Do-it-yourself wheel alignment on a VAZ 2112. Taxi Bolt

You can adjust the wheel alignment angles of your car with your own hands, using available tools and ordinary tools. In this material we will tell you how to do wheel alignment without the help of others at home, and what difficulties are encountered in most cases when adjusting wheel alignment angles.

Incorrect wheel alignment adjustment may be a prerequisite, for example, for rapid wear of tires, or for the fact that when driving in a straight line the car will steer to the left or to the right. At the end of this article you will find a video that carefully explains and shows everything you need to know about wheel alignment.

First, let's look at the theory: wheel alignment. What is this? What are the wheel alignment angles and how does the car’s behavior on the road depend on them? Wheel alignment. What is this anyway?

Destruction. This is the angle between the vertical and the plane of the wheel. It ensures reliable contact of the tire with the road (see picture above). Convergence. This is the angle between the direction of movement and the plane of rotation of the wheel. The stability of the car in corners and tire wear depend on it.

In rear-wheel drive vehicles, the wheels should be slightly pointed towards each other. this is called positive toe. When moving, they move apart and become parallel. For front-wheel drive. on the contrary, the toe should be negative (see diagram below).

Custer. this is the longitudinal inclination angle of the kingpin. This parameter very rarely needs to be adjusted, only on a newly assembled front suspension made from new parts, so we will NOT consider its adjustment.

Repairing the suspension or steering control (replacing the same shock absorbers or control joint) leads to a significant change in the mounting angles of the wheels. Everyday operation of the car also makes adjustments to these characteristics over time, so from time to time there is a need to adjust the wheel alignment.

It is ideal to adjust the wheel alignment twice a year, during seasonal tire changes. During this period of time, you will fall into a hole more than once or run over a curb, causing the chassis to become loose and the angles to change. Timely alignment adjustment will cost much less than a set of new tires.

In 1955, South American engineer Lee Hunter developed the first wheel alignment control panel. Sensors mounted on the wheels sent focused beams of light and accurately measured angles. That's why the shield was called optical. But already in 1969 it was connected to a computer, and in 1995, 3D technology was used for the first time to measure and adjust angles.

True, Russian car owners drove without any shields or computers. Using wrenches, calipers, a whine and a plumb line, they adjusted the camber and toe angles with their own hands. Note on how to adjust the wheel alignment yourself

Before you begin adjusting the camber and toe angles, you absolutely need to check the car's chassis. If repairs are needed, then doing a wheel alignment is stupid. Steering and suspension must be in perfect order.

Pay attention to three points on which the wheel alignment angles on a car very much depend: the serviceability of the chassis (more about diagnosing the car suspension) Tire pressure. Loading the car.

Before adjusting the wheel alignment, be sure to check the pressure in the tires and make sure that you have NOT accidentally left a couple of bags of potatoes or cement in the trunk :) As an example, we will describe how to do a wheel alignment with your own hands on a VAZ 2109 car.

Adjusting the camber angle of the wheels.

The camber angles are adjusted in the following order (We remind you that in our case the actions are described for a VAZ 2109 car):

Before adjusting the camber, the car must be parked on a level surface. We put two vertical marks along the diameter of the wheel rim with chalk. one on top, the other on bottom. We apply a cord with a plumb line to the wing, and along the marks with a ruler or caliper we measure the distance from the rim to the cord at the top mark, and then at the bottom.

The difference should be ± 3 mm. The rim may NOT be flawless, so it is better to roll the car, turn the wheel 90 °, and make 2 more vertical marks. Again we produce frozen.

Do the same on the second wheel and write down the result. Then turn the car 180° and again take measurements, write them down and compare them. Then remove the wheel and, using 2 19mm wrenches, loosen the two bolts securing the shock absorber strut bracket to the steering knuckle.

Move the steering knuckle with a wrench to 19 due to the eccentricity of the bolt head inward or outward to the required distance, thus achieving the desired camber angle. Tighten the bolts, put the wheel in place, lower the car and rock it a couple of times, pressing on the fender. Take measurements.

On rear-wheel drive cars, the camber angle should be within 1/3 mm, and on front-wheel drive cars, the usual range is 1 to 1 mm. Adjusting the wheel toe angle

To adjust the angle of convergence, it is most convenient to take measurements using a special telescopic ruler with a scale (look at the photo above). It is more convenient to work in a pit. The steering wheel should be in a straight-ahead position.

Before adjusting the toe, make one mark on the inside of the wheels with chalk on the left and right tires as close as possible to the rims. Having created a preparatory tension in the ruler, install it, resting its ends against the intended points so that its body does not touch the body parts and suspension. Shake the ruler a little, and on the moving scale combine “zero” with the fixed pointer.

Lock the scale. Carefully Roll the car forward so that the ruler together with the wheels moves backwards, but does not touch the suspension and body parts. Check the readings.

If on a VAZ 2109 the distance between the wheels at the rear is less than at the front, then the control rods need to be shortened, and if it is longer, then. lengthen

Using a 27 wrench, loosen the locknut on the control rods. Nuts with marks on the edges have a left-hand thread. Using a 24mm wrench, rotate the coupling to configure the length of the pull.

Don’t forget: Watch the horizontal position of the steering wheel spokes. Place the moving scale on the ruler to adjust the toe to “zero” and roll the car back. With readings from 1 to 1 mm, you can complete the adjustment of the toe angle.

Look in turn from the side of each front wheel to the alignment of each rear wheel. With the steering wheel spoke horizontal, you will simply see that there is either no displacement of both wheels to the left or to the right. If the displacement is noticeably obvious, then by unscrewing one rod and tightening the other by the same number of turns, correct the displacement.

READ What Benefits Removing the Catalyst from a Car

After adjusting the wheel alignment yourself, it’s worth thinking about which wheels to choose: stamped or cast? It is believed that cast wheels significantly reduce the load on the suspension, while stamped ones. more comfortable.

You can adjust the wheel alignment angles of your car with your own hands, using available tools and ordinary tools. In this material we will tell you how to do wheel alignment without the help of others at home, and what difficulties are encountered in most cases when adjusting wheel alignment angles.

Incorrect wheel alignment adjustment may be a prerequisite, for example, for rapid wear of tires, or for the fact that when driving in a straight line the car will steer to the left or to the right.

What should the installation angles be: negative and positive values?

Average value for a passenger car. either zero or slightly negative (i.e., the wheels should be slightly pointed outward with the bottom).

Possible setting to a positive value. from 0 to 4.5 degrees. In sports cars, a negative value of .5 to .5.5 degrees is used. This ensures the highest level of grip and increases cornering stability.

There are disadvantages to negative angles. So, when driving in a straight line, the inner edge of the tire will wear out faster, and instability is likely when accelerating and braking on a straight path. A good option is to set the indicator at 0.5 degrees.

Positive and negative destruction.

https://sjracing.ru/svoimi-rukami/sxod-razval-na-vaz-2110-svoimi-rukami-kak-sdelat-razval-sxozhdenie-svoimi-rukami-na-vaz-2110-video-chto-takoe- kaster-kogda-nuzhno-delat-i-kak-pravilno-vystavit-regulirovku-uglov-v.html

Adjustment

If the caster angle changes, self-locking nuts M12x1.25 will be needed. VAZ has a suitable article number - 16105011. If the angle is reduced, washers “2108-2904225” (part 24) are also needed. Installing one washer leads to a decrease in caster by 19 arc minutes.

Stretch (saber) and lever

To adjust any parameter, the wheel is hung up and removed. And when adjusting the caster, each of the two wheels is hung in turn. In general, the work ahead is long.

Caster angle

To add or remove washers, you need to remove the stretcher: use a flat 24 wrench to hold the stretcher itself, and use another wrench to unscrew the nut.

Removing suspension braces

Having unscrewed the nuts on both sides, the part cannot be removed immediately. You also need to unscrew the fastening of the lever to the stabilizer link (key “17”). To knock out the mounting pin, use an aluminum spacer.

The maximum number of washers is two in front and four in back (near the fist). Recommended tightening force – 43-52 N*m (stabilizer thrust), 160-176 N*m (stretch).

Camber angle

On all Tens, including the VAZ-2112, the camber is easily adjusted. The upper bolt, which holds the fist, is equipped with an eccentric. The nut on the bolt needs to be loosened and then rotated with a wrench - the camber angle will change.

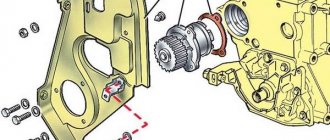

Adjusting the right wheel camber

Mark the standard position of the adjusting screw head (Fig. 1). Loosen the nut on the bottom screw. The same must be done with the top screw - do not unscrew the nut completely! After completing the adjustment, tighten the fastener. You need two keys “19” (Fig. 2).

The recommended torque when tightening the nuts is 78-96 N*m.

Toe angle

The photo shows how the steering rod assembly with tips is arranged. The hexagon is designed for a 17mm wrench, but before you rotate it, you need to loosen the tightening screw on each of the ends - internal and external.

Steering rod and its ends

If you look at the arch from the outside, then by rotating the hexagon clockwise, we reduce the length of the tie rod. And vice versa.

When unscrewing the screw marked with an arrow in the photo, the tip “a” must be held. The same applies to the adjustment operation - the plane of the ball joint must remain parallel to the plane of the lever “b”.

External tip and swing arm

Anyone who ignores our advice will change the tips every other day.

Procedure:

- To adjust the right thrust, the steering wheel must be turned to the left;

- Taking the key “13”, loosen the two tightening screws;

Outer Tip Pinch Screw

- Carry out the setup (you need a key “17”);

- Tighten the screw on the inner and then on the outer steering tip.

The tightening force for the coupling screws is 27-33 N*m.

Wheel alignment. what it is?

First, let's look at the theory: wheel alignment. What is this? What are the wheel alignment angles, and how does the car’s behavior on the road depend on them?

Destruction. This is the angle between the vertical and the plane of the wheel. It ensures reliable contact of the tire with the road (see picture above).

Convergence. This is the angle between the direction of movement and the plane of rotation of the wheel. The stability of the car in corners and tire wear depend on it.

- In rear-wheel drive vehicles, the wheels should be slightly pointed towards each other. this is called positive toe. When moving, they move apart and become parallel.

- In front-wheel drive. on the contrary, the toe should be negative (see diagram below).

Custer. this is the longitudinal inclination angle of the kingpin. This parameter very rarely needs to be adjusted, only on a newly assembled front suspension made from new parts, so we will NOT consider its adjustment.

Repairing the suspension or steering control (replacing the same shock absorbers or control joint) leads to a significant change in the mounting angles of the wheels. Everyday operation of the car also makes adjustments to these characteristics over time, so from time to time there is a need to adjust the wheel alignment.

It is ideal to adjust the wheel alignment twice a year, during seasonal tire changes. During this period of time, you will fall into a hole more than once or run over a curb, causing the chassis to become loose and the angles to change. Timely alignment adjustment will cost much less than a set of new tires.

In 1955, South American engineer Lee Hunter developed the first wheel alignment control panel. Sensors mounted on the wheels sent focused beams of light and accurately measured angles. That's why the shield was called optical. But already in 1969 it was connected to a computer, and in 1995, 3D technology was used for the first time to measure and adjust angles.

True, Russian car owners drove without any shields or computers. Using wrenches, calipers, a whine and a plumb line, they adjusted the camber and toe angles with their own hands.

More about the block

- Coolant level;

- Washer fluid level;

- Oil level in the crankcase;

- Indicator of non-working lamp;

- Brake pad wear indicator;

- Seat belt indicator;

- Indicator of the front left door not closed;

- Indicator of the front right door not closed;

- Indicator of the rear left door not closed;

- Indicator of the rear right door not closed;

Open doors

This function works thanks to limit switches in the door. When the door is opened, the switch contacts close and the door open lamp lights up. Each limit switch is responsible for the door in which it is installed.

Quite often it happens that due to oxidation of the limit switch contacts, the indication does not operate. This problem is solved by removing the end switch and cleaning its contacts with sandpaper.

Low oil level

A special oil level sensor is installed in the engine crankcase, which informs the driver when the level drops to a minimum value. The sensor is a reed switch with a float; the contacts of the reed switch close when the oil level drops, which leads to the lighting of the corresponding lamp on the display unit.

Low antifreeze level

This indication system is similar to the oil level design. A sensor is installed in the expansion tank, operating on the principle of an oil level sensor. When the coolant level decreases, the contacts on the sensor close and the low antifreeze level indicator lamp lights up.

Low washer fluid level

The principle of operation of this indicator is to measure the windshield washer fluid level. There is a level sensor in the washer reservoir, the same as in the expansion tank. It measures the level and, when the minimum mark is reached, lights the lamp on the display unit.

Front pad wear

This indication informs the driver about the wear of the front pads; this occurs using a sensor that is connected to the pad itself. It is important to note that in order for this indication to work, it is necessary to use special blocks in which this sensor is built-in.

Unfastened seat belt

This function has long been known on cars of foreign origin, but it was used for the first time in AvtoVAZ. The sensor built into the seat belt buckle closes its contacts when the belt clip is inserted into it. If you start driving without a seat belt fastened, the display unit will begin to emit a sound warning of danger.

Burnt out lamp indication

The essence of this function is to inform the driver about one of the burnt-out lamps in the headlights or taillights. This function works by measuring the resistance in the power supply circuit of headlights or flashlights. As soon as the lamp burns out, the power circuit is interrupted, which causes the indicator on the unit to light up.

Forgotten key in the ignition

After stopping the engine and turning off the ignition, if you open the door while the key is inserted into the lock, the display unit will emit a sound signal that will last 10 seconds and will stop if you close the door again or remove the key from the lock.

Instructions for adjusting wheel alignment yourself

Before you begin adjusting the camber and toe angles, you absolutely need to check the car's chassis. If repairs are needed, then doing a wheel alignment is stupid. Steering and suspension must be in perfect order.

Pay attention to three points on which the wheel alignment angles on a car very much depend:

- Serviceability of the chassis (more information about car suspension diagnostics)

- Tire pressure;

- Loading the machine.

Before adjusting the wheel alignment, be sure to check the pressure in the tires and make sure that you have NOT accidentally left a couple of bags of potatoes or cement in the trunk