle, install jack stands, and remove the wheel.

- Holding it at “fifteen” with the aforementioned wrench and unscrewing it with a special wrench, remove the hose tip.

- Plug the opened hole with a cap.

- Unscrew the hose from the caliper.

- Install the new hose in the reverse order, without twisting it.

Bleeding brakes on a VAZ-2110 model car

Purchase the items you need in advance:

- brake fluid;

- thin rubber tube (preferably transparent);

- empty bottle (transparent);

- key to "eight";

- assistant (we recommend, however, that you can bleed the brakes without his help).

Follow the instructions below carefully:

First, loosen the bleeder fitting.

Secondly, put the tube on the fitting and lower the other end into the bottle.

Thirdly, check the fluid level in the tank; if it is not enough, add it.

Fourthly, the assistant presses the brake pedal three times, keeping it depressed on the last press.

Fifthly, unscrew the fitting with the “eight” key.

Sixth, when the pedal becomes soft and falls through, tighten the fitting.

Seventh, repeat steps four through six several times until the liquid poured into the bottle flows without air bubbles.

You can learn how to carry out this procedure using the video “Bleeding the brakes on a VAZ.” Good luck and fair wind!

Jack up and remove the wheel.

Again, take the key for “fifteen” and a special key for unscrewing the brake pipes.

We hold the hose first, and unscrew the tube with the second. The latter should not rotate, only its tip.

They turned it off and it started flowing. We plug it with a standard rubber cap from the bleeder fitting.

Now unscrew the hose from the brake caliper.

Old and new hoses.

New TS.

Immediately before purchasing, focus on the surface indicated by the arrow in the image. It must have high precision surface treatment, without marks or burrs.

A clear and obvious sign that the hose needs to be changed (cracked).

Install the new hose in reverse order. IMPORTANT! The wheel is straight, the hose must not be twisted along its axis! To do this, we do not twist the hose, but only the tip of the tube.

When the hoses are replaced, air remains in the system. The latter, of course, needs to be eliminated. Bleeding: first equip yourself with new brake fluid, a thin rubber hose, preferably a transparent empty bottle and an “eight” key.

We break the tightness of the fitting, but do not unscrew it.

We put one end of the hose on the fitting, and lower the other into an empty vessel. We put an open-end wrench for “eight” on the fitting.

If necessary, add liquid to the tank. Bleeding: An assistant presses the brake pedal all the way 3 times and on the third time keeps the pedal pressed, and you loosen the fitting half a turn. Liquid pours into the container, the pedal has failed, tighten the fitting back, pump it. Repeat this procedure six to ten times until liquid flows out of the tube without bubbles.

Before bleeding the rear brakes, drive a screwdriver into the sorcerer.

Remove the rear wheel.

The pumping principle is the same. We advise you to start bleeding from the furthest wheel from the GTZ: right rear, left rear, right front, left front. Check the brake fluid level in the reservoir, check for leaks “by eye” and test brake in a safe place.

Good luck! Green traffic lights!

Design and principle of operation of brake pipes

The car is braked by pressing the brake pedal. The pedal lever acts on a vacuum or any other booster, which creates the necessary pressure on the brake fluid. The liquid compresses and goes into a zone where this pressure is minimal. It enters the brake pipes, through which it is directed to the working parts of the brake system. The fluid puts pressure on the brake pads, causing them to compress. When you release pressure on the brake pedal, the pressure in the booster decreases, and the spring drive of the brake pads unclenches them and sends the fluid back to the booster (the area of least pressure).

The passage of liquid is carried out through tubes made of metal. The tubes extend from the vacuum booster and are laid under the car to the working parts of the brake system. The joints of the tubes are made in the form of threaded connections, which makes it possible to achieve maximum reliability when creating high pressure in the system.

To increase the reliability of the braking system, the pipes are connected diagonally, which allows the brakes to be used if one of the lines fails. So, for example, from the vacuum booster, one tube connects the working part of the brakes of the front left and rear right wheels, and the second tube directs the brake fluid to the front right and rear left wheels. At the junction of all four pipes, a special pressure regulator is installed, which filters out excess pressure from the system so that it does not cause a breakthrough in the lines.

How to repair brake pipes

This process requires the car enthusiast to have extensive locksmith skills and the ability to use special tools. Repairs are carried out in cases where it is not possible to replace the damaged line; it involves saving money on the purchase of a new pipe system and extends the service life of the old one.

To carry out repairs you must:

1. Unscrew the damaged tube from the cylinder or brake caliper.

2. After disconnecting, it is necessary to cut off the damaged area using a pipe cutter.

3. Clamp the tube 50 millimeters from the edge of the cut and chamfer the edge of the tube using a drill.

4. Remove all that remains of the chips and insert a fitting intended for connecting the tube to the brake operating mechanism into the cut area.

5. Insert the end of the tube into the special equipment and flare it. The main line that has undergone repairs must be purged with compressed air. And only after this is it installed with a working mechanism or another pipeline system using an adapter.

As for the length of the tube, this parameter depends on the car model. On some cars, the brake pipes have a reserve that allows you to shorten the pipe and reconnect it to the working mechanism. The metal from which the brake tube is made is flexible, so there should not be any difficulties with its position.