Symptoms of air leaks in the intake manifold of a VAZ 2114

All car engines, regardless of their type (with an injector or carburetor), operate on a mixture of fuel and air.

The ratio of these components in the mixture is precisely calculated and regulated either electronically or mechanically. But, sometimes it happens that additional air leaks occur, the mixture is “diluted” and the motorist can observe a serious loss of power in his car (which is especially noticeable at low speeds). We’ll talk about why this happens and how to correct this situation in today’s article.

Air leaks and its symptoms

The phenomenon of suction is associated with the penetration of air into the fuel tract of the machine. It leads to a lean mixture and, as a result, greatly affects the operation of the engine, reducing its power and causing interruptions in operation.

If air leaks occur in the intake manifold, the symptoms of the VAZ 2114 may be as follows:

- unstable idle speed;

- engine tripping;

- “sagging” during acceleration;

- increased gasoline consumption;

- difficult starting even at high air temperatures;

- a sharp drop in power (especially at speeds below 3,000 min-1).

If the engine stalls very often, this may also indicate that there is an air leak in the VAZ 2114. You can additionally verify the presence of this problem by using a car scanner. The presence of suction may be indicated by errors P0171 (very lean mixture) and P300 (misfire observed).

Stable engine operation at high speeds does not at all indicate the absence of suction, since it is most clearly manifested at low speeds. It is worth remembering this so as not to be misled and start looking for other causes of problems.

As soon as you notice that there are signs of air leaks, you should immediately begin searching for a possible place where it has entered the system.

The main signs and causes of failure of the VAZ 2114 intake manifold

- The main symptom of a failed intake manifold is a sudden loss of car engine power.

- at the same time, there is an increase in fuel consumption , with a deterioration in traction and a drop in engine performance.

It is important to determine the cause of the breakdown and eliminate it in time.

- Often a problem is indicated by a missing stud in one of the manifold flanges. It simply comes off when the collector goes “screw”, that is, due to temperature changes, for example in winter, or over time (average service life is 7 years), the collector begins to bend along the plane, and the pin simply “spits out”, pulls out .

- Due to the fact that the manifold has “leaded,” a crack may form and, as a result, exhaust gases from the engine escape, and the manifold must be replaced. Before changing the gasket, make sure that all the studs are in place. When you remove the manifold, you also need to check the flatness of the exhaust manifold, because often these areas require grinding or replacing the entire part.

- Manifold flaps often fail. This happens for several reasons: low-quality material used to make these dampers, too high a temperature, the presence of oil condensate. A sign that oil consistency has entered the intake manifold is its increased consumption.

- The control valve for these dampers may also fail.

Places of possible suction

There are quite a few places through which air can get inside the fuel system, and during the test you will have to examine them all (we’ll talk about how to detect them a little lower).

For now, let's say that you have to check:

- The intake manifold gasket (its destruction or burnout in the vast majority of cases is the cause of suction).

- Hoses and pipes suitable for the manifold.

- Injector seals.

- Throttle gaskets.

- Plugs placed on the manifold.

- Bushings.

- Vacuum brake boosters.

If symptoms of air leaks appear in the VAZ 2114 injector, all these elements will have to be checked.

You should also check and, if necessary, replace the idle speed sensor. Very often they are of poor workmanship and are not sealed, leading to air entering the manifold.

How to find the leak location

There are 3 main methods by which you can find a leaky area:

- by monitoring the rarefaction of air in the line;

- using a smoke generator;

- using a volatile flammable liquid.

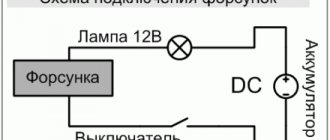

We will omit the first method, since it requires special equipment, which is not available at all service stations. But the second method deserves a lot of attention, since it is quite simple to implement and at the same time very accurate. It will require a compressor, a blow gun and cigarettes (the latter will serve as a source of smoke).

Before checking the air intake of the VAZ 2114, you will need to assemble the entire installation, namely, connect the gun to the compressor receiver, and insert a cigarette into the nozzle of the gun. After this, a pressure of about 0.8 atmospheres is built up and the smoke is directed into the collector using a gun.

The smoke itself created by such an installation is quite thick and quickly fills the entire system. All that remains for the motorist is to carefully monitor the place where the smoke is coming out, and after detecting it, carry out repair work.

In some cases, the leak can be found without additional means - the damaged area can be easily detected by the characteristic whistle or hiss that is produced by the intake air when the engine is running. True, this only happens if there are serious cracks and breaks.

If the proposed method using a smoke generator is not suitable (for example, there is no compressor available), then the test can also be performed using volatile flammable liquids packaged in pressurized cans. As such, you can use ethyl ether (although it is almost impossible to get it in its pure form now), a means for winter starting diesel engines (the main component of which is the same ether), as well as special cleaning products based on hydrocarbons.

In order to find the location of the leak, you need to start the car engine and, while idling, begin to spray all possible components, joints, plugs and hoses that relate to the manifold and may cause air penetration.

This should be done with pauses - after spraying one place, you should wait a few seconds. If you notice that the engine speed has increased sharply after the procedure, then the detected area should be thickly sprayed again. If after this the revolutions quickly go up again, then the leak point has been successfully found.

When is it necessary to replace and remove the intake manifold on a VAZ-2114

Huge temperature changes are the main problem faced by the exhaust manifold and the gasket, for which it is removed. The collector itself is made of a special grade of cast iron; it can withstand high temperatures (up to 800-900 degrees) , however, these are critical values, after which the collector may warp or crack.

Exhaust manifold VAZ-2114

Its main task is to collect exhaust gases and distribute them into the exhaust pipe of the muffler.

Replacing or dismantling the VAZ-2114 exhaust manifold is necessary in the following cases:

- Mechanical damage to the collector.

- Warping and loss of tightness at the junction with the cylinder head.

- Burnout of the gasket between the head and the manifold.

- The appearance of cracks as a result of engine overheating.

- Replacing the collector with a device of a different configuration, adapted to a more severe operating mode.

In the event that we are not going to participate in high-speed races for the prize of the head of the regional traffic police, replacing or dismantling the collector may be necessary in a number of cases.

Causes of malfunctions

The key factor that causes 90% of exhaust manifold malfunctions on VAZ 2114 cars is high temperature and poor quality materials from which the parts are made. During operation, the steel repeatedly heats up and cools down, which leads to the appearance of cracks in the body. This is a common occurrence for VAZ cars older than 7-8 years.

Auto repair shops offer crack welding services using argon welding. However, for a number of reasons, this activity is useless for cars older than 7 years.

1) Just removing and installing the exhaust manifold will cost about 2.5 thousand rubles. Taking into account the work of the welder and other actions, the cost of repairs can be 4-5 thousand rubles. If you do the work yourself, buying a new part will cost less.

2) Welding, even argon welding, disrupts the structure of “tired” metal. A boiled part rarely lasts longer than a year, after which new holes appear. The older the car, the faster the problem returns, and the collector has to be removed again. If the car is older than 8 years and there are problems with cracks in the manifold, it is better to remove the part and replace it with a new one.

- Wear . During operation, the car emits hot gases that destroy the surface of the gasket, as a result of which it can tear or delaminate.

- Since there is only one gasket for the intake and exhaust manifolds, gasoline entering through the first channel can get on the gasket, which also affects the integrity and structure of the material from which it is made.

- Part quality, not always high, even original, so when choosing, you should pay special attention to this.

Bent valves due to irregular valve timing do not threaten the 8-valve valve

Signs of trouble

Exhaust manifold gasket One of the main signs of a leak in the system is a “sporty” growling sound when the engine speed increases. This may be a symptom of various exhaust system problems. To check, it is better to take an assistant and go to a garage with a pit or to an overpass. Most often, you can determine by eye whether the problem lies in the muffler, resonator or exhaust.

Gasket wear may become apparent during planting. Open the hood and start the car - white or grayish smoke rising from the manifold during warm-up indicates a leak for this reason. VAZ car owners usually encounter this problem once every 3-4 years. When using low-quality spare parts and before. The solution may be to manufacture a custom-made steel gasket. It can last as long as the entire collector.

Service specialists, when attracting clients, like to tell scary stories about the explosion of the exhaust manifold on VAZ 2114 cars due to cracks. In reality this is nothing more than a myth. But the real problems are no less serious, so there is no point in putting off repairs.

A cracked exhaust manifold or worn gasket can cause your engine to run rough.

1) A lambda probe is installed in the exhaust manifold, which affects the operation of the injection system. Strong air suction disrupts the oxygen mass content in the exhaust; the lambda incorrectly adjusts the quality of the mixture, causing tripping, uneven idling, loss of power, and “black” spark plugs.

This is interesting: How to reset the service interval of a Renault Megane 2 car yourself

2) Another function is crankcase ventilation. Impaired air circulation causes disturbances in the operation of the gas distribution mechanism, increased wear of valves, the formation of carbon deposits on the pistons and other “joys”. If increased noise and unpleasant odors during engine operation are combined with dirty work, the car needs urgent repairs.

Places of possible suction

There are quite a few places through which air can get inside the fuel system, and during the test you will have to examine them all (we’ll talk about how to detect them a little lower).

For now, let's say that you have to check:

- The intake manifold gasket (its destruction or burnout in the vast majority of cases is the cause of suction).

- Hoses and pipes suitable for the manifold.

- Injector seals.

- Throttle gaskets.

- Plugs placed on the manifold.

- Bushings.

- Vacuum brake boosters.

If symptoms of air leaks appear in the VAZ 2114 injector, all these elements will have to be checked.

You should also check and, if necessary, replace the idle speed sensor. Very often they are of poor workmanship and are not sealed, leading to air entering the manifold.

How to find the leak location

There are 3 main methods by which you can find a leaky area:

- by monitoring the rarefaction of air in the line;

- using a smoke generator;

- using a volatile flammable liquid.

We will omit the first method, since it requires special equipment, which is not available at all service stations. But the second method deserves a lot of attention, since it is quite simple to implement and at the same time very accurate. It will require a compressor, a blow gun and cigarettes (the latter will serve as a source of smoke).

Before checking the air intake of the VAZ 2114, you will need to assemble the entire installation, namely, connect the gun to the compressor receiver, and insert a cigarette into the nozzle of the gun. After this, a pressure of about 0.8 atmospheres is built up and the smoke is directed into the collector using a gun.

The smoke itself created by such an installation is quite thick and quickly fills the entire system. All that remains for the motorist is to carefully monitor the place where the smoke is coming out, and after detecting it, carry out repair work.

In some cases, the leak can be found without additional means - the damaged area can be easily detected by the characteristic whistle or hiss that is produced by the intake air when the engine is running. True, this only happens if there are serious cracks and breaks.

If the proposed method using a smoke generator is not suitable (for example, there is no compressor available), then the test can also be performed using volatile flammable liquids packaged in pressurized cans. As such, you can use ethyl ether (although it is almost impossible to get it in its pure form now), a means for winter starting diesel engines (the main component of which is the same ether), as well as special cleaning products based on hydrocarbons.

In order to find the location of the leak, you need to start the car engine and, while idling, begin to spray all possible components, joints, plugs and hoses that relate to the manifold and may cause air penetration.

This should be done with pauses - after spraying one place, you should wait a few seconds. If you notice that the engine speed has increased sharply after the procedure, then the detected area should be thickly sprayed again. If after this the revolutions quickly go up again, then the leak point has been successfully found.

What does a faulty collector affect?

There are many stories about the rupture (and even explosion) of a cracked manifold while the car is moving.

Of course, none of them are true, but nevertheless, a leaky manifold is a very serious problem that requires an immediate solution, and here’s why: through burnouts and cracks, air can enter the exhaust system, diluting the exhaust gases.

As a result of this, the lambda sensor will incorrectly determine their composition and incorrectly adjust the composition of the fuel-air mixture injected into the engine, which will lead to tripping, a drop in speed and carbon deposits on the spark plugs.

Bent valves due to incorrect valve timing

These same cracks will affect the crankcase ventilation, disrupting it. This will lead to timing problems and increased valve wear. And finally, exhaust gases escaping through the burnouts will enter the engine compartment and, partially, into the interior, causing unpleasant odors and discomfort during trips.

A severely burnt manifold gasket can lead to exactly the same consequences as cracks on the part itself.

Replacing the intake manifold gasket on an injection VAZ-2114 with your own hands

Replacing the intake manifold gasket on a VAZ-2114 car, as well as replacing the exhaust manifold gasket, is a very complex procedure and requires certain knowledge and experience. Of course, you will have to do a colossal amount of work and spend a lot of time, but this will save 4-5 thousand rubles on replacement at a car service center.

The video below will tell you about replacing the receiver and manifold. During the replacement process, the intake manifold gasket is also changed:

The video will tell you how to properly replace the intake manifold gasket, and also tell you about some of the subtleties and nuances of the process.

Replacement of intake manifold gaskets VAZ 2114 8 cl (Kalina, 2110)

It is recommended to replace the gaskets on the VAZ intake manifold after each removal. But I had to do this prematurely, as I discovered a significant air leak, which mainly manifested itself on a cold engine. Every cold start was accompanied by a terrible tripping.

In addition to the tripping when cold, there was a slight drop in speed when sharply pressing the gas pedal. This applies to both a cold and a hot engine.

A homemade smoke generator made from a cigarette helped me detect the air leak. A very simple and primitive contraption that has helped me out more than once.

My car (Kalina 1.6 8 valves) has a plastic intake manifold (receiver). The same will be installed on all VAZ family cars with an 8-valve 1.6-liter engine (2114, 2110, etc.). 4 rubber rings act as gaskets. According to reviews, black rings last much longer than white ones. And I was convinced of this personally - these gaskets lasted for about six months and began to let air through. They felt like plastic to the touch. Unfortunately, I didn’t find black ones, so I’ll install white ones again. I hope these last longer.

To remove the intake manifold (receiver), you must first unscrew the corrugation from the air filter, the throttle cable, and the small crankcase ventilation hoses. I will not remove the throttle and its heating.

The intake manifold is attached to 5 studs - one in the center, two on the sides. To unscrew them you will need a 13mm socket. After unscrewing the nuts, you need to remove the receiver itself from the studs and move it to the side. Remove the old gaskets and wipe the seats from oil and dirt. You also need to wipe the seat on the engine.

The manifold has special grooves for guides on the gaskets. The gaskets must be installed with the higher side in the plastic manifold. It is the guide that will prevent you from making mistakes.

I additionally coated the areas near the guides with sealant on the outside of the gasket. Because it felt like that was where the ring entered the groove the deepest. In addition, there was a place for air leaks on the old gaskets.

After all procedures, the intake manifold can be installed back. I couldn't find any information on how tightly to tighten the mounting nuts. I delayed it at my own peril and risk. The main thing is not to overtighten, as the manifold is plastic and can crack.

This is how I replaced the old intake manifold gaskets on my Kalina with new ones. There is no more air leakage, the engine stopped stalling when cold and began to behave much better when warm.

Replacing the exhaust manifold and gasket on a VAZ 2114

The exhaust manifold is a unit that is responsible for ride quality, without which comfort is impossible. This is silence and the absence of exhaust smell under the hood, which can be drawn into the cabin through the hole in the cabin filter. Fixing a leak in the exhaust manifold of a VAZ 2114 is a necessary repair. Fortunately, it is not urgent; you can prepare in advance and choose a convenient moment.

Exhaust manifold for VAZ 2114

Exhaust system

The main elements of the exhaust system on these cars are the exhaust pipe, additional and main mufflers, as well as a converter. The exhaust pipe on the VAZ 2114 is connected to the converter using a special hinge. A similar design was already used on the VAZ 2109.

To ensure a more reliable and tight connection, there is a graphite ring between the flanges. In order to prevent the car body from heating up, engineers provided a special gasket above the neutralizer. It plays the role of a heat sink element.

VAZ developers installed a special oxygen sensor at the inlet part of the neutralizer. Car enthusiasts know it as a lambda probe. What functions does it perform? Everything is quite simple here. This part is needed in order to determine as accurately as possible the amount of oxygen in the exhaust gases.

So, the information received from this sensor is fed to the ECU and is then used to quickly adjust the amount of fuel that will then flow into the cylinder block. As in many other VAZ models, the mufflers are securely fixed to the underbody of the car. For this, engineers used special suspensions.

The vibration that accompanies the release of gases is significantly reduced with the help of these suspensions. This ensures silence in the car interior.

Causes of malfunctions

The key factor that causes 90% of exhaust manifold malfunctions on VAZ 2114 cars is high temperature and poor quality materials from which the parts are made. During operation, the steel repeatedly heats up and cools down, which leads to the appearance of cracks in the body. This is a common occurrence for VAZ cars older than 7-8 years.

Auto repair shops offer crack welding services using argon welding. However, for a number of reasons, this activity is useless for cars older than 7 years.

1) Just removing and installing the exhaust manifold will cost about 2.5 thousand rubles. Taking into account the work of the welder and other actions, the cost of repairs can be 4-5 thousand rubles. If you do the work yourself, buying a new part will cost less.

2) Welding, even argon welding, disrupts the structure of “tired” metal. A boiled part rarely lasts longer than a year, after which new holes appear. The older the car, the faster the problem returns, and the collector has to be removed again.

If the car is older than 8 years and there are problems with cracks in the manifold, it is better to remove the part and replace it with a new one.

Types of elements

Today two types of exhaust manifolds are produced:

- whole;

- tubular.

Solid parts have shorter channels, which are then combined into one chamber. Material: heat-resistant cast iron. The part has low gas removal efficiency. This is because the shorter manifold passages act as a barrier to gas pulses from the cylinder block.

Most parts are produced for mass use, and their quality often suffers. Such collectors do not have a vacuum zone. If they get too hot and then cool, the cast iron can crack. Then you will need to remove the VAZ 2114 exhaust manifold and replace it.

For sports and extreme use, a large number of exhaust manifolds are produced with various shapes and methods of connecting pipes. They are made of stainless steel. Car enthusiasts call these parts spiders. There are short spiders and long ones.

For example, on a 4-cylinder engine, the pipe system is represented by the formula 4-2-1. So, each cylinder has its own pipe. Then these pipes are connected into two, and then into one. This system is used in tuning. It allows you to increase the car's power and torque. The short 4-1 system is used in sports.

Signs of trouble

Exhaust manifold gasket

One of the main signs of a leak in the system is a “sporty” growling sound when the engine speed increases. This may be a symptom of various exhaust system problems. To check, it is better to take an assistant and go to a garage with a pit or to an overpass. Most often, you can determine by eye whether the problem lies in the muffler, resonator or exhaust.

Gasket wear may become apparent during planting. Open the hood and start the car - white or grayish smoke rising from the manifold during warm-up indicates a leak for this reason. VAZ car owners usually encounter this problem once every 3-4 years. When using low-quality spare parts and before. The solution may be to manufacture a custom-made steel gasket. It can last as long as the entire collector.

Service specialists, when attracting clients, like to tell scary stories about the explosion of the exhaust manifold on VAZ 2114 cars due to cracks. In reality this is nothing more than a myth. But the real problems are no less serious, so there is no point in putting off repairs.

A cracked exhaust manifold or worn gasket can cause your engine to run rough.

1) A lambda probe is installed in the exhaust manifold, which affects the operation of the injection system. Strong air suction disrupts the oxygen mass content in the exhaust; the lambda incorrectly adjusts the quality of the mixture, causing tripping, uneven idling, loss of power, and “black” spark plugs.

2) Another function is crankcase ventilation. Impaired air circulation causes disturbances in the operation of the gas distribution mechanism, increased wear of valves, the formation of carbon deposits on the pistons and other “joys”.

If increased noise and unpleasant odors during engine operation are combined with dirty work, the car needs urgent repairs.

Tools and necessary parts

To remove the exhaust manifold on a VAZ 2114 in order to replace the gasket or entire part, you will need the following tool:

- open-end and ring wrenches for 8, 10, 13, 17;

- wrench with heads 17, 19;

- screwdrivers, pliers.

It is also a good idea to have tools such as a Dremel, nut saw or nut pick on hand. As a rule, the fasteners on the exhaust system parts stick tightly.

A few days before your planned repair, begin treating accessible nuts with WD-40 or another penetrating lubricant. Repeat the operation 2-3 times. This will make the task of removing the manifold a little easier .

The question often arises: is it worth using a sealant after removing and replacing the gasket? Experts believe that if you apply sealant to the gasket, it should only be high-quality silicone. A bad sealant can bring a lot of trouble to a VAZ 2114 engine: when it burns out, it turns into “pellets” that are pulled into the crankcase. And this is unnecessary contamination of the piston system.

Tips for replacing the intake manifold

Also, do not neglect the procedures for repairing and cleaning the intake manifold. The stability of the VK is very important for the normal functioning of the car. A certain vacuum is formed in the intake manifold, which is the source of drive force for many systems: cruise control, windshield wipers, vacuum brake booster. In the event of a collector malfunction, this threatens the failure of one or more of the above systems.

To avoid the appearance of cracks and distortions, you must use a torque wrench to tighten the nuts on the manifold and follow the tightening order of 20.9-25.8 (2.13-2.63) N_m (kgf_m). As a rule, it is recommended to start tightening the nuts from the center and gradually move towards the periphery, alternately tightening the nut on one side or the other.

To work on removing and replacing the VAZ 2114 intake manifold on an 8-valve engine, we will need:

- keys “for 8”, “for 10”, “for 13”, “for 17”;

- “cardan” type nozzle and socket heads “17”, “19”;

- magnetic screwdriver;

- screwdrivers, pliers;

- new intake manifold.

By the way, the price for an intake manifold from a VAZ (article 21110100801420) will be 1,350 rubles.

The price is indicated for spring 2021 in Moscow and the region.

Loosen the clamp and disconnect the crankcase ventilation hose.

Exhaust manifold removal procedure

Before removing the exhaust manifold yourself, think 7 times. Having this work done by a service center is not cheap, but the inaccessibility and difficulty of unscrewing some nuts can be a serious problem.

Unscrew the bolt securing the intake pipe

It is important to drain the coolant before removal, as antifreeze may enter the cylinders during the process. The sequence of actions for cars with an injector is as follows:

- Disconnect the battery, release the throttle cable from the throttle valve.

- Disconnect the fuel line pipes.

- Disconnect the wires from the TPS and idle speed control.

- Release the crankcase ventilation, vacuum, and brake booster hoses.

- Remove the receiver, remove the injector block wires and remove the injector fuel rail.

- Remove the bracket and thermal shield.

- After this, you can disconnect the exhaust pipe, exhaust and intake manifolds from the manifold.

After disassembly, all gaskets are replaced with new ones. Please note when purchasing that the exhaust manifold gaskets for 8-valve and 16-valve VAZ 2114 are different. Select the parts carefully and you can avoid wasting time and money.

An exhaust manifold

Now let's talk about the exhaust manifold. The collector is designed to collect gases that are formed after fuel combustion. The gases exit through exhaust ports or windows in the cylinder block and are at a very high temperature. After leaving the manifold, they move towards the converter or catalyst, and then into the muffler through the resonator. The combustion products are then released into the atmosphere.

For a more comfortable ride, for efficient operation of the engine, you need to reduce the gas resistance at the outlet as much as possible and reduce noise at the same time. The gases that enter the VAZ manifold can be of very different temperatures. It directly depends on the mode in which the motor operates.

That is why the VAZ manifold must be able to operate in such a way that combustion products can enter it both when the engine is idling and when the engine is operating at maximum power resources. When the power unit operates at maximum power, the exhaust manifold can heat up to prohibitive temperatures and literally glow red-hot.

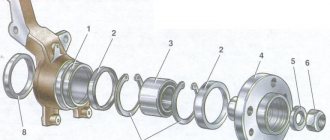

Removing the intake pipe and exhaust manifold: 1 – oil pressure warning lamp sensor; 2 – inlet pipe; 3 – warm air intake; 4 – bracket for the supply pipe of the coolant pump; 5 – exhaust manifold; 6 – gasket

Replacing the exhaust manifold gasket on a VAZ-2114 with your own hands

- Preparation stages

- Dismantling of collectors

The exhaust manifold is a component of the exhaust system that carries out the process of removing exhaust gases from the cylinders of the power unit into the exhaust pipe.

If the collector malfunctions, the culprit may be either the element itself or its gasket. Replacing the exhaust manifold (exhaust manifold) gasket is a common procedure when repairing a VAZ 2109.

Appearance of the unit

How to remove the manifold on a VAZ 2114

How to remove the exhaust manifold

Many VAZ car owners repair and maintain their cars without outside help. One of the most common problems when a car operates in slow mode is the combustion of the gasket between the exhaust manifold and the cylinder head, blocking of the catalyst, and deposition of combustion products on the walls of the exhaust system. All these obstacles negatively affect the removal of exhaust gases from the combustion chamber. Removing gases from the combustion chamber is the main point; their return to the chamber reduces the quality of the fuel-air consistency, which means a decrease in vehicle power will occur. In addition, burning the gaskets releases flammable gases into the engine compartment, which can cause a fire in the engine compartment. The sound during such work will be quite loud and annoying to others.

Causes of malfunctions

The key factor that causes 90% of exhaust manifold malfunctions on VAZ 2114 cars is high temperature and poor quality materials from which the parts are made. During operation, the steel repeatedly heats up and cools down, which leads to the appearance of cracks in the body. This is a common occurrence for VAZ cars older than 7-8 years.

Auto repair shops offer crack welding services using argon welding. However, for a number of reasons, this activity is useless for cars older than 7 years.

1) Just removing and installing the exhaust manifold will cost about 2.5 thousand rubles. Taking into account the work of the welder and other actions, the cost of repairs can be 4-5 thousand rubles. If you do the work yourself, buying a new part will cost less.

2) Welding, even argon welding, disrupts the structure of “tired” metal. A boiled part rarely lasts longer than a year, after which new holes appear. The older the car, the faster the problem returns, and the collector has to be removed again.

If the car is older than 8 years and there are problems with cracks in the manifold, it is better to remove the part and replace it with a new one.

Replacing the exhaust manifold gasket for Niva Chevrolet

The gasket of the intake pipe and exhaust manifold on a Niva Chevrolet is removed to replace it in the event of a breakdown. The gasket for the intake and exhaust manifolds is shared. In the event of a breakdown, engine tripping or exhaust gas poisoning with characteristic noise may be observed. If the defects cannot be eliminated by tightening the bolts, then we proceed to replacing it.

To carry out repair work, drive the car into an inspection hole or overpass, then prepare a standard set of tools and perform the following sequence of actions:

- First of all, we dismantle the intake pipe receiver.

- Next, unscrew the four nuts securing the exhaust pipe to the exhaust manifold.

- We unscrew the upper nut of the rear end of the intake pipe spacer, simply loosen the nut securing the lower end and move the spacer to the side.

- Unscrew the bolt securing the intermediate pipe.

- Using a Phillips screwdriver, loosen the clamp securing the heater radiator hose to the thermostat.

- And remove the hose along with the pipe.

- Next, unscrew the upper nut of the front strut of the intake pipe and also loosen the lower one, and move it to the side.

- We unscrew the right nut securing the inlet pipe and the heat shield, remove the nut and the transport eye located under it.

- Now unscrew the left nut securing the intake pipe.

- And the central nut of the heat shield.

- Remove the exhaust pipe from the studs and move it aside.

- Next, unscrew the upper right and left nuts securing the starter heat shield.

- We unscrew the lower nuts of the shield and move it a little to the side and remove it.

- Unscrew the remaining nuts securing the exhaust pipe and exhaust manifold. Remove the nuts and washers located underneath them.

- We remove the pipe and manifold, and then remove the gasket from the studs.

- Replace it, then install it in the reverse order. It is recommended to lubricate the new gasket with graphite grease to improve tightness and prevent burnout.

Tools:

- Socket wrench

- Extension for socket wrench

- Cardan for socket wrench

- Head for socket wrench 13

- High head for socket wrench 13

- Socket wrench 13

Parts and consumables:

- WD-40

- Intake and exhaust manifold gasket

1. We remove the receiver, as described here, and the fuel rail, as described here.

2. Using a 13mm socket, unscrew the bolt securing the front support bracket to the intake pipe.

3. Using a “13” wrench, loosen the tightening of the nut securing the front support bracket to the bracket of the right support of the power unit.

4. We remove the front support bracket from the intake pipe.

5. Using a 13mm socket, unscrew the bolt securing the rear support bracket to the intake pipe.

6. Using a 13mm wrench, loosen the upper starter mounting bolt and remove the rear support bracket from the intake pipe.

7. Using a 10mm spanner, unscrew the bolt securing the heater radiator outlet pipe bracket to the inlet pipe (for clarity, the heater radiator hose has been removed from the outlet pipe).

8. Using a 13mm socket, unscrew the nut securing the front eye of the power unit.

9. We remove the eye.

10. Using a 13mm socket, unscrew the nut for the rear fastening of the exhaust manifold screen to the cylinder head.

11. Similarly, unscrew the nut of the front fastening of the screen to the cylinder head.

12. Using a 13mm socket with an extension, unscrew the middle fastening nut located between the inlet pipe and the screen.

13. Using a 13mm spanner, unscrew the nut securing the screen to the exhaust manifold.

14. We take out the exhaust manifold screen.

15. Using a 13mm spanner, unscrew the two nuts of the upper fastening (one on each side) of the intake pipe and exhaust manifold to the cylinder head.

16. Unscrew the two nuts on the upper fastening of the intake pipe.

17. Using a 13mm socket with an extension, unscrew the two nuts for the lower fastening of the intake pipe and exhaust manifold.

18. Remove the nine washers from the mounting studs.

19. In four places at the junction of the intake pipe and exhaust manifold, thick washers are installed on studs.

20. Disconnect the exhaust pipe from the exhaust manifold.

21. Using a 13mm spanner, unscrew the nut securing the starter shield to the exhaust manifold...

22. We unscrew the bolt securing the shield to the bracket of the right support of the power unit.

23. We move the starter shield away from the exhaust manifold.

24. Using a 13mm spanner (or socket), unscrew the nut for the rear fastening of the exhaust manifold.

25. Using a high “13” head, unscrew the nut of the front fastening of the exhaust manifold.

26. Unscrew the nut for the middle fastening of the exhaust manifold.

27. Moving the exhaust manifold away from the cylinder head, remove the intake pipe from the cylinder head studs.

28. Remove the exhaust manifold.

29. Remove the sealing gasket of the intake pipe and exhaust manifold.

30. Before installation, we clean the mating surfaces of the cylinder head, intake pipe and exhaust manifold from the remains of the old gasket and carbon deposits.

31. Having installed a new gasket, we carry out the assembly in the reverse order. Apply graphite lubricant to the cylinder head studs.

Preparation stages

To replace the manifold or its gasket, in any case you will have to dismantle the VK. But before you get to the element you are looking for, you will first need to go through some preparatory steps. Namely, tighten the fasteners, and then remove the air filter and carburetor if the first stage does not help.

Stage of work

Your actions

Often, loose manifold fastenings caused the entry of contaminants, which disrupted the performance of the exhaust system. If the tightening did not give any result, then the gasket is definitely burned out or the collector itself is damaged, which is less likely

Removing the air filter

Removing the carburetor is carried out in the following sequence:

- Disconnect the coolant supply hose to the engine starting device from the fitting. To do this, unscrew the clamps;

- Be sure to drain the coolant into a prepared container;

- Disconnect the exhaust pipe that comes from the exhaust manifold and the BC bracket;

- Disconnect the throttle cable bracket. To do this, you need to remove one end of the spring from the damper control rod, and then remove the entire spring. Now loosen the nut on the bracket, which will allow you to remove the cable from the engagement;

- Disconnect the EPH sensor from the power plug;

- Disconnect the vacuum tube and a pair of hoses from the carburetor heating unit;

- Remove the engine crankcase ventilation hose;

- Remove the four mounting nuts holding the carburetor and intake manifold;

- Remove the carburetor carefully without yanking. It must be gradually removed from the studs.

All dismantling work must be carried out only on a cold engine. To make it easy to unscrew all fasteners, you can pre-treat them with WD40, several hours or even a day before the repair begins.

Replacing the exhaust manifold gasket of a VAZ 2110

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

The gasket is burnt out. Does anyone know a link that describes how to replace it yourself (or someone will tell you so in detail). otherwise I have no idea. what and how to shoot. and in what order

(Do I need to remove the receiver separately and change the gasket there? Do I need to remove the ramp? Do I need to disconnect the intake pipe from the exhaust manifold? And change the gasket there)

those yes and in what order. better in great detail. And what incidents can happen. and what tools and gaskets are needed. (and which pads are better to buy)

Sergg_

, I changed it to 99. I simply unscrewed everything that was in the way and then screwed it back. In fact, they are now selling good repair books with photographs that describe in detail, step by step, how to change something.

Sashka Khalturin2

, is this your avatar photo?

Exhaust manifold removal procedure

Before removing the exhaust manifold yourself, think 7 times. Having this work done by a service center is not cheap, but the inaccessibility and difficulty of unscrewing some nuts can be a serious problem.

Unscrew the bolt securing the intake pipe

It is important to drain the coolant before removal, as antifreeze may enter the cylinders during the process. The sequence of actions for cars with an injector is as follows:

- Disconnect the battery, release the throttle cable from the throttle valve.

- Disconnect the fuel line pipes.

- Disconnect the wires from the TPS and idle speed control.

- Release the crankcase ventilation, vacuum, and brake booster hoses.

- Remove the receiver, remove the injector block wires and remove the injector fuel rail.

- Remove the bracket and thermal shield.

- After this, you can disconnect the exhaust pipe, exhaust and intake manifolds from the manifold.

After disassembly, all gaskets are replaced with new ones. Please note when purchasing that the exhaust manifold for 8-valve and 16-valve VAZ 2114 are different. Select the parts carefully and you can avoid wasting time and money.

Replacing the collector on a VAZ 2110 with your own hands

To replace the device yourself, you need to:

- Place the car in the garage.

- Before carrying out all work, be sure to drain all the antifreeze from the tank.

- Remove the battery.

- Remove the pipe from the vacuum booster.

- Disconnect all hoses from the ramp pressure regulator cover.

- Disconnect the throttle sensor and its cable.

- Unscrew the clamp on the air supply pipe a little, then disconnect it completely.

- Then you need to remove the fastening from the throttle pipe and ventilation of gases from the crankcase.

- All hoses are removed in pairs.

- The clamp on the crankcase ventilation should be loosened.

- Then it is removed altogether.

- Do the same with all other hoses to make further work easier.

Open the hood and hang a special lamp with lantern protection.

It is worth remembering here that the receiver can only be removed together with the throttle assembly. You should also disconnect all adjacent hoses and chips from it, and of course loosen the fastenings. Do not forget about the places where the device is attached; if the replacement is being carried out for the first time, it is better to notice these places so as not to confuse anything. This is all necessary to correctly install the new part. All small fastening elements should be placed in one place so as not to be lost.

After all this, unscrew several nuts securing the receiver and the supply tube bracket. The receiver can then be removed and the gasket removed from it.