Repair / From Ekaterina Larina

- Several ways to check functionality

Method No. 1 - Method number 2

- Method number 3

- For what reasons can fuel pumps fail?

- Preparing tools

Electric fuel pumps are installed on VAZ 2108 and VAZ 2109 models. The task of this device is to supply fuel under certain pressure into the fuel rail, and from there the injection system distributes fuel into the engine cylinders. In other words, it ensures the transfer of gasoline from the tank to the engine unit. However, electrical devices can cause some problems for owners of VAZ 2108/2109 with a carburetor. Their performance is not always flawless. Owners of domestic cars need to be prepared to know and be able to carry out inspections, repairs and replacements with their own hands.

What fuel pumps are installed on the VAZ 2108/2109 (carburetor)

Initially, both carburetor and injection models of VAZ 2108/2109 cars are equipped with DAAZ brand fuel pumps. Their direct manufacturer is the AvtoVAZ plant itself. These devices are characterized by low cost and accessibility for a wide range of car owners: DAAZ can be bought at any auto store.

However, despite the prices of the domestic manufacturer (from 700 rubles per product), many car enthusiasts prefer to remove the factory one as quickly as possible and install another one. This desire is explained by the presence of a large number of negative reviews from owners regarding the quality of DAAZ.

I drove around a dozen before buying this! stores... I checked with friends... I scoured the Internet... in general, there is only DAAZ on sale as in the photo... they all leak along the pedal axis... I'm waiting for this one to leak...

Tavrovod11

https://www.e1.ru/talk/forum/read.php?f=17&i=655450&t=655450

The most budget-friendly type of equipment for fuel systems of domestic cars.

An alternative equipment option is a petrol pump from Pekar. It is more resistant to all types of influences, and is also characterized by durability. Pekar is a leading manufacturer of automotive components in Russia.

I've been driving for over 30 years. and I had a lot of fuel pumps and changed them often. Either the membrane will wear out, or the valves will fail. In 2004 I bought myself a new Pekar fuel pump and now I don’t know any grief. With old gas pumps I carried a rag with water in the hot weather. When the gas pump stopped pumping, I soaked a rag and laid it on top, but this gas pump can withstand any temperature. And during this time I only changed the valves, and the membrane is still working. The stem was also changed once. Very good fuel pump I recommend to everyone

Hariton2058

https://otzovik.com/reviews/benzonasos_pekar/

High-quality and durable devices have gained popularity among many Russian VAZ drivers.

At the owner's request, during repairs, a fuel pump manufactured by the German company Bosch can be installed on the VAZ 2108/2109. The cost of the original device is more than 2 thousand rubles, but the quality will completely cover all costs.

Fuel pumps in VAZ 2108/2109 cars with injection engines are not located under the hood. Therefore, the search for breakdowns and malfunctions should not begin with the traditional opening of the hood. The device is located directly in the gas tank. That is, getting to it in the event of a breakdown will be quite difficult - you will have to recline or dismantle the rear seat.

Several ways to check functionality

Experienced owners of VAZ 2108/2109 cars know exactly how to check the functionality of the fuel pump. Malfunctions related to incorrect fuel supply may not always relate specifically to the pumping device. Therefore, you will need to be able to identify problems with the device yourself.

Method No. 1

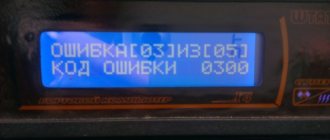

You will need to turn on the ignition and listen to whether the pump is working or not. A buzzing sound should be heard in the cabin behind one of the rear seats. If there is no characteristic sound of the pump operating, then you will need to check whether power is being supplied to it.

The block with the relay is dismantled. For the convenience of the driver, the assignments of all relays in the block have schematic assignments. If the relay and fuse are working, then it is recommended to recline or remove the rear seat, open the hatch and measure the voltage on the device itself. Typically, a multimeter or wiring with a low-power lamp is used for this.

Method number 2

You will need to replace the fuel pump with a new one. If the problems disappear immediately, it means that the fuel pump was indeed faulty. If the car still cannot be started due to low pressure in the fuel rail, the problem is not in the fuel pump, but in the fuel system itself. It is best to contact specialists.

Method number 3

The performance of a gas pump can be checked by measuring the amount of gasoline it pumps over a certain period of time.

You will need to organize access to the fuel rail and unscrew the spool on the tube. Connect a hose to the hole, the other end of which is lowered into a container for measurement (for example, a three-liter jar). The pump on the “eight” and “nine” pumps approximately one liter of fuel per minute. If the readings are much lower, it means the high pressure filter is clogged.

Signs of a fuel pump malfunction

Signs of a faulty fuel pump are:

- difficult engine start;

- Unstable engine operation at idle speed;

- “dips” when pressing the accelerator pedal;

- reduction in vehicle power.

Important : similar symptoms may be present in other malfunctions of the fuel system, as well as the ignition system. Before you begin repairing or replacing the fuel pump, it should be diagnosed.

What are the signs of a fuel pump malfunction and the possibility of repairing it?

The first sign of a malfunction may be a lack of pressure in the fuel supply system. This is expressed by interruptions in the operation of the engine unit (it begins to “cough”), after which the car stalls. Such symptoms can occur both while driving and when the engine is idling.

However, even earlier, before the fuel pump fails, an attentive driver can diagnose problems. These include:

- high tone of the engine;

- having problems starting the engine;

- gradual loss of power while driving.

Thus, if you listen to the nature of the sounds while driving and monitor the dynamic performance of the car, you can timely repair or replace the fuel pump without waiting for it to break down.

For what reasons can fuel pumps fail?

It is important not only to know exactly how to determine wear and tear of a fuel pump, but also to take into account the reasons why the device may fail.

The most common causes of breakdowns and incorrect operation of fuel pumps on VAZ 2108/2109 vehicles are:

- debris in the fuel tank;

- short circuit in the fuel system wiring;

- clogging in the fuel filter;

- pump overheating.

What to do if it leaks

Either fuel or lubricant (oil) may be leaking. If liquid leaks are found on the fuel pump body in a VAZ 2108/2109 car, it is recommended to take the following actions:

- tighten the clamps on the hoses of the device (at the “input” and “output”);

- check the integrity of hoses and connections;

- tighten the fuel pump cover bolt (or replace it if the thread has been stripped);

- replace the pump fitting.

What to do if fuel does not pump: repair

In cases where the device does not supply gasoline to the engine unit, you will need to establish the functionality of the gas pump itself. It is quite possible that it is functioning, but some element has failed.

Repairing a fuel pump is advisable only in cases where it is necessary to replace the smallest part of it. It is worth initially calculating the cost of materials, as well as taking into account the loss of time. It is quite possible that it is easier and cheaper to buy a new fuel pump.

Repair work to restore the functionality of the fuel pump, if it does not pump fuel from the tank, is carried out taking into account the following details:

- The fuel pump will need to be removed from the tank.

- Using the tool carefully, you will need to disassemble the device body.

- Inspect the pump components and find any damage.

Next proceed based on the existing problem:

- if one of the four springs bursts, you will need to replace it (as a rule, springs are inexpensive and are sold in almost all car stores);

- if the valve plate is seriously worn, this element will also need to be replaced, and the valve seat will need to be hammered into place with a blunt screwdriver;

- the pump drive rod has started to jam - you can straighten the surface of the rod to make it smoother;

- the surface of the fuel pump is dirty - you will need to clean the device with a soft, lint-free cloth

After troubleshooting, you should reinstall the fuel pump and check its functionality by starting the engine. If the ignition problems persist, most likely the problem lies in the fuel system itself, or your device will need to be replaced.

Video instruction: how to repair a fuel pump yourself

Checking and adjusting pump pressure

It's no secret that any car part has a certain resource. So the “nine” fuel pump, like any part, eventually stops pumping gasoline properly, our instructions will help you figure it out:

- Moreover, on the VAZ 2109 the problems with the fuel pump are always the same

- As a rule, the reasons are not tightness of the valves or housing, fuel wire, or diaphragm, perhaps the fuel filters are clogged, or the fuel supply lines are overheating

- The main problem is ultimately insufficient gasoline pressure at the outlet of the fuel pump.

- And in the case when your fuel pump initially could not show the appropriate (required) output pressure, then all the problems stated above only aggravate the situation

- You need to know exactly the output pressure (immediately before the carburetor) that the fuel pump should develop when the engine is idling.

- As a rule, all fuel pumps - both cars and trucks - must produce a pressure in the range from 0.20 atmospheres to 0.35 atmospheres. When your gas pump has a similar output pressure, then you should not have problems with gasoline supply

- The pressure is measured with a pressure gauge that has a scale with divisions of 1.6 atmospheres - on such a pressure gauge it will be possible to record the pressure of the fuel pump

- When the pressure is measured and it turns out to be below normal, you may just need to adjust the pump

- It is possible to adjust the fuel pump either by moving it closer or further from the engine block (by changing the thickness of the gasket)

- The second method is to strengthen the spring (washers are placed under it, the operation is performed taking into account the wear of existing parts and the strength of the spring)

- The third option is to change the length of the rod

- Any of the listed measures (or all in combination) make it possible to increase the pressure of the fuel pump to the level of 0.20 - 0.30 atmospheres

- The best thing, of course, is to bring the figure to 0.30-0.35 atmospheres at idle speed

- When the engine starts running at higher speeds, this figure will increase a little more.

Characteristics of the VAZ 2109 fuel pump

To understand how a working pump works and check its operation, it is important to know its operating characteristics:

- The length of its rod is 82.4 millimeters

- In this case, the rod protrudes above the gasket by 0.8 - 1.3 millimeters

- The thickness of the very first gasket is 0.3 millimeters

- And, the stroke of the rod is 2.5 - 2.8 millimeters

Useful tips

A couple of very useful recommendations for beginners on what to do if a fuel pump malfunction occurs on a VAZ 2109:

- It is important to note that on machines with a return line, the problem may arise due to the release hole being too large, then most of the pressure is relieved by the return line

- If the installed pump on your machine cannot be adjusted, you will have to replace it

- Today, dozens of models of pumps for VAZ from different manufacturers are sold on the market.

- In order not to buy a fake, you should approach the purchase very responsibly - choose a branded store and a reputable manufacturer, purchase only fuel pump models recommended by the VAZ plant

- And the most ideal option is to contact an official VAZ spare parts dealer in your region, then you will receive the necessary part quickly, and you won’t worry about whether you got a bad quality fuel pump, and you won’t have to look for and buy a new pump a second time

Replacing the fuel pump on a VAZ 2108/2109

The procedure for replacing a faulty fuel pump on a VAZ “eight” and “nine” is relatively simple. The main thing is to be careful so that when installing and dismantling you do not accidentally catch parts of other elements of the car.

Preparing tools

In order for the work to be completed quickly and not have to be distracted by searching for this or that tool, it is necessary to prepare everything in advance. So, to remove a faulty fuel pump and install a new one, you will need the following set of tools:

- Phillips screwdriver;

- flat screwdriver;

- socket wrench (or head) size 7 mm;

- extension;

- open-end wrench 17.

It is recommended to carry out all stages of operations with gloves so as not to stain or injure the skin on your hands.

Step-by-step instructions on how to remove a faulty fuel pump

The first stage of work is to dismantle the old device, which can be divided into several steps:

1. Turn off the ignition.

2. Fold down the rear seat in the cabin.

3. There is a small hatch under the foot carpet in the cabin; it must be opened by removing the fastening screws with a Phillips screwdriver.

4. Raise the hatch cover.

5. A plug will appear in your field of view; you will need to bend the latches on it and disconnect its parts.

6. Next, you need to unscrew the fuel pipes with a 17 wrench.

7. The tubes must be diverted in different directions so that they do not interfere with further work.

8. There is a pressure plate under the hatch - you will need to unscrew all the nuts on it to open it.

9. The fuel pump is located under the plate; to get it out you will need to pry off the rubber seal with a screwdriver.

10. As soon as you manage to lift the device a little, you will need to tilt it so as not to touch the body of the fuel level sensor.

Step-by-step instructions on how to install a new fuel pump

Further actions involve the reverse order:

- Carefully insert the new device into the hole, not forgetting to change the O-ring.

- Retighten all nuts on the pressure plate.

- Connect the fuel pipes to each other.

- Connect the two parts of the plug.

- Close the cavity with the hatch cover and screw the hatch.

- Place the carpet in its original place.

Video instruction: how to replace the fuel pump yourself

Thus, you can diagnose and repair the fuel pump in VAZ 2108/2109 cars yourself, without involving service station specialists. The procedure for determining the performance and replacing a faulty device is quite simple, so performing these procedures yourself will not cause difficulties even for inexperienced drivers.

Do-it-yourself fault diagnosis and repair of the Daewoo Nexia stove

Repair of carburetors VAZ 2108–2109

Checking the general condition of the fuel pump

First of all, let’s check whether the supply system of your VAZ 2109 is working at all. To do this, you need to take the following steps:

- Remove the pump fuel hose from the source or discharge fitting;

- Manually press the fuel pump lever several times;

- If the pump is operational, a strong stream of fuel will immediately flow through the fitting;

- If there is no jet or it is very weak, it will be necessary to carry out other checks.

Intake Valve Check

- Disconnect the hose from the suction fitting so that both hoses are eventually removed, each from its own fitting.

- Simply plug the suction fitting with your finger, then pull the lever several times to manually pump fuel. If everything works fine, your finger will begin to be sucked into the fitting. This effect indicates that the pump is working properly. Therefore, we look for the problem in the tank or lines.

- If there is no suction, you will have to disassemble the device to replace the inlet valve. Its tightness is most likely broken.

Pump diaphragm failure

You need to do the following for your fuel pump:

- Remove the upper part of the fuel pump housing and remove the diaphragm assembly from there;

- Unscrew the nut on the rod, and then pull out the 3 diaphragms;

- Replace faulty elements with new ones. They are available in any repair kit for the VAZ 2109 fuel pump;

- Reassemble the assembly in reverse order;

- If you have a Pekar pump, there is only one diaphragm. It can be removed by removing the cover;

- To disconnect the diaphragm assembly, rotate it 90 degrees.

Be sure to simultaneously check the condition of the spring located under the diaphragm. To do this, you need to remove the upper part of the pump housing, remove the diaphragm rod and look at the current state of the spring. If it is broken, deformed or lacks elasticity, replace the element.

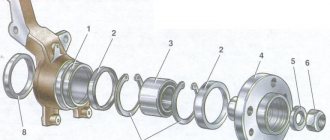

Node elements

Intake and exhaust valve malfunctions

If both valves raise doubts about their functionality, certain measures will have to be taken.

- Remove the cap from the fuel pump and remove the strainer.

- Visually assess the condition of the pump cavity and inlet valve.

- With the top of the pump body removed, you can take a look at the outlet valve.

- If both valves are not installed tightly enough, they are not pressed well or have become motionless, replace the entire pump completely.

- If you find traces of clogged valves, remove them and blow out the housing with compressed air.

In the case of the Pekar pump, two valves are located in the cover, so to assess their condition, simply remove the cover from the fuel pump housing.

Damage to the pusher

It is not uncommon for a fuel pump to fail to operate due to damage to the pusher. We have prepared separate instructions for this case.

- Remove the pump from the studs by unscrewing the fastening nuts. The thermal insulation insert, pusher and gaskets remain on the motor.

- Rotate the crankshaft to extend the pushrod as far as possible.

- Measure the distance that the pusher protrudes relative to the top gasket. Normally, the figure is 0.8-1.3 millimeters.

- If the protrusion is smaller or larger, try adjusting it using thicker or thinner shims.

- Between the thermal insulation insert and the pump there is an external gasket with the greatest thickness. It is this that needs to be changed when adjusting the protrusion.

- New gaskets are available in repair kits, although many make their own. To do this you will need a piece of paronite.